Professional Documents

Culture Documents

Stamicarbon Urea Process Data PDF

Stamicarbon Urea Process Data PDF

Uploaded by

treyzzztylerOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stamicarbon Urea Process Data PDF

Stamicarbon Urea Process Data PDF

Uploaded by

treyzzztylerCopyright:

Available Formats

Stamicarbon Urea Process Data

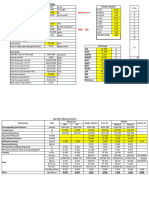

Typical consumption figures of a Stamicarbon urea plant per ton of urea:

Urea 2000Plus™ Low

Granulation Prilling Energy Unit

NH3 (100%) 564 566 566 kg

CO2 (100%) 730 733 733 kg

MP steam intake (23 bar - 330 ºC) 736 784 552 kg

Electricity use melt plant (excl. CO2 compressor) 1) 19 20 20 kWh

Electricity use granulation plant 1) 36 - - kWh

Cooling water circulating (T= 10 ºC) 69 75 63 t

LP steam export (4 bar saturated) 0 0 0 kg

Steam condensate export 539 430 223 kg

Purified process condensate export 273 654 630 kg

UF85 5 - - kg

1) Includes all e-power driven equipment

Typical product parameters:

Nitrogen 46.3 46.4 wt%

Biuret 0.85 0.85 wt%

Moisture 0.2 0.25 wt%

Formaldehyde 0.3 - wt%

Crushing strength (3.15 mm granule) 4.5 - kgf

Particle size distribution (2 - 4 mm) 95 - wt%

Particle size distribution (1 - 2.4 mm) - 97.5 wt%

Treated process condensate:

Ammonia 2 ppm wt

Urea 1 ppm wt

Emissions:

Ammonia from absorbers melt plant 0.016 0.014 0,020 kg/ton

Ammonia in finishing section vent 135 mg/Nm3

Ammonia in finishing vent 2) < 30 2) mg/Nm3

Urea in finishing section vent 25 3) 40 4)

40 4)

mg/Nm3

2) When acidic washing with nitric or sulfuric acid applied

3) Lower emissions are possible when Stamicarbon MMV scrubber is applied

4) When de-dusting system is applied

Typical consumption figures Stamicarbon UAN plant, per ton of UAN - 32%N:

Ammonia 296 kg

Carbon dioxide 353 kg

Nitric Acid (56%) 353 kg

Steam (23 bar - 330 ºC) 167 kg

Electricity (excl. CO2 compressor) 6 kWh

Corrosion inhibitor 1.4 kg

Steam produced (4 bar, saturated) 233 kg

V9-10-2013

PO Box 53, 6160 AB Geleen T +31 46 423 7070 info@stamicarbon.com

The Netherlands F +31 46 423 7001 www.stamicarbon.com

You might also like

- Ammonia Synthesis Loops Variables Investigated by Steady-State SimulationDocument14 pagesAmmonia Synthesis Loops Variables Investigated by Steady-State Simulationpolonium2310No ratings yet

- Shift CatalystDocument8 pagesShift Catalystraju100% (3)

- Urea UllmannsDocument40 pagesUrea UllmannsGeorge Van Bommel100% (3)

- A On Report Comparison Among All Manufacturing ProcessesDocument11 pagesA On Report Comparison Among All Manufacturing ProcessesMohit BayerNo ratings yet

- Catacarb Section, Dawood Hercules Fertilizers LimitedDocument16 pagesCatacarb Section, Dawood Hercules Fertilizers LimitedMuddassar Sultan100% (4)

- Urea ProductionDocument2 pagesUrea Productiongaur1234No ratings yet

- Borsodchem MCHZ, Czech Republic 6,000 NM /H HTCR Topsøe Hydrogen Plant A Case Story: 18 Months From Engineering To OperationDocument15 pagesBorsodchem MCHZ, Czech Republic 6,000 NM /H HTCR Topsøe Hydrogen Plant A Case Story: 18 Months From Engineering To OperationlaquetengoNo ratings yet

