Professional Documents

Culture Documents

Alternative Coke Saving Technologies

Alternative Coke Saving Technologies

Uploaded by

Uday PrakashCopyright:

Available Formats

You might also like

- Coal For Metallurgical Coke Production PDFDocument24 pagesCoal For Metallurgical Coke Production PDFS SITAPATI100% (1)

- A Technical Review On Coke Rate and Quality in Low-Carbon BlastDocument27 pagesA Technical Review On Coke Rate and Quality in Low-Carbon BlastDavid Francisco Flórez RamosNo ratings yet

- Coal To Coke PDFDocument9 pagesCoal To Coke PDFVenkata Krishnan RamanujamNo ratings yet

- To Go Bits Kaya 2018Document6 pagesTo Go Bits Kaya 2018Arash AbbasiNo ratings yet

- Isijinternational - ISIJINT 2015 264Document10 pagesIsijinternational - ISIJINT 2015 264mbg2012No ratings yet

- Combustibles LiquidosDocument7 pagesCombustibles LiquidosVictor Hugo CarreÓnNo ratings yet

- Abstract of Papaer On Coal Quality-Blending A Perspective at RINLDocument15 pagesAbstract of Papaer On Coal Quality-Blending A Perspective at RINLbhujakhia_748657110No ratings yet

- Comparison of Cupola Furnace and Blast Furnace Slags With Respect To Possibilities of Their UtilizationDocument10 pagesComparison of Cupola Furnace and Blast Furnace Slags With Respect To Possibilities of Their UtilizationAafan ShahidNo ratings yet

- 8 KovalyovDocument3 pages8 KovalyovJaq Plin PlinNo ratings yet

- Blast Furnace Ironmaking Process Using Pre-Reduced Iron Ore: Nippon Steel Technical Report No. 94 July 2006Document6 pagesBlast Furnace Ironmaking Process Using Pre-Reduced Iron Ore: Nippon Steel Technical Report No. 94 July 2006Farhan AkhterNo ratings yet

- B EAF: Riquetting of Dust For Its Utilisation in Metallurgical ProcessesDocument9 pagesB EAF: Riquetting of Dust For Its Utilisation in Metallurgical ProcessesJaq Plin PlinNo ratings yet

- Production of Special CokeDocument6 pagesProduction of Special CokeAryo Prastyo AjiNo ratings yet

- 3A3. Direct Iron Ore Smelting Reduction Process (DIOS)Document2 pages3A3. Direct Iron Ore Smelting Reduction Process (DIOS)Imran Hanif LubisNo ratings yet

- Nox Emissions of An Opposed Wall-Fired Pulverized Coal Utility BoilerDocument7 pagesNox Emissions of An Opposed Wall-Fired Pulverized Coal Utility BoilerAnonymous knICaxNo ratings yet

- Coal Selection CriteriaDocument31 pagesCoal Selection CriteriaHardik Kumar MendparaNo ratings yet

- Addition of Renewable Carbon To Liquid Steel: Plant Trials at Onesteel Sydney Steel MillDocument13 pagesAddition of Renewable Carbon To Liquid Steel: Plant Trials at Onesteel Sydney Steel MillRidwand KartikaNo ratings yet

- Tese Nswparte 2Document153 pagesTese Nswparte 2AndrelslNo ratings yet

- CrystallizationDocument9 pagesCrystallizationGAURAV VERMANo ratings yet

- HGI-vs Mill Loading PDFDocument8 pagesHGI-vs Mill Loading PDFDebabrata TantubaiNo ratings yet

- Russia, Current State and Economics of Low Pressure Coal LiquifactionDocument12 pagesRussia, Current State and Economics of Low Pressure Coal Liquifactionstefan-romocki-4927No ratings yet

- CRI Effect On Blast FurnaceDocument7 pagesCRI Effect On Blast FurnaceHuso100% (2)

- TSL 2009 349Document7 pagesTSL 2009 349Soo Sang ParkNo ratings yet

- Energy: Ivan Najdenov, Karlo T. Rai C, Gordana KokezaDocument9 pagesEnergy: Ivan Najdenov, Karlo T. Rai C, Gordana Kokeza......No ratings yet

- Coal For Metallurgical Coke ProductionDocument24 pagesCoal For Metallurgical Coke ProductionSamanway DasNo ratings yet

- Article CIS 09 Pp.11-15Document5 pagesArticle CIS 09 Pp.11-15Maheswar SethiNo ratings yet

- Application of Anthracite Dust in The Processing of Steel DustsDocument3 pagesApplication of Anthracite Dust in The Processing of Steel DustsXingwen LiuNo ratings yet

- 2-2-A-2-Pulverized Coal Injection For Blast Furnace (PCI)Document2 pages2-2-A-2-Pulverized Coal Injection For Blast Furnace (PCI)Tonny FebryanNo ratings yet

- Impact of Pci in Blast FurnaceDocument11 pagesImpact of Pci in Blast FurnaceSableen SinghNo ratings yet

- 2013-04 Iron and Steel CCS Study (Techno-Economics Integrated Steel Mill)Document642 pages2013-04 Iron and Steel CCS Study (Techno-Economics Integrated Steel Mill)imtinanNo ratings yet

