Professional Documents

Culture Documents

Serie D81 - Cetop 8

Serie D81 - Cetop 8

Uploaded by

Hugo MenendezOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Serie D81 - Cetop 8

Serie D81 - Cetop 8

Uploaded by

Hugo MenendezCopyright:

Available Formats

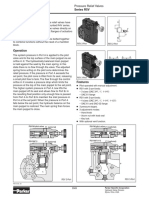

Catalog HY14-2500/US Directional Control Valves

Introduction Series D81

Application Features

Series D81 hydraulic directional control valves are high • Easy access mounting bolts.

A performance, solenoid controlled, pilot operated,

2-stage, 4-way valves. They are available in 2 or • 345 Bar (5000 PSI) pressure rating.

3-position styles and are manifold mounted. These • Flows to 622 LPM (160 GPM) depending on spool.

valves conform to NFPA’s D08, CETOP 8 mounting

pattern. • Choice of four operator styles.

Operation • Rugged four land spools.

Series D81 directional valves consist of a 5-chamber • Low pressure drop.

style main body, a case hardened sliding spool, and a

pilot valve or pilot operators (hydraulic or pneumatic). • Phosphate finish.

D81VW Solenoid Operated Plug-in Conduit Box D81VL Lever Operated

D8P Oil Pilot Operated D81VA Air Pilot Operated

D81.indd, dd

A160 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

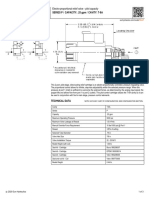

Technical Information Series D81V

General Description

Series D81VW directional control valves are

5-chamber, pilot operated, solenoid controlled valves.

They are available in 2 or 3-position styles. These

A

valves are manifold or subplate mounted, and conform

to NFPA’s D08, CETOP 8 mounting pattern.

Operation

Series D81VW pilot operated valves are standard with

low shock spools and pilot orifice. The orifice can be

removed if a faster shift is required. It is recommended,

however, that all systems operating above 138 Bar

(2000 PSI) use the standard valve to avoid severe

shock.

Features

• Low pressure drop design.

• Hardened spools provide long life.

• Fast response option available.

• Wide variety of voltages and electrical connection options.

• Explosion proof availability.

• No tools required for coil removal.

Response Time

Specifications

Response times (milliseconds) are measured at

Mounting Pattern NFPA D08, 345 Bar (5000 PSI) and 300 LPM (80 GPM) with

CETOP 8, NG25

various pilot pressures as indicated.

Maximum Operating 345 Bar (5000 PSI) Standard

Pressure 207 Bar (3000 PSI) 10 Watt Solenoid Pilot Pull-In Drop-Out

Type Pressure Std Fast Std Fast

CSA 207 Bar (3000 PSI)

Maximum Tank Line Internal Drain Model: 500 140 100 70 70

Pressure 103 Bar (1500 PSI) AC Only DC 1000 125 90 76 76

207 Bar (3000 PSI) DC Std., 2000 100 70 70 70

AC Optional

500 100 60 60 60

External Drain Model: AC 1000 85 50 60 60

345 Bar (5000 PSI)

2000 60 30 60 60

CSA 103 Bar (1500 PSI)

Because of the high drain line pressure transients gen-

Maximum Drain 103 Bar (1500 PSI) AC Only erated during shifting, use of the fast response option

Pressure 207 Bar (3000 PSI) DC Std.,

AC Optional is not recommended for pilot pressures exceeding 138

Bar (2000 PSI).

CSA 103 Bar (1500 PSI)

Minimum Pilot 5.1 Bar* (75 PSI)

Pressure

Maximum Pilot 345 Bar (5000 PSI) Standard

Pressure CSA 207 Bar (3000 PSI)

Nominal Flow 302 LPM (80 GPM)

* 6.9 Bar (100 PSI) for spool configurations 002, 007, 008, 009 & 014.

D81.indd, dd

A161 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Ordering Information Series D81V

D 81V

A Directional

Control Valve

Basic Valve Actuator Spool Style Pilot Supply

and Drain

Seal Solenoid

Voltage

Code Description

NFPA D08

N Nitrile

CETOP 8

DIN NG25 V Fluorocarbon

High Flow, D03 Pilot

Code Description

A* 24/50 VAC

Code Description Code Description D 120 VDC

W* Solenoid, Wet Pin, 1 Internal Pilot, G 198 VDC

Screw-in External Drain J 24 VDC

HW* Reversed Wiring 2 External Pilot, K 12 VDC

External Drain

* Valve schematic symbols are per NFPA/ N** 220/50 VAC

ANSI standards, providing flow P to 3 Internal Pilot w/Check,

Q* 100/60 VAC

A when energizing solenoid A. Note External Drain

QD† 100 VAC/60 Hz

operators reverse sides for #008 and 4* Internal Pilot,

100 VAC/50 Hz

#009 spools. See installation information Internal Drain

for details. To configure per DIN R 24/60 VAC

5 External Pilot,

standards (A coil over A port, B coil over Internal Drain T 240/60 - 220/50 VAC

B port) code valves as D81VHW***. 6 Internal Pilot w/Check, U 98 VDC

Internal Drain Y 120/60 - 110/50 VAC

* Not availble with 002, 007, Z 250 VDC

Code Symbol Code Symbol 008, 009, 014 & 030 spools. * High Watt Coil only.

A B A B

** Explosion Proof only.

001 012

† Available in DIN only.

P T P T

A B A B Code Description Symbol

002 014 b A B

P T P T B* Single solenoid, 2 position, spring offset.

A B A B

P to A and B to T in offset position. P T

003 015

b A B a

P T P T

A B

C Double solenoid, 3 position, spring centered.

A B

004 016 P T

b A B a

P

A

T

B

P T

D* Double solenoid, 2 position, detent.

A B

005 020* P T

b A B

P T

P T E Single solenoid, 2 position, spring centered.

006 A B

030** A B P to B and A to T when energized.

P T

b A B

P T P T F** Single solenoid, 2 position, spring offset,

A B

007 081 A B

energized to center. Position spool spacer on

A side. P to A and B to T in spring offset position. P T

P T P T

A B A B a

008* 082 A B

H* Single solenoid, 2 position, spring offset.

009** P to B and A to T in offset position.

P T P T P T

A B A B a

011 K Single solenoid, 2 position, spring centered.

P to A and B to T when energized.

P T P T

A B a

* 008 & 020 spool have closed crossover. M** Single solenoid, 2 position, spring offset,

** 009 & 030 spool have open crossover. energized to center position. Spool spacer on

B side. P to B and A to T in spring offset position. P T

* Available with 020 and 030 spools only.

** High watt coil only.

Bold: Designates Tier I products and options.

Non-bold: Designates Tier II products and options. These products will have longer lead times.

D81.indd, dd

A162 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Ordering Information Series D81V

A

Solenoid Coil Tube Manual Electrical Shift Approvals Valve Design

Connection Options Options Override Options Response Variations Series

Options and Indication NOTE:

Not required

when

Code Description Code Description ordering.

C* Leadwire Conduit Box Omit Standard Response,

D** Metric Plug (M12X1), No Switch See next page

DESINA I3 Monitor Switch,

E† Explosion Proof ‘A’ & ‘B’ Port End

G†† Plug-In Conduit Box I6 Monitor Switch,

‘A’ & ‘B’ Port Start

J# Deutsch (DT06-2S)

Note: Not CE or CSA approved.

M# Metri-Pack (150)

Not available with ‘F’ or ‘M’

P DIN with Plug styles.

S# Dual Spade

W† DIN w/o Plug

Code Description

* No variations – See Plug-in.