- Draft Report For Urea ProductionDocument59 pagesDraft Report For Urea ProductionBryan Jesher Dela CruzNo ratings yet

- Slip Calcluation in Ammonia PlantDocument8 pagesSlip Calcluation in Ammonia PlantRajat Chauhan0% (1)

- UREA Granulation UnitDocument26 pagesUREA Granulation UnitAdil AliNo ratings yet

- "The Comparison of Stamicarbon and Saipem Urea Technology": October 2016Document11 pages"The Comparison of Stamicarbon and Saipem Urea Technology": October 2016Alfonso BlancoNo ratings yet

- Final ReportDocument46 pagesFinal ReportVarun Gupta100% (1)

- Commissioning of The First Ammonia-Urea Complex: A Challenging Venture For The Vietnamese EconomyDocument13 pagesCommissioning of The First Ammonia-Urea Complex: A Challenging Venture For The Vietnamese Economyvaratharajan g rNo ratings yet

- KSFL ReportDocument56 pagesKSFL ReportAbhishek KumarNo ratings yet

- Co2 Compressor NewDocument6 pagesCo2 Compressor NewUzair Ashraf100% (1)

- Gbhe Ammonia Co2 Removal Systems WSV PDFDocument20 pagesGbhe Ammonia Co2 Removal Systems WSV PDFAaserElkenanyNo ratings yet

- Major Ammonia Leak From HP Ammonia Feed Pump: P.Hari Narayana Reddy, R. Raghavan and Ramashray SinghDocument10 pagesMajor Ammonia Leak From HP Ammonia Feed Pump: P.Hari Narayana Reddy, R. Raghavan and Ramashray Singhvaratharajan g rNo ratings yet

- Urea PDFDocument11 pagesUrea PDFSteve WanNo ratings yet

- Control of Evaporator in The Production of UreaDocument15 pagesControl of Evaporator in The Production of Ureatariq fareedNo ratings yet

- Ammonia The Next StepDocument11 pagesAmmonia The Next StepmuralleroNo ratings yet

- New KBR Process For Coal To Ammonia: Kamal Gursahani, Siva Ariyapadi, Meghji Shah and Richard StraitDocument12 pagesNew KBR Process For Coal To Ammonia: Kamal Gursahani, Siva Ariyapadi, Meghji Shah and Richard Straitvaratharajan g rNo ratings yet

- Urea Toyo ACES21 - BrochureDocument8 pagesUrea Toyo ACES21 - BrochureSanti SevenfoldNo ratings yet

- Aces Process Material Balance: RE AC TO RDocument4 pagesAces Process Material Balance: RE AC TO Rwaheed ahmadNo ratings yet

- Simulation of Ammonia Production From Synthesis GaDocument12 pagesSimulation of Ammonia Production From Synthesis Gasagar dasguptaNo ratings yet

- 2000 Development of The ACES 21 ProcessDocument17 pages2000 Development of The ACES 21 ProcessTTaddictNo ratings yet

- Reactor Kinetics of Urea Formation: November 2015Document21 pagesReactor Kinetics of Urea Formation: November 2015Javiera MellaNo ratings yet

- Urea Project Report 1 PDFDocument9 pagesUrea Project Report 1 PDFVirendra RathvaNo ratings yet

- JM Methanol BrochureDocument24 pagesJM Methanol BrochureM Alim Ur RahmanNo ratings yet

- Nitric Acid Overall Material BalanceDocument4 pagesNitric Acid Overall Material Balanceyogeshdama100% (1)

- AmmoniaDocument33 pagesAmmoniaWilly ChandraNo ratings yet

- Methanol Plant - 350 TPD: Stock Number: Capacity: Year Built: Status: TechnologyDocument3 pagesMethanol Plant - 350 TPD: Stock Number: Capacity: Year Built: Status: TechnologyPassmore DubeNo ratings yet

- 2008 Morikawa TEC IFA ACES21 Advanced Urea Production Technology - 2Document15 pages2008 Morikawa TEC IFA ACES21 Advanced Urea Production Technology - 2MubasharNo ratings yet

