Professional Documents

Culture Documents

100%(2)100% found this document useful (2 votes)

1K viewsJSA-Use of Temporary Energization (Power Generator)

JSA-Use of Temporary Energization (Power Generator)

Uploaded by

MajdiSahnounThis Job Safety Analysis summarizes the tasks, hazards, and controls for temporarily energizing electrical units using a power generator at a facility. Key steps include:

1) Ensuring a work permit is in place and all workers are competent and understand the risks.

2) Refueling the generator safely by using proper PPE, avoiding spills, and operating in clear areas away from ignition sources.

3) Working at height with fall protections such as safety harnesses, securing tools, and prohibiting throwing of objects.

4) Performing operations in the electrical panel using proper PPE, insulated tools, and having two trained persons in attendance. Controls include emergency response plans, first aid

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- JSA For Vegetation ClearingDocument4 pagesJSA For Vegetation ClearingSawLaiBoyan33% (3)

- Jsa - Cable TerminationDocument4 pagesJsa - Cable TerminationSantos Rex73% (15)

- Art of Scripting GuideDocument3 pagesArt of Scripting Guidesaminitsok100% (2)

- JSA For Excavation of Fiber Optical Cable WR-501 To WR-617 Community To Petro Rabigh......Document15 pagesJSA For Excavation of Fiber Optical Cable WR-501 To WR-617 Community To Petro Rabigh......Habib ur rahmanNo ratings yet

- JSA - Electrical Testing - Circuit Breaker Field TestDocument4 pagesJSA - Electrical Testing - Circuit Breaker Field TestTawfik Mohamed Abu Zaid0% (1)

- Job Hazard Assessment For Cable TestingDocument4 pagesJob Hazard Assessment For Cable TestingSamuel Carlos100% (2)

- Job Hazard Analysis For Crane DismantlingDocument2 pagesJob Hazard Analysis For Crane DismantlingKamlesh Bule Lonari100% (2)

- JSA Cable Laying PDFDocument2 pagesJSA Cable Laying PDFManoj WaskelNo ratings yet

- Job Safety Analysis Sheet: Electrical IsolationDocument1 pageJob Safety Analysis Sheet: Electrical IsolationLal Dhwoj67% (3)

- JSA InsulationDocument8 pagesJSA InsulationOlavilam Prakash100% (3)

- Jsa For Civil Confined Space EntryDocument11 pagesJsa For Civil Confined Space EntryKhuda BukshNo ratings yet

- Jsa Cable TerminationDocument4 pagesJsa Cable TerminationSyed Yousuf Ali100% (1)

- JHA Manual Excavation For Cable TrenchDocument5 pagesJHA Manual Excavation For Cable TrenchNasrullah Jan100% (5)

- Copy (2) of JSA For Removal of MS Sheet For E&P ShedDocument12 pagesCopy (2) of JSA For Removal of MS Sheet For E&P Shedmidozoty50% (2)

- Hope and Other Dangerous Pursuits - Discussion GuideDocument4 pagesHope and Other Dangerous Pursuits - Discussion GuideHoughton Mifflin Harcourt0% (2)

- JSA Cable DisconnectedDocument4 pagesJSA Cable Disconnectedwendypost730% (1)

- Jsa. Cable Laying and TerminationDocument10 pagesJsa. Cable Laying and TerminationMon Trang NguyễnNo ratings yet

- Job Safety Analysis Worksheet: Yes NoDocument8 pagesJob Safety Analysis Worksheet: Yes NoBorislav VulićNo ratings yet

- JSA Ladders Working at Heights 001Document2 pagesJSA Ladders Working at Heights 001Raman SawNo ratings yet

- Job Safety Analysis: Cable Jointing & Termination in Wind TurbinesDocument1 pageJob Safety Analysis: Cable Jointing & Termination in Wind TurbinesPerwez2186% (7)

- 004 Annexure D Job Safety SAnalysis JSADocument3 pages004 Annexure D Job Safety SAnalysis JSAAvoor Khan75% (4)

- JSA No. 9 - Safe Use of Pneumatic and Power ToolsDocument2 pagesJSA No. 9 - Safe Use of Pneumatic and Power ToolsAshok Suresh100% (1)

- JSA E&I 10.electrical Instrument Panels RemovalDocument3 pagesJSA E&I 10.electrical Instrument Panels RemovalAmyNo ratings yet

- JSA For Concrete WorkDocument6 pagesJSA For Concrete Worklê ngọc tùng0% (1)

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- Jha Energize Distribution DBDocument1 pageJha Energize Distribution DBAhmad Zahir100% (2)

- JSA-Loading-Offloading of Chemical Products With ForkliftDocument4 pagesJSA-Loading-Offloading of Chemical Products With ForkliftMajdiSahnoun100% (2)

- JSA - Repair-Coating and Finition WorkDocument3 pagesJSA - Repair-Coating and Finition WorkAMIN100% (1)

- JSA-Loading-Offloading of Chemical Products With ForkliftDocument4 pagesJSA-Loading-Offloading of Chemical Products With ForkliftMajdiSahnoun100% (2)