- Evaluation of The Co2 Re Activity of Chars Obtained Under Conventional and Oxyfuel AtmospheresDocument5 pagesEvaluation of The Co2 Re Activity of Chars Obtained Under Conventional and Oxyfuel AtmospheresjulianapohlmannufrgsNo ratings yet

- CSR Vs CRI Graph Coalformetallurgicalcokeproduction PDFDocument24 pagesCSR Vs CRI Graph Coalformetallurgicalcokeproduction PDFJANET GTNo ratings yet

- Ran Liu, Chunzhao LIANG, Xingjuan WANG, Shuai FENGDocument5 pagesRan Liu, Chunzhao LIANG, Xingjuan WANG, Shuai FENGAuliverKayMHNo ratings yet

- Continuous Coke Production: Coke and Chemistry August 2012Document8 pagesContinuous Coke Production: Coke and Chemistry August 2012atashi baran mohantyNo ratings yet

- New Technology PDFDocument27 pagesNew Technology PDFbasavarajNo ratings yet

- Tecnored Process - High Potential in Using Different Kinds of Solid FuelsDocument5 pagesTecnored Process - High Potential in Using Different Kinds of Solid FuelsRogerio CannoniNo ratings yet

- JMMCE 2014111809383149omoleDocument9 pagesJMMCE 2014111809383149omoleHassan ShirivandNo ratings yet

- Study of Coke Oven BatteryDocument18 pagesStudy of Coke Oven BatteryYeswanth Kumar100% (1)

- Direct Reduction-Are We Moving in The Right Direction?: by K. O. R. GebhardDocument2 pagesDirect Reduction-Are We Moving in The Right Direction?: by K. O. R. GebhardNadyaZulfaniNo ratings yet

- Applications Steel: Plexicoke in The VmezuelanDocument8 pagesApplications Steel: Plexicoke in The VmezuelanJose Marval RodriguezNo ratings yet

- Mousa 2013Document13 pagesMousa 2013kabamba KundaNo ratings yet

- Blast Furnace Japan DevelopmentDocument14 pagesBlast Furnace Japan DevelopmentShyam JiNo ratings yet

- Presentation On Preparation of Coke in Coke Oven Batteries: Presented By: Anil Kumar KhataiDocument18 pagesPresentation On Preparation of Coke in Coke Oven Batteries: Presented By: Anil Kumar KhataiKhatai Anil KumarNo ratings yet

- Thermal Properties of Carbon-Containing Iron Ore Composite Prepared by Vapor Deposition of Tar For LimoniteDocument14 pagesThermal Properties of Carbon-Containing Iron Ore Composite Prepared by Vapor Deposition of Tar For LimonitefaizahNo ratings yet

- Fuel2 2007Document9 pagesFuel2 2007DadanNo ratings yet

- 1 s2.0 S0016236123000145 MainDocument7 pages1 s2.0 S0016236123000145 MainSrikanth SrikantiNo ratings yet

- Coal Combustion Analysis Tool in Coal Fired Power Plant For Slagging and Fouling GuidelinesDocument8 pagesCoal Combustion Analysis Tool in Coal Fired Power Plant For Slagging and Fouling GuidelinesAnis SuryadiNo ratings yet

- Effect of Melting On C.I.Document4 pagesEffect of Melting On C.I.mkraijadaNo ratings yet

- Plasma Lighting System of LowDocument10 pagesPlasma Lighting System of LowStanislavNo ratings yet

- CEA Report On Coal BlendingDocument50 pagesCEA Report On Coal BlendingSudhir Jadhav100% (1)

- Comparison of Cupola Furnace and BLDocument9 pagesComparison of Cupola Furnace and BLst5154706No ratings yet

- MET 51 1 25 27 OleksiakDocument3 pagesMET 51 1 25 27 OleksiaknemezisnyxNo ratings yet

- PF 09 04 ccc147Document2 pagesPF 09 04 ccc147ukalNo ratings yet

- Effects of Preheating On Coking CoalDocument14 pagesEffects of Preheating On Coking CoalperekwamaNo ratings yet

- Establishing Correct Coal Quality For Achieving Optimum Boiler Efficiency & Performance - A Case Study in The Indian Utility IndustryDocument12 pagesEstablishing Correct Coal Quality For Achieving Optimum Boiler Efficiency & Performance - A Case Study in The Indian Utility Industrystark2006No ratings yet

- 1 s2.0 S095965261930647X AmDocument37 pages1 s2.0 S095965261930647X AmPriyatam KumarNo ratings yet

- Kumar Et Al-2016-Steel Research International1Document16 pagesKumar Et Al-2016-Steel Research International1Binay KumarNo ratings yet

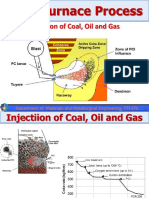

- Injection of Coal, Oil and Gas: Department of Materials and Metallurgical Engineering, FTI-ITSDocument24 pagesInjection of Coal, Oil and Gas: Department of Materials and Metallurgical Engineering, FTI-ITSSusan Keynes PevensieNo ratings yet

- Sponge Iron ManufacturingDocument14 pagesSponge Iron Manufacturingapi-2604165367% (3)

- Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementFrom EverandClean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementNo ratings yet

- Proceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014From EverandProceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014No ratings yet