Omit No Options

** DC only, lights, diode surge

suppressor, not CSA approved. J* Diode Surge

† Not available with lights. Suppressor

Z† Rectified Coil Code Description

†† Required for variations on

conduit box style. M

ust have Omit Standard Valve

* DC only.

lights. 3*† CSA US

DIN coil must include

# DC only, no lights, not CSA 4*# CSA Approved

plug with lights.

approved.

† DC tube standard. * Not available with AC high

pressure tube.

# Valve is derated with this

Code Description option.

Code Description Omit Standard † B, C, H styles only. J, K, Y, U

Omit* High Watt voltages only with C, G, W

P Extended

D** Explosion Proof, solenoid connections only.

with Boot

EEXD ATEX Conforms to UL429.

T† None

E** Explosion Proof,

EEXME ATEX † DC or AC Rectified only.

Manual Override options Valve Weight:

F† Low Watt not available with Explosion Double Solenoid 19.6 kg (43.2 lbs.)

L†† 10 Watt Proof. Seal Kit:

O** Explosion Proof, Nitrile SKD81VWN91

MSHA Fluorocarbon SKD81VWV91

T# Explosion Proof,

Ex d IIC ATEX/CSA Code Description Mounting Bolt Kits

U** Explosion Proof, Omit Standard Pressure UNC Bolt Kits for use with D6 and D8

UL/CSA 103 Bar (1500 PSI) AC Directional Control Valves & Sandwich Valves

* AC ambient temperature must 207 Bar (3000 PSI) DC Number of Sandwich Valves

not exceed 60°C (140°F). H* High Pressure, AC only @ 2.75″ (70mm) thickness

** 60 Hz only on AC, no options. 207 Bar (3000 PSI)

0 1 2 3

† AC only.

* Not available with CSA. D6 BK227 BK121 BK122 BK123

†† DC and AC rectified only.

# J, K and Y voltages only. Dual 2.50″ 5.25″ 8.00″ 10.75″

frequency on AC, no options. D6 plus BK161 BK170 BK171 BK172

tapping plate 3.50″ 6.25″ 9.00″ 11.75″

D8 BK228 BK131 BK132 BK133

3.00″ 5.75″ 8.50″ 11.25″

D8 plus BK173 BK174 BK175 BK114

tapping plate 4.00″ 6.75″ 9.50″ 12.125″

Note: All bolts are SAE grade 8, 1/2-13 UNC-3A thread,

torque to 133 N.m. (100 ft.-lbs.)

Bold: Designates Tier I products and options.

Non-bold: Designates Tier II products and options. These products will have longer lead times.

D81.indd, dd

A163 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Ordering Information Series D81V

Valve Variations

Code Description

A 5* Signal Lights – Standard

Signal Lights – Hirsch. (DIN with Plug)

7B** Manaplug – Brad Harrison (12x1) Micro with Lights

56** Manaplug (Mini) with Lights

20 Fast Response

1C** Manaplug (Mini) Single Sol. 5-pin, with Lights

1D** Manaplug (Micro) Single Sol. 5-pin, with Lights

1G** Manaplug (Mini) Single Sol. 5-pin,

with Stroke Adjust ‘A’ & ‘B’ End and Lights

1H** Manaplug (Micro) Single Sol. 5-pin,

with Stroke Adjust ‘A’ & ‘B’ End and Lights

1M** Manaplug Opposite Normal

1P Painted Body

1R Stroke Adjust ‘A’ & ‘B’ End with Pilot Choke Meter In

3A Pilot Choke Meter Out

3B Pilot Choke Meter In

3C Pilot Pressure Reducer

3D Stroke Adjust ‘B’ End

3E Stroke Adjust ‘A’ End

3F Stroke Adjust ‘A’ & ‘B’ End

3G* Pilot Choke Meter Out with Lights

3H* Pilot Choke Meter In with Lights

3J* Pilot Pressure Reducer with Lights

3K Pilot Choke Meter Out

with Stroke Adjust ‘A’ & ‘B’ End

3L** Pilot Choke Meter Out, Stroke Adjust ‘A’ & ‘B’ End

with Lights and Manaplug — Brad Harrison Mini

3M Pilot Choke Meter Out, Pilot Pressure Reducer,

Stroke Adjust ‘A’ & ‘B’ End

3R Pilot Choke Meter Out & Pilot Pressure Reducer

3S** Lights, Mini Manaplug, Pilot Choke Meter Out

7Y** M12x1 Manaplug (4-pin), Special Wiring, and Lights

* DESINA, plug-in conduit box, and DIN with plug styles only.

** Must have plug-in style conduit box.

D81.indd, dd

A164 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Technical Information Series D81V

Reference Data

A

MaximumFlow, Maximum Flow,

LPM (GPM) LPM (GPM)

Spool 345 Bar (5000 PSI) Spool 345 Bar (5000 PSI)

Model Symbol w/o Malfunction Model Symbol w/o Malfunction

A B A B

D81V*008

D81V*001 624 (160) 312 (80)

D81V*009

P T P T

A B A B

D81V*002 624 (160) D81V*011 624 (160)

P T P T

A B A B

D81V*003 624 (160) D81V*012 312 (80)

P T P T

A B A B

D81V*004 624 (160) D81V*014 312 (80)

P T P T

A B A B

D81V*005 624 (160) D81V*015 624 (160)

P T P T

A B A B

D81V*006 624 (160) D81V*016 624 (160)

P T P T

A B A B

D81V*020

D81V*007 312 (80) 624 (160)

P T D81V*030 P T

D81VW Pressure Drop Reference Chart – Curve Number

D81V* Series Pressure Drop Chart Spool

The following chart provides the flow vs. pressure drop No. P–A P–B P–T A–T B–T

curve reference for the Series D81V* valve by spool 001 1 1 – 3 4

type. 002 2 2 5 4 6

003 1 1 – 4 4

004 1 1 – 4 6

VISCOSITY CORRECTION FACTOR 005 2 2 – 3 4

Viscosity (SSU) 75 150 200 250 300 350 400 006 2 2 – 3 4

% of ∆P (Approx.) 93 111 119 126 132 137 141 007 1 2 8 3 6

Curves were generated using 100 SSU hydraulic oil. For any other 009 2 2 7 3 4

viscosity, pressure drop will change as per chart. 011 1 1 – 3 4

012 1 1 9 3 4

014 2 1 8 6 3

015 2 2 – 5 5

016 2 2 – 4 3

020/030 2 2 – 3 4

Performance Curves

D81.indd, dd

A165 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Technical Information Series D81V

Solenoid Ratings Explosion Proof Solenoid Ratings*

Insulation System Class F U.L. & CSA (EU) Class I, Div 1 & 2, Groups C & D

A Allowable Deviation -15% to +10% for DC and AC rectified coils

from rated voltage -5% to +5% for AC Coils

Class II, Div 1 & 2, Groups E, F & G

As defined by the N.E.C.

Armature Wet pin type MSHA (EO) Complies with 30CFR, Part 18

CSA File Number LR60407 ATEX (ED) Complies with ATEX requirements for:

Exd, Group IIB; EN50014:

Environmental DC Solenoids meet NEMA 4 and IP67

1999+ Amds. 1 & 2, EN50018: 2000

Capability when properly wired and installed. Contact

HVD for AC coil applications. ATEX & CSA/US (ET) Complies with ATEX EN60079-0,

EN60079-1 Ex d IIC; CSA/US Ex d IIC,

AEx d IIC for Class I, Zone 1, UL1203,

UL1604, CSA E61241,1 Class II, Div 1

* Allowable Voltage Deviation ±10%.

