Professional Documents

Culture Documents

Calculation Serbaraja 1

Calculation Serbaraja 1

Uploaded by

Nurfandi DewantoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calculation Serbaraja 1

Calculation Serbaraja 1

Uploaded by

Nurfandi DewantoCopyright:

Available Formats

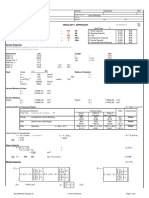

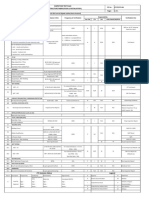

PT BERDIKARI PONDASI PERKASA Rev :

ENGINEERING DEPARTMENT 0

Proyek /Project : Tol Serbaraja Tanggal / Date : September 5, 2019

Rekanan / Client : PT WIKA Waktu / Time : 0:15:44

Pekerjaan /Job Title : Perhitungan struktur / Structure Calculation Perencana / Design By :

No. Pekerjaan / Job No. : 01/LT-BPP/VI/2017 Diperiksa /Checked By :

Perhitungan Rebar / Rebar Steel Calculation

Rebar Diamater Ф= 25.00 mm

Kuat Tarik Rebar / Tensile Stress of Rebar σt = 4,000.00 kg/cm2 Kebutuhan Rebar / Rebar Required

Jumlah Tiang Angkur / Quantity of Anchor Pile S= 4.00 Nos Diameter (mm) Qty / 1 Pile

Beban Rencana / Load Design P = 640,000.00 kg 25 18

Beban untuk 1 Angkur / Load for 1 Anchor Pile P' = 160,000.00 kg

Faktor Reduksi Pengelasan / Welding Reduction Factor ø = 0.20

Stress Allowable due to the welding reduction factor σt' = 3,200.00 kg/cm2 Steel Casing

Stress Allowable due to the shear factor σs = σt' * 0.58 = 1,856.00 kg/cm2

Luas Penampang Rebar/ Section area of 1 Rebar A = 4.91 cm2

Tensile capacity of 1 Rebar P' = 9,106.00 kg

Kebutuhan Rebar untuk 1 Angkur / Rebar Required for 1 Anchor Pile = 17.57 Nos

Dibulatkan / Rounded = 18.00 Nos

Jumlah Rebar yang dibutuhkan / Total of Rebar Required = 72.00 Nos Rebar `

Steel

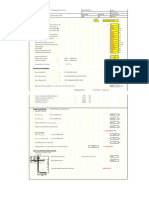

Perhitungan Pengelasan / Welding Calculation ( SNI Baja 2002 Page 110 )

Proses pengelasan / Welding Proccess = SMAW ( Shield Metal Arc Welding )

Kelas kawat Las / Class of electrode = E6010

Kuat Tarik kawat las / Tensile strenght of welding electrode fe = 60.00 Ksi

fe = 4,218.00 kg/cm2

Faktor Perlemahan akibat panas øw = 50%

Kuat Tarik Final kawat las / Final Tensile strenght fe'=fe.øw = 2,109.00 kg/cm2

Tegangan tarik putus ultimit / Fracture stress Max. of welding electrode fw = 1,265.40 kg/cm2

Tebal Plat Casing / Casing thickness s = 1.00 cm

Tebal Las / Throat thickness ( a = s cos 45 ) a = 0.71 cm

Tebal las minimum berdasarkan SNI Baja 2002 hal. 108 a = 0.40 cm apabila 7< s < 10 mm

= 0.50 cm apabila 10< s < 15 mm

= 0.60 cm apabila s > 15 mm

Tebal Las diambil yang terbesar/ Take the biggest value a = 0.71 cm

Gaya Geser Maks. / Max. Shear Stress Rv = 4,553.00 kg

Faktor Reduksi Fraktur / Fracture reduction factor ø = 0.75 Steel Casing

Panjang minimum Pengelasan / Welding Length minimum Lm = 6.78 cm

Panjang Pengelasan yang dipakai / Used length Lw = 10.00 cm

Welding throat P

Rebar steel s Rebar

Steel Casing

Steel

Kebutuhan Pengelasan / Welding Required

Tebal / Thickness Panjang / Length ( cm )

a Rebar Steel

0.71 10

Lw

Welding Throat

Steel Casing

1/2P 1/2P

You might also like

- Saudi Aramco Inspection Checklist: Review of WPS & Process Control Procedure (Pipelines) SAIC-W-2038 WeldDocument4 pagesSaudi Aramco Inspection Checklist: Review of WPS & Process Control Procedure (Pipelines) SAIC-W-2038 Weldhamidjoyia100% (2)

