Professional Documents

Culture Documents

Course Assesmnet Sheet

Course Assesmnet Sheet

Uploaded by

Maheen ArshadCopyright:

Available Formats

You might also like

- COMSATS University Islamabad: Course Description FileDocument8 pagesCOMSATS University Islamabad: Course Description FileSouban JavedNo ratings yet

- DFM Course IntroductionDocument21 pagesDFM Course IntroductionNitheeshNo ratings yet

- The FIDIC 1999 Forms of ContractDocument5 pagesThe FIDIC 1999 Forms of ContractAZNo ratings yet

- Case 14.56 - Accounting For Decision MakingDocument12 pagesCase 14.56 - Accounting For Decision MakingT Yoges Thiru MoorthyNo ratings yet

- Style Changeover Process Plan in Garment Industry - Lean MethodDocument1 pageStyle Changeover Process Plan in Garment Industry - Lean MethodArjun MNo ratings yet

- Course Assesmnet SheetDocument3 pagesCourse Assesmnet SheetMohsin QaziNo ratings yet

- Software TestingDocument10 pagesSoftware TestingYogeshwari J0% (1)

- Software TestingDocument10 pagesSoftware TestingjsspdacsNo ratings yet

- Separation Process II Course Outline UTPDocument4 pagesSeparation Process II Course Outline UTPQruisedNo ratings yet

- Manufacturing ProcessesDocument10 pagesManufacturing ProcessesMuhammad SyimirNo ratings yet

- Software TestingDocument10 pagesSoftware TestingJayanth NaikNo ratings yet

- CDF Optoelectronics 2022Document3 pagesCDF Optoelectronics 2022Muhammad Fayyaz Khan AP Electronics ABTNo ratings yet

- Faculty of Mechanical and Manufacturing Enginering: Lesson PlanDocument18 pagesFaculty of Mechanical and Manufacturing Enginering: Lesson PlanNatalia Fitri Clerin SusilowatiNo ratings yet

- Introduction EMT357-upload VerDocument19 pagesIntroduction EMT357-upload VerAmriNo ratings yet

- CPE241 Digital Logic DesignDocument9 pagesCPE241 Digital Logic DesignSouban JavedNo ratings yet

- CDF DLD TheoryDocument4 pagesCDF DLD TheoryMuhammad Fayyaz Khan AP Electronics ABTNo ratings yet

- CIMDocument3 pagesCIMOmkar KulkarniNo ratings yet

- Introduction To Structural Dynamics and Earthquake EngineeringDocument2 pagesIntroduction To Structural Dynamics and Earthquake EngineeringfefahimNo ratings yet

- Section A: Course Details: Unikl MicetDocument3 pagesSection A: Course Details: Unikl MicetColours Of LifeNo ratings yet

- CSC141 Introduction To Computer ProgrammingDocument8 pagesCSC141 Introduction To Computer ProgrammingSouban JavedNo ratings yet

- East West University: Department of Computer Science and Engineering Course Outline Spring 2019 SemesterDocument6 pagesEast West University: Department of Computer Science and Engineering Course Outline Spring 2019 Semesterthe rexaNo ratings yet

- SVNIT M. Tech. CAD-CAM - Syllabus - FinalDocument68 pagesSVNIT M. Tech. CAD-CAM - Syllabus - FinalAfzal BhatNo ratings yet

- Mumbai Univ SyllabusDocument18 pagesMumbai Univ SyllabusssaprodNo ratings yet

- Metrology & SQC - NewDocument4 pagesMetrology & SQC - NewKashif RazaqNo ratings yet

- 4.24 M. E. Mechanical CAD CAM Robotics1 PDFDocument77 pages4.24 M. E. Mechanical CAD CAM Robotics1 PDFAkshay KumarNo ratings yet

- ProgFun-Outline - OBE-F2023Document5 pagesProgFun-Outline - OBE-F2023Shoaib MushtaqNo ratings yet

- CE 321 Syllabus 2020-2021 5860Document4 pagesCE 321 Syllabus 2020-2021 5860Albasir Tiang Sedik REENo ratings yet

- Metrology Course SHeetDocument7 pagesMetrology Course SHeetMuhammad FaisalNo ratings yet