- Battery FillingDocument3 pagesBattery FillingMajdiSahnounNo ratings yet

- Electrical InstallationDocument3 pagesElectrical InstallationWalid KhelfaNo ratings yet

- Jsa-Ht & LT Panel InstallationDocument1 pageJsa-Ht & LT Panel Installationpushpanath reddy100% (2)

- Up Dated Job Safety Analysis-Gypsum Plastering WorksDocument12 pagesUp Dated Job Safety Analysis-Gypsum Plastering WorksAkhtar Ali100% (1)

- Jsa For The Installation of I EamDocument5 pagesJsa For The Installation of I EamMohammed MinhajNo ratings yet

- JSA Electrical WiringDocument10 pagesJSA Electrical WiringWeru Morris100% (1)

- JSA Template 2017-05-31 Cable Tray InstallationDocument19 pagesJSA Template 2017-05-31 Cable Tray InstallationJayvee Baradas ValdezNo ratings yet

- EF 1931-STCC-JSA-33 Fire Proofing of The Steel Structure and Vessel Foun...Document5 pagesEF 1931-STCC-JSA-33 Fire Proofing of The Steel Structure and Vessel Foun...Anis Uddin100% (2)

- Jha - Transformer Installation PDFDocument6 pagesJha - Transformer Installation PDFperquino oasan0% (1)

- Cable Pulling / Laying, Glanding and Termination SOP: Task Risk AssessmentDocument23 pagesCable Pulling / Laying, Glanding and Termination SOP: Task Risk AssessmentMon Trang Nguyễn100% (2)

- Safe Plan of Action Ramsu EnterpriseDocument5 pagesSafe Plan of Action Ramsu EnterpriseSanjeev Kumar100% (1)

- DLF PCC HiraDocument6 pagesDLF PCC HiraskfahimuddinNo ratings yet

- JSA For SealantDocument11 pagesJSA For SealantdipmipNo ratings yet

- JSA E&I 4.earthing Bonding InstallationDocument3 pagesJSA E&I 4.earthing Bonding InstallationAmyNo ratings yet

- JSA Earthpit Construction GeneralDocument4 pagesJSA Earthpit Construction Generalmukka88No ratings yet

- JSA Transformer InstallationDocument1 pageJSA Transformer Installationpushpanath reddyNo ratings yet

- JSA 150 Trench Excavation Backfilling Berming & Sand Removal KRT-2 KM 104 - 108Document10 pagesJSA 150 Trench Excavation Backfilling Berming & Sand Removal KRT-2 KM 104 - 108Zubair Khan100% (1)

- EEEPL - JSA Light Fitting ErectionDocument6 pagesEEEPL - JSA Light Fitting ErectionnishanthNo ratings yet

- JSA FOR Using The LadderDocument4 pagesJSA FOR Using The Laddertnssbhaskar100% (1)

- JSA Unloading & SHIFTING by Manually 10-01-2017Document16 pagesJSA Unloading & SHIFTING by Manually 10-01-2017PAVANKUMAR100% (1)

- JHA Chain HoistDocument1 pageJHA Chain HoistKrishna Patil100% (2)

- 003-JSA Pipe Loading and OffloadingDocument8 pages003-JSA Pipe Loading and OffloadingMoaatazz NouisriNo ratings yet

- JSA GC-5 Mobile ScaffoldingDocument6 pagesJSA GC-5 Mobile Scaffoldinggrande100% (2)

- Installation of Pannel JSADocument6 pagesInstallation of Pannel JSAOFFSHORE OFFSITENo ratings yet

- HV Cable Termination: Standard Work Method StatementDocument6 pagesHV Cable Termination: Standard Work Method StatementOsama SharafNo ratings yet

- JSP For AsphaltDocument8 pagesJSP For Asphaltmohammed tofiqNo ratings yet

- JSA For Electrical ActivitiesDocument14 pagesJSA For Electrical Activitiesdrparihary100% (3)

- JSA FOR Moving and Handling MaterialsDocument3 pagesJSA FOR Moving and Handling Materialswahyu nugrohoNo ratings yet

- Jsa forOperatingAForkliftDocument2 pagesJsa forOperatingAForkliftsupahing supahingNo ratings yet

- JSA 04 Confined Sapce EntryDocument1 pageJSA 04 Confined Sapce Entrywahyu nugrohoNo ratings yet

- JSA-Visual Inspection and Ultrasonic Thickness Measurement On Pressure VesselsDocument2 pagesJSA-Visual Inspection and Ultrasonic Thickness Measurement On Pressure VesselsMajdiSahnoun100% (1)

- Job Safety Analysis: Required References Jsa ReviewDocument3 pagesJob Safety Analysis: Required References Jsa ReviewMajdiSahnounNo ratings yet

- HVAC Fans Initial Energisation Battery RoomDocument3 pagesHVAC Fans Initial Energisation Battery RoomMajdiSahnounNo ratings yet

