Professional Documents

Culture Documents

Godrej 24 - ITP

Godrej 24 - ITP

Uploaded by

sanchayOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Godrej 24 - ITP

Godrej 24 - ITP

Uploaded by

sanchayCopyright:

Available Formats

INSPECTION & TEST PLAN (MATERIALS)

Project : GODREJ 24

MATERIAL TEST PARAMETER NORMS / SPECIFICATION FREQUENCY REPORTING CERTFICATION RESPONIBILITY

PARTICULARS

CHEMICAL REQUIREMENTS

1. Carbon (% ) 0.07 Max.

2.Sulphur (% ) 0.09 Max.

CHEMICAL TESTS

3.Phosphorus (% ) 0.028 Max.

(Contractor/Client Supplied Material)

Q.A.Engineer to review the manufacturer's test certificate on

4.Manganese (% ) 0.48 Max. receipt of material & commence usage with consultation of

5. Alumina (%) 0.0 Max. Every Lot Hard Copy Manufacturer Test Certificate CBRE.Same to be maintained throughout the project term.

Third party testing for chemical properties to be conducted,

GI Steel Tube C - Class (Pipe) IS - 1239(pt-1)

6. Silicon (%) 0.0 Max. every six months or change of source.

7.Chloride (%) 0.0 Max.

MECHANICAL PROPERTIES

1.Tensile Strength (MPa) 400 Max.

2. Elongation (%) 32 Max.

MECHANICAL PROPERTIES

3. Bend Test NA

4. Flattening Test OK

Q.A.Engineer to review the manufacturer's test certificate on

5. Mass of Zinc Coating gm/m2 440 Every Lot Hard Copy Manufacturer Test Certificate receipt of material & commence usage with consultation of

6. Uniformity OK CBRE.Same to be maintained throughout the project term.

7. HYDROTATIC TESTING

7.1 Pressure (Kg/Cm2) 51

7.2 Holding Time (Sec) 3

Material (Metal)

1. Forged Brass IS 6912 Gr. FLB

Approved Make : ZOLOTO

BRASS FORGED BALL VALVE Art - 400 SCR

(Contractor/Client Supplied Material)

Q.A.Engineer to review the manufacturer's test certificate on

2. Carbon Steel IS 1367

Material

receipt of material & commence usage with consultation of

Every Lot Hard Copy Manufacturer Test Certificate CBRE.Same to be maintained throughout the project term.

Third party testing for chemical properties to be conducted,

3.PTFE BS EN 12086 -1LB every six months or change of source.

Test Pressure .

1. shell Kg/Cm2 25 Max.

Hydraulic Test

Pressure

Q.A.Engineer to review the manufacturer's test certificate on

Every Lot Hard Copy Manufacturer Test Certificate receipt of material & commence usage with consultation of

2.Seat Kg/Cm2 16 Max. CBRE.Same to be maintained throughout the project term.

MATERIAL SPECIFICATION

1. Forged Bronze ASTM B584 CB3600

SPECIFICATION

Q.A.Engineer to review the manufacturer's test certificate on

MATERIAL

2. Brass Sheet ASTM B36 C6800 receipt of material & commence usage with consultation of

Every Lot Hard Copy Manufacturer Test Certificate CBRE.Same to be maintained throughout the project term.

(Contractor/Client Supplied Material) 3. Bronze Rod C863600 Third party testing for chemical properties to be conducted, on

4. Stainless Steel PTFE Coated ASTM A 167 S30400 change of source.

5. Brass Rod ASTM B 16 C3600

Sidewall & Upright Type Sprinkler UL Listed

A. PHYSICAL REQUIREMENTS

1.Response Type Standard Response.

2.Orintation Horizontal Sidewall/Vertical Upright.

3.Model No NI012 D / NI032

4.K-Factor 5.6 (80)

5. End Correction 1/2" Male thread.

PHYSICAL TEST

6. Temperature Rating 155 Deg F (68 Deg C) . Q.A.Engineer to review the manufacturer's test certificate on

7. Glass Bulb Size 5 mm Every Lot Hard Copy Manufacturer Test Certificate receipt of material & commence usage with consultation of

CBRE.Same to be maintained throughout the project term.