- 3B SyabusDocument2 pages3B SyabusSHIJONo ratings yet

- Manipal University Jaipur: Session: Jan 23 - May 23 - Class: IV Semester Dr. Renu Kumawat - Mr. Vivek SharmaDocument6 pagesManipal University Jaipur: Session: Jan 23 - May 23 - Class: IV Semester Dr. Renu Kumawat - Mr. Vivek SharmaqfekjwbNo ratings yet

- Silibus - Dka 1323Document5 pagesSilibus - Dka 1323azzkvbesutNo ratings yet

- Tutorial - An OverviewDocument17 pagesTutorial - An OverviewGrant HosieNo ratings yet

- SyllipusDocument4 pagesSyllipusAmeen AlzeidiNo ratings yet

- CSE320 Lecture0Document36 pagesCSE320 Lecture0akku.gautam23No ratings yet

- ME - III Year SyllabusDocument70 pagesME - III Year SyllabusDavid KiranNo ratings yet

- Final Year Syllabus CopeDocument61 pagesFinal Year Syllabus CopeSachin ANo ratings yet

- CPE314 Data Communication and Computer NetworksDocument9 pagesCPE314 Data Communication and Computer NetworksSouban JavedNo ratings yet

- CPE324 Digital Signal ProcessingDocument9 pagesCPE324 Digital Signal ProcessingSouban JavedNo ratings yet

- CSE 315 - COurseOutlineDocument11 pagesCSE 315 - COurseOutlineMustafizur Rahman RafeeNo ratings yet

- CSE320 Lecture0Document35 pagesCSE320 Lecture0aditya.raj60104No ratings yet

- Computer Science and Engineering S7 & S8Document11 pagesComputer Science and Engineering S7 & S8wastebasketNo ratings yet

- HCI-Nov10 Course OutlineDocument2 pagesHCI-Nov10 Course OutlineMuhammad HashimNo ratings yet

- BMCG 2513 - Teaching Plan Sem - 2 2016 2017 - BasriDocument11 pagesBMCG 2513 - Teaching Plan Sem - 2 2016 2017 - BasriW Mohd Zailimi AbdullahNo ratings yet

- CDF-CSC322 Operating SystemsDocument9 pagesCDF-CSC322 Operating SystemsHassam HafeezNo ratings yet

- BITSF110 Course HandoutDocument3 pagesBITSF110 Course HandoutultimateNo ratings yet

- Course Outline: 4 Embankment Drive Road, Sector 10, Uttara Model Town, Dhaka 1230, BangladeshDocument21 pagesCourse Outline: 4 Embankment Drive Road, Sector 10, Uttara Model Town, Dhaka 1230, BangladeshMahomuda AkterNo ratings yet

- Structural DynamicsDocument2 pagesStructural Dynamicsmythilispd_355305156No ratings yet

- Graphics SyllabusDocument9 pagesGraphics SyllabusAdarsh RNo ratings yet

- Computer Science and EngineeringDocument14 pagesComputer Science and EngineeringAbhinav GNo ratings yet

- Software EngineeringDocument10 pagesSoftware EngineeringManojNo ratings yet

- 5 SemDocument66 pages5 SemHarshad BBNo ratings yet

- Discuss The Difference Between Object Oriented Design and Object Oriented Analysis With The Help of Suitable Diagram?Document7 pagesDiscuss The Difference Between Object Oriented Design and Object Oriented Analysis With The Help of Suitable Diagram?vineet kholaNo ratings yet

- Professional Science Master's Degree in Construction ManagementDocument1 pageProfessional Science Master's Degree in Construction ManagementEDMUNDO APELONo ratings yet

- Course Plan CM Cie 3153 - 2020 (3 Credit)Document5 pagesCourse Plan CM Cie 3153 - 2020 (3 Credit)Don KarthikeyaNo ratings yet

- CDP Finalized Format AIDocument16 pagesCDP Finalized Format AICSE HODNo ratings yet

- Computer FundamentalDocument13 pagesComputer FundamentalasimNo ratings yet

- Course Plan: Department of Mechanical EnginneringDocument10 pagesCourse Plan: Department of Mechanical EnginneringEmperor89No ratings yet

- CIS Applied Calculus MS-102 CVDDocument5 pagesCIS Applied Calculus MS-102 CVDbilawal khanNo ratings yet

- CPE446 Real Time Embedded SystemsDocument10 pagesCPE446 Real Time Embedded SystemsSouban JavedNo ratings yet

- Course Information Sem 12134Document9 pagesCourse Information Sem 12134YooganNo ratings yet

