Professional Documents

Culture Documents

Budget of Work

Budget of Work

Uploaded by

Jocelyn Cortes Intano0 ratings0% found this document useful (0 votes)

24 views8 pagesThis document outlines a quarterly budget of work for nail care training. It includes 4 lessons over 2 quarters: 1) use of nail tools and equipment, 2) maintaining tools, 3) occupational health and safety, and 4) basic nail designs. Each lesson has learning objectives, competencies, activities and assessments. Tools, equipment, hazards, and basic nail shapes are taught. Students will be evaluated through written tests, performance evaluations, and practical demonstrations.

Original Description:

Grade 8 Dressmaking

Original Title

BUDGET OF WORK

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines a quarterly budget of work for nail care training. It includes 4 lessons over 2 quarters: 1) use of nail tools and equipment, 2) maintaining tools, 3) occupational health and safety, and 4) basic nail designs. Each lesson has learning objectives, competencies, activities and assessments. Tools, equipment, hazards, and basic nail shapes are taught. Students will be evaluated through written tests, performance evaluations, and practical demonstrations.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

24 views8 pagesBudget of Work

Budget of Work

Uploaded by

Jocelyn Cortes IntanoThis document outlines a quarterly budget of work for nail care training. It includes 4 lessons over 2 quarters: 1) use of nail tools and equipment, 2) maintaining tools, 3) occupational health and safety, and 4) basic nail designs. Each lesson has learning objectives, competencies, activities and assessments. Tools, equipment, hazards, and basic nail shapes are taught. Students will be evaluated through written tests, performance evaluations, and practical demonstrations.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 8

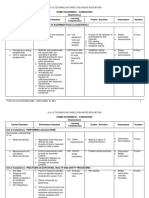

BUDGET OF WORK

TLE 8

QUARTER 1

LESSON 1: USE OF NAIL CARE TOOLS AND EQUIPMENT

Content Standard Performance Learning Project /

Assessment Duration

Standard Competencies Activities

Demonstrate 1. Tools and Identify Performance 3 hrs.

understanding equipment are LO1. Prepare different tools test

on: prepared the and Written

Nail care tools and based on necessary equipment examination

equipment salon tools and according to

procedure and equipment task

policies. for the requirement.

2. Tools and specific nail Prepare the

equipment are care activity. necessary

identified and tools,

checked materials and

according to equipment for

task the specific

requirements. nail care

services.

Uses of nail care 1. Tools and LO2. Use nail Demonstrate Written test 4 hrs.

tools equipment are care the proper use Performance

and equipment used tools and of nail care Test

according to equipment. tools and

task equipment.

requirements.

2. Safety

procedure of

using tools

and equipment

are observed.

LESSON 2 : MAINTAIN TOOLS AND EQUIPMENT

Demonstrate 1. Procedures LO1. Check Practical Performance 3 hrs.

understanding for sterilization condition of application on test

1. Procedures for and nail care tools the Written test

sterilization sanitation of and equipment proper

and sanitation of nail care tools handling and

nail care and care of

tools and equipment equipment are tools and

2. Classification of followed equipment

functional 2. Non- through group

and non functional functional activities

tools and tools and

equipment equipment are

3. Safekeeping and segregated

storage of and

tools and equipment labeled

4. PPE according to

classification

3. Tools and

equipment are

safely

stored in

accordance

with salon

requirements

and local

health

regulations

4.Conditions

of PPE are

checked

in accordance

with

manufacturer's

instruction

1.Safekeeping of 1.Nail care LO2.Perform Activity 1 Written test 3 hrs.

equipment tools and basic Practical Performance

and tools equipment preventive and demonstration test

2. Preventive are identified corrective of

maintenance 2.Appropriate maintenance proper way of

technique and cleaning keeping the

procedures procedure workplace

3.OHS workplace of nail care clean and

regulations tools and safe to

equipment individual

are applied. clients

3.Tools are Student’s

cleaned demonstration

according to on

standard sanitizing

procedures. equipment

4.Defective and

equipment and implements

tools

are inspected

and replaced

according to

manufacturer’s

specification.

5. Workplace

is cleaned and

kept

in safe state in

line with OHS

regulations

1 Inventory of tools 1.Inventory of LO3.Store nail Demonstration Performance 4 hrs

and tools, care of the proper test

equipment instruments tools and way of storing Written tests.

