Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

13 viewsElectrode Booklet F Web 80

Electrode Booklet F Web 80

Uploaded by

satnamThis document provides information on TENALLOY 4130 low alloy steel electrodes for welding AISI 4130 steel. It lists the key features of the electrodes including that they are basic coated and produce a Ni-Cr-Mo low alloy weld deposit. Proper preheat and post weld heat treatment are required to achieve the desired mechanical properties. Application examples are provided for welding heat treatable alloy steels. Chemical compositions and mechanical properties of the weld deposits are also specified.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- SAP MM NotesDocument242 pagesSAP MM NotesEvelyn RochaNo ratings yet

- Electrode Booklet F Web 85Document1 pageElectrode Booklet F Web 85satnamNo ratings yet

- Tenalloy 120G: LOW ALLOY STEEL (High Strength)Document1 pageTenalloy 120G: LOW ALLOY STEEL (High Strength)Devender NegiNo ratings yet

- Electrode Booklet F Web 23Document1 pageElectrode Booklet F Web 23satnamNo ratings yet

- Tenalloy 70D11Document1 pageTenalloy 70D11pach-thNo ratings yet

- Electrode Booklet F Web 73Document1 pageElectrode Booklet F Web 73satnamNo ratings yet

- Nimoten: LOW ALLOY STEEL (Nimoten Series)Document1 pageNimoten: LOW ALLOY STEEL (Nimoten Series)satnamNo ratings yet

- Nimoten Plus 535: LOW ALLOY STEEL (Nimoten Series)Document1 pageNimoten Plus 535: LOW ALLOY STEEL (Nimoten Series)satnam100% (1)

- Nimoten Plus 535 A: LOW ALLOY STEEL (Nimoten Series)Document1 pageNimoten Plus 535 A: LOW ALLOY STEEL (Nimoten Series)satnamNo ratings yet

- Electrode Booklet F Web 21Document1 pageElectrode Booklet F Web 21satnamNo ratings yet

- Electrode Booklet F Web 120Document1 pageElectrode Booklet F Web 120satnamNo ratings yet

- Electrode Booklet F Web 24Document1 pageElectrode Booklet F Web 24satnamNo ratings yet

- Electrode Booklet F Web 20Document1 pageElectrode Booklet F Web 20satnamNo ratings yet

- Tenalloy 125: LOW ALLOY STEEL (High Strength)Document1 pageTenalloy 125: LOW ALLOY STEEL (High Strength)satnamNo ratings yet

- Topstar 110: C-MN STEEL (High Efficiency)Document1 pageTopstar 110: C-MN STEEL (High Efficiency)satnamNo ratings yet

- Tenalloy Z PlusDocument1 pageTenalloy Z Plushemal ChauhanNo ratings yet

- Metalbond: Mild Steel General Purpose (MSGP)Document1 pageMetalbond: Mild Steel General Purpose (MSGP)satnamNo ratings yet

- Electrode Booklet F Web 9Document1 pageElectrode Booklet F Web 9satnamNo ratings yet

- Nicalloy Mo-12: NON FERROUS (Ni Alloys)Document1 pageNicalloy Mo-12: NON FERROUS (Ni Alloys)krupesh patelNo ratings yet

- Electrode Booklet F Web 105Document1 pageElectrode Booklet F Web 105satnamNo ratings yet

- Electrode Booklet F Web 22Document1 pageElectrode Booklet F Web 22satnamNo ratings yet

- Ebondm: Mild Steel General Purpose (MSGP)Document1 pageEbondm: Mild Steel General Purpose (MSGP)satnamNo ratings yet

- Nicalloy Fe 3 Basic Coated Nickel Based ElectrodeDocument1 pageNicalloy Fe 3 Basic Coated Nickel Based ElectroderravibharathNo ratings yet

- Sae 4140 ACTDocument1 pageSae 4140 ACTOSCARNo ratings yet

- Electrode Booklet F Web 101Document1 pageElectrode Booklet F Web 101satnamNo ratings yet

- High Tensile Steel 4140Document2 pagesHigh Tensile Steel 4140Lazzarus Az GunawanNo ratings yet

- Electrode Booklet F Web 14Document1 pageElectrode Booklet F Web 14satnamNo ratings yet