- Lab Report SW AzarDocument9 pagesLab Report SW AzarAZAR DANFUDI NAMAZINo ratings yet

- Institute of Aeronautical Engineering: Course DescriptionDocument11 pagesInstitute of Aeronautical Engineering: Course Descriptiondurga sharmaNo ratings yet

- Guidelines for Chemical Process Quantitative Risk AnalysisFrom EverandGuidelines for Chemical Process Quantitative Risk AnalysisRating: 5 out of 5 stars5/5 (1)

- Maruti - 4MDocument148 pagesMaruti - 4MPlant Head Prasad80% (5)

- Global Marketing - Ch10 Brand and Product Decisions in Global MarketingDocument22 pagesGlobal Marketing - Ch10 Brand and Product Decisions in Global MarketingIsmadth2918388No ratings yet

- Energy Audit ProposalDocument8 pagesEnergy Audit ProposalRuwan WijemanneNo ratings yet

- Sampath CVDocument3 pagesSampath CVnitheesh kumarNo ratings yet

- SAP PP Variant Configuration - StepsDocument13 pagesSAP PP Variant Configuration - StepsKoustubha KhareNo ratings yet

- The ABC of ERPDocument13 pagesThe ABC of ERPRoger AlexandreNo ratings yet

- Planning Guide For Server Farms and Environments For Microsoft SharePoint Server 2010 PDFDocument307 pagesPlanning Guide For Server Farms and Environments For Microsoft SharePoint Server 2010 PDFAmeliaPurnamaNo ratings yet

- Erdemir Product Catalog 2014 PDFDocument166 pagesErdemir Product Catalog 2014 PDFGantulga NerguiNo ratings yet

- Infinit-I Primer 2019: The IT Consulting and Data Analytics Club of IIM INDOREDocument13 pagesInfinit-I Primer 2019: The IT Consulting and Data Analytics Club of IIM INDORESoham SinhaNo ratings yet

- File 000096Document196 pagesFile 000096Wahyu PranataNo ratings yet

- Hybris Commerce Developer Training 1.09 - TransactionsDocument6 pagesHybris Commerce Developer Training 1.09 - TransactionsoblomirNo ratings yet

- BMC Best Practice Process FlowDocument50 pagesBMC Best Practice Process FlowliemdarenNo ratings yet

- SysAdmin AG v2010EEDocument222 pagesSysAdmin AG v2010EEharish_inNo ratings yet

- To Activate Road Side Assistance (RSA) Cover, SMS "ACTIVATE POLICY V6054244 " To 9222211100 (Standard SMS Charges Applicable)Document6 pagesTo Activate Road Side Assistance (RSA) Cover, SMS "ACTIVATE POLICY V6054244 " To 9222211100 (Standard SMS Charges Applicable)Ritik BidhuriNo ratings yet

- Eric Fauteux 21/08/2021: Drawn Checked QA MFG Approved TitleDocument4 pagesEric Fauteux 21/08/2021: Drawn Checked QA MFG Approved Titleaz123654No ratings yet

- Cobas Liat User Manual SW 3 2Document196 pagesCobas Liat User Manual SW 3 2Revathy Gunaseelan100% (1)

- BS 2901-3Document13 pagesBS 2901-3vuthuy94No ratings yet

- Freeloader Debt Itemized - Church of ScientologyDocument45 pagesFreeloader Debt Itemized - Church of ScientologyThe Department of Official InformationNo ratings yet

- ADB Project 41603012Document5 pagesADB Project 41603012arparagNo ratings yet

- AE1256 AerodynamicslabmanualsDocument48 pagesAE1256 AerodynamicslabmanualsSenthil ArumugamNo ratings yet

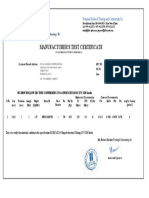

- Manufacturer'S Test Certificate: National Builtech Trading and Contracting CoDocument1 pageManufacturer'S Test Certificate: National Builtech Trading and Contracting CoQc QatarNo ratings yet

- Electric OsDocument429 pagesElectric OsAleejandro VaargasNo ratings yet

- High-Tech Industry DefinitionDocument2 pagesHigh-Tech Industry DefinitionSudipto MukherjeeNo ratings yet

- What Is Gripflow?: Bulletin 4Document1 pageWhat Is Gripflow?: Bulletin 4ks2000n1No ratings yet

