Professional Documents

Culture Documents

Every 1000M3 Mixture

Every 1000M3 Mixture

Uploaded by

dana setiawanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Every 1000M3 Mixture

Every 1000M3 Mixture

Uploaded by

dana setiawanCopyright:

Available Formats

QUALITY CONTROL TABLE

UPPER CISOKAN PUMPED STORAGE

POWER PLANT PROJECT PACKAGE 1 LOT 1B

UPPER AND LOWER DAMS

BAB IV

NO DESCRIPTION REFERENCE ACCEPTANCE CRITERIA/ TOLERANCE FREQUENCY

A SLOPE EXCAVATION PROTECTION

1 Grouted Anchor Bar

A. Material

- Anchor Bar ( Hot Rolled ), Tensile Strenght ATSM D3963. > 415 Mpa Initial approval

- Epoxy Coating Thickness ATSM D3963. > 350 Micron Initial approval

2 Rock bolt

A. Material

- Deformed Bar , Tensile Strenght ASTM F432 > 415 Mpa Initial approval

- Steel Face Plat ASTM F432 Dimension Diameter Initial approval

22 mm 120 mm and 8 mm Thick Plate

25 mm 150 mm and 8 mm Thick Plate

3 Shotcrete

A. Material

- Plain Shotcrete, Steel Mesh AS 1379 / ASTM C94 Initial approval

- Reinforced Shotcrete AS 1379 / ASTM C94 Initial approval

- Steel Fibre Reinforces AS 1379 / ASTM C94 Initial approval

B. General

1. Cemen

- Type - I AS 3972 / ASTM C 150 Cement Portland type 1 Initial approval

2. Fly - Ash AS 3582 / ASTM C 618 < 25 % Total Content Cemen Initial approval

3. Water AS 1379 / ASTM C94 Portable Water Initial approval

Non-Portable Water Initial approval

4. Admixtures

- Quick Hardening Admixture AS 1478 / ASTM C494 Initial approval

- Accelerating Admixture AS 2350.11 / ASTM C150 Initial approval

5. Aggregat Initial approval

- Gradation Combined Specification Every 1000M3 mixture

US Size Sieve (mm) % passing by weight

AS 2758.1 / ASTM C 33

1/2 12.7 mm 100

3/8 9.5 mm 88 - 99

1/4 6.7 mm 77 - 91

No. 4 4.75 mm 70 - 85

No. 8 2. 4 mm 50 - 70

No. 16 1.2 mm 35 - 55

No. 30 0.6 mm 20 - 35

No. 50 0.3 mm 8 - 20

No. 100 0.15 mm 2 - 10

No. 200 0.075 mm 0-2

- Specifi gravity ASTM C128-15 > 2.6 Initial approval

- Water Absorption ASTM C128-15

a. Fine & Course Aggregat < 2.5 % Initial approval

QUALITY CONTROL TABLE

UPPER CISOKAN PUMPED STORAGE

POWER PLANT PROJECT PACKAGE 1 LOT 1B

UPPER AND LOWER DAMS

BAB IV

NO DESCRIPTION REFERENCE ACCEPTANCE CRITERIA/ TOLERANCE FREQUENCY

b. Slag Aggregat <6% Initial approval

- Sand From Rock AS 1289.3 / ASTM C 117 Initial approval

- Petrographically ASTM C 295 Initial approval

6. Welded Wire Fabric Mesh

- Steel Mesh ASTM A185 / ASTM A497 > F41 ( Diameter 4 mm Weld on 100 mm Grid) Initial approval

7. Steel Fibre

- Type - I ( cold drawn wire ) deformed ASTM A820 > 800 Mpa Initial approval

C. General

1. Mix Proportion & Design Strength

- Batching Plant & Weighting Device ASTM C94 Initial approval

2. Shotcrete Age Plain Shotcrete SFR or SMR

- Minimum Cementitious Content - 400 Kg / M3 400 Kg / M3

- Maximum Water / Cement Ratio ( W/A) - 0.32 - 0.45 By Weight 0.32 - 0.45 By Weight

