Professional Documents

Culture Documents

Nimoten Plus 535: LOW ALLOY STEEL (Nimoten Series)

Nimoten Plus 535: LOW ALLOY STEEL (Nimoten Series)

Uploaded by

satnamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nimoten Plus 535: LOW ALLOY STEEL (Nimoten Series)

Nimoten Plus 535: LOW ALLOY STEEL (Nimoten Series)

Uploaded by

satnamCopyright:

Available Formats

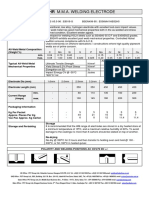

NIMOTEN PLUS 535

LOW ALLOY STEEL (Nimoten Series)

Low alloy steel Welding Electrode for application in steel mills and forging industries.

KEY FEATURES :

• Basic type medium-heavy coating • All position capability

• Low alloy type weld metal • Special application for joining and

• Tensile strength over 950 Mpa overlay work in steel mills and forging

industry

• Radiographic weld deposit

WELDING POSITION : AC (90 OCV)/DCEP

TYPICAL APPLICATIONS :

• Filling die impressions in forging dies • High tensile steel machinery parts

• Automotive parts • Parts of earth moving equipment

• Certain grades of armour steel • Steam turbine rotors at 538°C

• Ni-Cr-Mo steels in chemical plants • Case hardening steel parts repair after

• Crack repair in Ni-Cr hot working dies removing hard zone

REDRYING CONDITION : 250-300OC for minimum 1 hr.

CHEMICAL COMPOSITION OF UNDILUTED WELD METAL, Wt % :

C Mn Si Cr Ni

Typical 0.08 1.4 0.2 2.8 2.1

Range 0.07-0.09 1.20-1.70 0.15-0.25 2.5-3.0 1.8-2.2

Mo V S P

Typical 1.2 0.1 0.02 0.02

Range 1.0-1.5 0.1-0.2 0.03 max 0.03 max

MECHANICAL PROPERTIES OF ALL WELD METAL :

Condition UTS, MPa YS at 0.2% offset, MPa EL%

Typical 735 625 19

As Welded

Range 690-780 600-650 16-24

Hardness, 3 Layer: 260-330 BHN Diffusible H2 Content: <5 ml/100 gm

PARAMETERS - PACKING DATA :

Approx. Approx. wt.

Ø x L, mm Amperage, A Carton/Box

Pcs/Carton of 1000 pcs, Kg.

3.15 x 450 100-130 127 4 39

4.0 x 450 140-180 86 4 58

5.0 x 450 190-230 53 4 94

6.3 x 450 260-320 34 4 147

PASSION FOR WELDING SINCE 1951 www.adorwelding.com

86

You might also like

- Itunes Gifted Card Format-1Document1 pageItunes Gifted Card Format-1Mr Naijatim89% (281)

- GISA 7.0 Aug20 StudentWorkbookDocument205 pagesGISA 7.0 Aug20 StudentWorkbookHostDavid100% (1)

- How Can The Law Be Used As An Instrument For Creating Social Change - IpleadersDocument13 pagesHow Can The Law Be Used As An Instrument For Creating Social Change - IpleadersLeelakrishna VemuruNo ratings yet

- I. Introduction To Literary Genres 1. Understanding Conventions of Traditional GenresDocument5 pagesI. Introduction To Literary Genres 1. Understanding Conventions of Traditional GenresJessica Caisip0% (2)

- Electrode Booklet F Web 85Document1 pageElectrode Booklet F Web 85satnamNo ratings yet

- Nimoten: LOW ALLOY STEEL (Nimoten Series)Document1 pageNimoten: LOW ALLOY STEEL (Nimoten Series)satnamNo ratings yet

- Nimoten Plus 535 A: LOW ALLOY STEEL (Nimoten Series)Document1 pageNimoten Plus 535 A: LOW ALLOY STEEL (Nimoten Series)satnamNo ratings yet

- Electrode Booklet F Web 73Document1 pageElectrode Booklet F Web 73satnamNo ratings yet

- Electrode Booklet F Web 23Document1 pageElectrode Booklet F Web 23satnamNo ratings yet

- Electrode Booklet F Web 9Document1 pageElectrode Booklet F Web 9satnamNo ratings yet