- Billing & Customer Care For GSM Cellular Mobile Networks: GSM BB 4 RTTC MysoreDocument30 pagesBilling & Customer Care For GSM Cellular Mobile Networks: GSM BB 4 RTTC MysoreRaghu HbNo ratings yet

- Real Time Event Processing With Microsoft Azure Stream AnalyticsDocument31 pagesReal Time Event Processing With Microsoft Azure Stream Analyticschakri.unguturu2543100% (1)

- CCP Details - Ms. SheenaDocument3 pagesCCP Details - Ms. SheenaSheena MaiNo ratings yet

Course Assesmnet Sheet

Course Assesmnet Sheet

Uploaded by

Maheen ArshadOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Course Assesmnet Sheet

Course Assesmnet Sheet

Uploaded by

Maheen ArshadCopyright:

Available Formats

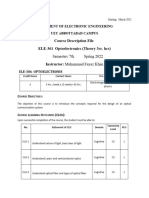

DEPARTMENT OF INDUSTRIAL ENGINEERING

UNIVERSITY OF ENGINEERING &TECHNOLOGY, PESHAWAR

Phone: +92-(0)91- 9222197 Fax: +92-(0)91- 9216663

IE244–Manufacturing Processes

Contact Hours Credit Hours

Theory : 48 Theory : 03

Lab : 48 Lab : 01

Total : 96 Total : 04

Knowledge Profile:

Semester :

Course Learning Outcomes (CLOs)

PLOs

Course Learning Assessment Activities & Weight Taxonomy Addressed by

CLO No.

Outcomes (CLOs) Percentage Domain Course (PLO

No.)

To be able to know basic Quiz1 10

concepts of various

manufacturing processes Assignement1 15

Engineering

1

Mid-TermExam 60 Knowledge

Final Exam 15

To be able to recognize the Assignement2 10

strong interrelationships

between material properties Quiz 2 10

and manufacturing processes

Engineering

2

Mid-Term Exam 30 Knowledge

Final-Term Exam 50

Assignment 3 20

Quiz 3 10

Mid-Term Exam 20 Problem

To be able to apply basic Analysis (2)

formulae for calculation of Final Term Exam 50

3

various process input /output

parameters

DEPARTMENT OF INDUSTRIAL ENGINEERING

UNIVERSITY OF ENGINEERING &TECHNOLOGY, PESHAWAR

Phone: +92-(0)91- 9222197 Fax: +92-(0)91- 9216663

HEC Course Content:

Basic concepts of manufacturing processes, Casting processes, Furnaces, Forming and

Joining processes, Welding, Brazing and soldering, Adhesive bonding, Traditional and non-

traditional machining operations, capabilities and limitations, Rapid prototyping operations,

Manufacturing of parts using polymer, composite and powder metallurgy, Process selection

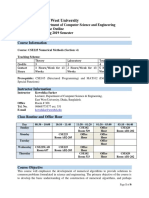

Grading Policy

Quizzes : 15%

Assignments : 10%

Mid Term : 25 %

Final : 50%

Text Books

Lab CLOs

PLOs

Course Learning Assessment Activities & Taxonomy Addressed

CLO No.

Outcomes (CLOs) Weight Percentage Domain by Course

(PLO No.)

1 To be able to investigate Report Writing 25 Design and

and communicate problems Development of

and its solution Solution (3),

Quiz 25

Communication

(10)

Tests 50

List of Practicals

S. No List of Practicals

1 Introduction to safety rules at various manufacturing shops

2 To design and manufacture a split pattern in Pattern Shop for sand casting

3 To design and make a mold of green sand for a split pattern using core

4 To cast a hollow piece by sand casting process

5 To observe various chip formation by changing process parameters

6 To Compare brazing and soldering welding processes

7 To study the effect of Oxyacetylene Welding process parameters

8 To Study the effect of Arc Welding Process Parameters

9 To study permanent mold/ injection mold process

DEPARTMENT OF INDUSTRIAL ENGINEERING

UNIVERSITY OF ENGINEERING &TECHNOLOGY, PESHAWAR

Phone: +92-(0)91- 9222197 Fax: +92-(0)91- 9216663

S. No List of Practicals

10 To study the rolling process and its parameters

11 To study rapid prototyping process and its parameters

12 To study the sheet metal working processes and its parameters

You might also like

- COMSATS University Islamabad: Course Description FileDocument8 pagesCOMSATS University Islamabad: Course Description FileSouban JavedNo ratings yet