- X Bond: Welding Electrode For Structural Welding ApplicationDocument1 pageX Bond: Welding Electrode For Structural Welding ApplicationAmit ChapagainNo ratings yet

- Celwel - 70P (Ador Electrodes)Document1 pageCelwel - 70P (Ador Electrodes)Harish KandollaNo ratings yet

- Electrode Booklet F Web 8Document1 pageElectrode Booklet F Web 8satnamNo ratings yet

- Electrode Booklet F Web 121Document1 pageElectrode Booklet F Web 121satnamNo ratings yet

- High Tensile: Voestalpine High Performance Metals (Australia) Pty LTDDocument5 pagesHigh Tensile: Voestalpine High Performance Metals (Australia) Pty LTDSinan YıldızNo ratings yet

- Electrode Booklet F Web 104Document1 pageElectrode Booklet F Web 104satnamNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Raj RajeshNo ratings yet

- Electrode Booklet F Web 100Document1 pageElectrode Booklet F Web 100satnamNo ratings yet

- Supabase-X-Plus AdorDocument1 pageSupabase-X-Plus AdorJagan TnNo ratings yet

- Wb56S M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb56S M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- Alloy 410s Spec SheetDocument2 pagesAlloy 410s Spec SheetALONSO GOMEZNo ratings yet

- Tigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-ADocument1 pageTigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-AsatnamNo ratings yet

- Electrode Booklet F Web 96Document1 pageElectrode Booklet F Web 96satnamNo ratings yet

- Electrode Booklet F Web 13Document1 pageElectrode Booklet F Web 13satnamNo ratings yet

- Bohler Fox N CM 2 KBDocument1 pageBohler Fox N CM 2 KBkamals55No ratings yet

- Electrode Booklet F Web 106Document1 pageElectrode Booklet F Web 106satnamNo ratings yet

- Betanox 308 Plus: STAINLESS STEEL (Austenitic Steel)Document1 pageBetanox 308 Plus: STAINLESS STEEL (Austenitic Steel)satnamNo ratings yet

- High Tensile Steel: Voestalpine High Performance Metals (Australia) Pty LTDDocument3 pagesHigh Tensile Steel: Voestalpine High Performance Metals (Australia) Pty LTDJoko tri SantosoNo ratings yet

- (17CrNiMo6) 4317 Case Hardening SteelDocument3 pages(17CrNiMo6) 4317 Case Hardening Steelazhar mohammedNo ratings yet

- 1.3505 100cr6 PDFDocument1 page1.3505 100cr6 PDFmcNo ratings yet

- AISI416Document2 pagesAISI416shamsi862620No ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- Alloy 410S Spec SheetDocument2 pagesAlloy 410S Spec SheetPrakash SundharamNo ratings yet

- Sandvik: Stainless Steel Wire ProductsDocument4 pagesSandvik: Stainless Steel Wire ProductsRemo StortiniNo ratings yet

- Case Hardening Steel A Is I 8620Document2 pagesCase Hardening Steel A Is I 8620fahriNo ratings yet

- SAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat TreatmentDocument2 pagesSAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat TreatmentAnush Swaminathan100% (1)

- Wb2318e E9018-MDocument1 pageWb2318e E9018-McwiksjNo ratings yet

- Betanox D Welding ElectrodeDocument1 pageBetanox D Welding ElectrodearavindpeetaNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- Wb35S M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb35S M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- Analytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryFrom EverandAnalytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- Automig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36Document1 pageAutomig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36satnamNo ratings yet

- Automig Cusn-A: Classification: Aws A/Sfa 5.7Document1 pageAutomig Cusn-A: Classification: Aws A/Sfa 5.7satnamNo ratings yet

- CWC-BookletF1 59Document1 pageCWC-BookletF1 59satnamNo ratings yet

- Tigfil Cuni: Classification: ApprovalsDocument1 pageTigfil Cuni: Classification: ApprovalssatnamNo ratings yet

- AUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalsDocument1 pageAUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalssatnamNo ratings yet

- AUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalsDocument1 pageAUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalssatnamNo ratings yet

- AUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-ADocument1 pageAUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-AsatnamNo ratings yet

- AUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalsDocument1 pageAUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalssatnamNo ratings yet