2. Tool and equipment equipment tools and

safekeeping/storage are conducted equipment

and Group activity

recorded per showing the

salon inventory

practices. procedure in a

2 .Tools and simulated

equipment are workplace.

stored

safely in

accordance

with

manufacturer’s

specifications

or

salon

procedure.

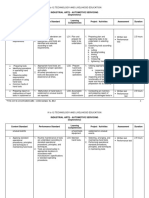

QUARTER 2

LESSON 3: PRACTICE OCCUPATIONAL HEALTH AND SAFETY PROCEDURES

Content Standard Performance Learning Project /

Assessment Duration

Standard Competencies Activities

Demonstrate 1. Work place LO1.Identify Venn Diagram Written 4hrs

understanding : hazards and hazards and Hazard examination

Hazards and risks risks. Recognition Performance

Risks are identified Activity. Test

Common in Beauty and clearly

salons explained.

2. Hazards

and risks and

its

corresponding

indicators are

identified in

the workplace.

3. Effects of

hazards are

determined.

Common workplace 1. Terms of Interview Written 6 hrs

hazards and their maximum 1. Terms of Film clips examination

control tolerable maximum Performance

measures limits are tolerable Evaluation

Electricity identified limits are

Chemical based on identified

hazard threshold limit based on

Slips, Trips, values (TLV). threshold limit

Falls 2. Effects of values (TLV).

Fire hazard hazards are 2. Effects of

Manual determined. hazards are

handling 3. OHS issues determined.

Biological and concerns 3. OHS issues

hazard are and concerns

identified in are

Ergonomics accordance identified in

hazards with accordance

workplace with

requirements workplace

4. Sets of requirements

personal 4. Sets of

clothing personal

equipment are clothing

used

LESSON 4: PRACTICE BASIC NAIL DESIGNS

Demonstrate 1. Nail LO1. Identify Written test 3 hrs.

understanding structure and nail Trimming

on: shapes are structure , nails applying

Structures of nail identified shapes and the different

Nail shapes 2. Nails are nail diseases / basic nail

Nail disorders and trimmed and disorders . shape

diseases varied

shapes are

applied;

3. Nail

disorders and

diseases

are identified

Basic nail designs Basic nail LO2. Create Project Performance 10 hrs

designs basic making - test

nail designs. Basic nail Written test

designs in

mock

Nails

QUARTER 3

LESSON 1: USE OF SEWING TOOLS

Content Standard Performance Learning Project /

Assessment Duration

Standard Competencies Activities

Demonstrate 1. Sewing LO1. Identify 1. Producing Written Test 4 hours

understanding tools and sewing tools a Performance

of/on: equipment and sewing kit test

1. Sewing tools are identified equipment and and

and 2. Types of their uses compiling the

equipment and sewing tools

their machines are and supplies

functions classified and properly

2. Classifying the their uses are 2. Students

types identified will visit

of sewing 2 or more

machines dress

and their uses shop and

gather

fabric

swatches

that will be

analyze and

classify its

textures and

quality.

LESSON 2: CARRY OUT MEASUREMENTS AND CALCULATIONS

Demonstrate 1. Parts of the LO1. Obtain 1. Using a Written 10 hours

understanding body are Measurements tape examination

of/on: measured measure, get Demonstration

1. Body 2. Appropriate the

measurements measuring length and

in ladies and tools are width of a

men’s selected for cloth to be

apparel job. used in

3. Reading of making a

measurements table

is napkin

practiced with 2. Taking

accuracy. body

4. Accurate measurement

measurements needed for

are ladies/

obtained. men’s

apparel

1. Metric 1. English and LO2. Perform 1. Students will Written 5 hours

conversion Metric simple take and examination

record body

measurements Performance

chart systems of calculations.

measurement test

of client,

are identified

gathered

and applied. measurements

2. Simple will be

calculations converted to

are centimeters

performed

based on the

job

requirement.

3. Reading of

measurements

is

practiced with

accuracy.