- Maximum Slump AS 1012.3 / ASTM C143 - 70 mm 70 mm

- Minimum Compressive Strength AS 1012.9 / ASTM Cl50

6 Hours 2 Mpa 5 Mpa

3 Day 15 Mpa 20 Mpa

7 Days 20 Mpa 25 Mpa

28 Days 25 Mpa 30 Mpa

- Minimum Flexural Strength AS 1012.11 7 Days N/A 2.5 Mpa

28 Days N/A 3.0 Mpa

- Sulphate ( SO 4 ) AS 1012 Method 20 <5% Initial approval

- Ion Chloride AS 1012 Method 20 <5% Initial approval

- The mass of acid-soluble chloride < 0.8 Kg/m3 for SFRS Initial approval

< 0.3 Kg/m3 for SFRS Initial approval

- Shrinkage of the shotcrete AS 1012.13 / ASTM C157. < 560 Microstrain Initial approval

- Thoughness ASTM C1018-89 < 375 Joules Initial approval

- Density AS 1012,12 / ASTM C138 > 98 % / 28 Days Initial approval

- Sample AS 1012.8 / ASTM C172 Initial approval

3. Execution General

- Thickness Shotcrete < 50 mm & 90 mm > Initial approval

- Wire Mesh > 5 cm Initial approval

- Curing of Shorcrete

a. Temperature < 5 °Celcius Initial approval

b. Wet Curing by Water AS 1379 / ASTM C31

c. Curing Coumpond AS 3799 / ASTM C309 0.2 Litre / m2 Initial approval

- Quality Control / Sampling

a. Panel Sampling for Compresive Test 2 Panel / 1000 m2 Initial approval

QUALITY CONTROL TABLE

UPPER CISOKAN PUMPED STORAGE

POWER PLANT PROJECT PACKAGE 1 LOT 1B

UPPER AND LOWER DAMS

BAB IV

NO DESCRIPTION REFERENCE ACCEPTANCE CRITERIA/ TOLERANCE FREQUENCY

b. Driiling, Thickness 1 Hole / 250 m2 Initial approval

c. Thickness Of Dense 75 mm Initial approval

d. Panel Test Size 610 mm X 610 mm X 89 mm Initial approval

e. Panel Test Permanent 40 m3 Initial approval

f. Steel Fibre Reinforced Content Design Drawing Comply Wika Drawing Initial approval

4 Welded Wire Fabric Mesh

a. Material Fabric Mesh ASTM A185 Initial approval

b. Size Diameter Ditto 2.4 mm < Diameter > 6 mm Initial approval

c. Space Wires Ditto 50 mm X 50 mm X 150 mm X 150 mm Initial approval

5 GALVANIZED WIRE NET FOR ROCK PROTECTION

a. Material, Wett ASTM-116 Initial approval

b. Size Diameter Ditto 3 mm < Diameter > 4 mm Initial approval

< 100 cm2

6 PRE - STRESSED ROCK ANCHORS

- Material, Stell / Cables ASTM A416M Initial approval

- Tendon Size Diameter Ditto 17.8 mm Initial approval

- Strenght, Capacity Ditto 125% breaking load Initial approval

7 GABIONS ( NA )

- Material

a. Mesh , Galvanized

b. Size Length : 1.8 m, Width : 1.2 m, Height : 1.0 m Initial approval

Mesh : 80 mm X 100 mm Initial approval

c. Rock Well graded, 22 - 25 cm, Void : 10 % Initial approval

b. Infill Rock

- Size 22 cm < N > 25 cm Initial approval

- Void < 10 % Initial approval

You might also like

- Wire Rope Test CertificateDocument2 pagesWire Rope Test CertificateDustin Xender60% (5)

- Astm F668Document2 pagesAstm F668Mahfuz AlamNo ratings yet

- Conveyor Safety ChecklistDocument1 pageConveyor Safety Checklistdana setiawanNo ratings yet

- Conveyor Safety ChecklistDocument1 pageConveyor Safety Checklistdana setiawanNo ratings yet

- Inspection Checklist - Batching Plant: Form Ref.: Project: Sub-Contractor: Structure Element: DateDocument4 pagesInspection Checklist - Batching Plant: Form Ref.: Project: Sub-Contractor: Structure Element: Datedana setiawan100% (1)