- Fuels: Principles of Classification of FuelsDocument9 pagesFuels: Principles of Classification of FuelsPatrick Joshua GregorioNo ratings yet

- Gas Story Fourth Edition Updated May 2016 ID 14057Document223 pagesGas Story Fourth Edition Updated May 2016 ID 14057rNo ratings yet

- Slide UCG HayDocument23 pagesSlide UCG HayVăn Đại - BKHNNo ratings yet

- Lakhmir Singh Sol Class 8 Science Chapter 5Document13 pagesLakhmir Singh Sol Class 8 Science Chapter 5nirmal krisna100% (1)

- AP&CDocument35 pagesAP&CChethan K. ReddyNo ratings yet

- Environmental Issues Related To Underground Coal Gasification Technology - NikhilDocument28 pagesEnvironmental Issues Related To Underground Coal Gasification Technology - NikhilNikhil SirdesaiNo ratings yet

- UCG For Power GenerationDocument52 pagesUCG For Power GenerationVăn Đại - BKHNNo ratings yet

- Coal and PetroleumDocument9 pagesCoal and PetroleumavaniNo ratings yet

- Lesson Plan Class VIII - Coal and PetroleumDocument4 pagesLesson Plan Class VIII - Coal and PetroleumPushpa Kumari100% (1)

- 100 Years of Waste Incineration in DenmarkDocument27 pages100 Years of Waste Incineration in Denmarkparchure123No ratings yet

- E-Notes PDF All-Units 20052019023702PMDocument191 pagesE-Notes PDF All-Units 20052019023702PMHasib IslamNo ratings yet

- Class 8 - Chapter 5 - Coal and PetroleumDocument9 pagesClass 8 - Chapter 5 - Coal and PetroleumsanaNo ratings yet

- PPE (Fuels)Document4 pagesPPE (Fuels)Vibin cvNo ratings yet

- Heating Measurement Technology: Practical HandbookDocument64 pagesHeating Measurement Technology: Practical HandbookSara ZaedNo ratings yet

- Calorific Test of Gaseous FuelDocument15 pagesCalorific Test of Gaseous FuelKal-el JamiasNo ratings yet

- Mech PDFDocument2 pagesMech PDFKartik NadigerNo ratings yet

- Coal and PetroleumDocument11 pagesCoal and PetroleumBrenda MartinezNo ratings yet

- Fuel Solid Liquid and Gaseous - JSS BrameDocument404 pagesFuel Solid Liquid and Gaseous - JSS BrameRituSharma100% (2)

- CoalDocument34 pagesCoalRamaOktavianNo ratings yet

- Gaseous Fuels PDFDocument57 pagesGaseous Fuels PDFmorsid aliudinNo ratings yet

- Coal & PetroleumDocument9 pagesCoal & PetroleumrahulpanditkgpNo ratings yet

- Coal and PetroleumDocument31 pagesCoal and PetroleumManas HoodaNo ratings yet

- VMC Class 8 Chemistry AssignmentDocument18 pagesVMC Class 8 Chemistry AssignmentAbhideep JainNo ratings yet

- Revision Notes Class - 8 Science Chapter 5 - Coal and PetroleumDocument4 pagesRevision Notes Class - 8 Science Chapter 5 - Coal and PetroleumArpit SharmaNo ratings yet

- WurzelDocument45 pagesWurzelCarmen Huaniquina TerrazasNo ratings yet

- M1 Lesson 1 History, Sources and General Characteristics of Organic Compounds A Brief History of Organic ChemistryDocument3 pagesM1 Lesson 1 History, Sources and General Characteristics of Organic Compounds A Brief History of Organic ChemistryEddie TanNo ratings yet

- Chemistry 8th+class Coal+and+petroleum Study+material+ (CSM)Document8 pagesChemistry 8th+class Coal+and+petroleum Study+material+ (CSM)Sanjaya SahooNo ratings yet

- Producers Gas PlantsDocument13 pagesProducers Gas PlantsHalil İbrahim KüplüNo ratings yet

- Internal Combustion Engines1Document68 pagesInternal Combustion Engines1Ahmed ShaabanNo ratings yet

- Anal - Coal M.coke27.3Document37 pagesAnal - Coal M.coke27.3MadhavanIceNo ratings yet

Alternative Coke Saving Technologies

Alternative Coke Saving Technologies

Uploaded by

Uday PrakashCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alternative Coke Saving Technologies

Alternative Coke Saving Technologies

Uploaded by

Uday PrakashCopyright:

Available Formats

Blast-Furnace Practice

UDC 669.162.16

Alternative Coke Saving Technologies are the Prospect of

Blast-Furnace Practice Development

I. G. Tovarovsky1, V. I. Bolshakov1, V. P. Lyalyuk2

1

Z. I. Nekrasov Iron & Steel Institute of National Academy of Sciences of Ukraine

1 Academician Starodubov Square, Dnipropetrovsk 49050, Ukraine

2

OJSC "ArcelorMittal Kryvyy Rih"

1 Ordzhonikidze St., Kryviy Rih, Dnepropetrovsk region 50095, Ukraine

The expansion of coal injection under shortage conditions of necessary coal grades and

dynamic change in prices needs the development of a wide range of coke replacement

production technologies for implementation of the most effective option at each stage on the

basis of combination with coke gas, stone coal, coal gasification products, etc. Blast-furnace

smelting with hot reducing gas injection - low-grade coal gasification products – needs to

work out for fundamental solution of coke saving problem.