- Beam DesignDocument35 pagesBeam DesignAli Aafaaq100% (1)

- Triangle Beam B1Document6 pagesTriangle Beam B1sallysel90No ratings yet

- Rectification of Beam Stirrub Rebar.: 149B, Selegie Road, Selegie Court Singapore 188314Document2 pagesRectification of Beam Stirrub Rebar.: 149B, Selegie Road, Selegie Court Singapore 188314jasekan.dcNo ratings yet

- Anchors1 3Document5 pagesAnchors1 3p_ignatiusNo ratings yet

- Pile Cap Design - ColumnsDocument7 pagesPile Cap Design - Columnsfeiz asgarNo ratings yet

- Pile Cap Design - ColumnsDocument7 pagesPile Cap Design - ColumnsJule LobresNo ratings yet

- Strut and WalingDocument2 pagesStrut and WalingChan Kin CheungNo ratings yet

- Pile Cap Design - ColumnsDocument7 pagesPile Cap Design - ColumnsNaziemi AhmadNo ratings yet

- 3 Pile Cap DesignDocument7 pages3 Pile Cap DesignSheikh Mizanur RahmanNo ratings yet

- 2.pile - Cap.design ColumnsDocument9 pages2.pile - Cap.design Columnstaha abu el hanaNo ratings yet

- Physics of Projection WeldingDocument38 pagesPhysics of Projection WeldingJoel BrasilBorgesNo ratings yet

- SC21B-A Along GL-4 SummaryDocument2 pagesSC21B-A Along GL-4 Summarymhazarath murariNo ratings yet

- Pile Cap Design - ColumnsDocument7 pagesPile Cap Design - ColumnsMohit VatsNo ratings yet

- Tann Designs & Engineers: Welding Design CheckDocument1 pageTann Designs & Engineers: Welding Design CheckSiva JaseNo ratings yet

- Corbel R C BracketDocument2 pagesCorbel R C BracketVijendra Singh SoniNo ratings yet

- RB8 1200x1200 PDFDocument6 pagesRB8 1200x1200 PDFsallysel90No ratings yet

- Steel To Concrete Simple Connection Example 1Document12 pagesSteel To Concrete Simple Connection Example 1CSEC Uganda Ltd.No ratings yet

- Beam Design (Singly Reinforced Concrete)Document26 pagesBeam Design (Singly Reinforced Concrete)Raymund Dale P. BallenasNo ratings yet

- Tann Designs & Engineers: PadeyeDocument3 pagesTann Designs & Engineers: PadeyejasekanNo ratings yet

- Aisc 14 Edition (Asd) : 14/jan/16 SN SN 0 1Document2 pagesAisc 14 Edition (Asd) : 14/jan/16 SN SN 0 1GousePeerzadeNo ratings yet

- Welded Connection Design INTER DOWNLOAD PDFDocument11 pagesWelded Connection Design INTER DOWNLOAD PDFhossinmaaNo ratings yet

- WeldDocument4 pagesWeldmjohnNo ratings yet

- Client: Project: Estimate No: Contract No: Sheet No: C06-C4/1Document7 pagesClient: Project: Estimate No: Contract No: Sheet No: C06-C4/1Krish ChandNo ratings yet

- Post-In Installed Anchor in ConcreteDocument9 pagesPost-In Installed Anchor in ConcreteJose royNo ratings yet

- Pilecap Design by Bending Theory To B.S 8110 & B.S 8004Document59 pagesPilecap Design by Bending Theory To B.S 8110 & B.S 8004azwanNo ratings yet

- Base Plate Hinged - Moment On Anchors Adjusted 09-06-2021Document2 pagesBase Plate Hinged - Moment On Anchors Adjusted 09-06-2021ahmed osmanNo ratings yet

- RC Beam - Simply Supported - EC2 PDFDocument3 pagesRC Beam - Simply Supported - EC2 PDFmayphyoNo ratings yet

- Base Plate Design Fixed BaseDocument3 pagesBase Plate Design Fixed BaseDass MNo ratings yet

- SC15 Along GL-D' SummaryDocument2 pagesSC15 Along GL-D' Summarymhazarath murariNo ratings yet