- Norma ASTM-A641Document5 pagesNorma ASTM-A641Dilmer CV100% (2)

- Lost Circulation Theory - SD-II - 6405340 - 01Document41 pagesLost Circulation Theory - SD-II - 6405340 - 01carloskilas100% (2)

- ASTM A193 Specification - Portland BoltDocument3 pagesASTM A193 Specification - Portland BoltJesús Alberto Díaz CostaNo ratings yet

- 7) Bolt & Nut Sample MTC 3.1 - AIIDocument2 pages7) Bolt & Nut Sample MTC 3.1 - AIITri Aditha NugrahaNo ratings yet

- Vampamid 6 0024 V0Document1 pageVampamid 6 0024 V0Plasticos CusenNo ratings yet

- Specs FRDocument9 pagesSpecs FRghansaNo ratings yet

- ASTM A194 - Portland BoltDocument3 pagesASTM A194 - Portland BoltJonathan DouglasNo ratings yet

- Ac-700 SpecificationDocument10 pagesAc-700 SpecificationTarek Abuzene100% (1)

- Fixfast DF2 LS Stitcher Datasheet 2Document6 pagesFixfast DF2 LS Stitcher Datasheet 2Jonathan DouglasNo ratings yet

- Memo 097.7 - 122719 - Item 454 Tunnel WaterproofingDocument6 pagesMemo 097.7 - 122719 - Item 454 Tunnel WaterproofingBai Alleha MusaNo ratings yet

- Usa Mechanical1046-01Document5 pagesUsa Mechanical1046-01Rick HenbidNo ratings yet

- Bolts SpacificationsDocument6 pagesBolts SpacificationsSaleem JaradatNo ratings yet

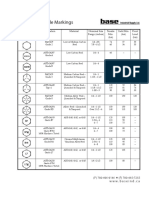

- Hex Bolt Head MarkingsDocument5 pagesHex Bolt Head MarkingscarangoretrepoNo ratings yet

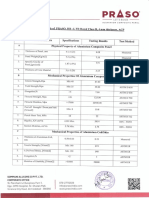

- Material Test Certificate (MTC) : Properties of Aluminium Coil: AW 5005Document4 pagesMaterial Test Certificate (MTC) : Properties of Aluminium Coil: AW 5005Waleed Obieden100% (1)

- Colorbond Ultra Datasheet New V8Document2 pagesColorbond Ultra Datasheet New V8Gireesh Krishna KadimiNo ratings yet

- Glass Fiber Reinforced PBT Material Injection Molding Grade Pellets / GranulesDocument2 pagesGlass Fiber Reinforced PBT Material Injection Molding Grade Pellets / GranulesmuthuNo ratings yet

- Astm A 829 - SAE 4140 / SAE 4142: CR Mo-Alloyed Vacuum Degassed SteelsDocument3 pagesAstm A 829 - SAE 4140 / SAE 4142: CR Mo-Alloyed Vacuum Degassed SteelsSuresh NairNo ratings yet

- Astm A 829 - SAE 4140 / SAE 4142: CR Mo-Alloyed Vacuum Degassed SteelsDocument3 pagesAstm A 829 - SAE 4140 / SAE 4142: CR Mo-Alloyed Vacuum Degassed Steelsssip officeNo ratings yet

- Astmproperty Astmproperty: Grade ResintypeDocument2 pagesAstmproperty Astmproperty: Grade Resintypejulius hasan33No ratings yet

- SA SL - VRV001 G 4514-Series-VRV-Product-LiteratureDocument4 pagesSA SL - VRV001 G 4514-Series-VRV-Product-Literatureenghassanain6486No ratings yet

- Metal Tek ScrewDocument2 pagesMetal Tek ScrewAmin SalahNo ratings yet

- Electrics Cables PDFDocument10 pagesElectrics Cables PDFemiliano2923No ratings yet

- PBT GF30 - Vampter 3026 V0 DFDocument1 pagePBT GF30 - Vampter 3026 V0 DFarmandoNo ratings yet

- Aludecor Al 45 Firewall En13501-1 Class A2 Technical SpecificationDocument2 pagesAludecor Al 45 Firewall En13501-1 Class A2 Technical Specificationsoham senNo ratings yet