- DFM Course IntroductionDocument21 pagesDFM Course IntroductionNitheeshNo ratings yet

- The FIDIC 1999 Forms of ContractDocument5 pagesThe FIDIC 1999 Forms of ContractAZNo ratings yet

- Case 14.56 - Accounting For Decision MakingDocument12 pagesCase 14.56 - Accounting For Decision MakingT Yoges Thiru MoorthyNo ratings yet

- Style Changeover Process Plan in Garment Industry - Lean MethodDocument1 pageStyle Changeover Process Plan in Garment Industry - Lean MethodArjun MNo ratings yet

- Course Assesmnet SheetDocument3 pagesCourse Assesmnet SheetMohsin QaziNo ratings yet

- Software TestingDocument10 pagesSoftware TestingYogeshwari J0% (1)

- Software TestingDocument10 pagesSoftware TestingjsspdacsNo ratings yet

- Separation Process II Course Outline UTPDocument4 pagesSeparation Process II Course Outline UTPQruisedNo ratings yet

- Manufacturing ProcessesDocument10 pagesManufacturing ProcessesMuhammad SyimirNo ratings yet

- Software TestingDocument10 pagesSoftware TestingJayanth NaikNo ratings yet

- CDF Optoelectronics 2022Document3 pagesCDF Optoelectronics 2022Muhammad Fayyaz Khan AP Electronics ABTNo ratings yet

- Faculty of Mechanical and Manufacturing Enginering: Lesson PlanDocument18 pagesFaculty of Mechanical and Manufacturing Enginering: Lesson PlanNatalia Fitri Clerin SusilowatiNo ratings yet

- Introduction EMT357-upload VerDocument19 pagesIntroduction EMT357-upload VerAmriNo ratings yet

- CPE241 Digital Logic DesignDocument9 pagesCPE241 Digital Logic DesignSouban JavedNo ratings yet

- CDF DLD TheoryDocument4 pagesCDF DLD TheoryMuhammad Fayyaz Khan AP Electronics ABTNo ratings yet

- CIMDocument3 pagesCIMOmkar KulkarniNo ratings yet

- Introduction To Structural Dynamics and Earthquake EngineeringDocument2 pagesIntroduction To Structural Dynamics and Earthquake EngineeringfefahimNo ratings yet

- Section A: Course Details: Unikl MicetDocument3 pagesSection A: Course Details: Unikl MicetColours Of LifeNo ratings yet

- CSC141 Introduction To Computer ProgrammingDocument8 pagesCSC141 Introduction To Computer ProgrammingSouban JavedNo ratings yet

- East West University: Department of Computer Science and Engineering Course Outline Spring 2019 SemesterDocument6 pagesEast West University: Department of Computer Science and Engineering Course Outline Spring 2019 Semesterthe rexaNo ratings yet

- SVNIT M. Tech. CAD-CAM - Syllabus - FinalDocument68 pagesSVNIT M. Tech. CAD-CAM - Syllabus - FinalAfzal BhatNo ratings yet

- Mumbai Univ SyllabusDocument18 pagesMumbai Univ SyllabusssaprodNo ratings yet

- Metrology & SQC - NewDocument4 pagesMetrology & SQC - NewKashif RazaqNo ratings yet

- 4.24 M. E. Mechanical CAD CAM Robotics1 PDFDocument77 pages4.24 M. E. Mechanical CAD CAM Robotics1 PDFAkshay KumarNo ratings yet

- ProgFun-Outline - OBE-F2023Document5 pagesProgFun-Outline - OBE-F2023Shoaib MushtaqNo ratings yet

- CE 321 Syllabus 2020-2021 5860Document4 pagesCE 321 Syllabus 2020-2021 5860Albasir Tiang Sedik REENo ratings yet

- Metrology Course SHeetDocument7 pagesMetrology Course SHeetMuhammad FaisalNo ratings yet

- 3B SyabusDocument2 pages3B SyabusSHIJONo ratings yet

- Manipal University Jaipur: Session: Jan 23 - May 23 - Class: IV Semester Dr. Renu Kumawat - Mr. Vivek SharmaDocument6 pagesManipal University Jaipur: Session: Jan 23 - May 23 - Class: IV Semester Dr. Renu Kumawat - Mr. Vivek SharmaqfekjwbNo ratings yet

- Silibus - Dka 1323Document5 pagesSilibus - Dka 1323azzkvbesutNo ratings yet

- Tutorial - An OverviewDocument17 pagesTutorial - An OverviewGrant HosieNo ratings yet