1. Estimate 1. Reading of LO3. Estimate 1. Calculating Written 4 hours

appropriate measurement appropriate materials examination

quantities is quantities needed Performance

practiced with in a certain test

accuracy suggested

2. The project

fundamentals

of

arithmetic

operations are

practiced with

accuracy

3. Cost of

project

materials are

estimated

based on

current

price

QUARTER 4

LESSON 3: CREATE DESIGN FOR A SIMPLE PROJECT

Content

Performance Learning Project /

Standard Assessment Duration

Standard Competencies Activities

Demonstrate 1. Design for LO1. Sketch 1. Sketching Written 6 hours

understanding a simple simple a Examination

of/on: project is project design design for a Performance test

1. Principles of sketched with different pocket

design applying the types sewing

2. Color theory principles of of patch tools

design and pockets. organizer

applying the

color

harmonies.

1. Basic hand 1. Project LO2. Produce 1. Creating Demonstration 10 hours

stitches produced in simple project patch WrittenExaminatio

accordance pockets n

to the 2. Making a

specifications pocket

of designs sewing tools

organizer

with

different

types of

patch

pockets and

labeled with

basic

hand

stitches.

3. Sew an

apron with

creative

patchwork

LESSON 4: PERFORM BASIC MAINTENANCE

Demonstrate Proper LO1. Operate 1. Making Written 10 hours

understanding handling of machine and sample examination

of/on: machine is assess its runs Performance test

1. Machine observed. performance (straight and

operation 2. Correct circular

Lower and procedures in lines)

upper machine 2. Assess a

threading of operation are sewing

sewing identified. machine

machine 3. Common

Common machine

sewing troubles

machine troubles are resolved.

and

its remedies

Quality of

stitches

and tensions

2. Sewing

machine and its

troubles and

remedies

1. Care of Sewing 1. Regular LO2. Clean 1. Cleaning Written

Machine cleaning of and and examination

machine lubricate lubricating Observation 6 hours

is observed machine sewing

2. Safety machines

procedures in and other

machine tools like

cleaning are pair of

followed. scissors,

3. Regular shears and

maintenance others.

schedules

are observed

and

recorded.

LESSON 5: PRACTICE OCCUPATIONAL SAFETY

Demonstrate 1. Workplace 1. Poster Situation analysis 4 hours

understanding hazards and LO1. Identify making on Practical

of: risks and hazards and examination

1. Hazards and are identified evaluate risks Written

risks and clearly hazards and examination

identification and explained. risks

control

1. Organizational 1. LO2. Control 1. Conduct Written 3 hours

safety Occupational hazards and an examination 4 hours

and health Health and risks interview in

protocol Safety school

2. Contingency (OHS) or in the

measures procedures community

and procedures for who has a

controlling specific

hazards and responsibility

risk are for

strictly safety

followed.

Prepared by:

JOCELYN R. CORTES

Teacher Noted by:

KIRK ANDREW B. ABELLANOSA

School Principal

You might also like

- III Unit 4a at The ToyshopDocument3 pagesIII Unit 4a at The ToyshopAna-Maria Gugu100% (1)

- Lesson-Plan-Tle-7-Nail Care ServicesDocument7 pagesLesson-Plan-Tle-7-Nail Care Servicesma kathrine cecille macapagalNo ratings yet

- Autism and AstrologyDocument9 pagesAutism and AstrologyJatinder Sandhu100% (1)

- Beauty Care Services-Nail Care (UNPACKED)Document2 pagesBeauty Care Services-Nail Care (UNPACKED)Leahsyl AyubanNo ratings yet

- Curriculum Map in Household ServicesDocument6 pagesCurriculum Map in Household ServicesMelcanie91% (11)

- Use Business EqipmentsDocument20 pagesUse Business Eqipmentsnigus100% (1)

- K To 12 CG - Nail Care - v1.0Document5 pagesK To 12 CG - Nail Care - v1.0ROWELYN DIPOSONo ratings yet

- Curguide NailcareDocument5 pagesCurguide NailcareOlive AsuncionNo ratings yet

- Curriculum Map: Demonstrate Understanding Of/onDocument2 pagesCurriculum Map: Demonstrate Understanding Of/onKIMBERLY AGUSTINNo ratings yet

- EEP - Grade 7 &8 MELCs CaregivingDocument2 pagesEEP - Grade 7 &8 MELCs CaregivingDANILYN BARGASAO100% (1)