- HVAC Fans Initial Energisation Battery RoomDocument3 pagesHVAC Fans Initial Energisation Battery RoomMajdiSahnoun0% (1)

- CPF-JSA-018 Drilling and Pipes Support Erection ZONE CLASS0Document5 pagesCPF-JSA-018 Drilling and Pipes Support Erection ZONE CLASS0MajdiSahnounNo ratings yet

- JSA-054 Crossing WorksDocument6 pagesJSA-054 Crossing WorksMajdiSahnounNo ratings yet

- Jsa-046 Highway Crossing and Steel CasingDocument11 pagesJsa-046 Highway Crossing and Steel CasingMajdiSahnounNo ratings yet

- Job Safety Analysis: Required References Jsa ReviewDocument3 pagesJob Safety Analysis: Required References Jsa ReviewMajdiSahnounNo ratings yet

- JSA-Visual Inspection and Ultrasonic Thickness Measurement On Pressure VesselsDocument2 pagesJSA-Visual Inspection and Ultrasonic Thickness Measurement On Pressure VesselsMajdiSahnoun100% (1)

- JSA For Hydro Test Activites GenericDocument4 pagesJSA For Hydro Test Activites GenericMajdiSahnounNo ratings yet

- Annex 17 - Induction Nawara ProjDocument18 pagesAnnex 17 - Induction Nawara ProjMajdiSahnounNo ratings yet

- Nawara Project - Introduction of Positive Pressure Hazards and ControlsDocument1 pageNawara Project - Introduction of Positive Pressure Hazards and ControlsMajdiSahnounNo ratings yet

- Harc OffshoreDocument5 pagesHarc OffshoreMajdiSahnounNo ratings yet

- HVAC Fans Initial Energisation Battery RoomDocument3 pagesHVAC Fans Initial Energisation Battery RoomMajdiSahnoun0% (1)

- Harc Snoop Test OperationDocument7 pagesHarc Snoop Test OperationMajdiSahnounNo ratings yet

- Battery FillingDocument3 pagesBattery FillingMajdiSahnounNo ratings yet

- HVAC Fans Initial Energisation Battery RoomDocument3 pagesHVAC Fans Initial Energisation Battery RoomMajdiSahnounNo ratings yet

- Lorenzo v. Posadas Case DigestDocument2 pagesLorenzo v. Posadas Case DigestPatrick Anthony Llasus-NafarreteNo ratings yet

- ECO402 Solved Mid Term Corrected by Suleyman KhanDocument15 pagesECO402 Solved Mid Term Corrected by Suleyman KhanSuleyman KhanNo ratings yet

- First Sunday MassDocument3 pagesFirst Sunday MassRONALD ESCABALNo ratings yet

- Nota Hbet1403Document3 pagesNota Hbet1403Encik Emjaywai100% (1)

- Hoërskool Roodepoort: COVID-19 PolicyDocument24 pagesHoërskool Roodepoort: COVID-19 PolicyScarfacembali MbaliNo ratings yet

- Advances in Accounting, Incorporating Advances in International AccountingDocument14 pagesAdvances in Accounting, Incorporating Advances in International AccountingWihl Mathew ZalatarNo ratings yet

- Preference Shares - January 11 2017Document1 pagePreference Shares - January 11 2017Tiso Blackstar GroupNo ratings yet

- Android Update For SAMSUNG Galaxy Tab 7.0 Plus (GT-P6200) - Android Updates DownloadsDocument5 pagesAndroid Update For SAMSUNG Galaxy Tab 7.0 Plus (GT-P6200) - Android Updates DownloadsJoeJojoNo ratings yet

- A Catholic Framework For Economic LifeDocument3 pagesA Catholic Framework For Economic LifeAnonymousNo ratings yet

- Creative Sparks of Innovations - Part 3Document95 pagesCreative Sparks of Innovations - Part 3Justin NilanjanNo ratings yet

- Disaster Waste Management in Malaysia: Significant Issues, Policies & StrategiesDocument7 pagesDisaster Waste Management in Malaysia: Significant Issues, Policies & Strategiesmuhamadrafie1975No ratings yet

- Assignment 3 Group 6 (Ta19171, Ta19092, Ta19160, Ta19121, Ta19120)Document6 pagesAssignment 3 Group 6 (Ta19171, Ta19092, Ta19160, Ta19121, Ta19120)kameeneNo ratings yet

- BrochureDocument7 pagesBrochureapi-596896646No ratings yet

- My Musical Instrument Book BDocument9 pagesMy Musical Instrument Book BGIPSYNo ratings yet

- Henry FieldingDocument12 pagesHenry FieldingMary Rose BaluranNo ratings yet

- Transferance of SpiritsDocument13 pagesTransferance of SpiritsMiracle Internet Church50% (2)

- SRC, Ppsa, LocDocument7 pagesSRC, Ppsa, LocKLNo ratings yet

- Kosambi Marxism and Indian HistoryDocument4 pagesKosambi Marxism and Indian Historyroopeshkappy9315No ratings yet