- Metalbond: Mild Steel General Purpose (MSGP)Document1 pageMetalbond: Mild Steel General Purpose (MSGP)satnamNo ratings yet

- Electrode Booklet F Web 22Document1 pageElectrode Booklet F Web 22satnamNo ratings yet

- Electrode Booklet F Web 20Document1 pageElectrode Booklet F Web 20satnamNo ratings yet

- Electrode Booklet F Web 21Document1 pageElectrode Booklet F Web 21satnamNo ratings yet

- Tenalloy 120G: LOW ALLOY STEEL (High Strength)Document1 pageTenalloy 120G: LOW ALLOY STEEL (High Strength)Devender NegiNo ratings yet

- Electrode Booklet F Web 101Document1 pageElectrode Booklet F Web 101satnamNo ratings yet

- Tenalloy 70D11Document1 pageTenalloy 70D11pach-thNo ratings yet

- Supabase-X-Plus AdorDocument1 pageSupabase-X-Plus AdorJagan TnNo ratings yet

- Tenalloy 125: LOW ALLOY STEEL (High Strength)Document1 pageTenalloy 125: LOW ALLOY STEEL (High Strength)satnamNo ratings yet

- Tigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-ADocument1 pageTigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-AsatnamNo ratings yet

- Electrode Booklet F Web 13Document1 pageElectrode Booklet F Web 13satnamNo ratings yet

- Electrode Booklet F Web 14Document1 pageElectrode Booklet F Web 14satnamNo ratings yet

- Ebondm: Mild Steel General Purpose (MSGP)Document1 pageEbondm: Mild Steel General Purpose (MSGP)satnamNo ratings yet

- Electrode Booklet F Web 8Document1 pageElectrode Booklet F Web 8satnamNo ratings yet

- Kingbond S: Mild Steel General Purpose (MSGP)Document1 pageKingbond S: Mild Steel General Purpose (MSGP)satnamNo ratings yet

- Electrode Booklet F Web 96Document1 pageElectrode Booklet F Web 96satnamNo ratings yet

- Tenalloy Z PlusDocument1 pageTenalloy Z Plushemal ChauhanNo ratings yet

- Celwel - 70P (Ador Electrodes)Document1 pageCelwel - 70P (Ador Electrodes)Harish KandollaNo ratings yet

- X Bond: Welding Electrode For Structural Welding ApplicationDocument1 pageX Bond: Welding Electrode For Structural Welding ApplicationAmit ChapagainNo ratings yet

- Electrode Booklet F Web 104Document1 pageElectrode Booklet F Web 104satnamNo ratings yet

- Nicalloy Mo-12: NON FERROUS (Ni Alloys)Document1 pageNicalloy Mo-12: NON FERROUS (Ni Alloys)krupesh patelNo ratings yet

- Electrode Booklet F Web 105Document1 pageElectrode Booklet F Web 105satnamNo ratings yet

- Electrode Booklet F Web 100Document1 pageElectrode Booklet F Web 100satnamNo ratings yet

- Electrode Booklet F Web 93Document1 pageElectrode Booklet F Web 93satnamNo ratings yet

- Electrode Booklet F Web 121Document1 pageElectrode Booklet F Web 121satnamNo ratings yet

- Betanox D Welding ElectrodeDocument1 pageBetanox D Welding ElectrodearavindpeetaNo ratings yet

- Electrode Booklet F Web 24Document1 pageElectrode Booklet F Web 24satnamNo ratings yet

- Electrode Booklet F Web 18Document1 pageElectrode Booklet F Web 18satnamNo ratings yet

- Wb56S M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb56S M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- Automig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48Document1 pageAutomig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48satnamNo ratings yet

- Electrode Booklet F Web 120Document1 pageElectrode Booklet F Web 120satnamNo ratings yet

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Document1 pageTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamNo ratings yet

- Ador Welding Cromoten D For c5 & f5 WeldingDocument1 pageAdor Welding Cromoten D For c5 & f5 WeldingShar MathewNo ratings yet

- Topstar 110: C-MN STEEL (High Efficiency)Document1 pageTopstar 110: C-MN STEEL (High Efficiency)satnamNo ratings yet

- Wb88Shr M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb88Shr M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- Electrode Booklet F Web 97Document1 pageElectrode Booklet F Web 97satnamNo ratings yet