Keywords: PULVERIZED COAL, RANGE OF COAL GRADES, COKE REPLACEMENT,

COKE GAS, STONE COAL, COAL GASIFICATION PRODUCTS, ALTERNATIVE

PRODUCTION TECHNOLOGIES

Introduction adoption at Alchevsk Integrated Iron & Steel

Works have been discussed recently. The authors

Growing natural gas prices stimulate the of report [2] showed raw material and

development of production technologies with the technological restrictions in mining-metallurgical

use of pulverized coal fuel (PCF) mastered and and fuel complexes of Ukraine based on the

widely applied in the advanced countries. The corresponding analysis. Coal injection is

necessity of this production technology problematic at levels above 120 kg/t of pig-iron.

development at Ukrainian plants has no doubts. Specialists from East Scientific and Research

However considering this method like a “single Coal-Chemical Institute of Russia [3] mention that

prospect” of blast-furnace practice [1] contradicts it is not simple to implement coal injection in

the prevailing conditions and technological general and at high coal consumption in particular.

principles of industrial engineering. It was noted on the fifth international congress on

First of all, the above is true for increased theory and blast-furnace operation practice

requirements to coke quality and charge coal (Shanghai, 2009) that power engineering,

composition as well as coal grades for PCF environmental contamination and short supply of

preparation. These requirements are impossible to natural resources turned back the development of

meet because of short supply of necessary coal iron and steel industry in the majority of countries

grades not only in Ukraine but also in the majority [4]. On this basis, specialists from different

of countries at inaccessibility of the world market countries mentioned a number of risks caused by

for Ukrainian plants. Other factor (organizational- depletion of coked coal reserves and started

technological) does not allow effective developing combined coke-replacing blast-furnace

implementation of coal injection technology in operation practice.

case of small coal consumption restricted by real

conditions on coke quality and range of injected Results and Discussion

coals.

In view of stated above, the problems of this It is shown earlier that implementation of

method implementation at metallurgical plants of expected results of coal injection needs, first of all,

Ukraine and Russia and especially considering not solution of technical problems related to radical

quite successful results of pulverized coal fuel improvement of coke and iron-ore raw material

© Metallurgical and Mining Industry, 2011, Vol. 3, No. 2 33

Blast-Furnace Practice

properties [1, 5]. Solution of process control at improvement of metallurgical properties of raw

problems at low coke consumption are also materials and coke should be accompanied by

referred to mentioned-above problems. working out complementary and alternative

The specified restrictions, not observed in the production technologies. More and more

initial stage of using coal injection in Europe and specialists follow this ideology including its former

Asia, are now not only characteristic for Ukraine opponents [5].

and Russia but soon will have a conjunctural effect Mobile combination of pulverized coal fuel

on the development of the whole world metallurgy. and coke gas (or other reducing gas) is one of coal

In view of the aforesaid, it is necessary to injection alternatives. This method enables to

combine coal injection development with working inject 100-150 kg/t of pulverized coal fuel on

out alternative coke-replacing production particular blast furnaces at lack of required coal

technologies. In this conjunction, we notice that a grades. In this case, it is necessary to inject 100-

“single prospect” coal injection declared in [1] 150 m3/t of coke gas or equivalent amount of other

under conditions of growing deficiency of coked reducing gas, for example, multipurpose

coals and coals for pulverized coal fuel pulverized coal fuel [6] with coke consumption

preparation, and also high-quality iron-ore raw corresponding to injection of 200 kg/t pulverized

materials can become a deadlock prospect for coal fuel for maintenance of optimum temperature

certain plants. in lances. If required metallurgical properties of

This strategic step in the development of coke are impossible to reach (for any reasons) it is

blast-furnace practice in Ukraine and Russia needs expedient to reduce pulverized coal fuel

thorough understanding as the arguments against consumption up to zero and increase coke gas rate

alternative technologies stated in [1] are at least to 200-250 m3/t that will allow coke saving.

unconvincing: Now the Japanese specialists are developing a

1. Coke gas injection is rejected in [1] because method of iron smelting with coke gas injection in

of its short supply, while the question is about not blast furnace. And this coke gas is subjected to

additional resources of coke gas but rational conversion and has high hydrogen content [10].

balance at the plant, under which coke gas Charging practice of prepared lumpy hard

resources required for blast-furnace smelting can coal can be used in various combinations with

be found by coke replacement with coal pulverized coal fuel. The most indicative results of

gasification products [6]. this production technology are achieved at JSC

2. Partial replacement of coke by anthracitic “ArselorMittal Kryvyy Rih” during the periods

coal is accepted [1]. In addition, the specificity for when there was no hard coal short supply [8]. So,

replacement of only 10-20 % coke and also long- in October 2006 the coke consumption in the

term positive experience of using this method in furnace with capacity 5000 m3 was 426.8 kg/t at

blast furnaces with capacity from 1143 to hard coal consumption 56 kg/t and natural gas rate

5000 m3 at JSC “ArselorMittal Kryvyy Rih” [7], 87.1 m3/t, and in BF-6 with capacity 2000 m3 in

JSC “Makeevskiy Iron & Steel Works” [8], August, 2006 the coke rate was 436.1 kg/t at hard

OJSC “Alchevsk Iron & Steel Works” [9], etc. are coal consumption 74 kg/t and natural gas rate 69.9

ignored. m3/t [11].