- ToyoDocument17 pagesToyoZeeshan Khan100% (1)

- Aiche-36-021Equipment Performance of AmmoniaDocument9 pagesAiche-36-021Equipment Performance of AmmoniaHsein Wang100% (1)

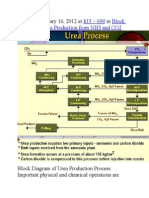

- Published January 16, 2012 at In: 813 × 699 Block Diagram of Urea Production From NH3 and CO2Document9 pagesPublished January 16, 2012 at In: 813 × 699 Block Diagram of Urea Production From NH3 and CO2himanshuchawla654No ratings yet

- Urea Manufacturing Plant-StamicarbonDocument4 pagesUrea Manufacturing Plant-StamicarbonRadhika PillayNo ratings yet

- Urea Plant Nangal 2014Document8 pagesUrea Plant Nangal 2014Ishan HaiderNo ratings yet

- Process DescriptionDocument6 pagesProcess Descriptionافكر اشتري كورياNo ratings yet

- Catacarb Section, Dawood Hercules Fertilizers LimitedDocument16 pagesCatacarb Section, Dawood Hercules Fertilizers LimitedMuddassar Sultan100% (1)

- Ag Report UreaDocument40 pagesAg Report UreaVakul AgarwalNo ratings yet

- UreaDocument19 pagesUreakrit138No ratings yet

- AmmoniaDocument59 pagesAmmoniavcoolkrazy0% (3)

- Amine Process Simulation Model DevelopmentDocument9 pagesAmine Process Simulation Model DevelopmentacetilenaNo ratings yet

- Manufacture of UreaDocument36 pagesManufacture of UreaNandadulal GhoshNo ratings yet

- Lurgi 2001 Methanol Casale Experience With A Russian Methanol Project FIMDocument14 pagesLurgi 2001 Methanol Casale Experience With A Russian Methanol Project FIMFer MugrabiNo ratings yet

- Urea PlantDocument25 pagesUrea PlantHarsh DholakiyaNo ratings yet

- Methanol Plant 380 TPD 2362Document14 pagesMethanol Plant 380 TPD 2362Nontokozo Duma100% (1)

- Problem Statement: To Design A UREA PLANT of Capacity 1000 Ton/day Using Ammonia and Carbon Di-Oxide As Raw MaterialDocument24 pagesProblem Statement: To Design A UREA PLANT of Capacity 1000 Ton/day Using Ammonia and Carbon Di-Oxide As Raw MaterialaamliagarNo ratings yet

- 2009 Margarita Seminar - 10 Successful Applications of Casale Technology To Grass-Roots PlantsDocument32 pages2009 Margarita Seminar - 10 Successful Applications of Casale Technology To Grass-Roots PlantsIvonneNo ratings yet

- Nirbhay Urea Final PDFDocument99 pagesNirbhay Urea Final PDFHimanshu vikram100% (1)

- PSA 50 Paper PDFDocument5 pagesPSA 50 Paper PDFshashi kant kumarNo ratings yet

- Comparative Evaluation of Cryogenic Air SeparationDocument21 pagesComparative Evaluation of Cryogenic Air SeparationmuratNo ratings yet

- REACTOR DESIGN - Docx Fyp MyDocument5 pagesREACTOR DESIGN - Docx Fyp Myabdul rehmanNo ratings yet

- Materials and Processes for CO2 Capture, Conversion, and SequestrationFrom EverandMaterials and Processes for CO2 Capture, Conversion, and SequestrationNo ratings yet

- Heat BalanceDocument33 pagesHeat BalanceIrshad Hussain100% (2)

- Environmental Product Declaration: Protect Protective Relays SPACOM 100 SeriesDocument4 pagesEnvironmental Product Declaration: Protect Protective Relays SPACOM 100 Seriesss subramanyamNo ratings yet