- Electrode Booklet F Web 80Document1 pageElectrode Booklet F Web 80satnamNo ratings yet

- Wb35S M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb35S M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- Electrode Booklet F Web 110Document1 pageElectrode Booklet F Web 110satnamNo ratings yet

- Celwel - 60 (Adore Electrodes)Document1 pageCelwel - 60 (Adore Electrodes)Harish KandollaNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Raj RajeshNo ratings yet

- Nicalloy Fe 3 Basic Coated Nickel Based ElectrodeDocument1 pageNicalloy Fe 3 Basic Coated Nickel Based ElectroderravibharathNo ratings yet

- Betanox 308 Plus: STAINLESS STEEL (Austenitic Steel)Document1 pageBetanox 308 Plus: STAINLESS STEEL (Austenitic Steel)satnamNo ratings yet

- Bohler Fox N CM 2 KBDocument1 pageBohler Fox N CM 2 KBkamals55No ratings yet

- Tiginox 385: Classification: en Iso 14343-ADocument1 pageTiginox 385: Classification: en Iso 14343-AJagannath SahuNo ratings yet

- Cu ZN 10Document2 pagesCu ZN 10wjjt6chgtmNo ratings yet

- Electrode Booklet F Web 106Document1 pageElectrode Booklet F Web 106satnamNo ratings yet

- Wb76S M.M.A. Welding Electrode: Classifications & ApprovalsDocument1 pageWb76S M.M.A. Welding Electrode: Classifications & Approvalslathasri78No ratings yet

- CWC-BookletF1 24Document1 pageCWC-BookletF1 24Jagannath SahuNo ratings yet

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 pagesDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelHugo RodriguezNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- Cu ZN 15Document2 pagesCu ZN 15wjjt6chgtmNo ratings yet

- Tigfil Cuni: Classification: ApprovalsDocument1 pageTigfil Cuni: Classification: ApprovalssatnamNo ratings yet

- Automig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36Document1 pageAutomig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36satnamNo ratings yet

- CWC-BookletF1 59Document1 pageCWC-BookletF1 59satnamNo ratings yet

- Automig Cusn-A: Classification: Aws A/Sfa 5.7Document1 pageAutomig Cusn-A: Classification: Aws A/Sfa 5.7satnamNo ratings yet

- AUTOMIG 1100: Classification: Aws A/Sfa 5.10Document1 pageAUTOMIG 1100: Classification: Aws A/Sfa 5.10satnamNo ratings yet

- AUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalsDocument1 pageAUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalssatnamNo ratings yet

- AUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalsDocument1 pageAUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalssatnamNo ratings yet

- AUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalsDocument1 pageAUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalssatnamNo ratings yet

- Automig Nicu-7 / Tigfil Nicu-7: Ernicu-7 Sni 4060Document1 pageAutomig Nicu-7 / Tigfil Nicu-7: Ernicu-7 Sni 4060satnamNo ratings yet

- Automig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28Document1 pageAutomig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28satnamNo ratings yet

- CWC-BookletF1 17Document1 pageCWC-BookletF1 17satnamNo ratings yet

- AUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-ADocument1 pageAUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-AsatnamNo ratings yet

- Tiginox 385: Classification: en Iso 14343-ADocument1 pageTiginox 385: Classification: en Iso 14343-AJagannath SahuNo ratings yet

- TIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48Document1 pageTIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48satnamNo ratings yet

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Document1 pageTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamNo ratings yet

- Automig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalsDocument1 pageAutomig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalssatnamNo ratings yet

- Tigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-ADocument1 pageTigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-AsatnamNo ratings yet

- CWC-BookletF1 9Document1 pageCWC-BookletF1 9satnamNo ratings yet

- CWC-BookletF1 15Document1 pageCWC-BookletF1 15satnamNo ratings yet

- CWC-BookletF1 12Document1 pageCWC-BookletF1 12satnamNo ratings yet

- Tigfil 70S-2: Aws A/sfa 5.18 en Iso 636-ADocument1 pageTigfil 70S-2: Aws A/sfa 5.18 en Iso 636-AsatnamNo ratings yet

- CWC-BookletF1 9Document1 pageCWC-BookletF1 9satnamNo ratings yet

- Tigfil 70S-2: Aws A/sfa 5.18 en Iso 636-ADocument1 pageTigfil 70S-2: Aws A/sfa 5.18 en Iso 636-AsatnamNo ratings yet