- K To 12 CG Animal Production v1.0Document6 pagesK To 12 CG Animal Production v1.0Wildfox DawnNo ratings yet

- OAP - Common CompetenciesDocument13 pagesOAP - Common CompetenciesFe Marie JisonNo ratings yet

- CG HorticultureDocument7 pagesCG HorticultureEl G. Se ChengNo ratings yet

- Detailed Lesson Plan in TLEDocument7 pagesDetailed Lesson Plan in TLEma kathrine cecille macapagalNo ratings yet

- Agriculture/Fishery - Horticulture (Exploratory) : K To 12 Technology and Livelihood EducationDocument5 pagesAgriculture/Fishery - Horticulture (Exploratory) : K To 12 Technology and Livelihood EducationRonel Suan100% (1)

- DLL EIM11 1stSem1stQuarter Week1Document4 pagesDLL EIM11 1stSem1stQuarter Week1Gelo Dela TorreNo ratings yet

- K To 12 Technology and Livelihood Education: Home Economics - Caregiving (Exploratory)Document14 pagesK To 12 Technology and Livelihood Education: Home Economics - Caregiving (Exploratory)Bri CorpuzNo ratings yet

- Course Syllabus Nail CareDocument3 pagesCourse Syllabus Nail CareChristineJoyGalloNo ratings yet

- Hand ToolsDocument1 pageHand Toolsthess22No ratings yet

- Common Modules of Instruction Agriculture NC IIDocument13 pagesCommon Modules of Instruction Agriculture NC IIMEAMALLORCANo ratings yet

- Ia - Drafting CGDocument4 pagesIa - Drafting CGArlyn AgustinNo ratings yet

- Apply Safety Practices CLMDocument127 pagesApply Safety Practices CLMRonaldo CruzNo ratings yet

- Course Outline 1st To 3rd TrimDocument13 pagesCourse Outline 1st To 3rd TrimJoma RupisanNo ratings yet

- Sihhind201a r1Document11 pagesSihhind201a r1shalinikanchana8No ratings yet

- CG Mechanical DraftingDocument6 pagesCG Mechanical DraftingLENIN BRIONESNo ratings yet

- 3rd Quarter Examination Grade 7 Household Services TOSDocument3 pages3rd Quarter Examination Grade 7 Household Services TOSAngellie Arsaga AlaparNo ratings yet

- K To 12 CG - Agri-Crops - v1.0Document6 pagesK To 12 CG - Agri-Crops - v1.0may tagalogon villacoraNo ratings yet

- Curriculum Map TLE Computer Hardware 7/8Document6 pagesCurriculum Map TLE Computer Hardware 7/8billy jane ramosNo ratings yet

- ICT Grade 7 2ndDocument7 pagesICT Grade 7 2ndRhayan Dela Cruz DaquizNo ratings yet

- Workshop Tec Os Eo L5Document1 pageWorkshop Tec Os Eo L5Peter KathuvihNo ratings yet

- Caregiving q3 Grade 7Document37 pagesCaregiving q3 Grade 7Pahad SalendabNo ratings yet

- DLL - CAREGIVING WEEK2Document5 pagesDLL - CAREGIVING WEEK2Gracel Kay Valdez Gacisano100% (2)

- CM 7Document4 pagesCM 7daryl jay BelecarioNo ratings yet

- EEP Grade 7 8 Technical DraftingDocument4 pagesEEP Grade 7 8 Technical DraftingMark Christopher A. Ibay100% (1)

- TLE 9 - 2 Grading PeriodDocument3 pagesTLE 9 - 2 Grading PeriodJohn LesterNo ratings yet

- Tle DLL Week 1 and 2Document8 pagesTle DLL Week 1 and 2Mikko GomezNo ratings yet

- CM Tle 7 Q4Document4 pagesCM Tle 7 Q4Anday Par LizaNo ratings yet

- Nail CareDocument4 pagesNail CareRima Pigar Goza Meleloa100% (1)

- Beauty Care (Nail Care) Services PDFDocument4 pagesBeauty Care (Nail Care) Services PDFSmol ToksNo ratings yet