3. Efficiency of hot reducing gas (coal Comparison of operational experience of

gasification products) injection is called in BF-5 with capacity 1719 m3 at OJSC “Alchevsk

question based on unreasonable acceptance of loss Iron & Steel Works” by two production

value 30-50 % in [1] and an emotional announce of technologies with charging lumpy hard coal

efficiency of hot reducing gas (coal gasification through the furnace mouth and coal injection since

products) injection decreased in 10 times as 2006 till November 2010 showed the following:

compared to coal injection. Having asserted that at - at hard coal charging the minimum coke

coal injection there were no such losses, the consumption was 444 kg/t at hard coal

authors [1] ignored the known considerable losses consumption 44 kg/t (on the average for 2006) and

hidden in incomplete carbon gasification and natural gas rate 89 m3/t [9];

fluidization of pulverized coal fuel ash in lances as - at coal injection the minimum coke

well as restrictions of acceptable concentration of consumption was reached in March 2009 - 477 kg/t

ash and sulfur in the coal. at pulverized coal fuel consumption - 64 kg/t of

Thus, to reduce technical advance in the blast- pig-iron and natural gas rate 51.8 m3/t.

furnace practice to using only coal injection in the A variety of reasons of unsuccessful

modern dynamical world of market economy under mastering of coal injection technology do not

short supply of all resources means making many allow well-founded conclusions, however lessons

plants naked to unexpected turns of market learned need further study. Considering the

condition. Expansion of coal injection technology problems of coke replacement by blowing

34 © Metallurgical and Mining Industry, 2011, Vol. 3, No. 2

Blast-Furnace Practice

components it is necessary to keep in view that 3. Yu. A. Zolotukhin, N. S. Andreychikov. Stal,

technological measures of "compensation" [1, 5] to 2009, No. 6, pp. 3-7. *

raise coal injection efficiency promote the 4. I. F. Kurunov. Proceedings of 5th International

substantial improvement of blast-furnace smelting Congress on Theory and Practice of Ironmaking,

parameters. The specified measures are the Bulleten Nauchno-Tekhnicheskoy Informatsii Chernaya

elements of blast-furnace practice advancement Metallurgiya, 2010, No. 3, pp. 32-49. *

system to ensure the minimum coke rate at high 5. S. L. Yaroshevsky, Z. K. Afanaseva,

efficiency of units. А. В. Kuzin, I. V. Mishin. Novyny Nauky Pridniprov'ya.

The problem related to reduction of coke rate Naukovo-Praktichny Zhurnal, May 2010, pp. 25-31. *

6. I. G. Tovarovsky. Domennaya Plavka.

with the use of low-grade coal for replacement can

Monography, 2nd edition, Dnepropetrovsk, Porogi,

be solved on the basis of working out new

2009, 768 p. *

production technology of blast-furnace smelting 7. V. P. Lyalyuk, I. G. Tovarovsky,

with injection of hot reducing gas - pulverized coal D. A. Demchuk, et al. Koksozameshchayushchie

fuel produced in special gasificators [6]. Tekhnologii v Domennoy Plavke, Dnepropetrovsk,

Theoretical interest to the problem is not Porogi, 2006, 276 p. *

diminished, however expected difficulties of 8. V. P. Lyalyuk, I. G. Tovarovsky,

practical implementation restrict the initiative of D. A. Demchuk, et al. Antratsit i Termoantratsit v

potential users. Nevertheless, [5] there is a hope for Shikhte Domennoy Plavki, Dnepropetrovsk, Porogi,

understanding the real situation with coal resources 2008, 245 p. *

and necessity to solve this problem urgently [6]. 9. I. G. Tovarovsky, V. P. Lyalyuk,

Т. G. Shevchenko, V. S. Listopadov, et al. Proceedings

Conclusions of 15-th International Conference “Heat Engineering

and Power Engineering in Metallurgy”, 7-9 October,

A wide range of coke replacement 2008, NMetAU, Dnepropetrovsk, pp. 240-241. *

technologies by various energy resources need to 10. T. Shishido, T. Okayama, M. Hamaguchi, et

be developed under market conditions at al. ISIJ, 2009, Vol. 22, No. 2, p. 777.

dynamical change of fuel prices and transportation 11. V. P. Lyalyuk, I. G. Tovarovsky,

possibilities. Expansion of coal injection V. A. Sheremet, et al. Bulleten Nauchno-Tekhnicheskoy

Informatsii Chernaya Metallurgiya, 2010, No. 1, pp. 37-

technology at improvement of raw materials and

41. *

coke properties should be accompanied by working 12. I. G. Tovarovskiy, V. N. Khomich,

out complementary and alternative methods. The G. P. Boyarovsky. Stal, 1982, No. 6, pp. 5-11. *

production technology of mobile combination of

pulverized coal fuel, coke gas and stone coal is one * Published in Russian

of coal injection alternatives. Received December 16, 2010

Coke consumption with the use of low-grade

coals for replacement can be reduced on the basis Альтернативные коксосберегающие

of working out new production technologies of технологии – перспектива развития

blast-furnace smelting with injection of hot доменного производства

reducing gases - coal gasification products

produced in special gasificators under modern Товаровский И.Г., Большаков В.И.,

conditions of short supply of necessary coal grades Лялюк В.П.