- Tiginox 385: Classification: en Iso 14343-ADocument1 pageTiginox 385: Classification: en Iso 14343-AJagannath SahuNo ratings yet

- AUTOMIG 1100: Classification: Aws A/Sfa 5.10Document1 pageAUTOMIG 1100: Classification: Aws A/Sfa 5.10satnamNo ratings yet

- Automig Nicu-7 / Tigfil Nicu-7: Ernicu-7 Sni 4060Document1 pageAutomig Nicu-7 / Tigfil Nicu-7: Ernicu-7 Sni 4060satnamNo ratings yet

- CWC-BookletF1 9Document1 pageCWC-BookletF1 9satnamNo ratings yet

- Automig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48Document1 pageAutomig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48satnamNo ratings yet

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Document1 pageTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamNo ratings yet

- Tigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-ADocument1 pageTigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-AsatnamNo ratings yet

- Automig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28Document1 pageAutomig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28satnamNo ratings yet

- CWC-BookletF1 15Document1 pageCWC-BookletF1 15satnamNo ratings yet

- CWC-BookletF1 12Document1 pageCWC-BookletF1 12satnamNo ratings yet

- CWC-BookletF1 17Document1 pageCWC-BookletF1 17satnamNo ratings yet

- Automig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalsDocument1 pageAutomig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalssatnamNo ratings yet

- TIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48Document1 pageTIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48satnamNo ratings yet

- Tigfil 70S-2: Aws A/sfa 5.18 en Iso 636-ADocument1 pageTigfil 70S-2: Aws A/sfa 5.18 en Iso 636-AsatnamNo ratings yet

- CWC-BookletF1 10Document1 pageCWC-BookletF1 10satnamNo ratings yet

- Tigfil 70S-2: Aws A/sfa 5.18 en Iso 636-ADocument1 pageTigfil 70S-2: Aws A/sfa 5.18 en Iso 636-AsatnamNo ratings yet

- CWC-BookletF1 9Document1 pageCWC-BookletF1 9satnamNo ratings yet

- CWC-BookletF1 5Document1 pageCWC-BookletF1 5satnamNo ratings yet

- CWC-BookletF1 3Document1 pageCWC-BookletF1 3satnamNo ratings yet

- Automig 70S-6: AWS A/SFA 5.18 Csa W48Document1 pageAutomig 70S-6: AWS A/SFA 5.18 Csa W48satnamNo ratings yet

- CWC-BookletF1 2Document1 pageCWC-BookletF1 2satnamNo ratings yet

- CWC-BookletF1 4Document1 pageCWC-BookletF1 4satnamNo ratings yet

- Ch20 Quản trị tồn kho OSCMDocument7 pagesCh20 Quản trị tồn kho OSCMThanhHuongNo ratings yet

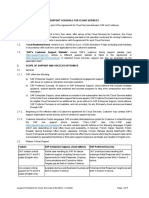

- B - Support Schedule For Cloud ServicesDocument5 pagesB - Support Schedule For Cloud ServicesUlysse TpnNo ratings yet

- CV MDK 1Document7 pagesCV MDK 1mdkhandaveNo ratings yet

- Sociotechnical Management Model For Governance of An ECO System..Document11 pagesSociotechnical Management Model For Governance of An ECO System..Antonio José BalloniNo ratings yet

- Introductory Slides MPM701Document19 pagesIntroductory Slides MPM701PayalNo ratings yet

- Introduction and Instructions: ForewordDocument19 pagesIntroduction and Instructions: Forewordjose floresNo ratings yet

- OM All Chapers in OneDocument261 pagesOM All Chapers in OneShalle said AdenNo ratings yet

- Distribution & Logistics Management On Bose Corporation IndiaDocument18 pagesDistribution & Logistics Management On Bose Corporation IndiaSaurav HaldarNo ratings yet

- Operation Management - Unit 5 - Mid Term QuizDocument4 pagesOperation Management - Unit 5 - Mid Term Quizprithvirajdk70% (1)

- Project Report On Tps in Brakes India PVT LTDDocument21 pagesProject Report On Tps in Brakes India PVT LTDkumaran100% (1)

- Fundamentals of Metal CastingDocument53 pagesFundamentals of Metal CastingRohail AfzalNo ratings yet