Note that Explosion Proof AC coils are single frequency only.

Code

Voltage In Rush Amps In Rush Holding Amps Watts Resistance

Voltage Power Amperage VA @ 3MM

Code Code

D L 120 VDC N/A N/A 0.09 Amps 10 W 1584.00 ohms

D Omit 120 VDC N/A N/A 0.26 Amps 30 W 528.00 ohms

G Omit 198 VDC N/A N/A 0.15 Amps 30 W 1306.80 ohms

J L 24 VDC N/A N/A 0.44 Amps 10 W 51.89 ohms

J Omit 24 VDC N/A N/A 1.32 Amps 30 W 17.27 ohms

K L 12 VDC N/A N/A 0.88 Amps 10 W 12.97 ohms

K Omit 12 VDC N/A N/A 2.64 Amps 30 W 4.32 ohms

L L 6 VDC N/A N/A 1.67 Amps 10 W 3.59 ohms

L Omit 6 VDC N/A N/A 5.00 Amps 30 W 1.20 ohms

Q Omit 100 VAC / 60 Hz 2.05 Amps 170 VA 0.77 Amps 30 W 19.24 ohms

QD F 100 VAC / 60 Hz 1.35 Amps 135 VA 0.41 Amps 18 W 31.20 ohms

QD F 100 VAC / 50 Hz 1.50 Amps 150 VA 0.57 Amps 24 W 31.20 ohms

R F 24/60 VAC, Low Watt 6.67 Amps 160 VA 2.20 Amps 23 W 1.52 ohms

T Omit 240/60 VAC 0.83 Amps 199 VA 0.30 Amps 30 W 120.40 ohms

T Omit 220/50 VAC 0.87 Amps 191 VA 0.34 Amps 30 W 120.40 ohms

T F 240/60 VAC, Low Watt 0.70 Amps 168 VA 0.22 Amps 21 W 145.00 ohms

T F 220/50 VAC, Low Watt 0.75 Amps 165 VA 0.26 Amps 23 W 145.00 ohms

U L 98 VDC N/A N/A 0.10 Amps 10 W 960.00 ohms

U Omit 98 VDC N/A N/A 0.31 Amps 30W 288.00 ohms

Y Omit 120/60 VAC 1.7 Amps 204 VA 0.60 Amps 30 W 28.20 ohms

Y Omit 110/50 VAC 1.7 Amps 187 VA 0.68 Amps 30 W 28.20 ohms

Y F 120/60 VAC, Low Watt 1.40 Amps 168 VA 0.42 Amps 21 W 36.50 ohms

Y F 110/50 VAC, Low Watt 1.50 Amps 165 VA 0.50 Amps 23 W 36.50 ohms

Z L 250 VDC N/A N/A 0.04 Amps 10 W 6875.00 ohms

Z Omit 250 VDC N/A N/A 0.13 Amps 30 W 1889.64 ohms

Explosion Proof Solenoids

R 24/60 VAC 7.63 Amps 183 VA 2.85 Amps 27 W 1.99 ohms

T 240/60 VAC 0.76 Amps 183 VA 0.29 Amps 27 W 1.34 ohms

N 220/50 VAC 0.77 Amps 169 VA 0.31 Amps 27 W 1.38 ohms

Y 120/60 VAC 1.60 Amps 192 VA 0.58 Amps 27 W 33.50 ohms

P 110/50 VAC 1.47 Amps 162 VA 0.57 Amps 27 W 34.70 ohms

K 12 VDC N/A N/A 2.75 Amps 33 W 4.36 ohms

J 24 VDC N/A N/A 1.38 Amps 33 W 17.33 ohms

"ET" Explosion Proof Solenoids

K 12 VDC N/A N/A 1.00 Amps 12 W 12.00 ohms

J 24 VDC N/A N/A 1.00 Amps 13 W 44.30 ohms

Y 120/60-50 VAC N/A N/A 0.16 Amps 17 W 667.00 ohms

D81.indd, dd

A166 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Dimensions Series D81V

Inch equivalents for millimeter dimensions are shown in (**)

Plug-in Conduit Box, Double AC Solenoid

A

M6 x 1 Plug for Variations 1, 2 & 3

Torque to:

1.78 ±0.22 Nm

(16 ±2 in-lbs)

1/16 Plug for Variations 2 & 5 Do Not Loctite

Torque to:

11.67 ±1.67 Nm

(105 ±15 in-lbs)

Do Not Loctite

Note: 57mm (2.24") from bottom of bolt hole counterbore to bottom of valve.

D81.indd, dd

A167 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Dimensions Series D81V

Inch equivalents for millimeter dimensions are shown in (**)

Conduit Box and Stroke Adjust, Double AC Solenoid

A

Note: 57mm (2.24") from bottom of bolt hole counterbore to bottom of valve.

Conduit Box and Pilot Choke Control, Conduit Box, Single AC Solenoid

Double AC Solenoid

D81.indd, dd

A168 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Dimensions Series D81V

Inch equivalents for millimeter dimensions are shown in (**)

Plug-In Conduit Box, Double DC Solenoid

A

Note: 57mm (2.24") from bottom of bolt hole counterbore to bottom of valve.

D81.indd, dd

A169 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Dimensions Series D81V

Inch equivalents for millimeter dimensions are shown in (**)

Plug-In Conduit Box and Stroke Adjust, Double DC Solenoid

A

Note: 57mm (2.24") from bottom of bolt hole counterbore to bottom of valve.

Hirschmann and Pilot Choke Control, Plug-In Conduit Box, Single DC

Double DC Solenoid Solenoid

D81.indd, dd

A170 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Dimensions Series D81V

Inch equivalents for millimeter dimensions are shown in (**)

Plug-In Conduit Box, Double AC Solenoid

with Variation I3 (Monitor Switch) A

Monitor Switch

(Variation I3 and I6)

Position Control Switch

This feature provides for electrical confirmation of

the spool shift. This can be used in safety circuits, Sensor / Driver

to assure proper sequencing, etc. Circuitry

PIN 2

Switch Data Input PIN 1

Pin 1 and Pin 3 have outputs equal to the input. 18-42 VDC Outputs

When the monitor switch has the output to Pin 1, PIN 3

Pin 3 will have an output of zero, and vice-versa.

When the valve is switched, Pin 1 and Pin 3 will Load 0.2 A Max

switch outputs.

D81.indd, dd

A171 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Accessories Series D81V

Manaplug (Options 56 & 1C) Micro Connector Options (7B & 1D)

Interface – Brad Harrison Plug

A – 3-Pin for Single Solenoid

– 5-Pin for Double Solenoid

Ground

Wire #1 (Green)

Solenoid (Negative)

Solenoid (Positive)

Wire #3 (Red/Black)

Wire #2 (Red/White)

3-Pin Manaplug (Mini) with Lights

Single Solenoid Valves – Installed Opposite Side of Solenoid

Pins are as seen on valve (male pin connectors)

Conduit Box Option C Signal Lights (Option 5) — Plug-in Only

– No Wiring Options Available – LED Interface

– Meets Nema 4/IP67

Hirschmann Plug with Lights (Option P5) DESINA Connector (Option D)

ISO 4400/DIN 43650 Form “A” M12 pin assignment

Pin #3

Standard

(Ground) DESINA – design

Pin 1 and 2

connected

Pin #1 1 = Not used

Pin #2

(Negative)

4 1

2 = Not used

(Positive) 2

3 = 0V

3

4 = Signal (24 V) 1 3

5 = Earth Ground

4

5

2 5

Face View of Plug

Pins are as seen on valve (male pin connectors)

D81.indd, dd

A172 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Technical Information Series D81VA

General Description

Series D81VA directional control valves are 5-chamber,

air pilot operated valves. They are available in 2 or

3-position styles. These valves are manifold or subplate

A

mounted, and conform to NFPA’s D08, CETOP 8 mount-

ing pattern.