- Bolt & Stud Grade MarkingsDocument2 pagesBolt & Stud Grade MarkingsJacobNo ratings yet

- TDS Certificate09052022131255Document3 pagesTDS Certificate09052022131255SK Emran AliNo ratings yet

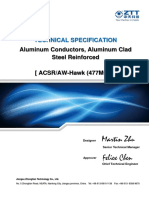

- Martin Zhu: Technical SpecificationDocument5 pagesMartin Zhu: Technical SpecificationalfredoNo ratings yet

- Nyco Grease GN 3058Document1 pageNyco Grease GN 3058Virender KumarNo ratings yet

- BRFL Textiles PVT LTD: Sample DescriptionDocument1 pageBRFL Textiles PVT LTD: Sample DescriptionNarendraSinghNo ratings yet

- ASTM A193 - Portland Bolt PDFDocument2 pagesASTM A193 - Portland Bolt PDFJonathan Douglas100% (1)

- WSG (KR) - ASME - BPEDocument35 pagesWSG (KR) - ASME - BPEThomas C. Lane100% (1)

- Detailed Specification Kadi TholDocument22 pagesDetailed Specification Kadi TholMAULIK RAVALNo ratings yet

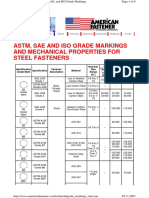

- American FastenersDocument6 pagesAmerican Fastenersashraf elsayedNo ratings yet

- Bolt Grades Strength Chart - Imperial Steel BoltsDocument5 pagesBolt Grades Strength Chart - Imperial Steel BoltsEduardo LunaNo ratings yet

- PlugDocument2 pagesPlugJalal AlbadriNo ratings yet

- Mechanical Metigurical DimensionalDocument4 pagesMechanical Metigurical DimensionalPaviter SinghNo ratings yet

- FT Valvula Compuerta Clase 800 SWDocument1 pageFT Valvula Compuerta Clase 800 SWFernando CarreñoNo ratings yet

- Test Report For CAP MICROCRETE: Sample InformationDocument1 pageTest Report For CAP MICROCRETE: Sample InformationsayedNo ratings yet

- Xydar® SRT-900 by Syensqo ADPDocument3 pagesXydar® SRT-900 by Syensqo ADPFAUSANo ratings yet

- Procedure Manual: Forged Valve ProductionDocument12 pagesProcedure Manual: Forged Valve ProductionJaison JoseNo ratings yet

- Tds A1105 en 2017pdfpdfDocument2 pagesTds A1105 en 2017pdfpdfagungNo ratings yet

- T700S Technical Data Sheet PDFDocument2 pagesT700S Technical Data Sheet PDFjairoNo ratings yet

- For Solid Concrete Interlocking Paving UnitsDocument7 pagesFor Solid Concrete Interlocking Paving UnitsomerNo ratings yet

- Properties and Grades of FastenersDocument3 pagesProperties and Grades of Fastenerschez ezNo ratings yet

- Certificate: Parker Hannifin Instrumentation (Changzhou) Co., LTDDocument3 pagesCertificate: Parker Hannifin Instrumentation (Changzhou) Co., LTDgroupj.sr.servicesNo ratings yet

- Wimpey - Wacg-22-222-5Document6 pagesWimpey - Wacg-22-222-5jaas jawadNo ratings yet

- Astm A490 Type3 BoltsDocument1 pageAstm A490 Type3 BoltsgwamendolaNo ratings yet

- Astm A194Document3 pagesAstm A194poerwntiNo ratings yet

- SABIC PC Resin - PC0703R - Technical - Data - SheetDocument3 pagesSABIC PC Resin - PC0703R - Technical - Data - SheetAryaNo ratings yet

- PPS Ryton R-4-230Document3 pagesPPS Ryton R-4-230thegeneral2040No ratings yet

- SHAIC AC-700: P.E. Anti-Corrosion TapeDocument1 pageSHAIC AC-700: P.E. Anti-Corrosion TapeTarek AbuzeneNo ratings yet