- Marketing MixDocument14 pagesMarketing MixNhư QuỳnhNo ratings yet

- A Annual Consumption 0 Cost of Placing Order C Carrying Cost Per UnitDocument8 pagesA Annual Consumption 0 Cost of Placing Order C Carrying Cost Per UnitJaimin PatelNo ratings yet

- Incoterms 2020 Rules Chart of Responsibility: Any Transport Mode Sea/Inland Waterway Transport Any Transport ModeDocument2 pagesIncoterms 2020 Rules Chart of Responsibility: Any Transport Mode Sea/Inland Waterway Transport Any Transport ModeRicardo PirelaNo ratings yet

- "Export Procedure and Documentation": Bba 5 Semester By: Dr. Madhvi KushDocument28 pages"Export Procedure and Documentation": Bba 5 Semester By: Dr. Madhvi Kushekta singhNo ratings yet

- Cost of Goods SoldDocument4 pagesCost of Goods SoldemprotNo ratings yet

- Bajaj Electricals Limited: Job Title Job Code Department/ BU LocationDocument3 pagesBajaj Electricals Limited: Job Title Job Code Department/ BU LocationabhijitNo ratings yet

- Customer Value, Satisfaction and Loyalty at UberDocument3 pagesCustomer Value, Satisfaction and Loyalty at UberAmar narayanNo ratings yet

- Journal On Electronic Human Resource ManagementDocument7 pagesJournal On Electronic Human Resource Managementmohammedakbar88No ratings yet

- Case Study About 2Document5 pagesCase Study About 2Larga Lyka MaeNo ratings yet

- A2 - Managerial EconomicsDocument2 pagesA2 - Managerial EconomicsNishtha GargNo ratings yet

- Order Management System: Take Control of Your Order ProcessesDocument8 pagesOrder Management System: Take Control of Your Order ProcessesRicky ChanNo ratings yet

- Sales ManagementDocument56 pagesSales ManagementNITIN MehtaNo ratings yet

- AVCN1-ENP309 - 202 - CN01-Nhóm 4-KEYDocument4 pagesAVCN1-ENP309 - 202 - CN01-Nhóm 4-KEYVũ NguyễnNo ratings yet

- 007 Out of SpecificationDocument12 pages007 Out of Specificationmarkandey gupta100% (2)

- Validation and Qualification of Pharmaceutical ProductsDocument25 pagesValidation and Qualification of Pharmaceutical ProductsUgas Husen100% (1)

- Kelola,+03+ +JIMKES+2020+Vol+8+No+3+TitoDocument12 pagesKelola,+03+ +JIMKES+2020+Vol+8+No+3+TitoChikaaNo ratings yet

- ProtineX Case StudyDocument12 pagesProtineX Case StudysanaNo ratings yet

- HOOKED CoDocument10 pagesHOOKED CoNor Afidah Mohd HadzirNo ratings yet

Electrode Booklet F Web 80

Electrode Booklet F Web 80

Uploaded by

satnam0 ratings0% found this document useful (0 votes)

13 views1 pageThis document provides information on TENALLOY 4130 low alloy steel electrodes for welding AISI 4130 steel. It lists the key features of the electrodes including that they are basic coated and produce a Ni-Cr-Mo low alloy weld deposit. Proper preheat and post weld heat treatment are required to achieve the desired mechanical properties. Application examples are provided for welding heat treatable alloy steels. Chemical compositions and mechanical properties of the weld deposits are also specified.

Original Description:

Electrode Booklet F Web 80

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides information on TENALLOY 4130 low alloy steel electrodes for welding AISI 4130 steel. It lists the key features of the electrodes including that they are basic coated and produce a Ni-Cr-Mo low alloy weld deposit. Proper preheat and post weld heat treatment are required to achieve the desired mechanical properties. Application examples are provided for welding heat treatable alloy steels. Chemical compositions and mechanical properties of the weld deposits are also specified.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

13 views1 pageElectrode Booklet F Web 80

Electrode Booklet F Web 80

Uploaded by

satnamThis document provides information on TENALLOY 4130 low alloy steel electrodes for welding AISI 4130 steel. It lists the key features of the electrodes including that they are basic coated and produce a Ni-Cr-Mo low alloy weld deposit. Proper preheat and post weld heat treatment are required to achieve the desired mechanical properties. Application examples are provided for welding heat treatable alloy steels. Chemical compositions and mechanical properties of the weld deposits are also specified.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

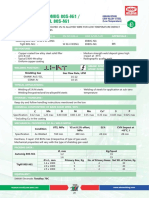

TENALLOY 4130

LOW ALLOY STEEL (High Strength)

Low alloy Steel Electrode for welding AISI 4130 steel.