- Notice No. 08-2022 2nd Phase of Advt. No. 02-2022Document10 pagesNotice No. 08-2022 2nd Phase of Advt. No. 02-2022Sagar KumarNo ratings yet

- Greeting Lesson PlanDocument4 pagesGreeting Lesson Planhawanur266No ratings yet

- 07 MalnutritionDocument132 pages07 MalnutritionMary Marjorie RodaviaNo ratings yet

- MC 4 Inventory A201 StudentDocument5 pagesMC 4 Inventory A201 Studentlim qsNo ratings yet

- Analyzing The External Environment of The FirmDocument16 pagesAnalyzing The External Environment of The FirmPrecious JirehNo ratings yet

- Holy Eucharist - PotDocument19 pagesHoly Eucharist - PotMargie CalumpitNo ratings yet

- Magellan International Corp. v. Salzgitter Handel GMBHDocument10 pagesMagellan International Corp. v. Salzgitter Handel GMBHNga DinhNo ratings yet

- Cre Form 1 2020 Schemes of WorkDocument12 pagesCre Form 1 2020 Schemes of Worklydia mutuaNo ratings yet

- Wire-And Strand-Wound Circular, Prestressed Concrete Water TanksDocument72 pagesWire-And Strand-Wound Circular, Prestressed Concrete Water TanksarminmandalNo ratings yet

- Idioms To Describe People: Match Up The Words and Definitions. Write Your Answers Boxes BelowDocument1 pageIdioms To Describe People: Match Up The Words and Definitions. Write Your Answers Boxes BelowzuperNo ratings yet

JSA-Use of Temporary Energization (Power Generator)

JSA-Use of Temporary Energization (Power Generator)

Uploaded by

MajdiSahnoun100%(2)100% found this document useful (2 votes)

1K views4 pagesThis Job Safety Analysis summarizes the tasks, hazards, and controls for temporarily energizing electrical units using a power generator at a facility. Key steps include:

1) Ensuring a work permit is in place and all workers are competent and understand the risks.

2) Refueling the generator safely by using proper PPE, avoiding spills, and operating in clear areas away from ignition sources.

3) Working at height with fall protections such as safety harnesses, securing tools, and prohibiting throwing of objects.

4) Performing operations in the electrical panel using proper PPE, insulated tools, and having two trained persons in attendance. Controls include emergency response plans, first aid

Original Description:

Temporary Energization

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis Job Safety Analysis summarizes the tasks, hazards, and controls for temporarily energizing electrical units using a power generator at a facility. Key steps include:

1) Ensuring a work permit is in place and all workers are competent and understand the risks.

2) Refueling the generator safely by using proper PPE, avoiding spills, and operating in clear areas away from ignition sources.

3) Working at height with fall protections such as safety harnesses, securing tools, and prohibiting throwing of objects.

4) Performing operations in the electrical panel using proper PPE, insulated tools, and having two trained persons in attendance. Controls include emergency response plans, first aid

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

100%(2)100% found this document useful (2 votes)

1K views4 pagesJSA-Use of Temporary Energization (Power Generator)

JSA-Use of Temporary Energization (Power Generator)

Uploaded by

MajdiSahnounThis Job Safety Analysis summarizes the tasks, hazards, and controls for temporarily energizing electrical units using a power generator at a facility. Key steps include:

1) Ensuring a work permit is in place and all workers are competent and understand the risks.

2) Refueling the generator safely by using proper PPE, avoiding spills, and operating in clear areas away from ignition sources.

3) Working at height with fall protections such as safety harnesses, securing tools, and prohibiting throwing of objects.

4) Performing operations in the electrical panel using proper PPE, insulated tools, and having two trained persons in attendance. Controls include emergency response plans, first aid

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 4

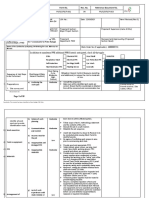

JOB SAFETY ANALYSIS

Ref: – JSA-…….

Facility / Site: CPF Location within Site: ESS Permit No: Permit Type: Hot Date:

Task Description: Temporary Energization Of electrical Units Using A Power Generator

REQUIRED REFERENCES JSA REVIEW

Have the relevant Procedures, Standards, Guidelines,

or Safe Work Practices been reviewed? Yes N/A

Pending confirmation by the Task Leader of site conditions, I agree that the attached JSA identifies the

significant Task Steps, Hazards, and Controls.

JSA REVIEWER (Supervisor or Designate):

RISK ASSESSMENT

Must existing Procedures or Work Practices be

Yes No Name / Signature: David BAIRD Company: MSBI

modified to perform this work?

After mitigation, are there any hazards that continue to WORK SITE VERIFICATION

present a potentially significant risk? (Scenario-Based Yes No

Risk Assessment required)

The Work Team has assessed the worksite conditions and confirms:

The JSA addresses the applicable hazards and necessary controls.

PPE REQUIRED DURING THIS TASK

The Team has the appropriate resources (people and equipment) to do the job safely.

HARD HAT SAFETY GLASSES

Others that could be affected by the work have been informed.