- SyllipusDocument4 pagesSyllipusAmeen AlzeidiNo ratings yet

- CSE320 Lecture0Document36 pagesCSE320 Lecture0akku.gautam23No ratings yet

- ME - III Year SyllabusDocument70 pagesME - III Year SyllabusDavid KiranNo ratings yet

- Final Year Syllabus CopeDocument61 pagesFinal Year Syllabus CopeSachin ANo ratings yet

- CPE314 Data Communication and Computer NetworksDocument9 pagesCPE314 Data Communication and Computer NetworksSouban JavedNo ratings yet

- CPE324 Digital Signal ProcessingDocument9 pagesCPE324 Digital Signal ProcessingSouban JavedNo ratings yet

- CSE 315 - COurseOutlineDocument11 pagesCSE 315 - COurseOutlineMustafizur Rahman RafeeNo ratings yet

- CSE320 Lecture0Document35 pagesCSE320 Lecture0aditya.raj60104No ratings yet

- Computer Science and Engineering S7 & S8Document11 pagesComputer Science and Engineering S7 & S8wastebasketNo ratings yet

- HCI-Nov10 Course OutlineDocument2 pagesHCI-Nov10 Course OutlineMuhammad HashimNo ratings yet

- BMCG 2513 - Teaching Plan Sem - 2 2016 2017 - BasriDocument11 pagesBMCG 2513 - Teaching Plan Sem - 2 2016 2017 - BasriW Mohd Zailimi AbdullahNo ratings yet

- CDF-CSC322 Operating SystemsDocument9 pagesCDF-CSC322 Operating SystemsHassam HafeezNo ratings yet

- BITSF110 Course HandoutDocument3 pagesBITSF110 Course HandoutultimateNo ratings yet

- Course Outline: 4 Embankment Drive Road, Sector 10, Uttara Model Town, Dhaka 1230, BangladeshDocument21 pagesCourse Outline: 4 Embankment Drive Road, Sector 10, Uttara Model Town, Dhaka 1230, BangladeshMahomuda AkterNo ratings yet

- Structural DynamicsDocument2 pagesStructural Dynamicsmythilispd_355305156No ratings yet

- Graphics SyllabusDocument9 pagesGraphics SyllabusAdarsh RNo ratings yet

- Computer Science and EngineeringDocument14 pagesComputer Science and EngineeringAbhinav GNo ratings yet

- Software EngineeringDocument10 pagesSoftware EngineeringManojNo ratings yet

- 5 SemDocument66 pages5 SemHarshad BBNo ratings yet

- Discuss The Difference Between Object Oriented Design and Object Oriented Analysis With The Help of Suitable Diagram?Document7 pagesDiscuss The Difference Between Object Oriented Design and Object Oriented Analysis With The Help of Suitable Diagram?vineet kholaNo ratings yet

- Professional Science Master's Degree in Construction ManagementDocument1 pageProfessional Science Master's Degree in Construction ManagementEDMUNDO APELONo ratings yet

- Course Plan CM Cie 3153 - 2020 (3 Credit)Document5 pagesCourse Plan CM Cie 3153 - 2020 (3 Credit)Don KarthikeyaNo ratings yet

- CDP Finalized Format AIDocument16 pagesCDP Finalized Format AICSE HODNo ratings yet

- Computer FundamentalDocument13 pagesComputer FundamentalasimNo ratings yet

- Course Plan: Department of Mechanical EnginneringDocument10 pagesCourse Plan: Department of Mechanical EnginneringEmperor89No ratings yet

- CIS Applied Calculus MS-102 CVDDocument5 pagesCIS Applied Calculus MS-102 CVDbilawal khanNo ratings yet

- CPE446 Real Time Embedded SystemsDocument10 pagesCPE446 Real Time Embedded SystemsSouban JavedNo ratings yet

- Course Information Sem 12134Document9 pagesCourse Information Sem 12134YooganNo ratings yet

- Lab Report SW AzarDocument9 pagesLab Report SW AzarAZAR DANFUDI NAMAZINo ratings yet

- Institute of Aeronautical Engineering: Course DescriptionDocument11 pagesInstitute of Aeronautical Engineering: Course Descriptiondurga sharmaNo ratings yet

- Guidelines for Chemical Process Quantitative Risk AnalysisFrom EverandGuidelines for Chemical Process Quantitative Risk AnalysisRating: 5 out of 5 stars5/5 (1)