KEY FEATURES :

• Basic coated electrode • Recommended preheat and interpass

• Ni-Cr-Mo low alloy weld deposit temperature is 200-315°C

• Hardening and tempering is required • All position capability

to achieve desired properties • Radiographic quality weld

WELDING POSITION : DCEP

TYPICAL APPLICATIONS :

• Welding heat treatable alloy type AISI/SAE 4130 • Suitable for steel casting with

and 8630 comparable hardening characteristics

REDRYING CONDITION : 250-300OC for minimum 1 hr.

CHEMICAL COMPOSITION OF UNDILUTED WELD METAL, Wt % :

C Mn Si Ni

Range 0.12-0.25 1.0-1.80 0.25-0.75 1.0-1.80

Cr Mo S P

Range 0.5-1.0 0.20-0.50 0.020 max 0.025 max

MECHANICAL PROPERTIES OF ALL WELD METAL :

YS at 0.2%

Condition UTS, MPa EL%

offset, MPa

PWHT: 871°C-Oil quenching 800-1000 700-900 16 min

Tempering at 621°C

Range

PWHT: 871°C-Oil quenching 1000-1200 900-1100 16 min

Tempering at 510°C

PARAMETERS - PACKING DATA :

Approx. Approx. wt.

Ø x L, mm Amperage, A Carton/Box

Pcs/Carton of 1000 pcs, Kg.

3.15 x 450 90-120 114 4 44

4.0 x 450 130-170 78 4 64

5.0 x 450 180-250 50 4 100

PASSION FOR WELDING SINCE 1951 www.adorwelding.com

80

You might also like

- SAP MM NotesDocument242 pagesSAP MM NotesEvelyn RochaNo ratings yet

- Electrode Booklet F Web 85Document1 pageElectrode Booklet F Web 85satnamNo ratings yet

- Tenalloy 120G: LOW ALLOY STEEL (High Strength)Document1 pageTenalloy 120G: LOW ALLOY STEEL (High Strength)Devender NegiNo ratings yet

- Electrode Booklet F Web 23Document1 pageElectrode Booklet F Web 23satnamNo ratings yet

- Tenalloy 70D11Document1 pageTenalloy 70D11pach-thNo ratings yet

- Electrode Booklet F Web 73Document1 pageElectrode Booklet F Web 73satnamNo ratings yet

- Nimoten: LOW ALLOY STEEL (Nimoten Series)Document1 pageNimoten: LOW ALLOY STEEL (Nimoten Series)satnamNo ratings yet

- Nimoten Plus 535: LOW ALLOY STEEL (Nimoten Series)Document1 pageNimoten Plus 535: LOW ALLOY STEEL (Nimoten Series)satnam100% (1)

- Nimoten Plus 535 A: LOW ALLOY STEEL (Nimoten Series)Document1 pageNimoten Plus 535 A: LOW ALLOY STEEL (Nimoten Series)satnamNo ratings yet

- Electrode Booklet F Web 21Document1 pageElectrode Booklet F Web 21satnamNo ratings yet

- Electrode Booklet F Web 120Document1 pageElectrode Booklet F Web 120satnamNo ratings yet

- Electrode Booklet F Web 24Document1 pageElectrode Booklet F Web 24satnamNo ratings yet

- Electrode Booklet F Web 20Document1 pageElectrode Booklet F Web 20satnamNo ratings yet

- Tenalloy 125: LOW ALLOY STEEL (High Strength)Document1 pageTenalloy 125: LOW ALLOY STEEL (High Strength)satnamNo ratings yet

- Topstar 110: C-MN STEEL (High Efficiency)Document1 pageTopstar 110: C-MN STEEL (High Efficiency)satnamNo ratings yet