B. PRESSURE RATING

1. Minimum Working Pressure 7 psi (0.5 bar)

2. Maximum Working Pressure 175 psi ( 12 bar)

3. Factory hydrotest Pressure 350 psi (25 bar)

MATERIAL SPECIFICATION

MATERIAL SPECIFICATION

(Contractor/Client Supplied Material)

1. Carbon Steel (Powder Coated) 0

2. PTFE / Bronze BSEN 12086-1 / IS 318 Gr. LTB 2.

Q.A.Engineer to review the manufacturer's test certificate on

3. Stainless steel ASTM A 276 Type 410

Every Lot Hard Copy Manufacturer Test Certificate receipt of material. Same to be maintained throughout the

4. S. G Iron ASTM A 536 / IS 1865 project term.

5. Aluminium 0

Butterfy Valve (wafer Type) PN-16

6. Nitrile Rubber IS 5192 - 1

7. EPDM / Nitrile IS 5192 - 1

PHYSICAL TEST

1. Test Pressure Kg/Cm2

PHYSICAL TEST

1.1. Body 24 QA Engineer to record relevant information prior to sampling.

1.2. Seat 18 Every Lot Hard Copy Manufacturer Test Certificate Q.A.Engineer to review third party certificate & commence

IS:13095

usage with consultation of CBRE

2. Working Temperature 90 Deg C (Max)

3. Working Pressure 16 Kg/Cm2

MATERIAL SPECIFICATION

1. Inner Tube Neoprene

SPECIFICATION

QA Engineer to record relevant information prior to sampling.

(Contractor/Client Supplied Material)

MATERIAL

2. Cover Neoprene Q.A.Engineer to review third party certificate & commence

Every Lot Hard Copy Manufacturer Test Certificate usage with consultation of CBRE

3. Reinforcement GI Wire Reinforcement Third party certification for Chemical peoperties to be

4. Flanges Table E conducted for approval of source.

Expansion Rubber Bellow

TECHINACAL DATA

1. Test Pressure (Hydrostatic) 24 Kg

PHYSICAL TEST

2. Working Pressure 16 Kg/Cm2

QA Engineer to record relevant information prior to sampling.

3. Working Tempreature 70 deg cels Every Lot Hard Copy Manufacturer Test Certificate Q.A.Engineer to review third party certificate & commence

4. SRR Standard As per IS:2062 usage with consultation of CBRE

You might also like

- Def Stan 80-34 Issue 1995Document17 pagesDef Stan 80-34 Issue 1995Said AdingniNo ratings yet

- Best Practice: SABP-A-059 26 April 2015Document23 pagesBest Practice: SABP-A-059 26 April 2015laudivelNo ratings yet

- Positive Material Identification: ScopeDocument15 pagesPositive Material Identification: Scopebenedicto soto mestanzaNo ratings yet

- FA - Geosynthetics LaboratoryDocument43 pagesFA - Geosynthetics LaboratoryJufriadi Civil EngineeringNo ratings yet

- Astm C 1069 - 86 R04 PDFDocument2 pagesAstm C 1069 - 86 R04 PDFo_l_0No ratings yet

- Standard QA Plan (Elastomeric Bearings)Document8 pagesStandard QA Plan (Elastomeric Bearings)ghaghra bridgeNo ratings yet

- Sabp A 059 PDFDocument23 pagesSabp A 059 PDFWalid MegahedNo ratings yet

- 07 - Apollo - Iocl - Actuator GTV - R1Document1 page07 - Apollo - Iocl - Actuator GTV - R19893203028No ratings yet

- Supplier Standardised Process Guide: - Raw Material Testing - RM Processing - ForgingDocument22 pagesSupplier Standardised Process Guide: - Raw Material Testing - RM Processing - ForgingBhavna Acharya100% (1)

- 01b. Quality Plan For Construction Materials 13.03.2021Document11 pages01b. Quality Plan For Construction Materials 13.03.2021V.m. RajanNo ratings yet

- MK Tron Auto Part: Procedure of Leak TestingDocument1 pageMK Tron Auto Part: Procedure of Leak Testingsachin kadamNo ratings yet

- Wss-M99p1111-A - 26 02 2007Document4 pagesWss-M99p1111-A - 26 02 2007Veysel Emre BozkurtNo ratings yet