Specifications

Mounting Pattern NFPA D08 , CETOP 8, NG25

Max. Operating 345 Bar (5000 PSI)

Pressure

Max. Tank Internal Drain Model:

Line Pressure 34 Bar (500 PSI)

External Drain Model:

207 Bar (3000 PSI)

Max. Drain Pressure 34 Bar (500 PSI)

Maximum Flow See Switching Limit Charts

Pilot Pressure Air Min 3.4 Bar (50 PSI)

Air Max 10.2 Bar (150 PSI)

Varies with pilot line size and Features

Response Time length, pilot pressure, pilot valve • Low pressure drop design.

shift time & flow capacity (GPM)

• Fast response option available.

Ordering Information • Hardened spools provide long life.

D 81V A

Directional Basic Air Operated Spool Style Pilot Supply Seal Valve Design

Control Valve Valve Pilot and Drain Variations Series

NFPA D08 Code Description Code Description NOTE:

CETOP 8 Not required

N Nitrile Omit Standard

DIN NG25 when ordering.

V Fluorocarbon 7 Pilot Choke –

Meter Out

Code Symbol Code Symbol Code Description 8 Stroke Adj. ‘B’ End

A B A B

1 Int. pilot/Ext. drain 9 Stroke Adj. ‘A’ End

001 011 2 Ext. pilot/Ext. drain

P T P T

60 Pilot Choke –

A B A B 4# Int. pilot/Int. drain Meter In

002 012 5 Ext. pilot/Int. drain 89 Stroke Adj.

P T P T

# Not available with 002, ‘A’ & ‘B’ Ends

A B A B

008, 009 & 030 spools. 90 1/4 BSPP Threads

004 020*

P T P T Code Description Symbol

A B A B b A B

009** 030** B† Sgl. operator, 2 position, spring offset.

P T P T P to A and B to T in offset position. P T

b A B a

* 020 spool has closed crossover. C Dbl. operator, 3 position,

** 009 & 030 spools have open crossover. spring centered. P T

b A B a

Valve schematic symbols are per NFPA/ANSI D† Dbl. operator, 2 position, detent.

standards, providing flow P to A when energizing P T

operator A. Note operators reverse sides for #9 b A B

E Sgl. operator, 2 position, spring centered.

spool. See installation information for details.

P to B and A to T when energized. P T

Valve Weight: Single Operated A B a

19.9 kg (43.9 lbs.) H† Sgl. operator, 2 position, spring offset.

P to B and A to T in offset position. P T

Standard Bolt Kit: BK228 A B

K Sgl. operator, 2 position. Spring centered. This condition

Metric Bolt Kit: BKM228 varies with

P to A and B to T when energized. P T

spool code.

† Available with 020 & 030 spools only.

Bold: Designates Tier I products and options.

Non-bold: Designates Tier II products and options. These products will have longer lead times.

D81.indd, dd

A173 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Dimensions Series D81VA

Inch equivalents for millimeter dimensions are shown in (**)

Air Operated

A

Note: 57mm (2.24") from bottom of bolt hole counterbore to bottom of valve.

D81.indd, dd

A174 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Technical Information Series D81VL

General Description

Series D81VL directional control valves are 5-chamber,

lever operated valves. They are available in 2 or

3-position styles. These valves are manifold or subplate

A

mounted, and conform to NFPA’s D08, CETOP 8 mount-

ing pattern.

Specifications

Mounting Pattern NFPA D08, CETOP 8, NG25

Max. Operating 350 Bar (5000 PSI)

Pressure

Max. Tank Line Internal Drain Model

Pressure 34 Bar (500 PSI)

External Drain Model

350 Bar (5000 PSI)

Maximum Drain 34 Bar (500 PSI)

Pressure

Maximum Flow See Reference Data Charts

Pilot Oil Min 6.9 Bar (100 PSI)

Pressure Oil Max 350 Bar (5000 PSI)

Response Time Varies with pilot line size and length,

pilot pressure, pilot valve shift time &

flow capacity (GPM)

Ordering Information

D 81V L

Directional Basic Lever Operated Spool Style Pilot Supply Seal Valve Design

Control Valve Valve Pilot and Drain Variations Series

NOTE:

NFPA D08 Code Description Code Description Not

CETOP 8 N Nitrile Omit Standard required

V Fluorocarbon 7 Pilot Choke – when

Meter Out ordering.

Code Description

Code Symbol Code Symbol 8 Stroke Adj. ‘B’

1 Int. pilot/Ext. drain

A B A B

2 Ext. pilot/Ext. drain 9 Stroke Adj. ‘A’

001 011 60 Pilot Choke –

4# Int. pilot/Int. drain

P T P

A

T

B 5 Ext. pilot/Int. drain Meter In

A B

002 012 # Not available with 002, 008, 89 Stroke Adj. ‘A’ & ‘B’

P T P T 009 & 030 spools.

A B A B

004 020* Code Description Symbol

A B

P T P

A

T

B

B† Sgl. operator, 2 position, spring offset.

A B

008* 030** P to A and B to T in offset position. P T

A B

009** P T P T C Dbl. operator, 3 position, spring centered.

* 008 & 020 spools have closed crossover. A

P

B

T

** 009 & 030 spools have open crossover. D† Dbl. operator, 2 position, detent.

P T

Valve schematic symbols are per NFPA/ANSI A B

standards, providing flow P to A when energizing E Sgl. operator, 2 position, spring centered.

operator A. Note operators reverse sides for #9 P to B and A to T in shifted position. P T

A B

spool. See installation information for details. H† Sgl. operator, 2 position, spring offset. P to B

and A to T in offset position. P T

A B This condi-

Valve Weight: 19.6 kg (43.2 lbs.) K Sgl. operator, 2 position. Spring centered. tion varies

Standard Bolt Kit: BK228 P to A and B to T in shifted position. P T with spool

code.

Metric Bolt Kit: BKM228 † Available with 020 & 030 spools only.

Bold: Designates Tier I products and options.

Non-Bold: Designates Tier II products and options. These products will have longer lead times.

D81.indd, dd

A175 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Dimensions Series D81VL

Inch equivalents for millimeter dimensions are shown in (**)

Lever Operated

A

Note: 57mm (2.24") from bottom of bolt hole counterbore to bottom of valve.

D81.indd, dd

A176 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Technical Information Series D8P

General Description

Series D8P directional control valves are 5-chamber,

pilot operated valves. They are available in 2 or

3-position styles. These valves are manifold or sub-

A

plate mounted, and conform to NFPA’s D08, CETOP 8

mounting pattern.

Features

• Low pressure drop design.

• Hardened spools provide long life.

Specifications

Mounting Pattern NFPA D08,

CETOP 8, NG25

Max. Operating Pressure 345 Bar (5000 PSI)

Max. Tank Line Pressure 345 Bar (5000 PSI)

Max. Drain Pressure 345 Bar (5000 PSI)

Min. Pilot Pressure 5.1 Bar* (75 PSI)

Max. Pilot Pressure 345 Bar (5000 PSI)

Nominal Flow 302 LPM (80 GPM) Response Time

Max. Flow See Reference Data Chart Response time will vary with pilot line size, pilot line

* 6.9 Bar (100 PSI) for 2, 8, 9 & 12 spools length, pilot pressure shift time and flow capacity of the

control valve.