[6].

Расширение вдувания пылеугольного

References топлива в условиях дефицита углей

1. S. L. Yaroshevsky, V. E. Popov, необходимого сортамента и динамичного

А. М. Kuznetsov, et al. Proceedings of 2-nd изменения цен требует развития широкого

International Conference “Problems of Prolongation of арсенала технологий замещения кокса для

Blast Furnace Operation and Mastering of Coal реализации на каждом этапе наиболее

Injection. Modern Solutions and Practical Experience”, эффективного варианта на основе сочетания с

18-22 May, 2009, Dnepropetrovsk, Union of Iron коксовым газом, кусковым антрацитом,

Producers, pp. 90-97.* продуктами газификации углей и др. Для

2. V. S. Kharahulah, A. G. Starovoyt, фундаментального решения проблемы

N. N. Izyumsky. Proceedings of International Congress

коксосбережения необходима разработка

of Blast-Furnace Men “Blast-Furnace Practice 21-st

Century”, 12-16 April, 2010, Moscow, Kodeks, pp. 92-

технологии доменной плавки с вдуванием

99. * горячих восстановительных газов – продуктов

газификации низкосортных углей.

© Metallurgical and Mining Industry, 2011, Vol. 3, No. 2 35

You might also like

- Coal For Metallurgical Coke Production PDFDocument24 pagesCoal For Metallurgical Coke Production PDFS SITAPATI100% (1)

- A Technical Review On Coke Rate and Quality in Low-Carbon BlastDocument27 pagesA Technical Review On Coke Rate and Quality in Low-Carbon BlastDavid Francisco Flórez RamosNo ratings yet

- Coal To Coke PDFDocument9 pagesCoal To Coke PDFVenkata Krishnan RamanujamNo ratings yet

- To Go Bits Kaya 2018Document6 pagesTo Go Bits Kaya 2018Arash AbbasiNo ratings yet

- Isijinternational - ISIJINT 2015 264Document10 pagesIsijinternational - ISIJINT 2015 264mbg2012No ratings yet

- Combustibles LiquidosDocument7 pagesCombustibles LiquidosVictor Hugo CarreÓnNo ratings yet

- Abstract of Papaer On Coal Quality-Blending A Perspective at RINLDocument15 pagesAbstract of Papaer On Coal Quality-Blending A Perspective at RINLbhujakhia_748657110No ratings yet

- Comparison of Cupola Furnace and Blast Furnace Slags With Respect To Possibilities of Their UtilizationDocument10 pagesComparison of Cupola Furnace and Blast Furnace Slags With Respect To Possibilities of Their UtilizationAafan ShahidNo ratings yet

- 8 KovalyovDocument3 pages8 KovalyovJaq Plin PlinNo ratings yet

- Blast Furnace Ironmaking Process Using Pre-Reduced Iron Ore: Nippon Steel Technical Report No. 94 July 2006Document6 pagesBlast Furnace Ironmaking Process Using Pre-Reduced Iron Ore: Nippon Steel Technical Report No. 94 July 2006Farhan AkhterNo ratings yet

- B EAF: Riquetting of Dust For Its Utilisation in Metallurgical ProcessesDocument9 pagesB EAF: Riquetting of Dust For Its Utilisation in Metallurgical ProcessesJaq Plin PlinNo ratings yet

- Production of Special CokeDocument6 pagesProduction of Special CokeAryo Prastyo AjiNo ratings yet

- 3A3. Direct Iron Ore Smelting Reduction Process (DIOS)Document2 pages3A3. Direct Iron Ore Smelting Reduction Process (DIOS)Imran Hanif LubisNo ratings yet

- Nox Emissions of An Opposed Wall-Fired Pulverized Coal Utility BoilerDocument7 pagesNox Emissions of An Opposed Wall-Fired Pulverized Coal Utility BoilerAnonymous knICaxNo ratings yet

- Coal Selection CriteriaDocument31 pagesCoal Selection CriteriaHardik Kumar MendparaNo ratings yet

- Addition of Renewable Carbon To Liquid Steel: Plant Trials at Onesteel Sydney Steel MillDocument13 pagesAddition of Renewable Carbon To Liquid Steel: Plant Trials at Onesteel Sydney Steel MillRidwand KartikaNo ratings yet

- Tese Nswparte 2Document153 pagesTese Nswparte 2AndrelslNo ratings yet

- CrystallizationDocument9 pagesCrystallizationGAURAV VERMANo ratings yet

- HGI-vs Mill Loading PDFDocument8 pagesHGI-vs Mill Loading PDFDebabrata TantubaiNo ratings yet

- Russia, Current State and Economics of Low Pressure Coal LiquifactionDocument12 pagesRussia, Current State and Economics of Low Pressure Coal Liquifactionstefan-romocki-4927No ratings yet

- CRI Effect On Blast FurnaceDocument7 pagesCRI Effect On Blast FurnaceHuso100% (2)

- TSL 2009 349Document7 pagesTSL 2009 349Soo Sang ParkNo ratings yet

- Energy: Ivan Najdenov, Karlo T. Rai C, Gordana KokezaDocument9 pagesEnergy: Ivan Najdenov, Karlo T. Rai C, Gordana Kokeza......No ratings yet

