Professional Documents

Culture Documents

Safe Work Method For Hydro Test

Safe Work Method For Hydro Test

Uploaded by

Eswar RaoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safe Work Method For Hydro Test

Safe Work Method For Hydro Test

Uploaded by

Eswar RaoCopyright:

Available Formats

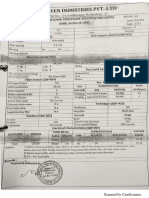

Safe Work Method for chilled water piping Hydro test –

1. Work area will be inspected by engineer for free access and safe for work.

2. All equipment documents are checked related to work by concern engineer and

consultant.

3. Ensure proper illumination and work related PPE’s before starting the work.

4. Ensure appropriate power tools required for testing. It will be verified before start of the

work.

5. Ensure all tools, tackles and equipments are properly cleaned.

6. Make sure that hydro test positive displacement pump is placed on leveled surface.

7. Check all the necessary accessories are installing to hydro test skid like barrel nipple,

socket, pressure gauge etc.

8. Check power supply is available near to the pumpset position.

9. Connect the MS pipe and pumpset with rubber hose.

10. Fill the water as per requirement and during water filling ensure that there is no air trap

in piping.

11. Use air vents / ball valve at air trap position or highest position in the system.

12. Take a review with the entire flanged joints, welding joints and fitting for any leakage.

13. Give inspection call to consultant for pressurization testing.

14. Ensure that hydro test pressure in the system is 1.5 times the working pressure.

15. Disconnect the pump from system and hold the pressure as per instructions.

16. Ensure that drain valve is installed in the system to drain the water. The same valve will

be use during flushing of the systems.

17. Ensure used pipes, drums, cans will be shifted to appropriate location after pipeline

pressurization.

18. Use proper sign board for instruction and barricade respective area for movement.

19. After completion of work, all work area will be properly and neatly clean.

Aqua Chill Systems India Pvt. Ltd., Pune

You might also like

- Method Statement - Pressing of Plate To Be Pipe - SignDocument9 pagesMethod Statement - Pressing of Plate To Be Pipe - SignrichadNo ratings yet

- Method Statement - Erection, Installation of Above Ground Piping - POXDocument11 pagesMethod Statement - Erection, Installation of Above Ground Piping - POXHabib ur rahmanNo ratings yet

- Method Statement - Roof VentilatorDocument7 pagesMethod Statement - Roof VentilatorJuwe Pkdo100% (2)

- Method Statement & Risk Assessment Hydrostatic Leak TestDocument7 pagesMethod Statement & Risk Assessment Hydrostatic Leak TestWalid AmdouniNo ratings yet

- WMS JOB Procedure FOR PIPING WORKDocument9 pagesWMS JOB Procedure FOR PIPING WORKsatyamech1_395565923No ratings yet

- Jsa Nitrogen Purging PDFDocument2 pagesJsa Nitrogen Purging PDFBISWA RANJAN SAHOONo ratings yet

- CSWIP 3.1 Question PaperDocument4 pagesCSWIP 3.1 Question PaperEswar RaoNo ratings yet

- Method Statement For Hydro TestDocument3 pagesMethod Statement For Hydro TestSandeep kumar100% (1)

- MOS of BackfillingDocument2 pagesMOS of BackfillingPoru ManNo ratings yet

- Jha Lin FillingDocument6 pagesJha Lin FillingLuqman OsmanNo ratings yet

- SOP Mobile CraneDocument1 pageSOP Mobile CraneTricolor C ANo ratings yet

- 001-Sample Method Statement Piping ShutdownDocument10 pages001-Sample Method Statement Piping ShutdownS.C.Satish ChanderNo ratings yet

- Caretaker Risk Assessment - Working at HeightDocument8 pagesCaretaker Risk Assessment - Working at HeightLina MarcelaNo ratings yet

- MS For Pipe Demolation at MT-OffshoreDocument5 pagesMS For Pipe Demolation at MT-OffshoreahmadNo ratings yet

- Commissioning and Decommissioning of Pipelines, District Isolation TestDocument13 pagesCommissioning and Decommissioning of Pipelines, District Isolation TestSevet Gnow DrachirNo ratings yet

- Lecture 3.2.3: Erection III: Steel Construction: Fabrication and ErectionDocument4 pagesLecture 3.2.3: Erection III: Steel Construction: Fabrication and ErectionMihajloDjurdjevicNo ratings yet

- HSE-OCP-013. Cold CuttingDocument4 pagesHSE-OCP-013. Cold Cuttingibrahim0% (1)