- Tenalloy Z PlusDocument1 pageTenalloy Z Plushemal ChauhanNo ratings yet

- Metalbond: Mild Steel General Purpose (MSGP)Document1 pageMetalbond: Mild Steel General Purpose (MSGP)satnamNo ratings yet

- Electrode Booklet F Web 9Document1 pageElectrode Booklet F Web 9satnamNo ratings yet

- Nicalloy Mo-12: NON FERROUS (Ni Alloys)Document1 pageNicalloy Mo-12: NON FERROUS (Ni Alloys)krupesh patelNo ratings yet

- Electrode Booklet F Web 105Document1 pageElectrode Booklet F Web 105satnamNo ratings yet

- Electrode Booklet F Web 22Document1 pageElectrode Booklet F Web 22satnamNo ratings yet

- Ebondm: Mild Steel General Purpose (MSGP)Document1 pageEbondm: Mild Steel General Purpose (MSGP)satnamNo ratings yet

- Nicalloy Fe 3 Basic Coated Nickel Based ElectrodeDocument1 pageNicalloy Fe 3 Basic Coated Nickel Based ElectroderravibharathNo ratings yet

- Sae 4140 ACTDocument1 pageSae 4140 ACTOSCARNo ratings yet

- Electrode Booklet F Web 101Document1 pageElectrode Booklet F Web 101satnamNo ratings yet

- High Tensile Steel 4140Document2 pagesHigh Tensile Steel 4140Lazzarus Az GunawanNo ratings yet

- Electrode Booklet F Web 14Document1 pageElectrode Booklet F Web 14satnamNo ratings yet

- X Bond: Welding Electrode For Structural Welding ApplicationDocument1 pageX Bond: Welding Electrode For Structural Welding ApplicationAmit ChapagainNo ratings yet

- Celwel - 70P (Ador Electrodes)Document1 pageCelwel - 70P (Ador Electrodes)Harish KandollaNo ratings yet

- Electrode Booklet F Web 8Document1 pageElectrode Booklet F Web 8satnamNo ratings yet

- Electrode Booklet F Web 121Document1 pageElectrode Booklet F Web 121satnamNo ratings yet

- High Tensile: Voestalpine High Performance Metals (Australia) Pty LTDDocument5 pagesHigh Tensile: Voestalpine High Performance Metals (Australia) Pty LTDSinan YıldızNo ratings yet

- Electrode Booklet F Web 104Document1 pageElectrode Booklet F Web 104satnamNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Raj RajeshNo ratings yet

- Electrode Booklet F Web 100Document1 pageElectrode Booklet F Web 100satnamNo ratings yet

- Supabase-X-Plus AdorDocument1 pageSupabase-X-Plus AdorJagan TnNo ratings yet

- Wb56S M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb56S M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- Alloy 410s Spec SheetDocument2 pagesAlloy 410s Spec SheetALONSO GOMEZNo ratings yet

- Tigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-ADocument1 pageTigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-AsatnamNo ratings yet

- Electrode Booklet F Web 96Document1 pageElectrode Booklet F Web 96satnamNo ratings yet

- Electrode Booklet F Web 13Document1 pageElectrode Booklet F Web 13satnamNo ratings yet

- Bohler Fox N CM 2 KBDocument1 pageBohler Fox N CM 2 KBkamals55No ratings yet

- Electrode Booklet F Web 106Document1 pageElectrode Booklet F Web 106satnamNo ratings yet

- Betanox 308 Plus: STAINLESS STEEL (Austenitic Steel)Document1 pageBetanox 308 Plus: STAINLESS STEEL (Austenitic Steel)satnamNo ratings yet

- High Tensile Steel: Voestalpine High Performance Metals (Australia) Pty LTDDocument3 pagesHigh Tensile Steel: Voestalpine High Performance Metals (Australia) Pty LTDJoko tri SantosoNo ratings yet

- (17CrNiMo6) 4317 Case Hardening SteelDocument3 pages(17CrNiMo6) 4317 Case Hardening Steelazhar mohammedNo ratings yet

- 1.3505 100cr6 PDFDocument1 page1.3505 100cr6 PDFmcNo ratings yet

- AISI416Document2 pagesAISI416shamsi862620No ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- Alloy 410S Spec SheetDocument2 pagesAlloy 410S Spec SheetPrakash SundharamNo ratings yet