- DanlyIEM PunchCalcPrefPress 0903Document2 pagesDanlyIEM PunchCalcPrefPress 0903salvador hernandezNo ratings yet

- SB46 Along GL-2 SummaryDocument2 pagesSB46 Along GL-2 Summarymhazarath murariNo ratings yet

- Mic Op Le de IgnDocument9 pagesMic Op Le de Ignc2mengNo ratings yet

- Aisc 14 Edition (Asd) : 0 1 18/jan/16 13/jun/16 SN SN AN ANDocument5 pagesAisc 14 Edition (Asd) : 0 1 18/jan/16 13/jun/16 SN SN AN ANGousePeerzadeNo ratings yet

- Site: Date: Job No. Designer: Sheet No.: Calculation/ SketchDocument5 pagesSite: Date: Job No. Designer: Sheet No.: Calculation/ SketchAlma M. LaraNo ratings yet

- EA - Design of Nonprestressed Rectangular RC Beams For Shear & Torsion ACI 318M-14Document3 pagesEA - Design of Nonprestressed Rectangular RC Beams For Shear & Torsion ACI 318M-14ZELALEMNo ratings yet

- Top Slab Design SheetDocument3 pagesTop Slab Design SheetersivarajNo ratings yet

- CN 05Document3 pagesCN 05GousePeerzadeNo ratings yet

- Base Plate INDIA CODEDocument4 pagesBase Plate INDIA CODEbama sankari100% (1)

- Calculation of Decking Capacity &Document9 pagesCalculation of Decking Capacity &Waqar FaziNo ratings yet

- Member Design - Reinforced Concrete Beam BS8110Document37 pagesMember Design - Reinforced Concrete Beam BS8110sanusi69No ratings yet

- RC Beam - CantileverDocument2 pagesRC Beam - CantilevermayphyoNo ratings yet

- Sanken Construction (PVT) Ltd. Design OfficeDocument9 pagesSanken Construction (PVT) Ltd. Design OfficeAnonymous H4T2MGT7PNo ratings yet

- 02) PIPE244.5x6.3 V-BRACE - GUSSET PLT.Document117 pages02) PIPE244.5x6.3 V-BRACE - GUSSET PLT.Asaru Deen100% (1)

- Base Plate Design (Fixed Base)Document3 pagesBase Plate Design (Fixed Base)Saravana NNo ratings yet

- Slab Design Strip Method v1.0Document4 pagesSlab Design Strip Method v1.0Kyra AlesonNo ratings yet

- Design Project Sructure Type Engineer: Load and Resistance Factor Design (LRFD)Document5 pagesDesign Project Sructure Type Engineer: Load and Resistance Factor Design (LRFD)Jose royNo ratings yet

- Masonry Anchor Bolt DesignDocument1 pageMasonry Anchor Bolt DesignEdgardo ArriesgadoNo ratings yet

- SB21C Along GL-5, 10 & F' Summary Grid 5Document2 pagesSB21C Along GL-5, 10 & F' Summary Grid 5mhazarath murariNo ratings yet

- Member Design Reinforced Concrete Corbel bs8110 v2015 01Document10 pagesMember Design Reinforced Concrete Corbel bs8110 v2015 01Aboalmaali100% (1)

- Client: Project: Estimate No: Contract No: Sheet No: C06-C2/1Document5 pagesClient: Project: Estimate No: Contract No: Sheet No: C06-C2/1Krish ChandNo ratings yet

- PC3 QmaxDocument1 pagePC3 QmaxCuong TranNo ratings yet

- InputsDocument6 pagesInputskeerthivasan_mrvNo ratings yet

- MRT Section 1: File:///conversion/tmp/scratch/469876014Document10 pagesMRT Section 1: File:///conversion/tmp/scratch/469876014Paypal BusinessNo ratings yet

- Crack Width - Moment - Circular SectionDocument16 pagesCrack Width - Moment - Circular Sectiontaha abu el hanaNo ratings yet

- Shear Connection For Ismb 300 TO ISMB350 COL: Bolt CalculationDocument4 pagesShear Connection For Ismb 300 TO ISMB350 COL: Bolt CalculationNitin SakpalNo ratings yet

- Case 1 Positive Moment: Geometrical Properties Material PropertiesDocument3 pagesCase 1 Positive Moment: Geometrical Properties Material Propertiessidiq7No ratings yet