- AST Nozzle Repair Req.Document10 pagesAST Nozzle Repair Req.Irvansyah RazadinNo ratings yet

- Leak Test and VacuumDocument2 pagesLeak Test and VacuumLinh TruongNo ratings yet

- Checklist Before Hydrotest HEAVY SLOPEDocument10 pagesChecklist Before Hydrotest HEAVY SLOPEcahyaNo ratings yet

- Method Statement PerlitageDocument6 pagesMethod Statement PerlitageHussein Adnan FneishNo ratings yet

- Brazing and Jointing of Copper PipesDocument3 pagesBrazing and Jointing of Copper Pipessunny_84t100% (1)

- JMS - Snuffing Pipe Installation Rev 1Document17 pagesJMS - Snuffing Pipe Installation Rev 1mohd as shahiddin jafriNo ratings yet

- Method Statement & Safety Procedure For HPWJ Cleaning Helideck Retro Jetting For The Below Listed LinesDocument8 pagesMethod Statement & Safety Procedure For HPWJ Cleaning Helideck Retro Jetting For The Below Listed LinesDheeraj Chowdary DhanekulaNo ratings yet

- Flange Weld Testers (FWT)Document1 pageFlange Weld Testers (FWT)moonstar_dmeNo ratings yet

- Oxy Acetylene Cutting TorchDocument2 pagesOxy Acetylene Cutting TorchChristian Makande100% (1)

- Hydro Test ProcedureDocument2 pagesHydro Test ProcedureDhanushka B HerathNo ratings yet

- Fire Protection Pipes Method Statement PDFDocument16 pagesFire Protection Pipes Method Statement PDFفاعل خيرNo ratings yet

- Method Statement For Vertical StructureDocument7 pagesMethod Statement For Vertical StructureAdel SaqqaNo ratings yet

- Method Statement For Ferrite Test: DCSM Project 2019Document5 pagesMethod Statement For Ferrite Test: DCSM Project 2019Thinh NguyenNo ratings yet

- Cms For Piping - Smp6a's Workshop - 10.jul.15Document282 pagesCms For Piping - Smp6a's Workshop - 10.jul.15langcvNo ratings yet

- 41-JSA-Construction of Access Road and Structure Pads - Backfilling Leveling Compaction Activities-MLCC PDFDocument10 pages41-JSA-Construction of Access Road and Structure Pads - Backfilling Leveling Compaction Activities-MLCC PDFFarhan MNo ratings yet

- Released: Company Document No: Document ClassDocument32 pagesReleased: Company Document No: Document ClassShajahan AsanarNo ratings yet

- Pressure Tests of Piping Systems-Hydrotest Vs Pneumatic TestDocument4 pagesPressure Tests of Piping Systems-Hydrotest Vs Pneumatic TestRakesh RanjanNo ratings yet

- Method Statement of Installing I-BeamDocument1 pageMethod Statement of Installing I-BeamfaizbukhariNo ratings yet

- Method Statement For Installation of VAV BoxDocument3 pagesMethod Statement For Installation of VAV BoxRamakrishnanNo ratings yet

- Work Procedure Pipe SupportDocument10 pagesWork Procedure Pipe Supportmc chesterNo ratings yet

- Page 1 of 7 1.0 Title: Method Statement For Water Chlorination TestDocument7 pagesPage 1 of 7 1.0 Title: Method Statement For Water Chlorination Testarshad iqbal100% (1)

- Ripen Offshore Calmbuoy Cleaning and Painting Works ProcedureDocument6 pagesRipen Offshore Calmbuoy Cleaning and Painting Works ProcedureAdamu Jebo100% (1)

- Pre-Commissioning & Commissioning Method Statement For Fire Hose Racks & Fire Hose ReelDocument2 pagesPre-Commissioning & Commissioning Method Statement For Fire Hose Racks & Fire Hose ReelDong VanraNo ratings yet

- JSA For Cleaning Boiler, SCR & ESP InternalDocument18 pagesJSA For Cleaning Boiler, SCR & ESP InternalThái Đạo Phạm LêNo ratings yet

- Hydrotest JHADocument29 pagesHydrotest JHABenjamin EmmanuelNo ratings yet

- Lifting Plan No:-Project IWWTP at Banyan Project: Mobile CraneDocument7 pagesLifting Plan No:-Project IWWTP at Banyan Project: Mobile CraneHtin Lin Aung100% (1)

- ACROPOLIS Method Statement For Domestic Water Piping Installation UG & AGDocument14 pagesACROPOLIS Method Statement For Domestic Water Piping Installation UG & AGVontrex EngrNo ratings yet