For flow path, pilot drain and pilot pressure details, see Installation

Information. Shift Volume

The pilot chamber requires a volume of 1.35 in3

Ordering Information (22.1 cc) for center to end.

D 8 P

Directional Basic Actuator Spool Style Pilot Supply Seal Valve Design

Control Valve Valve and Drain Variations Series

NFPA D08 Oil Code Type Code Description NOTE:

CETOP 8 Operator Not

N Nitrile Omit Standard required

DIN NG25 7 Pilot Choke –

V Fluorocarbon when

Code Symbol Code Symbol Meter Out ordering.

Code Description 8 Stroke Adj. ‘B’ End

A B A B

2 Ext. Pilot / Ext. Drain 9 Stroke Adj. ‘A’ End

1 11

P T P T 5# Ext. Pilot / Int. Drain 60 Pilot Choke –

A B A B Meter In

# Available in “B” and “H” style only.

2 12 89 Stroke Adj. ‘A’ & ‘B’ Ends

P T P T

A B A B

Code Description Symbol

4 20*

P T P T B† Sgl. operator, 2 position, spring offset.

A B A B

P to A and B to T in offset position.

7 30**

P T P T C Dbl. operator, 3 position, spring centered.

A B

9** This condition

P T

H† Sgl. operator, 2 position, spring offset. P to B varies with

* 20 spool has closed crossover. and A to T in offset position. spool code.

** 9 & 30 spools have open crossover. † Available with 20 & 30 spools only.

Valve schematic symbols are per NFPA/ANSI Valve Weight: 18.9 kg (41.7 lbs.) Standard Bolt Kit: BK228 Metric Bolt Kit: BKM228

standards, providing flow P to A when energizing

operator X. Note operators reverse sides for #9

spool. See installation information for details.

Bold: Designates Tier I products and options.

Non-Bold: Designates Tier II products and options. These products will have longer lead times.

D81.indd, dd

A177 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Dimensions Series D8P

Inch equivalents for millimeter dimensions are shown in (**)

Standard Pilot Operated

A

Pilot Operated with Pilot Choke Control

39.6

(1.56)

Pilot Choke

Control

Variation 7 212.4

(8.37)

Note: 57mm (2.24") from bottom of bolt hole counterbore to bottom of valve.

D81.indd, dd

A178 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Technical Information Series D81V, D8P

Installation Information

Silting

FOR MAXIMUM VALVE RELIABILITY, ADHERE TO

THE FOLLOWING INSTALLATION INFORMATION.

Silting can cause any sliding spool valve to stick

and not spring return if held under pressure for long

A

periods of time. The valve should be cycled periodically

The following is important installation information to prevent sticking.

which applies to all directional control valves

described in this catalog.

Special Installations

Consult your Parker representative for any application

Mounting Position requiring the following:

Detent – Horizontal

Spring Offset – Unrestricted • Pressure above rating.

Spring Centered – Unrestricted • Fluid other than those specified.

• Oil temperature above 71.1°C (160°F).

Fluid Recommendations • Flow path other than normal.

Premium quality hydraulic oil with a viscosity range

between 32-54 cSt. (150-250 SSU) At 38°C (100°F) is

recommended. The absolute operating viscosity range Mounting Patterns

is from 16-220 cSt. (80-1000 SSU). Oil should have

maximum anti-wear properties and rust and oxidation Series NFPA CETOP

treatment. D81V*, D8P D08 3/4”

Fluids and Seals

Valves using synthetic, fire-resistant fluids require

Torque Specifications

special seals. When phosphate esters or its blends are

The recommended torque values for the bolts which

used, FLUOROCARBON seals are required. Water-

mount the valve to the manifold or subplate are as

glycol, water-in-oil emulsions and petroleum oil may be

follows: 135.6 Nm (100 ft-lbs).

used with STANDARD seals.

Filtration

For maximum valve and system component life, the

system should be protected from contamination at

a level not to exceed 125 particles greater than 10

microns per milliliter of fluid (SAE class 4/ISO 16/13).

D81.indd, dd

A179 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Installation Information Series D81V

Series D81VW, D81VA, D81VL Internal: Flow is internally ported from the pressure

port of the main valve body to the “P” port of the pilot

Tank and Drain Line Surges

A If several valves are piped with a common tank or drain

line, flow surges in the line may cause an unexpected

valve. The pressure developed at the “P” port of the

pilot valve must be 5.1 Bar (75 PSI) minimum at all

times or 6.9 Bar (100 PSI) for spools 002, 007, 008,

spool shift. Detent style valves are most susceptible to 009 & 014.

this. Separate tank and drain lines should be piped in

installations where line surges are expected. Integral Check: Valves using internal pilot and internal

drain with an open center spool (spools 2, 7, 8 & 9)

Electrical Characteristics (Detented Spool) can be ordered with an integral check valve in the

Only a momentary energizing of the solenoid is pressure port of the main valve codes 3 & 6. Pilot oil

necessary to shift and hold a detented spool. Minimum will be internally ported from the upstream side of

duration of the signal is 0.1 seconds for DC voltages. this check to the “P” port of the pilot valve, ensuring

For AC voltages the response time is 0.06 seconds. sufficient pilot pressure. A 1/16” pipe plug will be

Spool position will be held provided the spool present in the main body. The “X” port in the subplate

centerline is in a horizontal plane, and not shock or must be plugged when using the integral check.

vibration is present to displace the spool. Pilot Valve Drain: Maximum pressure 102 Bar

(1500 PSI) AC optional, 207 Bar (3000 PSI)

Electrical Failure or Loss of

DC standard.

Pilot Pressure (D81V or D81VA)

Should electric power fail or loss of pilot pressure External: When using an external drain, a M6 x 1 x

occur, spring offset and spring centered valves will 6mm long set screw must be present in the main body

shift to the spring held position. Detented valves will drain passage. (For details see Dimension pages.)

stay in the last position held before power failure. If This plug will be furnished in valves ordered with drain

main flow does not fail or stop at the same time power code 1, 2 or 3.

fails, machine actuators may continue to function in an Drain flow from the pilot valve is at the “Y” port of

undesirable manner or sequence. the main body and must be piped directly to tank.

Maximum drain line pressure is 102 Bar (1500

Pilot/Drain Characteristics PSI), AC optional, 207 Bar (3000 PSI) DC standard.

Pilot Pressure: Any drain line back pressure is additive to the pilot

5.1 to 345 Bar (75 to 5000 PSI) pressure requirement.

6.9 Bar (100 PSI) for spools 002, 007, 008, 009 & 014

Internal: Drain flow from the pilot valve is internally

External: An oil source sufficient to maintain minimum connected to the main valve tank port. Tank and drain

pilot pressure must be connected to the “X” port of the pressure are then identical so tank line pressure

main body. When using the external pilot variation, a should not exceed 102 Bar (1500 PSI) AC optional,

1/16" pipe plug must be present in the main body pilot 207 Bar (3000 PSI) DC standard. Any tank line

passage. (For details see Dimension pages.) This plug back pressure is also additive to the pilot pressure

will be furnished in valves ordered with pilot code 2, 3, requirement. If flow surges (a cause of pressure

5 or 6. surges) are anticipated in the tank line, an external

drain variation is recommended. The “Y” port in the

subplate must be plugged when using an internal

D81V* Flow Paths drain.