- PG NPK-MCH-CA-EN-027 Cyclone For Dryer CalculationDocument8 pagesPG NPK-MCH-CA-EN-027 Cyclone For Dryer CalculationHermantoro W. PradanaNo ratings yet

- Mix Design For Segments of 80 MPaDocument4 pagesMix Design For Segments of 80 MPaForood TorabianNo ratings yet

- WteDocument36 pagesWteAjy thakareNo ratings yet

- PROPOSALDocument3 pagesPROPOSALNidhal KahouliNo ratings yet

- Stamicarbon Urea Process Data: 1) Includes All E-Power Driven EquipmentDocument1 pageStamicarbon Urea Process Data: 1) Includes All E-Power Driven EquipmentPermata AdindaNo ratings yet

- NetlogDocument1 pageNetlogtreyzzztylerNo ratings yet

- Modified Ludzack Ettinger Example PDFDocument3 pagesModified Ludzack Ettinger Example PDFtreyzzztylerNo ratings yet

- 6200 Area - Urea Plant: Process OverviewDocument8 pages6200 Area - Urea Plant: Process OverviewtreyzzztylerNo ratings yet

- Assignment 1 - Iso SketchDocument1 pageAssignment 1 - Iso SketchtreyzzztylerNo ratings yet

- Chemical Precipitation: Solution With Soluble Ions Insoluble Complexes "Clean Water" +Document3 pagesChemical Precipitation: Solution With Soluble Ions Insoluble Complexes "Clean Water" +treyzzztylerNo ratings yet

- L Lysine Clay Danielle Casey Kashne FINAL REPORTDocument50 pagesL Lysine Clay Danielle Casey Kashne FINAL REPORTtreyzzztylerNo ratings yet

- Steady State Analysis of A Falling Film PDFDocument10 pagesSteady State Analysis of A Falling Film PDFtreyzzztylerNo ratings yet

- Poly-L-Lysine Produced by Streptomyces. Part Ii. Taxonomy and Fermentation StudiesDocument6 pagesPoly-L-Lysine Produced by Streptomyces. Part Ii. Taxonomy and Fermentation StudiestreyzzztylerNo ratings yet

- United States Patent (10) Patent No.: US 7,674,932 B2: Davey Et Al. (45) Date of Patent: Mar. 9, 2010Document6 pagesUnited States Patent (10) Patent No.: US 7,674,932 B2: Davey Et Al. (45) Date of Patent: Mar. 9, 2010treyzzztylerNo ratings yet

- Block DiagramDocument1 pageBlock DiagramtreyzzztylerNo ratings yet

- 3.4 Complete Process Description: Synthesis SectionDocument3 pages3.4 Complete Process Description: Synthesis SectiontreyzzztylerNo ratings yet

- Appendix A: AmmoniaDocument20 pagesAppendix A: AmmoniatreyzzztylerNo ratings yet

- Compile ReferenceDocument6 pagesCompile ReferencetreyzzztylerNo ratings yet

- Mixing Index Vs Mixing Time: Experiment D: Determination of Mixing Index of SolidsDocument4 pagesMixing Index Vs Mixing Time: Experiment D: Determination of Mixing Index of SolidstreyzzztylerNo ratings yet

- Dokumen - Tips - K or Depriester Chart PDFDocument4 pagesDokumen - Tips - K or Depriester Chart PDFtreyzzztylerNo ratings yet

- New Duplex Stainless Steel DP28W Contributes To Safe and Reliable Operation of Urea PlantDocument4 pagesNew Duplex Stainless Steel DP28W Contributes To Safe and Reliable Operation of Urea Plantvaratharajan g rNo ratings yet

- Guide Urine Therapy PDFDocument12 pagesGuide Urine Therapy PDFMyland SaguNo ratings yet

- Design and Fabrication of PortableDocument7 pagesDesign and Fabrication of PortableWILLIAM CAMILO ESPINOSA ROJASNo ratings yet