FACE SHIELD TASK LEADER:

SAFETY SHOES / BOOTS

GOGGLES

Name / Signature: Company:MSBI

FALL PROTECTION

FALL RESTRAINT

COMPLETE THE SECTION BELOW IF THIS JSA IS NOT PART OF A PERMIT PACK

GLOVES:

COTTON Work Team Declaration:

LEATHER I acknowledge that I have reviewed the attached JSA, I understand my roles

and responsibilities, and I will comply with the instructions for this task.

IMPACT PROTECTION

Name (print): Name (print):

Dust mask OTHER (specify):

Work clothes

OTHER PPE (specify):

TASK STEPS POTENTIAL HAZARDS HAZARDS CONTROLS HAZARD PORT

(Number) (What could go wrong?) (How can harm be prevented?) MITIGATION STATES

PTW signed by authorised person.

Ensure correct PPE available for task

Procedure or task unclear Carry out toolbox talk

Miscommunication Clear access and area around panel.

MSBI Emergency

1- Work permit in place Workers involved in the tasks are not All workers involved are competent and

Response plan

competent They understand the scope of the work

Incorrect tools or PPE and the hazards/risks associated with

the task.

Clean and arrange the work area.

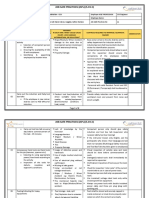

Use proper PPE’s when filling generator

with fuel.

Exercise care when filling up tank. Do

not overfill and use a secondary

container to catch any overfill. MSBI Emergency

Spillage of fuel and exposure to spilled fuel. Avoid parking the truck in steep response Plan

2- Refueling of the power Flash fire and problems related to operating locations; the generator requires a level First Aid kit in

generator a portable energy source.

parking area. place

Operate the generator in an area free Spill kit in place

from ignition sources and wet

conditions.

Exercise caution. Make sure that the

truck is in a clear area free from

physical obstructions.

Fall of person From height PTW and TBT must be held before MSBI

Hands injuries starting work. Emergency

Electrical tools Check medical fitness certificates response Plan

Slips Trips and fall Persons with vertigo are strictly First aid box on

Heat stress prohibited to work at heights. place

Falling object Use of safety harness Emergency contact

3-Working at height Vertigo Use of proper PPE’s. list to be in place

Faulty of fixation Tools and equipment to be secured

against falls i.e. tied down,

Throwing of tools and materials

are strictly prohibited, use rope

Workers and minimal weight of

materials and tools.

4- Performing operations in Shock or electrocution Use the proper PPE in accordance with

the panel and instrument the supply voltage.

Only use insulated tools MSBI Emergency

Two persons in attendance at all times response Plan

Only trained and qualified personnel to Fire extinguisher

perform the task suitable for

Equipment to be left in safe condition electrical fires

when no one in attendance with all Qualified/authorised

panels closed personnel on the

worksite

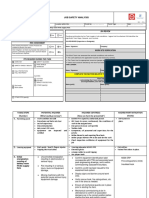

Refer to OMV ATEX Zoning.

Adhere to PTW system & LOTO Fire extinguisher to

procedure (if applicable) be in place

First aid kits and first

Use of proper PPE’s (anti-static

aiders in place

coverall).

when needed

Use of proper access or safe work MSBI Emergency

platforms. Response Plan

Continuous testing and monitoring of

the atmosphere (multi-gas detector) to

confirm absence of flammable &toxic

atmosphere at worksite.

Presence of toxic and inflammable gas in the Sparks arrestor for vehicles.

5- Working in classified area work area.

Smoking is prohibited.

Fire.

Explosion. Cell phone is prohibited.

No electrical tools near the well head.

Check the availability of suitable &

approved Fire Extinguishers at site.

Ensure that all tools are ATEX inspected

(ZONE CLASS 0).

Do not wear jewellery, rings... (ZONE

CLASS 0/1).

Full time supervision (watchman in

place) (ZONE CLASS 0/1).

Use non Sparking Tools: branz hammer,

keys, clamping tools (ZONE CLASS 0).

Keep work area tidy and clean MSBI Emergency

Slips trips and falls

response Plan

5- Housekeeping Unsafe access Regular Housekeeping and keep all area

Obstacles in work area

First Aid kit in

free from hazards place

Name Position Date Signed

Prepared By

Checked By Area HSSE Supervisor

Approved By PTW Coordinator

You might also like

- JSA For Vegetation ClearingDocument4 pagesJSA For Vegetation ClearingSawLaiBoyan33% (3)

- Jsa - Cable TerminationDocument4 pagesJsa - Cable TerminationSantos Rex73% (15)

- Art of Scripting GuideDocument3 pagesArt of Scripting Guidesaminitsok100% (2)

- JSA For Excavation of Fiber Optical Cable WR-501 To WR-617 Community To Petro Rabigh......Document15 pagesJSA For Excavation of Fiber Optical Cable WR-501 To WR-617 Community To Petro Rabigh......Habib ur rahmanNo ratings yet