- FinalDocument33 pagesFinalAnonymous sfkedkymNo ratings yet

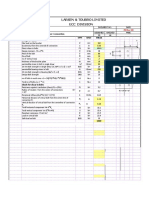

- Larsen & Toubro Limited Ecc Division: Description SYM Unit Value Design of BoltsDocument6 pagesLarsen & Toubro Limited Ecc Division: Description SYM Unit Value Design of BoltsSrishti Project ConsultantsNo ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- AWS D1 1 D1 1M 2015 Structural Welding Code Steel Errata PDFDocument2 pagesAWS D1 1 D1 1M 2015 Structural Welding Code Steel Errata PDFbilling cbi housingNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-2)Document19 pagesHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-2)Mohamed AtefNo ratings yet

- Eddie SorianoDocument3 pagesEddie SorianoHarry DemeterioNo ratings yet

- UEE & T Notes (1) (6th Semester Electrical) - MergedDocument199 pagesUEE & T Notes (1) (6th Semester Electrical) - MergedAmit HansdaNo ratings yet

- Honeywell RTH8500 Series Quick Installation Guide PDFDocument60 pagesHoneywell RTH8500 Series Quick Installation Guide PDFbandihootNo ratings yet

- Iso 15614-3-2008 PDFDocument24 pagesIso 15614-3-2008 PDFAlex RotsNo ratings yet

- ElectrodesDocument2 pagesElectrodesDeepak SartanNo ratings yet

- Hi Static PDFDocument46 pagesHi Static PDFAbdelhameed Tarig AlemairyNo ratings yet

- Technical Specification TREO CF I48CA1Document1 pageTechnical Specification TREO CF I48CA1Razvan CorciuNo ratings yet

- New Microsoft Office Excel WorksheetDocument2 pagesNew Microsoft Office Excel Worksheetg_sanchetiNo ratings yet

- Set-Up Welding Equipment LO1-1.1Document7 pagesSet-Up Welding Equipment LO1-1.1Joy BuycoNo ratings yet

- Robot WeldingDocument6 pagesRobot WeldingsrrsekarNo ratings yet

- CSWIP 3.0 - Visual Welding Inspector - 181-261Document81 pagesCSWIP 3.0 - Visual Welding Inspector - 181-261Attalh Djaafar AttalhNo ratings yet

- Welded Joint Design 3rd EditionDocument155 pagesWelded Joint Design 3rd EditionThuận Hoàng94% (16)

- Kecacatan KimpalanDocument26 pagesKecacatan KimpalanMaruan MuhammadNo ratings yet

- GB Rca Car 2023 001Document2 pagesGB Rca Car 2023 001cameron toolseeNo ratings yet

- Stick or MSAW Welding: Process Characteristics of Shielded Metal Arc Welding (SMAW/Stick)Document3 pagesStick or MSAW Welding: Process Characteristics of Shielded Metal Arc Welding (SMAW/Stick)senthil4youNo ratings yet

- WPS&PQR Examination Taghavi.0002Document50 pagesWPS&PQR Examination Taghavi.0002Anon YmousNo ratings yet

- DPT 166Document1 pageDPT 166Sam RajaNo ratings yet

- Asme Section IX Educational SeriesDocument144 pagesAsme Section IX Educational Seriesglazetm100% (6)

- Repair API 1104Document1 pageRepair API 1104محمد أزها نو الدين67% (3)

- Wps Sa106 Grbeil Gtaw SmawDocument5 pagesWps Sa106 Grbeil Gtaw SmawRajmahesh DakhoreNo ratings yet

- Daily Fit-Up/Welding Inspection ReportDocument7 pagesDaily Fit-Up/Welding Inspection ReportRichard PeriyanayagamNo ratings yet

- Long Seam: Long Seam/Circ Seam Weld KG & Run Time EstimationDocument14 pagesLong Seam: Long Seam/Circ Seam Weld KG & Run Time EstimationmhsalihNo ratings yet

- Company BrochureDocument2 pagesCompany BrochureJeremy OngNo ratings yet

- Approved ITP 06012023 For WT6Document1 pageApproved ITP 06012023 For WT6mohamed irsath100% (1)

- Positive Material Identification-Summary: 8/4/2020 Spectro Test Txc03Document1 pagePositive Material Identification-Summary: 8/4/2020 Spectro Test Txc03norman moralesNo ratings yet

- Aws A5.22 (1995) PDFDocument45 pagesAws A5.22 (1995) PDFDhanushNo ratings yet