- Centre Pivot Assembly (Top & Bottom) (Mod-1) 97049 QM-C-7.1-BOGIE-0001-C-MOD-1Document4 pagesCentre Pivot Assembly (Top & Bottom) (Mod-1) 97049 QM-C-7.1-BOGIE-0001-C-MOD-1kapilparyani100% (1)

- Masjid Sahabat - Testing PlanDocument14 pagesMasjid Sahabat - Testing PlanDinn NsNo ratings yet

- Slag Cement: Validation of Using Slag Cement For Mass / Dam ConstructionDocument11 pagesSlag Cement: Validation of Using Slag Cement For Mass / Dam Constructionthangamuthu baskarNo ratings yet

- R.E Wall Test SummaryDocument1 pageR.E Wall Test SummaryBiplab dattaNo ratings yet

- Comparative Analysis of Chemical and Physical Properties of Mini Cement Plant and Major Cement PlantDocument3 pagesComparative Analysis of Chemical and Physical Properties of Mini Cement Plant and Major Cement PlantJournal 4 ResearchNo ratings yet

- 40L溶解乙炔气瓶英文版图纸Document1 page40L溶解乙炔气瓶英文版图纸Bilel AzzouniNo ratings yet

- Pressure Vessel ITP Rev 0Document21 pagesPressure Vessel ITP Rev 0Ahmad HasnanNo ratings yet

- 1.5mm SCH21089-finalDocument4 pages1.5mm SCH21089-finalluis.fuentes.g96No ratings yet

- Batch Test CertificateDocument3 pagesBatch Test Certificatekarthikeyan1003No ratings yet

- LNG-80-100937-RA-6065-00023-0000 HT PipingDocument7 pagesLNG-80-100937-RA-6065-00023-0000 HT PipingMohammad AftabNo ratings yet

- Labs - For SolitacDocument3 pagesLabs - For Solitacluis valdezNo ratings yet

- Sampling Station: Source: Sampling Date: Testing Date:: Determination of Aggregate Crushing Value (ACV)Document1 pageSampling Station: Source: Sampling Date: Testing Date:: Determination of Aggregate Crushing Value (ACV)Tewodros TadesseNo ratings yet

- Construction Procedures and Internal Quality ControlDocument17 pagesConstruction Procedures and Internal Quality ControlbienndcNo ratings yet

- 10.COOPERHEAT HT ProcedureDocument16 pages10.COOPERHEAT HT Procedurethanga balanNo ratings yet

- QAP - Rubber liningBORLDocument1 pageQAP - Rubber liningBORLdada shaikNo ratings yet

- Field Qulity Plan: 1. Chemical TestDocument3 pagesField Qulity Plan: 1. Chemical TestVinoth Kumar RavindranNo ratings yet

- ITP ConcreteDocument9 pagesITP ConcreteTwin Bulls100% (1)

- QAP (WO No. 58 & 59) PDFDocument3 pagesQAP (WO No. 58 & 59) PDFKailasNo ratings yet

- QA/QC of Concrete For Bridge ConstructionDocument43 pagesQA/QC of Concrete For Bridge ConstructionASHUTOSH RANJANNo ratings yet

- Method Statement SubgradeDocument8 pagesMethod Statement Subgradeabhishekks26No ratings yet

- Pipe Specimen For Aut Calibration Selection Thickness Survey & Laminations Checks Rev c1.Document12 pagesPipe Specimen For Aut Calibration Selection Thickness Survey & Laminations Checks Rev c1.EdAlmNo ratings yet

- API 610 CentrifugalDocument6 pagesAPI 610 CentrifugalAnonymous 4lFgg25MENo ratings yet

- Characterization of Atmospheric Test Sites: Standard Practice ForDocument5 pagesCharacterization of Atmospheric Test Sites: Standard Practice Formohammed karasnehNo ratings yet

- Week No 40,43 GR, 3 Day'sDocument1 pageWeek No 40,43 GR, 3 Day'sshinde rushiNo ratings yet

- Template SertifikatDocument1 pageTemplate SertifikatSubhan MuhammadNo ratings yet

- Mastic-Mix DesignDocument10 pagesMastic-Mix DesignVaasu KotyadaNo ratings yet

- Kuat TarikDocument1 pageKuat TarikSeptian Ega PrasetyoNo ratings yet

- Laboratories Testing Concrete and Concrete Aggregates For Use in Construction and Criteria For Laboratory EvaluationDocument6 pagesLaboratories Testing Concrete and Concrete Aggregates For Use in Construction and Criteria For Laboratory EvaluationAbid HussainNo ratings yet