Style No Solenoid/Operator Solenoid/Operator A Solenoid/Operator B

Code Description Energized Energized Energized

B Spring Offset P➝A and B➝T — P➝B and A➝T

C Spring Centered Centered P➝A and B➝T P➝B and A➝T

D Detented Last Position Held P➝A and B➝T P➝B and A➝T

E Spring Centered Centered — P➝B and A➝T

F† Spring Offset, Shift to Center P➝A and B➝T — Centered

H Spring Offset P➝B and A➝T P➝A and B➝T —

K Spring Centered Centered P➝A and B➝T —

M† Spring Offset, Shift to Center P➝B and A➝T Centered —

† D81VW only.

D81.indd, dd

A180 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Installation Information Series D8P

Series D8P Pilot Drain Characteristics

Tank and Drain Line Surges Pilot Pressure:

If several valves are piped with a common tank or drain

line, flow surges in the line may cause an unexpected

5.1 to 350 Bar (75 to 5000 PSI)

6.9 Bar (100 PSI) for spools 2, 7, 8, 9 & 14 A

spool shift. Detent style valves are most susceptible to Direct pilot operated valves use the “X” and “Y” ports

this. Separate tank and drain lines should be piped in to supply pilot oil directly to the ends of the spool,

installations where line surges are expected. providing spool shifting force. A block mounted on

top of the valve body is internally cored to make the

Loss of Pilot Pressure necessary connections. Thus when “X” is pressurized,

Should a loss of pilot pressure occur, spring offset “Y” is used as a drain; and when “Y” is pressurized, “X”

and spring centered valves will shift to the spring held becomes the drain.

position. No spring valves will stay in the last position Any back pressure in these lines when they are

held. If main hydraulic flow does simultaneously stop, being used as a drain is additive to the pilot pressure

machine actuators may continue to function in an requirement.

undesirable manner or sequence.

Internal Drain: On spring offset models, only the “X”

port is pressurized, as the spring returns the spool

to its at rest position. On these models, “Y” may be

internally drained through the main tank passage in

the valve.

Flow Path/Pilot Pressure

Recommended

Style Description “X” & “Y” “X” Port “Y” Port Special Notes Control Valve

Code De-Pressurized Pressurized Pressurized For Pilot Oil

Two Position “X” Port may be pressurized to

B Spring Offset P➝A, B➝T P➝A, B➝T P➝B, A➝T assist spring in returning spool

to offset position (ext. only)

Three Position Flow paths will be reversed on

C Spring Centered Center P➝A, B➝T P➝B, A➝T valves with tandem center

(9) spools

Two-Position “Y” Port may be pressurized

H Spring Offset P➝B, A➝T P➝A, B➝T P➝B, A➝T to assist spring in returning

spool to offset position

D81.indd, dd

A181 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Installation Information Series D81V, D8P

Subplate Mounting

NFPA D08, CETOP 8 & NG25

A

Recommended Mounting Surface

Surface must be flat within .102 mm (0.0004 inch) T.I.R

and smooth within 812.8 micro-meters (32 micro-inch).

Torque bolts to 135.6 Nm (100 ft-lbs).

For maximum

valve reliability,

Mounting Position adhere to the following

Valve Type Mounting Position installation information.

Detent (Solenoid) Horizontal

Spring Offset Unrestricted

Spring Centered Unrestricted

Mounting Pattern — NFPA D08, CETOP 8 & NG25

Inch equivalents for millimeter dimensions are shown in (**)

152.4

(6.00)

-B-

130.2

(5.13) 112.7

(4.44)

100.8

(3.97) 94.5

(3.72)

77.0

(3.03) ½ – 13 UNC – 2Bx22.22

53.2 min th'd dp. (M12 x 0.875)

(2.09) 6 holes

29.4 0.28

17.5 4.8 (1.16) A B

17.5 (0.011) S

(0.69) (0.19)

(0.69)

-A- O 11.2 (0.441) max.

3 holes

0.56

(0.022)

L A B

74.6 73.0

130.0 92.1 (2.94) (2.88)

(3.63) O 23.42 (0.922) max.

(5.12)

4 holes

0.56

(0.022)

L A B

O 0.288 / .272 x 0.31 min dp.

(7.32 / 6.91 x 8)

2 holes

0.28

(0.011)

L A B

D81.indd, dd

A182 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

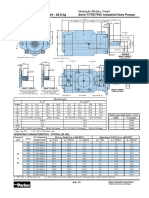

Technical Information Series D9L

General Description

Series D9L directional control valves are 5-chamber,

4 way, 2 0r 3-position valves. They are operated by a

hand lever which is directly connected to the spool. A

The hand lever can be located either on the A or B

side. Spring offset and detent designs are available.

Features

• Streamlined internal channels ensure minimum pressure

drop at maximum flow.

• Hardened spools provide long life.

Specifications

General Hydraulic (cont.)

Actuation Lever Fluid Hydraulic oil in accordance with

Size NG25 DIN 51524 / 51525

Mounting Interface DIN 24340 A25 Fluid Temperature -25°C to +70°C (-13°F to +158°F)

ISO 4401 Viscosity 2.8 to 400 cSt / mm2/s

NFPA D08 Permitted (13 to 1854 SSU)

CETOP RP 121-H Viscosity 30 to 80 cSt / mm2/s

Mounting Position Unrestricted, preferably horizontal Recommended (139 to 371 SSU)

Ambient Temperature -25°C to +50°C (-13°F to +122°F) Filtration ISO 4406 (1999);

Hydraulic 18/16/13 (meet NAS 1638: 7)

Maximum Operating External Drain Maximum Flow 700 LPM (185.2 GPM)

Pressure P, A, B, T 350 Bar (5075 PSI) Leakage at up to 800 ml per minute

X, Y 10 Bar (145 PSI) 350 Bar (5075 PSI) (per flow path) (depending on spool)

Internal Drain

P, A, B 350 Bar (5075 PSI)

T, X, Y 10 Bar (145 PSI)

D81.indd, dd

A183 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Ordering Information Series D9L

D 9

A Directional

Control

Valve

Basic

Valve

Actuator Spool Style Pilot Supply

and Drain

Seal Design

Series

NOTE:

Not required

NFPA D08 when ordering.

CETOP 8

DIN NG25 Code Description

32 mm N Nitrile

V Fluorocarbon

Code Description

Code Actuation

2* External Pilot External Drain

L Lever Side B

5** External Pilot Internal Drain

LB Lever Side A

* Pressure T-port < 10 bar

** Pressure T-port > 10 bar

Code Symbol Code Symbol Code Description Symbol

A B A B Single operator,

01 09 B 2 position,

P T P T

spring offset.

A B A B Double operator,

C 3 position,

02 14

spring centered.

P T P T

Double operator,

A B A B

D 2 position,

03 15 detent.

P T P T

Single operator,

A B A B E 2 position,

04 20 spring centered.

P T P T Single operator,

A B A B H 2 position,

spring offset.

07 30

P T P T Single operator,

K 2 position,

spring centered.

Double operator,

N 3 position,

detent.

Weight: 17.0 kg (37.5 lbs.)

D81.indd, dd

A184 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Performance Curves Series D9L

The flow curve diagram shows the flow versus pressure drop curves for all spool types. The relevant curve num-

ber for each spool type, operating position and flow direction is given in the table below.