- JSA - Electrical Testing - Circuit Breaker Field TestDocument4 pagesJSA - Electrical Testing - Circuit Breaker Field TestTawfik Mohamed Abu Zaid0% (1)

- Job Hazard Assessment For Cable TestingDocument4 pagesJob Hazard Assessment For Cable TestingSamuel Carlos100% (2)

- Job Hazard Analysis For Crane DismantlingDocument2 pagesJob Hazard Analysis For Crane DismantlingKamlesh Bule Lonari100% (2)

- JSA Cable Laying PDFDocument2 pagesJSA Cable Laying PDFManoj WaskelNo ratings yet

- Job Safety Analysis Sheet: Electrical IsolationDocument1 pageJob Safety Analysis Sheet: Electrical IsolationLal Dhwoj67% (3)

- JSA InsulationDocument8 pagesJSA InsulationOlavilam Prakash100% (3)

- Jsa For Civil Confined Space EntryDocument11 pagesJsa For Civil Confined Space EntryKhuda BukshNo ratings yet

- Jsa Cable TerminationDocument4 pagesJsa Cable TerminationSyed Yousuf Ali100% (1)

- JHA Manual Excavation For Cable TrenchDocument5 pagesJHA Manual Excavation For Cable TrenchNasrullah Jan100% (5)

- Copy (2) of JSA For Removal of MS Sheet For E&P ShedDocument12 pagesCopy (2) of JSA For Removal of MS Sheet For E&P Shedmidozoty50% (2)

- Hope and Other Dangerous Pursuits - Discussion GuideDocument4 pagesHope and Other Dangerous Pursuits - Discussion GuideHoughton Mifflin Harcourt0% (2)

- JSA Cable DisconnectedDocument4 pagesJSA Cable Disconnectedwendypost730% (1)

- Jsa. Cable Laying and TerminationDocument10 pagesJsa. Cable Laying and TerminationMon Trang NguyễnNo ratings yet

- Job Safety Analysis Worksheet: Yes NoDocument8 pagesJob Safety Analysis Worksheet: Yes NoBorislav VulićNo ratings yet

- JSA Ladders Working at Heights 001Document2 pagesJSA Ladders Working at Heights 001Raman SawNo ratings yet

- Job Safety Analysis: Cable Jointing & Termination in Wind TurbinesDocument1 pageJob Safety Analysis: Cable Jointing & Termination in Wind TurbinesPerwez2186% (7)

- 004 Annexure D Job Safety SAnalysis JSADocument3 pages004 Annexure D Job Safety SAnalysis JSAAvoor Khan75% (4)

- JSA No. 9 - Safe Use of Pneumatic and Power ToolsDocument2 pagesJSA No. 9 - Safe Use of Pneumatic and Power ToolsAshok Suresh100% (1)

- JSA E&I 10.electrical Instrument Panels RemovalDocument3 pagesJSA E&I 10.electrical Instrument Panels RemovalAmyNo ratings yet

- JSA For Concrete WorkDocument6 pagesJSA For Concrete Worklê ngọc tùng0% (1)

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- Jha Energize Distribution DBDocument1 pageJha Energize Distribution DBAhmad Zahir100% (2)

- JSA-Loading-Offloading of Chemical Products With ForkliftDocument4 pagesJSA-Loading-Offloading of Chemical Products With ForkliftMajdiSahnoun100% (2)

- JSA - Repair-Coating and Finition WorkDocument3 pagesJSA - Repair-Coating and Finition WorkAMIN100% (1)

- JSA-Loading-Offloading of Chemical Products With ForkliftDocument4 pagesJSA-Loading-Offloading of Chemical Products With ForkliftMajdiSahnoun100% (2)

- Battery FillingDocument3 pagesBattery FillingMajdiSahnounNo ratings yet

- Electrical InstallationDocument3 pagesElectrical InstallationWalid KhelfaNo ratings yet

- Jsa-Ht & LT Panel InstallationDocument1 pageJsa-Ht & LT Panel Installationpushpanath reddy100% (2)

- Up Dated Job Safety Analysis-Gypsum Plastering WorksDocument12 pagesUp Dated Job Safety Analysis-Gypsum Plastering WorksAkhtar Ali100% (1)

- Jsa For The Installation of I EamDocument5 pagesJsa For The Installation of I EamMohammed MinhajNo ratings yet

- JSA Electrical WiringDocument10 pagesJSA Electrical WiringWeru Morris100% (1)

- JSA Template 2017-05-31 Cable Tray InstallationDocument19 pagesJSA Template 2017-05-31 Cable Tray InstallationJayvee Baradas ValdezNo ratings yet

- EF 1931-STCC-JSA-33 Fire Proofing of The Steel Structure and Vessel Foun...Document5 pagesEF 1931-STCC-JSA-33 Fire Proofing of The Steel Structure and Vessel Foun...Anis Uddin100% (2)

- Jha - Transformer Installation PDFDocument6 pagesJha - Transformer Installation PDFperquino oasan0% (1)