- Sandvik: Stainless Steel Wire ProductsDocument4 pagesSandvik: Stainless Steel Wire ProductsRemo StortiniNo ratings yet

- Case Hardening Steel A Is I 8620Document2 pagesCase Hardening Steel A Is I 8620fahriNo ratings yet

- SAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat TreatmentDocument2 pagesSAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat TreatmentAnush Swaminathan100% (1)

- Wb2318e E9018-MDocument1 pageWb2318e E9018-McwiksjNo ratings yet

- Betanox D Welding ElectrodeDocument1 pageBetanox D Welding ElectrodearavindpeetaNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- Wb35S M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb35S M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- Analytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryFrom EverandAnalytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- Automig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36Document1 pageAutomig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36satnamNo ratings yet

- Automig Cusn-A: Classification: Aws A/Sfa 5.7Document1 pageAutomig Cusn-A: Classification: Aws A/Sfa 5.7satnamNo ratings yet

- CWC-BookletF1 59Document1 pageCWC-BookletF1 59satnamNo ratings yet

- Tigfil Cuni: Classification: ApprovalsDocument1 pageTigfil Cuni: Classification: ApprovalssatnamNo ratings yet

- AUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalsDocument1 pageAUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalssatnamNo ratings yet

- AUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalsDocument1 pageAUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalssatnamNo ratings yet

- AUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-ADocument1 pageAUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-AsatnamNo ratings yet

- AUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalsDocument1 pageAUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalssatnamNo ratings yet

- Tiginox 385: Classification: en Iso 14343-ADocument1 pageTiginox 385: Classification: en Iso 14343-AJagannath SahuNo ratings yet

- AUTOMIG 1100: Classification: Aws A/Sfa 5.10Document1 pageAUTOMIG 1100: Classification: Aws A/Sfa 5.10satnamNo ratings yet

- Automig Nicu-7 / Tigfil Nicu-7: Ernicu-7 Sni 4060Document1 pageAutomig Nicu-7 / Tigfil Nicu-7: Ernicu-7 Sni 4060satnamNo ratings yet

- CWC-BookletF1 9Document1 pageCWC-BookletF1 9satnamNo ratings yet

- Automig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48Document1 pageAutomig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48satnamNo ratings yet

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Document1 pageTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamNo ratings yet

- Tigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-ADocument1 pageTigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-AsatnamNo ratings yet

- Automig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28Document1 pageAutomig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28satnamNo ratings yet

- CWC-BookletF1 15Document1 pageCWC-BookletF1 15satnamNo ratings yet

- CWC-BookletF1 12Document1 pageCWC-BookletF1 12satnamNo ratings yet

- CWC-BookletF1 17Document1 pageCWC-BookletF1 17satnamNo ratings yet

- Automig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalsDocument1 pageAutomig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalssatnamNo ratings yet

- TIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48Document1 pageTIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48satnamNo ratings yet

- Tigfil 70S-2: Aws A/sfa 5.18 en Iso 636-ADocument1 pageTigfil 70S-2: Aws A/sfa 5.18 en Iso 636-AsatnamNo ratings yet

- CWC-BookletF1 10Document1 pageCWC-BookletF1 10satnamNo ratings yet

- Tigfil 70S-2: Aws A/sfa 5.18 en Iso 636-ADocument1 pageTigfil 70S-2: Aws A/sfa 5.18 en Iso 636-AsatnamNo ratings yet

- CWC-BookletF1 9Document1 pageCWC-BookletF1 9satnamNo ratings yet

- CWC-BookletF1 5Document1 pageCWC-BookletF1 5satnamNo ratings yet

- CWC-BookletF1 3Document1 pageCWC-BookletF1 3satnamNo ratings yet

- Automig 70S-6: AWS A/SFA 5.18 Csa W48Document1 pageAutomig 70S-6: AWS A/SFA 5.18 Csa W48satnamNo ratings yet

- CWC-BookletF1 2Document1 pageCWC-BookletF1 2satnamNo ratings yet

- CWC-BookletF1 4Document1 pageCWC-BookletF1 4satnamNo ratings yet

- Ch20 Quản trị tồn kho OSCMDocument7 pagesCh20 Quản trị tồn kho OSCMThanhHuongNo ratings yet