Spool Curve Number

A

Code P-A P-B P-T A-T B-T

1 3 2 - 3 5

2 2 1 1 3 5

3 4 2 - 3 6

4 4 3 - 3 5

7 3 1 7 3 5

9 4 8 9 4 10

14 1 3 7 5 3

15 2 4 - 5 3

20 6 5 - 6 8

30 3 2 - 3 5

D81.indd, dd

A185 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Dimensions Series D9L

Inch equivalents for millimeter dimensions are shown in (**)

D9L

A

D9LB

Surface Finish Seal

6x M5x75 108 Nm Nitrile: SK-D9LN

BK360

DIN 912 12.9 ±15% Fluorocarbon: SK-D9LV

D81.indd, dd

A186 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

You might also like

- Instructions For Operation As Delivered En-1Document187 pagesInstructions For Operation As Delivered En-1OSAMA100% (1)

- Axial Piston Variable Double Pump A20V (L) O: Series 1Document68 pagesAxial Piston Variable Double Pump A20V (L) O: Series 1Michael Akhramovich100% (1)

- MLT629Rev 05-03Document1,068 pagesMLT629Rev 05-03Razvan Mitru50% (2)

- Denison Hydraulics Proportional Pressure Control Valves: Series P2 & 4VP01Document12 pagesDenison Hydraulics Proportional Pressure Control Valves: Series P2 & 4VP01abuzer1981No ratings yet

- Lehnhoff Complete Program 2013 enDocument68 pagesLehnhoff Complete Program 2013 enM MNo ratings yet

- Estacion HAWE Compacta HKDocument26 pagesEstacion HAWE Compacta HKJasierNo ratings yet

- Maintenance of Plastic Processing MachinesDocument37 pagesMaintenance of Plastic Processing Machinesnishantbhore6830100% (1)

- Serie D61 - Cetop 8Document23 pagesSerie D61 - Cetop 8Hugo MenendezNo ratings yet

- Valvula Direcional D81VW ParkerDocument12 pagesValvula Direcional D81VW ParkerMax Sander SoneghettNo ratings yet

- Series D61: Directional Control ValvesDocument16 pagesSeries D61: Directional Control ValvesmhaioocNo ratings yet

- Serie D101 - Cetop 10Document23 pagesSerie D101 - Cetop 10Hugo MenendezNo ratings yet

- Serie D31 - Cetop 5Document35 pagesSerie D31 - Cetop 5Hugo MenendezNo ratings yet

- Direction Control ValveDocument5 pagesDirection Control ValvefazarNo ratings yet

- DV1 New PDFDocument14 pagesDV1 New PDFANTHONY REYES REYESNo ratings yet

- Series D1VWDocument3 pagesSeries D1VWGuillermo Pablo ColladoNo ratings yet

- Series R5V P2 (Flange Mounted) Technical Information General DescriptionDocument7 pagesSeries R5V P2 (Flange Mounted) Technical Information General Descriptionshahrol effendy rodziNo ratings yet

- Series DPR103C Technical Information General Description: Proportional ValvesDocument4 pagesSeries DPR103C Technical Information General Description: Proportional ValvesHenry CorreaNo ratings yet

- Subplacas Com Válvula de Alívio Modelo RaspDocument4 pagesSubplacas Com Válvula de Alívio Modelo RaspTedson BragaNo ratings yet

- Moog ServovalvesDocument8 pagesMoog Servovalvesdylan_dearing@hotmail.com100% (1)

- YF-8580 Gas Control Valve SpecsheetDocument3 pagesYF-8580 Gas Control Valve SpecsheetAmtNo ratings yet

- D 631 Series ValvesDocument12 pagesD 631 Series ValvesNo PromisesNo ratings yet

- D 631 Series ValvesDocument12 pagesD 631 Series ValvesJosé OlaveNo ratings yet

- IH RedukDocument14 pagesIH RedukPioneer PaperboyNo ratings yet

- Electric Barrel Pumps: Grease & Fluid GreaseDocument4 pagesElectric Barrel Pumps: Grease & Fluid Greasejp_neumanNo ratings yet

- Vickers DG4V-3 DG4V-3S 6xDocument32 pagesVickers DG4V-3 DG4V-3S 6xCarlos Javier Torrico BarreroNo ratings yet

- Ktm512 en MainDocument12 pagesKtm512 en MainFilip SerafimovNo ratings yet

- 9500 Butterfly Valve BuletinDocument8 pages9500 Butterfly Valve BuletinRizalfariz HasbiNo ratings yet

- Model Solenoid Operated Ventable Relief Assembly: CAPACITY: 30 GPMDocument7 pagesModel Solenoid Operated Ventable Relief Assembly: CAPACITY: 30 GPManandsubbiahNo ratings yet

- STE0363 - 92 Rev.06 - 22-07-2022Document22 pagesSTE0363 - 92 Rev.06 - 22-07-2022emunozNo ratings yet

- Electro Valvulas TitanDocument4 pagesElectro Valvulas TitanAlvaro Escalona GtzNo ratings yet

- Series DSH081 and DSH091 Technical Information General DescriptionDocument4 pagesSeries DSH081 and DSH091 Technical Information General DescriptionEugeniu CebotariNo ratings yet

- Digital Control ValveDocument8 pagesDigital Control Valvecnrk777100% (1)

- 3-Way Vale 15mm-50mm SizeDocument18 pages3-Way Vale 15mm-50mm Sizesantosh yadavNo ratings yet

- Product Data Sheet Damcos Solenoid Operated Directional Control Valves Type 2 en 60682 PDFDocument7 pagesProduct Data Sheet Damcos Solenoid Operated Directional Control Valves Type 2 en 60682 PDFHendiko PanggabeanNo ratings yet

- RainFlo Pump Installation InstructionsDocument4 pagesRainFlo Pump Installation InstructionsMark Nathan VillaNo ratings yet

- Series D1VW Characteristics: Directional Control ValveDocument9 pagesSeries D1VW Characteristics: Directional Control ValvejuanNo ratings yet

- Series R1E02 General Description Technical Information: Pressure Relief ValvesDocument3 pagesSeries R1E02 General Description Technical Information: Pressure Relief Valvesshahrol effendy rodziNo ratings yet

- r5v Sales d049Document6 pagesr5v Sales d049Junior Francisco QuijanoNo ratings yet

- Gas Pressure Reducing: Gas Pressure Reducing & Shut-Off Valve & Shut-Off Valve Series 71P11A Series 71P11ADocument4 pagesGas Pressure Reducing: Gas Pressure Reducing & Shut-Off Valve & Shut-Off Valve Series 71P11A Series 71P11AĐình Sơn HoàngNo ratings yet

- RPEI en Us A4Document1 pageRPEI en Us A4Rafael GoulartNo ratings yet

- Electro-Prop ValveDocument2 pagesElectro-Prop Valvemaikel.mNo ratings yet

- 04-20kva Alternator Data Sheet Es10456927-N20g4-D-W212-20Document4 pages04-20kva Alternator Data Sheet Es10456927-N20g4-D-W212-20Muse AFNo ratings yet

- Series 4D01 (Denison) Characteristics: Directional Control ValveDocument6 pagesSeries 4D01 (Denison) Characteristics: Directional Control ValveKhaled MahranNo ratings yet

- Parker (D1V, D1VW) Directional Control Valves, Manifold MountedDocument15 pagesParker (D1V, D1VW) Directional Control Valves, Manifold MounteddoarzevelNo ratings yet

- Bomba Pavc100 ParkerDocument10 pagesBomba Pavc100 ParkerDaniel MarNo ratings yet

- RPEI Full en Metric LetterDocument4 pagesRPEI Full en Metric LetteressamNo ratings yet

- A 4 D 03Document14 pagesA 4 D 03Eng-Mohammed SalemNo ratings yet

- General Description Technical Information Series D FL: Proportional Directional Control ValvesDocument7 pagesGeneral Description Technical Information Series D FL: Proportional Directional Control ValvesMohamed RiyazNo ratings yet