- Cable Pulling / Laying, Glanding and Termination SOP: Task Risk AssessmentDocument23 pagesCable Pulling / Laying, Glanding and Termination SOP: Task Risk AssessmentMon Trang Nguyễn100% (2)

- Safe Plan of Action Ramsu EnterpriseDocument5 pagesSafe Plan of Action Ramsu EnterpriseSanjeev Kumar100% (1)

- DLF PCC HiraDocument6 pagesDLF PCC HiraskfahimuddinNo ratings yet

- JSA For SealantDocument11 pagesJSA For SealantdipmipNo ratings yet

- JSA E&I 4.earthing Bonding InstallationDocument3 pagesJSA E&I 4.earthing Bonding InstallationAmyNo ratings yet

- JSA Earthpit Construction GeneralDocument4 pagesJSA Earthpit Construction Generalmukka88No ratings yet

- JSA Transformer InstallationDocument1 pageJSA Transformer Installationpushpanath reddyNo ratings yet

- JSA 150 Trench Excavation Backfilling Berming & Sand Removal KRT-2 KM 104 - 108Document10 pagesJSA 150 Trench Excavation Backfilling Berming & Sand Removal KRT-2 KM 104 - 108Zubair Khan100% (1)

- EEEPL - JSA Light Fitting ErectionDocument6 pagesEEEPL - JSA Light Fitting ErectionnishanthNo ratings yet

- JSA FOR Using The LadderDocument4 pagesJSA FOR Using The Laddertnssbhaskar100% (1)

- JSA Unloading & SHIFTING by Manually 10-01-2017Document16 pagesJSA Unloading & SHIFTING by Manually 10-01-2017PAVANKUMAR100% (1)

- JHA Chain HoistDocument1 pageJHA Chain HoistKrishna Patil100% (2)

- 003-JSA Pipe Loading and OffloadingDocument8 pages003-JSA Pipe Loading and OffloadingMoaatazz NouisriNo ratings yet

- JSA GC-5 Mobile ScaffoldingDocument6 pagesJSA GC-5 Mobile Scaffoldinggrande100% (2)

- Installation of Pannel JSADocument6 pagesInstallation of Pannel JSAOFFSHORE OFFSITENo ratings yet

- HV Cable Termination: Standard Work Method StatementDocument6 pagesHV Cable Termination: Standard Work Method StatementOsama SharafNo ratings yet

- JSP For AsphaltDocument8 pagesJSP For Asphaltmohammed tofiqNo ratings yet

- JSA For Electrical ActivitiesDocument14 pagesJSA For Electrical Activitiesdrparihary100% (3)

- JSA FOR Moving and Handling MaterialsDocument3 pagesJSA FOR Moving and Handling Materialswahyu nugrohoNo ratings yet

- Jsa forOperatingAForkliftDocument2 pagesJsa forOperatingAForkliftsupahing supahingNo ratings yet

- JSA 04 Confined Sapce EntryDocument1 pageJSA 04 Confined Sapce Entrywahyu nugrohoNo ratings yet

- JSA-Visual Inspection and Ultrasonic Thickness Measurement On Pressure VesselsDocument2 pagesJSA-Visual Inspection and Ultrasonic Thickness Measurement On Pressure VesselsMajdiSahnoun100% (1)

- Job Safety Analysis: Required References Jsa ReviewDocument3 pagesJob Safety Analysis: Required References Jsa ReviewMajdiSahnounNo ratings yet

- HVAC Fans Initial Energisation Battery RoomDocument3 pagesHVAC Fans Initial Energisation Battery RoomMajdiSahnounNo ratings yet

- HVAC Fans Initial Energisation Battery RoomDocument3 pagesHVAC Fans Initial Energisation Battery RoomMajdiSahnoun0% (1)

- CPF-JSA-018 Drilling and Pipes Support Erection ZONE CLASS0Document5 pagesCPF-JSA-018 Drilling and Pipes Support Erection ZONE CLASS0MajdiSahnounNo ratings yet

- JSA-054 Crossing WorksDocument6 pagesJSA-054 Crossing WorksMajdiSahnounNo ratings yet

- Jsa-046 Highway Crossing and Steel CasingDocument11 pagesJsa-046 Highway Crossing and Steel CasingMajdiSahnounNo ratings yet

- Job Safety Analysis: Required References Jsa ReviewDocument3 pagesJob Safety Analysis: Required References Jsa ReviewMajdiSahnounNo ratings yet

- JSA-Visual Inspection and Ultrasonic Thickness Measurement On Pressure VesselsDocument2 pagesJSA-Visual Inspection and Ultrasonic Thickness Measurement On Pressure VesselsMajdiSahnoun100% (1)

- JSA For Hydro Test Activites GenericDocument4 pagesJSA For Hydro Test Activites GenericMajdiSahnounNo ratings yet

- Annex 17 - Induction Nawara ProjDocument18 pagesAnnex 17 - Induction Nawara ProjMajdiSahnounNo ratings yet

- Nawara Project - Introduction of Positive Pressure Hazards and ControlsDocument1 pageNawara Project - Introduction of Positive Pressure Hazards and ControlsMajdiSahnounNo ratings yet