- WSA SPECS - Aggregate MaterialsDocument8 pagesWSA SPECS - Aggregate MaterialsConnor RegierNo ratings yet

- Name of The Work:: Quality Assurance PlanDocument21 pagesName of The Work:: Quality Assurance PlanSharat SahaNo ratings yet

- Part-2-July21 A P P E N D I X 1 0 Procedure For The Approval of Aluminum ManufacturersDocument5 pagesPart-2-July21 A P P E N D I X 1 0 Procedure For The Approval of Aluminum ManufacturersSergio AlejandroNo ratings yet

- GroutDocument1 pageGroutR.K. CONSULTANCY AND CONTRACTORNo ratings yet

- Field Quality PlanDocument8 pagesField Quality PlanJaydip NathNo ratings yet

- Hollow Block (20x20x40) (Sampling Date 24-06-2023)Document2 pagesHollow Block (20x20x40) (Sampling Date 24-06-2023)MGNo ratings yet

- Inspection & Testing Plan For Crusher Production-Sub Base: INF-AP-QUA-ITP-08 Rev. 0 Date: 04.07.2018Document2 pagesInspection & Testing Plan For Crusher Production-Sub Base: INF-AP-QUA-ITP-08 Rev. 0 Date: 04.07.2018jerin sam kurianNo ratings yet

- AN1013 Rev A0 Brake Kit Module - 2017.078v8Document5 pagesAN1013 Rev A0 Brake Kit Module - 2017.078v8arstjunkNo ratings yet

- Mds-Ongc-C-Dss-Astm-A995-4a-Nace-6d-001-Rev A - (M3709)Document5 pagesMds-Ongc-C-Dss-Astm-A995-4a-Nace-6d-001-Rev A - (M3709)SPACE ALLOYSNo ratings yet

- KK Concrete Aug 2008Document50 pagesKK Concrete Aug 2008Ganapathyramasamy NNo ratings yet

- 19-07-22 8.2 (B) Turbine Governor Control Checks Including A Steam Governor Overspeed TestDocument7 pages19-07-22 8.2 (B) Turbine Governor Control Checks Including A Steam Governor Overspeed TestsarmastNo ratings yet

- Check Sheet-MPTTHCouplerDocument12 pagesCheck Sheet-MPTTHCouplerOmeNo ratings yet

- Road Embankment ITPDocument6 pagesRoad Embankment ITPMahendraSinghNo ratings yet

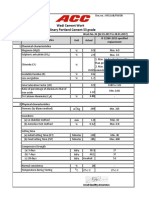

- Wadi Cement Work Ordinary Portland Cement 53 Grade: Chemical CharacteristicsDocument1 pageWadi Cement Work Ordinary Portland Cement 53 Grade: Chemical CharacteristicsAshish SontakkeNo ratings yet

- Teste de Propriedades de Atrito de FixadoresDocument31 pagesTeste de Propriedades de Atrito de FixadoresRICARDONo ratings yet

- EUEC Mercury NumberDocument12 pagesEUEC Mercury NumberRobert HustonNo ratings yet

- Geotechnical Report 10 Eastern Creek Drive Eastern Creek Part2 - RemovedDocument1 pageGeotechnical Report 10 Eastern Creek Drive Eastern Creek Part2 - RemovedJonathan Lopez MatizNo ratings yet

- ADA-CS PAC Handling and Safety EUEC 2016 1 27 2016Document18 pagesADA-CS PAC Handling and Safety EUEC 2016 1 27 2016Robert HustonNo ratings yet

- Plastics Testing and Characterization: Industrial ApplicationsFrom EverandPlastics Testing and Characterization: Industrial ApplicationsNo ratings yet

- Energía de FracturaDocument6 pagesEnergía de FracturaAngel PecinaNo ratings yet

- Friction Coefficient of Steel On Concrete or GroutDocument7 pagesFriction Coefficient of Steel On Concrete or GroutLuis Ernesto Ramirez OsorioNo ratings yet

- Efflorescence in ConcreteDocument4 pagesEfflorescence in Concretebala subramanyamNo ratings yet