- B - Support Schedule For Cloud ServicesDocument5 pagesB - Support Schedule For Cloud ServicesUlysse TpnNo ratings yet

- CV MDK 1Document7 pagesCV MDK 1mdkhandaveNo ratings yet

- Sociotechnical Management Model For Governance of An ECO System..Document11 pagesSociotechnical Management Model For Governance of An ECO System..Antonio José BalloniNo ratings yet

- Introductory Slides MPM701Document19 pagesIntroductory Slides MPM701PayalNo ratings yet

- Introduction and Instructions: ForewordDocument19 pagesIntroduction and Instructions: Forewordjose floresNo ratings yet

- OM All Chapers in OneDocument261 pagesOM All Chapers in OneShalle said AdenNo ratings yet

- Distribution & Logistics Management On Bose Corporation IndiaDocument18 pagesDistribution & Logistics Management On Bose Corporation IndiaSaurav HaldarNo ratings yet

- Operation Management - Unit 5 - Mid Term QuizDocument4 pagesOperation Management - Unit 5 - Mid Term Quizprithvirajdk70% (1)

- Project Report On Tps in Brakes India PVT LTDDocument21 pagesProject Report On Tps in Brakes India PVT LTDkumaran100% (1)

- Fundamentals of Metal CastingDocument53 pagesFundamentals of Metal CastingRohail AfzalNo ratings yet

- Marketing MixDocument14 pagesMarketing MixNhư QuỳnhNo ratings yet

- A Annual Consumption 0 Cost of Placing Order C Carrying Cost Per UnitDocument8 pagesA Annual Consumption 0 Cost of Placing Order C Carrying Cost Per UnitJaimin PatelNo ratings yet

- Incoterms 2020 Rules Chart of Responsibility: Any Transport Mode Sea/Inland Waterway Transport Any Transport ModeDocument2 pagesIncoterms 2020 Rules Chart of Responsibility: Any Transport Mode Sea/Inland Waterway Transport Any Transport ModeRicardo PirelaNo ratings yet

- "Export Procedure and Documentation": Bba 5 Semester By: Dr. Madhvi KushDocument28 pages"Export Procedure and Documentation": Bba 5 Semester By: Dr. Madhvi Kushekta singhNo ratings yet

- Cost of Goods SoldDocument4 pagesCost of Goods SoldemprotNo ratings yet

- Bajaj Electricals Limited: Job Title Job Code Department/ BU LocationDocument3 pagesBajaj Electricals Limited: Job Title Job Code Department/ BU LocationabhijitNo ratings yet

- Customer Value, Satisfaction and Loyalty at UberDocument3 pagesCustomer Value, Satisfaction and Loyalty at UberAmar narayanNo ratings yet

- Journal On Electronic Human Resource ManagementDocument7 pagesJournal On Electronic Human Resource Managementmohammedakbar88No ratings yet

- Case Study About 2Document5 pagesCase Study About 2Larga Lyka MaeNo ratings yet

- A2 - Managerial EconomicsDocument2 pagesA2 - Managerial EconomicsNishtha GargNo ratings yet

- Order Management System: Take Control of Your Order ProcessesDocument8 pagesOrder Management System: Take Control of Your Order ProcessesRicky ChanNo ratings yet

- Sales ManagementDocument56 pagesSales ManagementNITIN MehtaNo ratings yet

- AVCN1-ENP309 - 202 - CN01-Nhóm 4-KEYDocument4 pagesAVCN1-ENP309 - 202 - CN01-Nhóm 4-KEYVũ NguyễnNo ratings yet

- 007 Out of SpecificationDocument12 pages007 Out of Specificationmarkandey gupta100% (2)

- Validation and Qualification of Pharmaceutical ProductsDocument25 pagesValidation and Qualification of Pharmaceutical ProductsUgas Husen100% (1)

- Kelola,+03+ +JIMKES+2020+Vol+8+No+3+TitoDocument12 pagesKelola,+03+ +JIMKES+2020+Vol+8+No+3+TitoChikaaNo ratings yet

- ProtineX Case StudyDocument12 pagesProtineX Case StudysanaNo ratings yet

- HOOKED CoDocument10 pagesHOOKED CoNor Afidah Mohd HadzirNo ratings yet