- DLL Lo3Document7 pagesDLL Lo3shiela wayasNo ratings yet

- CoCUDocument8 pagesCoCUmohd hamdi shafawiNo ratings yet

- Tle Jhs MelcsDocument53 pagesTle Jhs MelcscozimrelNo ratings yet

- 1ST Workshop PeacDocument21 pages1ST Workshop PeacJulia Maria Lovite100% (2)

- Common Competency in MasonryDocument12 pagesCommon Competency in MasonryColette BarillaNo ratings yet

- Industrial Arts - Automotive Servicing (Exploratory) : K To 12 Technology and Livelihood EducationDocument7 pagesIndustrial Arts - Automotive Servicing (Exploratory) : K To 12 Technology and Livelihood Educationjayson acunaNo ratings yet

- CC-5 Assessment Tool TemplateDocument6 pagesCC-5 Assessment Tool TemplateJayrod MoralesNo ratings yet

- Common Competency in Carpentry - (Module 2)Document12 pagesCommon Competency in Carpentry - (Module 2)Colette BarillaNo ratings yet

- GINA3Document2 pagesGINA3Norman T. RegalNo ratings yet

- Commercial Cooking 7 8Document6 pagesCommercial Cooking 7 8billy jane ramos50% (2)

- MELC - HE - Nail Care - G7-8Document1 pageMELC - HE - Nail Care - G7-8Edilbert Bonifacio Gayo100% (1)

- Teaching Guide Quarter 1-Tle 7Document3 pagesTeaching Guide Quarter 1-Tle 7Christy ParinasanNo ratings yet

- Competency Profile (CP) : Sub Sector After Sales Job Area Automotive After Sales Service Level TWODocument40 pagesCompetency Profile (CP) : Sub Sector After Sales Job Area Automotive After Sales Service Level TWONORISHAM BIN A RAHIMNo ratings yet

- Dll-Chs-Lo1-1.2, 1.3Document7 pagesDll-Chs-Lo1-1.2, 1.3Lauro Jr. AtienzaNo ratings yet

- DLL-agri11 3rd qrtr-6th WKDocument9 pagesDLL-agri11 3rd qrtr-6th WKgenesisaaron4No ratings yet

- MELC HE Caregiving G7-8Document2 pagesMELC HE Caregiving G7-8Edilbert Bonifacio GayoNo ratings yet

- Caregiving 7-8 MelcsDocument2 pagesCaregiving 7-8 MelcsEdilbert Bonifacio Gayo0% (1)

- TLE Carpentry7-8 Weeks2-3Document5 pagesTLE Carpentry7-8 Weeks2-3Ric Jhon LoraNo ratings yet

- Curriculum Guide: Exploratory Course On Household ServicesDocument5 pagesCurriculum Guide: Exploratory Course On Household ServicesJovanni Mancao PodadorNo ratings yet

- Cpccohs2001a - Module 1Document32 pagesCpccohs2001a - Module 1Nazareno BalagaNo ratings yet

- Nail Care Week 2Document4 pagesNail Care Week 2beverly leano100% (5)

- Use Business Eqipments PDocument18 pagesUse Business Eqipments PDemenaNo ratings yet

- Powerpoint in Grade 2 Musical InstrumentsDocument13 pagesPowerpoint in Grade 2 Musical InstrumentsJocelyn Cortes IntanoNo ratings yet

- How To AssessDocument1 pageHow To AssessJocelyn Cortes IntanoNo ratings yet

- Field Study: Technology in The Learning EnvironmentDocument2 pagesField Study: Technology in The Learning EnvironmentJocelyn Cortes IntanoNo ratings yet

- Lesson Plan in Tve Iii - Dressmaking Grand DemonstrationDocument7 pagesLesson Plan in Tve Iii - Dressmaking Grand DemonstrationJocelyn Cortes IntanoNo ratings yet

- Annual Poster-Making Contest Entitled Apoy, Bagyo, Kalamidad: Dibuhong Pambata (ABKD)Document1 pageAnnual Poster-Making Contest Entitled Apoy, Bagyo, Kalamidad: Dibuhong Pambata (ABKD)Jocelyn Cortes IntanoNo ratings yet

- Application For Leave: Cortes Jocelyn RapasDocument2 pagesApplication For Leave: Cortes Jocelyn RapasJocelyn Cortes IntanoNo ratings yet