- Solvay Specialty Polymers Xydar G 930 Liquid Crystal Polymer LCP NbspUnverified DataDocument4 pagesSolvay Specialty Polymers Xydar G 930 Liquid Crystal Polymer LCP NbspUnverified DataFAUSANo ratings yet

- Formosa Ldpe Data SheetDocument5 pagesFormosa Ldpe Data SheetBasant AGarwalNo ratings yet

- Galvanizing - Mtbe ReportDocument1 pageGalvanizing - Mtbe ReportTASNEEMNo ratings yet

- TP Wanhua Clarnate A1227 Vs Lexan 243RDocument2 pagesTP Wanhua Clarnate A1227 Vs Lexan 243RMitja GorseNo ratings yet

- Wanhua PC Injection Moulding 20 Mfi Clarnate A1227Document2 pagesWanhua PC Injection Moulding 20 Mfi Clarnate A1227lucasNo ratings yet

- BRFL Textiles PVT LTD: Sample DescriptionDocument1 pageBRFL Textiles PVT LTD: Sample DescriptionNarendraSinghNo ratings yet

- Technyl Safe C 116FC NCDocument3 pagesTechnyl Safe C 116FC NCkls.thorodinsonNo ratings yet

- Carlisle Epdm 60 MIL MTC - IIIDocument1 pageCarlisle Epdm 60 MIL MTC - IIIHimanshu ChaudharyNo ratings yet

- Label Odner BantexDocument4 pagesLabel Odner Bantexdana setiawanNo ratings yet

- Soil Support Testing With DCP ToolsDocument2 pagesSoil Support Testing With DCP Toolsdana setiawanNo ratings yet

- Soil Support Testing With DCP ToolsDocument2 pagesSoil Support Testing With DCP Toolsdana setiawanNo ratings yet

- AsdsaDocument14 pagesAsdsadana setiawanNo ratings yet

- 1 Lot 1a Vol 2 of 10 235Document1 page1 Lot 1a Vol 2 of 10 235dana setiawanNo ratings yet

- 2.6.3.1 Water - Cooled.chiller - Construction.checklistDocument4 pages2.6.3.1 Water - Cooled.chiller - Construction.checklistdana setiawanNo ratings yet

- Package Lot A - Upper and Lower Dams Upper Cisokan Pumped Storage Power Plant Project Section Teclmical SpecificationsDocument1 pagePackage Lot A - Upper and Lower Dams Upper Cisokan Pumped Storage Power Plant Project Section Teclmical Specificationsdana setiawanNo ratings yet

- Quality Control TableDocument12 pagesQuality Control Tabledana setiawanNo ratings yet

- JKDocument4 pagesJKdana setiawanNo ratings yet

- Package 1 Lot La - Upper and Lower Dams Upper Cisokan Storage Power P!ant Project Section Teclznica! SpecificationsDocument1 pagePackage 1 Lot La - Upper and Lower Dams Upper Cisokan Storage Power P!ant Project Section Teclznica! Specificationsdana setiawanNo ratings yet

- TDS MasterRoc SA 192 PDFDocument3 pagesTDS MasterRoc SA 192 PDFdana setiawanNo ratings yet

- QWQDocument2 pagesQWQdana setiawanNo ratings yet

- Rheobuild 2000PFDocument2 pagesRheobuild 2000PFdana setiawanNo ratings yet

- BASF MasterRoc® HCA 10 Tds PDFDocument2 pagesBASF MasterRoc® HCA 10 Tds PDFdana setiawanNo ratings yet

- QQDocument2 pagesQQdana setiawanNo ratings yet

- Master Rheobuild 1100: High Range Water-Reducing Superplasticising AdmixtureDocument2 pagesMaster Rheobuild 1100: High Range Water-Reducing Superplasticising Admixturedana setiawanNo ratings yet

- Masterroc Sa 192: Alkali-Free, Liquid, Solution Type High Performance Set Accelerator For Sprayed ConcreteDocument3 pagesMasterroc Sa 192: Alkali-Free, Liquid, Solution Type High Performance Set Accelerator For Sprayed Concretedana setiawanNo ratings yet

- CementManufacturing v13b01Document17 pagesCementManufacturing v13b01ystdfmNo ratings yet