- Coal For Metallurgical Coke ProductionDocument24 pagesCoal For Metallurgical Coke ProductionSamanway DasNo ratings yet

- Article CIS 09 Pp.11-15Document5 pagesArticle CIS 09 Pp.11-15Maheswar SethiNo ratings yet

- Application of Anthracite Dust in The Processing of Steel DustsDocument3 pagesApplication of Anthracite Dust in The Processing of Steel DustsXingwen LiuNo ratings yet

- 2-2-A-2-Pulverized Coal Injection For Blast Furnace (PCI)Document2 pages2-2-A-2-Pulverized Coal Injection For Blast Furnace (PCI)Tonny FebryanNo ratings yet

- Impact of Pci in Blast FurnaceDocument11 pagesImpact of Pci in Blast FurnaceSableen SinghNo ratings yet

- 2013-04 Iron and Steel CCS Study (Techno-Economics Integrated Steel Mill)Document642 pages2013-04 Iron and Steel CCS Study (Techno-Economics Integrated Steel Mill)imtinanNo ratings yet

- Evaluation of The Co2 Re Activity of Chars Obtained Under Conventional and Oxyfuel AtmospheresDocument5 pagesEvaluation of The Co2 Re Activity of Chars Obtained Under Conventional and Oxyfuel AtmospheresjulianapohlmannufrgsNo ratings yet

- CSR Vs CRI Graph Coalformetallurgicalcokeproduction PDFDocument24 pagesCSR Vs CRI Graph Coalformetallurgicalcokeproduction PDFJANET GTNo ratings yet

- Ran Liu, Chunzhao LIANG, Xingjuan WANG, Shuai FENGDocument5 pagesRan Liu, Chunzhao LIANG, Xingjuan WANG, Shuai FENGAuliverKayMHNo ratings yet

- Continuous Coke Production: Coke and Chemistry August 2012Document8 pagesContinuous Coke Production: Coke and Chemistry August 2012atashi baran mohantyNo ratings yet

- New Technology PDFDocument27 pagesNew Technology PDFbasavarajNo ratings yet

- Tecnored Process - High Potential in Using Different Kinds of Solid FuelsDocument5 pagesTecnored Process - High Potential in Using Different Kinds of Solid FuelsRogerio CannoniNo ratings yet

- JMMCE 2014111809383149omoleDocument9 pagesJMMCE 2014111809383149omoleHassan ShirivandNo ratings yet

- Study of Coke Oven BatteryDocument18 pagesStudy of Coke Oven BatteryYeswanth Kumar100% (1)

- Direct Reduction-Are We Moving in The Right Direction?: by K. O. R. GebhardDocument2 pagesDirect Reduction-Are We Moving in The Right Direction?: by K. O. R. GebhardNadyaZulfaniNo ratings yet

- Applications Steel: Plexicoke in The VmezuelanDocument8 pagesApplications Steel: Plexicoke in The VmezuelanJose Marval RodriguezNo ratings yet

- Mousa 2013Document13 pagesMousa 2013kabamba KundaNo ratings yet

- Blast Furnace Japan DevelopmentDocument14 pagesBlast Furnace Japan DevelopmentShyam JiNo ratings yet

- Presentation On Preparation of Coke in Coke Oven Batteries: Presented By: Anil Kumar KhataiDocument18 pagesPresentation On Preparation of Coke in Coke Oven Batteries: Presented By: Anil Kumar KhataiKhatai Anil KumarNo ratings yet

- Thermal Properties of Carbon-Containing Iron Ore Composite Prepared by Vapor Deposition of Tar For LimoniteDocument14 pagesThermal Properties of Carbon-Containing Iron Ore Composite Prepared by Vapor Deposition of Tar For LimonitefaizahNo ratings yet

- Fuel2 2007Document9 pagesFuel2 2007DadanNo ratings yet

- 1 s2.0 S0016236123000145 MainDocument7 pages1 s2.0 S0016236123000145 MainSrikanth SrikantiNo ratings yet

- Coal Combustion Analysis Tool in Coal Fired Power Plant For Slagging and Fouling GuidelinesDocument8 pagesCoal Combustion Analysis Tool in Coal Fired Power Plant For Slagging and Fouling GuidelinesAnis SuryadiNo ratings yet

- Effect of Melting On C.I.Document4 pagesEffect of Melting On C.I.mkraijadaNo ratings yet

- Plasma Lighting System of LowDocument10 pagesPlasma Lighting System of LowStanislavNo ratings yet

- CEA Report On Coal BlendingDocument50 pagesCEA Report On Coal BlendingSudhir Jadhav100% (1)

- Comparison of Cupola Furnace and BLDocument9 pagesComparison of Cupola Furnace and BLst5154706No ratings yet

- MET 51 1 25 27 OleksiakDocument3 pagesMET 51 1 25 27 OleksiaknemezisnyxNo ratings yet

- PF 09 04 ccc147Document2 pagesPF 09 04 ccc147ukalNo ratings yet

- Effects of Preheating On Coking CoalDocument14 pagesEffects of Preheating On Coking CoalperekwamaNo ratings yet