- Automig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48Document1 pageAutomig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48satnamNo ratings yet

- CWC-BookletF1 10Document1 pageCWC-BookletF1 10satnamNo ratings yet

- CWC-BookletF1 4Document1 pageCWC-BookletF1 4satnamNo ratings yet

- Automig 70S-6: AWS A/SFA 5.18 Csa W48Document1 pageAutomig 70S-6: AWS A/SFA 5.18 Csa W48satnamNo ratings yet

- CWC-BookletF1 5Document1 pageCWC-BookletF1 5satnamNo ratings yet

- CWC-BookletF1 3Document1 pageCWC-BookletF1 3satnamNo ratings yet

- CWC-BookletF1 2Document1 pageCWC-BookletF1 2satnamNo ratings yet

- Administradora de Estaciones de Servicio Sa de CV: BPJURIH 10852 76100Document1 pageAdministradora de Estaciones de Servicio Sa de CV: BPJURIH 10852 76100gordoasesinoNo ratings yet

- Chapter 1: IntroductionDocument48 pagesChapter 1: IntroductionnemchandNo ratings yet

- Tiểu luận TemplateDocument7 pagesTiểu luận TemplateThảo NguyênNo ratings yet

- 16 Legacy B1 - P1 Quiz 8BDocument2 pages16 Legacy B1 - P1 Quiz 8BKremena Mihova100% (2)

- 2nd Person StoryDocument1 page2nd Person Storynya.cooktillettNo ratings yet

- Laporan Auditor Independen PT UnileverDocument72 pagesLaporan Auditor Independen PT UnileverYasin AlriyadiNo ratings yet

- Davis HabitabilidadDocument62 pagesDavis HabitabilidadchiodesantiagoNo ratings yet

- Solucion Error Cargue Mediante OPENROWSEDocument4 pagesSolucion Error Cargue Mediante OPENROWSEJEBUSOOONo ratings yet

- What Is Letter?Document4 pagesWhat Is Letter?Angelly V VelascoNo ratings yet

- Sales and Distribution Management Channel Management (Retail) Group-5 PDFDocument14 pagesSales and Distribution Management Channel Management (Retail) Group-5 PDFSneha KhandelwalNo ratings yet

- Kumar Sabnani Org CultureDocument2 pagesKumar Sabnani Org CultureAayushi SinghNo ratings yet

- Axis 210/211 User's ManualDocument60 pagesAxis 210/211 User's ManualGotoMyCameraNo ratings yet

- 500 Oncology QuestionsDocument52 pages500 Oncology QuestionsCha ChaNo ratings yet

- Brands Hatch On TrackDocument2 pagesBrands Hatch On TrackManuel MachadoNo ratings yet

- Logistics Management QuizDocument9 pagesLogistics Management Quizcountryboy9jaNo ratings yet

- DAPUSDocument5 pagesDAPUSEni NurainiNo ratings yet

- Tripping Rules For D&D 5eDocument1 pageTripping Rules For D&D 5eubernexNo ratings yet

- 중3 동아 윤정미 7과Document97 pages중3 동아 윤정미 7과Ито ХиробумиNo ratings yet

- Boysen PlexibondDocument3 pagesBoysen PlexibondlimbadzNo ratings yet

- SBU 105 Introduction To ComputersDocument2 pagesSBU 105 Introduction To ComputersSaviourNo ratings yet

- Principles of Organization & ManagementDocument6 pagesPrinciples of Organization & Managementsehj888No ratings yet

- Turn Your Lights Down Low: Bob MarleyDocument5 pagesTurn Your Lights Down Low: Bob MarleyIvan ChicaneNo ratings yet

- UNITAS 91 1 Bayani Santos Translating Banaag at Sikat PDFDocument24 pagesUNITAS 91 1 Bayani Santos Translating Banaag at Sikat PDFCharles DoradoNo ratings yet

- (Me 15) Bosh - Lecture 02Document36 pages(Me 15) Bosh - Lecture 02Strong Boy OgkoNo ratings yet

- Noob's Character Sheet 2.3 (Cypher System)Document4 pagesNoob's Character Sheet 2.3 (Cypher System)Pan100% (1)