- Influence of Geopolymers in The Stabilization of Clay SoilDocument13 pagesInfluence of Geopolymers in The Stabilization of Clay SoilAmmar AhmedNo ratings yet

- Kuettner Shaft FurnaceDocument6 pagesKuettner Shaft FurnacemrrazaviNo ratings yet

- B.Arch Syllabus and Structure 2019Document152 pagesB.Arch Syllabus and Structure 2019Harshita MittalNo ratings yet

- Civil - Structural DBRDocument20 pagesCivil - Structural DBRUmesh MaheshwariNo ratings yet

- ACC (Company) - WikipediaDocument5 pagesACC (Company) - WikipediaAkash GoreNo ratings yet

- Part - I Chapter - Iv Explanatory Notes TO Tender ScheduleDocument41 pagesPart - I Chapter - Iv Explanatory Notes TO Tender ScheduleHetal PatelNo ratings yet

- Unit1 and 2 CHE 882Document146 pagesUnit1 and 2 CHE 882Ms Mayank YadavNo ratings yet

- 1 s2.0 S2238785423001345 MainDocument10 pages1 s2.0 S2238785423001345 MainHamada Shoukry MohammedNo ratings yet

- Concrete Strength TestingDocument16 pagesConcrete Strength TestingSara Vera100% (2)

- Rate AnalysisDocument6 pagesRate AnalysisRaj BharathNo ratings yet

- Broas CE152P-2 A71 Experiment5 Module2Document6 pagesBroas CE152P-2 A71 Experiment5 Module2Godwin BroasNo ratings yet

- Welcome TO Lecture On Process For Nonprocess Engineers: K.P.Pradeep KumarDocument170 pagesWelcome TO Lecture On Process For Nonprocess Engineers: K.P.Pradeep Kumarpacoto livingstoneNo ratings yet

- Welding Alloys - MillCarbDocument4 pagesWelding Alloys - MillCarbYoussef KhaliNo ratings yet

- India - Cement Directory 2012: © Ibis Research Information Services Private LimitedDocument72 pagesIndia - Cement Directory 2012: © Ibis Research Information Services Private LimitedPiyush A JoshiNo ratings yet

- Speed Dry Mix BrochureDocument12 pagesSpeed Dry Mix BrochureBijaya RaulaNo ratings yet

- 6.4 BenchmarksDocument6 pages6.4 BenchmarksYhaneNo ratings yet

- Chapter 19 PDFDocument10 pagesChapter 19 PDFruel delacruzNo ratings yet

- Internship Final ReportDocument35 pagesInternship Final Reportlalu kalu100% (4)

- Laboratory Report No. 6 Standard Test Method For Normal Consistency of Hydraulic Cement ASTM C187 - 98Document4 pagesLaboratory Report No. 6 Standard Test Method For Normal Consistency of Hydraulic Cement ASTM C187 - 98Junnaz BalacuitNo ratings yet

- 4 Volume-IIDocument31 pages4 Volume-IIChirag SharmaNo ratings yet

- Analysis of Financial Performance of Cement IndustryDocument137 pagesAnalysis of Financial Performance of Cement IndustryRikesh Daliya91% (11)

- A Summer Training ReportDocument9 pagesA Summer Training ReportNiteesh kumar ShuklaNo ratings yet

- Chapter 1. Introduction To ConcreteDocument9 pagesChapter 1. Introduction To ConcreteKhaled Al-SwairkiNo ratings yet

- Conbuildmat S 19 15365Document38 pagesConbuildmat S 19 15365tsheikh6361No ratings yet

- Goals: I. II. Iii.Document68 pagesGoals: I. II. Iii.ganeshlalkumawatNo ratings yet

- SF - Precast Structural ConcreteDocument11 pagesSF - Precast Structural ConcreteMuwafaq_mibNo ratings yet

- Investigation of The Effect of Palm Bunch Ash On Concrete PropertiesDocument6 pagesInvestigation of The Effect of Palm Bunch Ash On Concrete PropertiesJonatan Porras PeñaNo ratings yet

- Recycle of Construction Waste: A User Define Project ReportDocument49 pagesRecycle of Construction Waste: A User Define Project ReportEr Hardik SandishNo ratings yet