- Establishing Correct Coal Quality For Achieving Optimum Boiler Efficiency & Performance - A Case Study in The Indian Utility IndustryDocument12 pagesEstablishing Correct Coal Quality For Achieving Optimum Boiler Efficiency & Performance - A Case Study in The Indian Utility Industrystark2006No ratings yet

- 1 s2.0 S095965261930647X AmDocument37 pages1 s2.0 S095965261930647X AmPriyatam KumarNo ratings yet

- Kumar Et Al-2016-Steel Research International1Document16 pagesKumar Et Al-2016-Steel Research International1Binay KumarNo ratings yet

- Injection of Coal, Oil and Gas: Department of Materials and Metallurgical Engineering, FTI-ITSDocument24 pagesInjection of Coal, Oil and Gas: Department of Materials and Metallurgical Engineering, FTI-ITSSusan Keynes PevensieNo ratings yet

- Sponge Iron ManufacturingDocument14 pagesSponge Iron Manufacturingapi-2604165367% (3)

- Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementFrom EverandClean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementNo ratings yet

- Proceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014From EverandProceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014No ratings yet

- Fuels: Principles of Classification of FuelsDocument9 pagesFuels: Principles of Classification of FuelsPatrick Joshua GregorioNo ratings yet

- Gas Story Fourth Edition Updated May 2016 ID 14057Document223 pagesGas Story Fourth Edition Updated May 2016 ID 14057rNo ratings yet

- Slide UCG HayDocument23 pagesSlide UCG HayVăn Đại - BKHNNo ratings yet

- Lakhmir Singh Sol Class 8 Science Chapter 5Document13 pagesLakhmir Singh Sol Class 8 Science Chapter 5nirmal krisna100% (1)

- AP&CDocument35 pagesAP&CChethan K. ReddyNo ratings yet

- Environmental Issues Related To Underground Coal Gasification Technology - NikhilDocument28 pagesEnvironmental Issues Related To Underground Coal Gasification Technology - NikhilNikhil SirdesaiNo ratings yet

- UCG For Power GenerationDocument52 pagesUCG For Power GenerationVăn Đại - BKHNNo ratings yet

- Coal and PetroleumDocument9 pagesCoal and PetroleumavaniNo ratings yet

- Lesson Plan Class VIII - Coal and PetroleumDocument4 pagesLesson Plan Class VIII - Coal and PetroleumPushpa Kumari100% (1)

- 100 Years of Waste Incineration in DenmarkDocument27 pages100 Years of Waste Incineration in Denmarkparchure123No ratings yet

- E-Notes PDF All-Units 20052019023702PMDocument191 pagesE-Notes PDF All-Units 20052019023702PMHasib IslamNo ratings yet

- Class 8 - Chapter 5 - Coal and PetroleumDocument9 pagesClass 8 - Chapter 5 - Coal and PetroleumsanaNo ratings yet

- PPE (Fuels)Document4 pagesPPE (Fuels)Vibin cvNo ratings yet

- Heating Measurement Technology: Practical HandbookDocument64 pagesHeating Measurement Technology: Practical HandbookSara ZaedNo ratings yet

- Calorific Test of Gaseous FuelDocument15 pagesCalorific Test of Gaseous FuelKal-el JamiasNo ratings yet

- Mech PDFDocument2 pagesMech PDFKartik NadigerNo ratings yet

- Coal and PetroleumDocument11 pagesCoal and PetroleumBrenda MartinezNo ratings yet

- Fuel Solid Liquid and Gaseous - JSS BrameDocument404 pagesFuel Solid Liquid and Gaseous - JSS BrameRituSharma100% (2)

- CoalDocument34 pagesCoalRamaOktavianNo ratings yet

- Gaseous Fuels PDFDocument57 pagesGaseous Fuels PDFmorsid aliudinNo ratings yet

- Coal & PetroleumDocument9 pagesCoal & PetroleumrahulpanditkgpNo ratings yet

- Coal and PetroleumDocument31 pagesCoal and PetroleumManas HoodaNo ratings yet

- VMC Class 8 Chemistry AssignmentDocument18 pagesVMC Class 8 Chemistry AssignmentAbhideep JainNo ratings yet

- Revision Notes Class - 8 Science Chapter 5 - Coal and PetroleumDocument4 pagesRevision Notes Class - 8 Science Chapter 5 - Coal and PetroleumArpit SharmaNo ratings yet

- WurzelDocument45 pagesWurzelCarmen Huaniquina TerrazasNo ratings yet

- M1 Lesson 1 History, Sources and General Characteristics of Organic Compounds A Brief History of Organic ChemistryDocument3 pagesM1 Lesson 1 History, Sources and General Characteristics of Organic Compounds A Brief History of Organic ChemistryEddie TanNo ratings yet

- Chemistry 8th+class Coal+and+petroleum Study+material+ (CSM)Document8 pagesChemistry 8th+class Coal+and+petroleum Study+material+ (CSM)Sanjaya SahooNo ratings yet

- Producers Gas PlantsDocument13 pagesProducers Gas PlantsHalil İbrahim KüplüNo ratings yet

- Internal Combustion Engines1Document68 pagesInternal Combustion Engines1Ahmed ShaabanNo ratings yet

- Anal - Coal M.coke27.3Document37 pagesAnal - Coal M.coke27.3MadhavanIceNo ratings yet