- Maruti - 4MDocument148 pagesMaruti - 4MPlant Head Prasad80% (5)

- Global Marketing - Ch10 Brand and Product Decisions in Global MarketingDocument22 pagesGlobal Marketing - Ch10 Brand and Product Decisions in Global MarketingIsmadth2918388No ratings yet

- Energy Audit ProposalDocument8 pagesEnergy Audit ProposalRuwan WijemanneNo ratings yet

- Sampath CVDocument3 pagesSampath CVnitheesh kumarNo ratings yet

- SAP PP Variant Configuration - StepsDocument13 pagesSAP PP Variant Configuration - StepsKoustubha KhareNo ratings yet

- The ABC of ERPDocument13 pagesThe ABC of ERPRoger AlexandreNo ratings yet

- Planning Guide For Server Farms and Environments For Microsoft SharePoint Server 2010 PDFDocument307 pagesPlanning Guide For Server Farms and Environments For Microsoft SharePoint Server 2010 PDFAmeliaPurnamaNo ratings yet

- Erdemir Product Catalog 2014 PDFDocument166 pagesErdemir Product Catalog 2014 PDFGantulga NerguiNo ratings yet

- Infinit-I Primer 2019: The IT Consulting and Data Analytics Club of IIM INDOREDocument13 pagesInfinit-I Primer 2019: The IT Consulting and Data Analytics Club of IIM INDORESoham SinhaNo ratings yet

- File 000096Document196 pagesFile 000096Wahyu PranataNo ratings yet

- Hybris Commerce Developer Training 1.09 - TransactionsDocument6 pagesHybris Commerce Developer Training 1.09 - TransactionsoblomirNo ratings yet

- BMC Best Practice Process FlowDocument50 pagesBMC Best Practice Process FlowliemdarenNo ratings yet

- SysAdmin AG v2010EEDocument222 pagesSysAdmin AG v2010EEharish_inNo ratings yet

- To Activate Road Side Assistance (RSA) Cover, SMS "ACTIVATE POLICY V6054244 " To 9222211100 (Standard SMS Charges Applicable)Document6 pagesTo Activate Road Side Assistance (RSA) Cover, SMS "ACTIVATE POLICY V6054244 " To 9222211100 (Standard SMS Charges Applicable)Ritik BidhuriNo ratings yet

- Eric Fauteux 21/08/2021: Drawn Checked QA MFG Approved TitleDocument4 pagesEric Fauteux 21/08/2021: Drawn Checked QA MFG Approved Titleaz123654No ratings yet

- Cobas Liat User Manual SW 3 2Document196 pagesCobas Liat User Manual SW 3 2Revathy Gunaseelan100% (1)

- BS 2901-3Document13 pagesBS 2901-3vuthuy94No ratings yet

- Freeloader Debt Itemized - Church of ScientologyDocument45 pagesFreeloader Debt Itemized - Church of ScientologyThe Department of Official InformationNo ratings yet

- ADB Project 41603012Document5 pagesADB Project 41603012arparagNo ratings yet

- AE1256 AerodynamicslabmanualsDocument48 pagesAE1256 AerodynamicslabmanualsSenthil ArumugamNo ratings yet

- Manufacturer'S Test Certificate: National Builtech Trading and Contracting CoDocument1 pageManufacturer'S Test Certificate: National Builtech Trading and Contracting CoQc QatarNo ratings yet

- Electric OsDocument429 pagesElectric OsAleejandro VaargasNo ratings yet

- High-Tech Industry DefinitionDocument2 pagesHigh-Tech Industry DefinitionSudipto MukherjeeNo ratings yet

- What Is Gripflow?: Bulletin 4Document1 pageWhat Is Gripflow?: Bulletin 4ks2000n1No ratings yet

- Billing & Customer Care For GSM Cellular Mobile Networks: GSM BB 4 RTTC MysoreDocument30 pagesBilling & Customer Care For GSM Cellular Mobile Networks: GSM BB 4 RTTC MysoreRaghu HbNo ratings yet

- Real Time Event Processing With Microsoft Azure Stream AnalyticsDocument31 pagesReal Time Event Processing With Microsoft Azure Stream Analyticschakri.unguturu2543100% (1)

- CCP Details - Ms. SheenaDocument3 pagesCCP Details - Ms. SheenaSheena MaiNo ratings yet