- Tank Building Methodology: Sourcing Energy To Our LivesDocument43 pagesTank Building Methodology: Sourcing Energy To Our LiveskopnangNo ratings yet

- Lift Plan FormDocument1 pageLift Plan Formخالد نسیمNo ratings yet

- NS2-DD09-P0ZEN-740027 HDPE Piping Hydrostatic Test ProcedureDocument36 pagesNS2-DD09-P0ZEN-740027 HDPE Piping Hydrostatic Test ProceduretuanphamNo ratings yet

- Fuel Tank Lifting REV01Document7 pagesFuel Tank Lifting REV01armagan55No ratings yet

- Quality Assurance ManualDocument6 pagesQuality Assurance ManualEdgarDavidDiazCamposNo ratings yet

- CL TrenchExcavationDocument2 pagesCL TrenchExcavationMathan RajNo ratings yet

- Mgo Msds PDFDocument5 pagesMgo Msds PDFProtitNazirNo ratings yet

- Risk Ass - ProcessDocument4 pagesRisk Ass - ProcessBalakrishnan Sivagnanam SNo ratings yet

- Hydrostatic Test ProcedureDocument7 pagesHydrostatic Test Procedurelaleye_olumideNo ratings yet

- Method Statement For Insulation WorksDocument16 pagesMethod Statement For Insulation WorksAhmed Farman AlqaysiNo ratings yet

- Vessel Final BoxDocument14 pagesVessel Final Boxmanoj thakkarNo ratings yet

- Sample Work Activities For Process Tank FabricationDocument4 pagesSample Work Activities For Process Tank FabricationMuhammad Zubair100% (1)

- Safety Alert Space HeatersDocument2 pagesSafety Alert Space HeatersRamadan KareemNo ratings yet

- Re-Welding, Expansion & HT ProcedureDocument6 pagesRe-Welding, Expansion & HT Proceduresuria qaqcNo ratings yet

- Sprinkler MethodDocument6 pagesSprinkler Methodakram husseinNo ratings yet

- Hydrostatic Pressure Test Safety ChecklistDocument3 pagesHydrostatic Pressure Test Safety ChecklistJerry Faria60% (5)

- General Guiidelines For Precommissioning and Commissioning A Chemical Process PlantDocument2 pagesGeneral Guiidelines For Precommissioning and Commissioning A Chemical Process Plantankur2061100% (1)

- (Payment Receipt) Booking Checked-Out - OYO 72156 Akshaya Inn: Booking No.: AKSI4578Document2 pages(Payment Receipt) Booking Checked-Out - OYO 72156 Akshaya Inn: Booking No.: AKSI4578Eswar RaoNo ratings yet

- Ride Details Bill DetailsDocument2 pagesRide Details Bill DetailsEswar RaoNo ratings yet

- Ride Details Bill Details: Thanks For Travelling With Us, B ESWAR RAODocument2 pagesRide Details Bill Details: Thanks For Travelling With Us, B ESWAR RAOEswar RaoNo ratings yet

- Ride Details Bill DetailsDocument2 pagesRide Details Bill DetailsEswar RaoNo ratings yet

- Ride Details Bill Details: Thanks For Travelling With Us, B ESWAR RAODocument2 pagesRide Details Bill Details: Thanks For Travelling With Us, B ESWAR RAOEswar RaoNo ratings yet

- INKOLLU To Hyderabad: Vikram Srikrishna Travels Service # VSK - 07Document2 pagesINKOLLU To Hyderabad: Vikram Srikrishna Travels Service # VSK - 07Eswar RaoNo ratings yet

- Eticket: Inkollu Saturday, March 21, 2020Document3 pagesEticket: Inkollu Saturday, March 21, 2020Eswar RaoNo ratings yet

- Ride Details Bill Details: 08 Jun, 2020 Invoice Serial Id:CXCFYPD204678Document4 pagesRide Details Bill Details: 08 Jun, 2020 Invoice Serial Id:CXCFYPD204678Eswar RaoNo ratings yet

- New Doc 2020-05-08 21.03.20Document13 pagesNew Doc 2020-05-08 21.03.20Eswar RaoNo ratings yet

- New Doc 2020-07-18 12.36.25Document2 pagesNew Doc 2020-07-18 12.36.25Eswar RaoNo ratings yet

- New Doc 2020-05-11 21.27.50Document4 pagesNew Doc 2020-05-11 21.27.50Eswar RaoNo ratings yet

- INDIA Product BrochureDocument40 pagesINDIA Product BrochureEswar RaoNo ratings yet

- Aluminium ComparisionDocument2 pagesAluminium ComparisionEswar RaoNo ratings yet