- Acv Automatic Control Valves PDFDocument20 pagesAcv Automatic Control Valves PDFabdallah391No ratings yet

- Banco Con Control Electrico Proporcional L218Document60 pagesBanco Con Control Electrico Proporcional L218Agustín TorresNo ratings yet

- PRDC Sun ValveDocument3 pagesPRDC Sun ValvekhairulanuarjunNo ratings yet

- Centrifugal PumpDocument2 pagesCentrifugal Pumpsong LiNo ratings yet

- SD 11 eDocument12 pagesSD 11 eseaqu3stNo ratings yet

- 3 Way Sauter ValveDocument8 pages3 Way Sauter ValverkssNo ratings yet

- Fisher 377 Trip Valve: FeaturesDocument12 pagesFisher 377 Trip Valve: FeaturesGOPIKRISHNAHPTNo ratings yet

- G761 SeriesDocument8 pagesG761 SeriesDipti BhanjaNo ratings yet

- 62 SeriesDocument8 pages62 SeriesDevendra BangarNo ratings yet

- SCX180 Catalog REV 01-08Document32 pagesSCX180 Catalog REV 01-08Horea CordunianuNo ratings yet

- Pulsar VPL Series (Non-Compensated) General Description Technical InformationDocument4 pagesPulsar VPL Series (Non-Compensated) General Description Technical InformationMarcos SuarezNo ratings yet

- RBAP Full en Us Letter PDFDocument3 pagesRBAP Full en Us Letter PDFfrancis_15inNo ratings yet

- Webtec Products LimitedDocument20 pagesWebtec Products LimitedtecnicomanelNo ratings yet

- RDJA Full en Metric LetterDocument2 pagesRDJA Full en Metric LetteressamNo ratings yet

- DBAFMCV924 Full en Metric LetterDocument6 pagesDBAFMCV924 Full en Metric LetterMechanical2022No ratings yet

- Vickers: Proportional Pressure Control Valve With Integrated ElectronicsDocument8 pagesVickers: Proportional Pressure Control Valve With Integrated ElectronicsAlex KarimNo ratings yet

- Serie D41 - Cetop 7Document22 pagesSerie D41 - Cetop 7Hugo MenendezNo ratings yet

- Bomba de Paletas 04-04 - T7-T67-T6C-uk-728-33Document1 pageBomba de Paletas 04-04 - T7-T67-T6C-uk-728-33Hugo MenendezNo ratings yet

- Serie D61 - Cetop 8Document23 pagesSerie D61 - Cetop 8Hugo MenendezNo ratings yet

- Serie ULAC+ULOC+ULDC+ULHCDocument32 pagesSerie ULAC+ULOC+ULDC+ULHCHugo MenendezNo ratings yet

- Serie D111VW - Cetop 10Document12 pagesSerie D111VW - Cetop 10Hugo MenendezNo ratings yet

- Serie D101 - Cetop 10Document23 pagesSerie D101 - Cetop 10Hugo MenendezNo ratings yet

- Serie D3 - Cetop 5Document33 pagesSerie D3 - Cetop 5Hugo MenendezNo ratings yet

- Serie D31 - Cetop 5Document35 pagesSerie D31 - Cetop 5Hugo MenendezNo ratings yet

- Serie D1 - Cetop 3Document39 pagesSerie D1 - Cetop 3Hugo MenendezNo ratings yet

- Serie Mma CilindrosDocument20 pagesSerie Mma CilindrosHugo MenendezNo ratings yet

- Cilindros CatálogoDocument24 pagesCilindros CatálogoHugo MenendezNo ratings yet

- Cilindros HidráulicosDocument30 pagesCilindros HidráulicosHugo MenendezNo ratings yet

- Serie 3L CILINDROS PDFDocument92 pagesSerie 3L CILINDROS PDFHugo MenendezNo ratings yet

- OB121Document1 pageOB121Hugo MenendezNo ratings yet

- PC45MR3Document572 pagesPC45MR3ปูหลน ไซไซNo ratings yet

- ManitouDocument306 pagesManitouJarosław100% (2)

- Af125 CatDocument14 pagesAf125 CatAntonio MartínezNo ratings yet

- Catalogo Actuadores HidraulicosDocument68 pagesCatalogo Actuadores HidraulicosErnesto Sánchez GómezNo ratings yet

- Operating Instructions: Linde Fork Lift Truck H 35D - 05 / H 40D - 05 / H 45D - 05 / H 50D - 05Document99 pagesOperating Instructions: Linde Fork Lift Truck H 35D - 05 / H 40D - 05 / H 45D - 05 / H 50D - 05Jno PartsNo ratings yet

- Industrieseilwinden en WindlasDocument44 pagesIndustrieseilwinden en WindlasAli QomariahNo ratings yet

- PC120-6 PC120LC-6: With Tier 2 SAA4D102E-2 EngineDocument12 pagesPC120-6 PC120LC-6: With Tier 2 SAA4D102E-2 EngineThai HoangNo ratings yet

- Customer - GID-208-CI-EAC-BS-54131 - R2 - PF Control PhilosophyDocument9 pagesCustomer - GID-208-CI-EAC-BS-54131 - R2 - PF Control Philosophysivasakti chp2No ratings yet

- Komatsu Hydraulic Excavator Pc750 6 Shop ManualDocument9 pagesKomatsu Hydraulic Excavator Pc750 6 Shop Manualandrew100% (48)

- Ho (V) - 4-1 Side ThrustersDocument125 pagesHo (V) - 4-1 Side ThrustershamzehNo ratings yet

- PLC Programming Case Study For Hydraulic PositioniDocument6 pagesPLC Programming Case Study For Hydraulic PositioniDicky DarmawanNo ratings yet

- MISCELLANEOUS - Lubrication SystemDocument10 pagesMISCELLANEOUS - Lubrication SystemRSS347No ratings yet

- Linde Hd16 Service TraningDocument238 pagesLinde Hd16 Service TraningDragan94% (17)

- ExtracotDocument30 pagesExtracotricardovargasrinconNo ratings yet

- Parts Manual: L1806D Wheeled LoaderDocument7 pagesParts Manual: L1806D Wheeled LoaderPeetNo ratings yet

- Hydraulic Excavator: Engine Power (ISO 14396) Operating WeightDocument12 pagesHydraulic Excavator: Engine Power (ISO 14396) Operating Weightyonathan yonathanNo ratings yet

- CASE Wx148 Wx168 BrochureDocument24 pagesCASE Wx148 Wx168 BrochureLuka BornaNo ratings yet

- Use and Maintenance Manual & Part Manual MAXLIFTDocument212 pagesUse and Maintenance Manual & Part Manual MAXLIFTazis fauzanNo ratings yet

- Hoses and Couplings For Oil IndustryDocument24 pagesHoses and Couplings For Oil IndustryGordan KanižajNo ratings yet

- Maintenance Book 6520-3902015-01Document43 pagesMaintenance Book 6520-3902015-01rendi setiawanNo ratings yet

- Slide Gate System DevelopmentDocument14 pagesSlide Gate System DevelopmentA.S.M. Mosayeb RafiNo ratings yet

- Directional High Response Valve 4wrte With Obe Re29083Document24 pagesDirectional High Response Valve 4wrte With Obe Re29083Kiagus Abdul HadiNo ratings yet

- CAT PS360cDocument12 pagesCAT PS360cjoao mariaNo ratings yet

- Compact Track LoaderDocument1 pageCompact Track Loadermiraç burak navruzNo ratings yet