- Undrained Soil Behavior (And Modeling) : Gioacchino (Cino) ViggianiDocument45 pagesUndrained Soil Behavior (And Modeling) : Gioacchino (Cino) ViggianiFelipe Ignacio Alarcon ArayaNo ratings yet

- The Road of Experimental Pavement Structures: Experience of Five Years OperationDocument8 pagesThe Road of Experimental Pavement Structures: Experience of Five Years OperationsdfsfNo ratings yet

- F1 ScienceDocument2 pagesF1 Sciencebestrabbit010No ratings yet

- Trusses How They WorkDocument7 pagesTrusses How They Workprabhu81No ratings yet

- EPDM Grade SlateDocument2 pagesEPDM Grade SlateMaeon Laboratories100% (1)

- Module 1.2 Fire ChemistryDocument62 pagesModule 1.2 Fire ChemistryAnonymous 1MXWIawNo ratings yet

- Chem Lab Magnesium ChlorideDocument2 pagesChem Lab Magnesium Chloridespine624925125No ratings yet

- High Grade Water Soluble SOP For FertigationDocument2 pagesHigh Grade Water Soluble SOP For FertigationRómulo Del ValleNo ratings yet

- Phy G11 H OfficialDocument93 pagesPhy G11 H OfficialbarakatNo ratings yet

- Slope ProtectionDocument7 pagesSlope ProtectionMarjun SuperalesNo ratings yet

- Pamphlet On Quality Assurance For Cement PlasteringDocument4 pagesPamphlet On Quality Assurance For Cement PlasteringD V BHASKARNo ratings yet

- q4 Ia Smaw 12 Week 1Document4 pagesq4 Ia Smaw 12 Week 1ALEX SARAOSOSNo ratings yet

- DAY 15 Mixture and Alligation (16 Days 16 Marathon)Document5 pagesDAY 15 Mixture and Alligation (16 Days 16 Marathon)digaNo ratings yet

- A Spherical Pressure Vessel Has An Inside Diameter...Document2 pagesA Spherical Pressure Vessel Has An Inside Diameter...RjNo ratings yet

- SNC1D Exam Review Student RDocument6 pagesSNC1D Exam Review Student RtccrokidasNo ratings yet

- Career Point - Chemical BondingDocument3 pagesCareer Point - Chemical BondingKeshav BandilNo ratings yet

- BamDocument9 pagesBamBaghiu TeodorNo ratings yet

- Characterization of The Morphological, Physical, and Mechanical PropertiesDocument6 pagesCharacterization of The Morphological, Physical, and Mechanical Propertieskuhan moganNo ratings yet

- Winterisation InsulationDocument6 pagesWinterisation InsulationRajan Singh PalNo ratings yet

- Strengthening Reinforced Concrete by Using FRPDocument24 pagesStrengthening Reinforced Concrete by Using FRPAgus SantoNo ratings yet

- Expansive Soil StabiliazationDocument51 pagesExpansive Soil StabiliazationSyed Jibran Ishtiaq0% (1)

- DSC 214 Polyma - Differential Scanning Calorimeter (-170°C To 600°C)Document24 pagesDSC 214 Polyma - Differential Scanning Calorimeter (-170°C To 600°C)NETZSCH - Leading Thermal AnalysisNo ratings yet

- June 2019 MSDocument23 pagesJune 2019 MSmarcoscervantes006No ratings yet

- Introduction Tomarine Chemistry. J. P. Riley and R. Chester. Academic Press, LondonDocument2 pagesIntroduction Tomarine Chemistry. J. P. Riley and R. Chester. Academic Press, LondonAariz KhanNo ratings yet

- Advantages and Disadvantages of Reinforced Cement Concrete (R.C.C)Document5 pagesAdvantages and Disadvantages of Reinforced Cement Concrete (R.C.C)awaw awawNo ratings yet

- K 2017-08-01 ME H. Pelders S M. Ummelen ME VCL E. Jordaan/hpe 1 of 1Document1 pageK 2017-08-01 ME H. Pelders S M. Ummelen ME VCL E. Jordaan/hpe 1 of 1mokie305No ratings yet

- ASTM F-894 High-Density Spirolite Polyethylene Pipe Product Data SpiroliteDocument19 pagesASTM F-894 High-Density Spirolite Polyethylene Pipe Product Data SpiroliteS KarthikeyanNo ratings yet