- Harc OffshoreDocument5 pagesHarc OffshoreMajdiSahnounNo ratings yet

- HVAC Fans Initial Energisation Battery RoomDocument3 pagesHVAC Fans Initial Energisation Battery RoomMajdiSahnoun0% (1)

- Harc Snoop Test OperationDocument7 pagesHarc Snoop Test OperationMajdiSahnounNo ratings yet

- Battery FillingDocument3 pagesBattery FillingMajdiSahnounNo ratings yet

- HVAC Fans Initial Energisation Battery RoomDocument3 pagesHVAC Fans Initial Energisation Battery RoomMajdiSahnounNo ratings yet

- Lorenzo v. Posadas Case DigestDocument2 pagesLorenzo v. Posadas Case DigestPatrick Anthony Llasus-NafarreteNo ratings yet

- ECO402 Solved Mid Term Corrected by Suleyman KhanDocument15 pagesECO402 Solved Mid Term Corrected by Suleyman KhanSuleyman KhanNo ratings yet

- First Sunday MassDocument3 pagesFirst Sunday MassRONALD ESCABALNo ratings yet

- Nota Hbet1403Document3 pagesNota Hbet1403Encik Emjaywai100% (1)

- Hoërskool Roodepoort: COVID-19 PolicyDocument24 pagesHoërskool Roodepoort: COVID-19 PolicyScarfacembali MbaliNo ratings yet

- Advances in Accounting, Incorporating Advances in International AccountingDocument14 pagesAdvances in Accounting, Incorporating Advances in International AccountingWihl Mathew ZalatarNo ratings yet

- Preference Shares - January 11 2017Document1 pagePreference Shares - January 11 2017Tiso Blackstar GroupNo ratings yet

- Android Update For SAMSUNG Galaxy Tab 7.0 Plus (GT-P6200) - Android Updates DownloadsDocument5 pagesAndroid Update For SAMSUNG Galaxy Tab 7.0 Plus (GT-P6200) - Android Updates DownloadsJoeJojoNo ratings yet

- A Catholic Framework For Economic LifeDocument3 pagesA Catholic Framework For Economic LifeAnonymousNo ratings yet

- Creative Sparks of Innovations - Part 3Document95 pagesCreative Sparks of Innovations - Part 3Justin NilanjanNo ratings yet

- Disaster Waste Management in Malaysia: Significant Issues, Policies & StrategiesDocument7 pagesDisaster Waste Management in Malaysia: Significant Issues, Policies & Strategiesmuhamadrafie1975No ratings yet

- Assignment 3 Group 6 (Ta19171, Ta19092, Ta19160, Ta19121, Ta19120)Document6 pagesAssignment 3 Group 6 (Ta19171, Ta19092, Ta19160, Ta19121, Ta19120)kameeneNo ratings yet

- BrochureDocument7 pagesBrochureapi-596896646No ratings yet

- My Musical Instrument Book BDocument9 pagesMy Musical Instrument Book BGIPSYNo ratings yet

- Henry FieldingDocument12 pagesHenry FieldingMary Rose BaluranNo ratings yet

- Transferance of SpiritsDocument13 pagesTransferance of SpiritsMiracle Internet Church50% (2)

- SRC, Ppsa, LocDocument7 pagesSRC, Ppsa, LocKLNo ratings yet

- Kosambi Marxism and Indian HistoryDocument4 pagesKosambi Marxism and Indian Historyroopeshkappy9315No ratings yet

- Notice No. 08-2022 2nd Phase of Advt. No. 02-2022Document10 pagesNotice No. 08-2022 2nd Phase of Advt. No. 02-2022Sagar KumarNo ratings yet

- Greeting Lesson PlanDocument4 pagesGreeting Lesson Planhawanur266No ratings yet

- 07 MalnutritionDocument132 pages07 MalnutritionMary Marjorie RodaviaNo ratings yet

- MC 4 Inventory A201 StudentDocument5 pagesMC 4 Inventory A201 Studentlim qsNo ratings yet

- Analyzing The External Environment of The FirmDocument16 pagesAnalyzing The External Environment of The FirmPrecious JirehNo ratings yet

- Holy Eucharist - PotDocument19 pagesHoly Eucharist - PotMargie CalumpitNo ratings yet

- Magellan International Corp. v. Salzgitter Handel GMBHDocument10 pagesMagellan International Corp. v. Salzgitter Handel GMBHNga DinhNo ratings yet

- Cre Form 1 2020 Schemes of WorkDocument12 pagesCre Form 1 2020 Schemes of Worklydia mutuaNo ratings yet

- Wire-And Strand-Wound Circular, Prestressed Concrete Water TanksDocument72 pagesWire-And Strand-Wound Circular, Prestressed Concrete Water TanksarminmandalNo ratings yet

- Idioms To Describe People: Match Up The Words and Definitions. Write Your Answers Boxes BelowDocument1 pageIdioms To Describe People: Match Up The Words and Definitions. Write Your Answers Boxes BelowzuperNo ratings yet