- The Truth About Urea: Ballang, Pancy Jane P. MTW 9:30AM-11:30AM BSN/1/4Document3 pagesThe Truth About Urea: Ballang, Pancy Jane P. MTW 9:30AM-11:30AM BSN/1/4PanJan BalNo ratings yet

- Urea NPN SourcesDocument60 pagesUrea NPN SourcesDr Anais AsimNo ratings yet

- Modelacion UreaDocument20 pagesModelacion UreaJesus Enrique Alfonzo RiveroNo ratings yet

- Unit Urea: Nama: Dewi Yuliani Nim: 021160029Document1 pageUnit Urea: Nama: Dewi Yuliani Nim: 021160029Kade RohayantiNo ratings yet

- Bio6 1Document6 pagesBio6 1HarmonyChuiNo ratings yet

- Employee Welfare at IffcoDocument74 pagesEmployee Welfare at IffcoMegha SaxenaNo ratings yet

- Clinical Chemistry 2Document6 pagesClinical Chemistry 2Romie SolacitoNo ratings yet

- Report For GSFC UNIVERSITY InternshipDocument55 pagesReport For GSFC UNIVERSITY InternshipPruthvisinh Jadav100% (2)

- Day 1 Mock Board Exam: Name: DateDocument9 pagesDay 1 Mock Board Exam: Name: DateXZ Louise Pauleen Palmares100% (1)

- Activity No. 27: Constituents of UrineDocument50 pagesActivity No. 27: Constituents of Urinemhai requilmanNo ratings yet

- Syaukani Muhammad AliDocument6 pagesSyaukani Muhammad AlidotcomNo ratings yet

- Biuret in Urea Fertilizers - R.L MikellsenDocument2 pagesBiuret in Urea Fertilizers - R.L MikellsenRizka MaharanaNo ratings yet

- History of Organic ChemistryDocument17 pagesHistory of Organic ChemistryWilliam da CostaNo ratings yet

- Synthesis of Bismuth Oxide Nanoparticles Using Bismuth Nitrate and UreaDocument3 pagesSynthesis of Bismuth Oxide Nanoparticles Using Bismuth Nitrate and UreaVijay ThakorNo ratings yet

- SMD-PE-FF-91-001-01 Fire Protection System Philosophy (Indoor and Outdoor)Document17 pagesSMD-PE-FF-91-001-01 Fire Protection System Philosophy (Indoor and Outdoor)Yaser AhmadNo ratings yet

- Diagrama HysysDocument21 pagesDiagrama HysysFerran Cordoba del CuraNo ratings yet

- ANSWERS To Previous Board Exam AGRI LEA (Autosaved) 1Document61 pagesANSWERS To Previous Board Exam AGRI LEA (Autosaved) 1Glöbelyn MabunaNo ratings yet

- CV Shabbir Ahmed DarDocument3 pagesCV Shabbir Ahmed DarFederico SeniorNo ratings yet

- What Is SCR: Jonathan Scott 11/30/2017Document3 pagesWhat Is SCR: Jonathan Scott 11/30/20179629330773No ratings yet

- Estimation of Blood Urea by Enzymatic Berthelot MethodDocument7 pagesEstimation of Blood Urea by Enzymatic Berthelot MethodJeevarathinam SeshachalamNo ratings yet

- Qualitative Organic AnalysisDocument24 pagesQualitative Organic AnalysisSofia FuentesNo ratings yet

- ESTIMATION OF SERUM UreaDocument4 pagesESTIMATION OF SERUM Ureasoroutaditya04No ratings yet

- 1 PBDocument14 pages1 PBwww050No ratings yet

- Ammonia Excretion and Urea Handling by Fish GillsDocument18 pagesAmmonia Excretion and Urea Handling by Fish GillsRaluca-Cristina GuriencuNo ratings yet

- Nat 5 Chem SQApp Unused 2020Document36 pagesNat 5 Chem SQApp Unused 2020muntazNo ratings yet

- Clinical Chemistry 1 - Notes NPNDocument4 pagesClinical Chemistry 1 - Notes NPNlcrujidoNo ratings yet