- An Analysis of Students Anxiety in Speaking Class PDFDocument9 pagesAn Analysis of Students Anxiety in Speaking Class PDFIrwan WunarlanNo ratings yet

- ARK Trivings: Mark StrivingsDocument37 pagesARK Trivings: Mark Strivingstrixter11793100% (1)

- Module 3 Prof Educ 6 Part 2 Focus On The LearnerDocument14 pagesModule 3 Prof Educ 6 Part 2 Focus On The LearnerJohn Abe NasayaoNo ratings yet

- OLEDAN, IVAN GIL - J - Week 1 - Defining ArtDocument3 pagesOLEDAN, IVAN GIL - J - Week 1 - Defining ArtIvan Gil OledanNo ratings yet

- GR V3N1Document102 pagesGR V3N1Snežana PopovićNo ratings yet

- DLL Week 5Document3 pagesDLL Week 5Bai Mon100% (1)

- Waterfall ModelDocument6 pagesWaterfall ModelAswin MageshNo ratings yet

- EUSD Board Agenda, May 4, 2010Document51 pagesEUSD Board Agenda, May 4, 2010AsEUSDInConversationNo ratings yet

- Strategies - GistDocument4 pagesStrategies - Gistapi-260878103No ratings yet

- ESTP Personality Type - Persuader Profile - Personality MaxDocument7 pagesESTP Personality Type - Persuader Profile - Personality MaxDeanNo ratings yet

- MGT-312 Organizational Behavior Course SyllabusDocument12 pagesMGT-312 Organizational Behavior Course SyllabusCuevas-SantiagoAddieNo ratings yet

- Dracula EssayDocument3 pagesDracula Essaycjawrknbf100% (2)

- 2015 Use of EEG To Diagnose ADHD MARKEDDocument19 pages2015 Use of EEG To Diagnose ADHD MARKEDPiotr BuczkowiczNo ratings yet

- Cross Cultural Case Study PDFDocument33 pagesCross Cultural Case Study PDFlin_guardianangelNo ratings yet

- Laugh and LearnDocument10 pagesLaugh and LearnGitta Permata WNo ratings yet

- Greetings: Ways To Say HelloDocument2 pagesGreetings: Ways To Say HelloJessicaNo ratings yet

- Jona Gangan-GURO21 - Action-Plan-Template - VersionDocument2 pagesJona Gangan-GURO21 - Action-Plan-Template - VersionMaria Jonalyn GanganNo ratings yet

- Artículo - Inglés - Borderline Personality Disorder and Childhood Trauma. Evidence For A Causal RelationshipDocument6 pagesArtículo - Inglés - Borderline Personality Disorder and Childhood Trauma. Evidence For A Causal RelationshipMarian J SanmartiNo ratings yet

- CCEA - AS - Health and Social Care - Socio Economic Factors - UNIT 3Document23 pagesCCEA - AS - Health and Social Care - Socio Economic Factors - UNIT 3rubaalsirahmedNo ratings yet

- Kajian Keandalan Utilitas Bangunan Gedung Rusunawa Di Kota Banda AcehDocument10 pagesKajian Keandalan Utilitas Bangunan Gedung Rusunawa Di Kota Banda AcehUly Ulfa DyahNo ratings yet

- Book TactileDocument46 pagesBook TactileAnne WolburgNo ratings yet

- Understanding The Self PDFDocument100 pagesUnderstanding The Self PDFjextxadoreNo ratings yet

- Lesson Plan 5 - Investigating Different Groups of AnimalsDocument2 pagesLesson Plan 5 - Investigating Different Groups of Animalsapi-254197475No ratings yet

- Chapter 2 Operations StrategyDocument19 pagesChapter 2 Operations StrategyMedeaNo ratings yet

- Lacan, Jacques - Other Is Missing, (1987) 40 October 131Document4 pagesLacan, Jacques - Other Is Missing, (1987) 40 October 131yasin.almanca.1995No ratings yet

- Cpe 1 Reading Part 6 Test 4 AnswersDocument3 pagesCpe 1 Reading Part 6 Test 4 AnswersIryna DribkoNo ratings yet

- TRIZ Future 2015Document5 pagesTRIZ Future 2015kahloongNo ratings yet

- Syllabus Ecn204 F12Document5 pagesSyllabus Ecn204 F12RobMagooNo ratings yet