Professional Documents

Culture Documents

Pipe Flushing and Inspection

Pipe Flushing and Inspection

Uploaded by

RajOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipe Flushing and Inspection

Pipe Flushing and Inspection

Uploaded by

RajCopyright:

Available Formats

ENGINEERING & PROJECT MANAGEMENT CONSULTANCY FOR

CREATION OF FIELD GAS GATHERING STATION (FGGS) AT

BAGHJAN IN UPPER ASSAM FOR OIL INDIA LTD

SPECIFICATION FOR INSPECTION, FLUSHING AND TESTING OF

PIPING

OIL INDIA

JPEC DOC.NO.:FGGS-BJN-PIP-SPC-5002 REV.0 DATE:20-06-19 Page 1 of 8

LIMITED

LY

N

O

E

S

O

SPECIFICATION FOR INSPECTION, FLUSHING AND

P

TESTING OF PIPING

R

U

P

R

E

D

N

E

T

R

FO

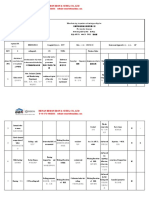

A Issued for ITB 20-06-19 AF RD KPM

A Issued for Information 20-03-19 AF RD KPM

REV. DESCRIPTION DATE BY CHECKED APPROVED CLIENT

Page 1071 of 2248

ENGINEERING & PROJECT MANAGEMENT CONSULTANCY FOR

CREATION OF FIELD GAS GATHERING STATION (FGGS) AT

BAGHJAN IN UPPER ASSAM FOR OIL INDIA LTD

SPECIFICATION FOR INSPECTION, FLUSHING AND TESTING OF

PIPING

OIL INDIA

JPEC DOC.NO.:FGGS-BJN-PIP-SPC-5002 REV.0 DATE:20-06-19 Page 2 of 8

LIMITED

TABLE OF CONTENTS

1.0 SCOPE ................................................................................................................................. 3

2.0 INSPECTION ........................................................................................................................ 3

3.0 FLUSHING ............................................................................................................................ 3

4.0 TESTING............................................................................................................................... 4

LY

4.1 Extent of Testing ................................................................................................................. 4

N

O

4.2 General Requirements / Test Preparation for Testing ...................................................... 5

E

4.3 Testing Media, Test Pressure and Test Pressure Gauges................................................ 6

S

O

4.4 Testing Procedure ............................................................................................................... 7

P

R

U

P

R

E

D

N

E

T

R

FO

Page 1072 of 2248

ENGINEERING & PROJECT MANAGEMENT CONSULTANCY FOR

CREATION OF FIELD GAS GATHERING STATION (FGGS) AT

BAGHJAN IN UPPER ASSAM FOR OIL INDIA LTD

SPECIFICATION FOR INSPECTION, FLUSHING AND TESTING OF

PIPING

OIL INDIA

JPEC DOC.NO.:FGGS-BJN-PIP-SPC-5002 REV.0 DATE:20-06-19 Page 3 of 8

LIMITED

1.0 SCOPE

This specification covers the general requirements for inspection, flushing and testing of

piping systems.

Flushing and testing of all piping systems shall be witnessed by the Engineer-in Charge.

2.0 INSPECTION

During various stages and after completion of fabrication and erection, the piping system

shall be inspected by the Engineer-in-charge to ensure that:-

LY

Ø Proper piping material has been used.

N

Ø Piping has been erected as per drawings and instructions of Engineer-in-Charge.

O

Ø All supports have been installed, correctly as per the pipe support index and

E

instructions of Engineer-in-Charge.

Ø

S

Test preparations mentioned in this specification have been carried out.

O

P

3.0 FLUSHING

R

Flushing of all lines shall be done before pressure testing.

U

P

Flushing shall be done by fresh potable water or dry compressed air, wherever water

flushing is not desirable, to clean the pipe of all dirt, debris or loose foreign material.

R

E

In line instruments like control valves, orifice plates, rotameters, safety valves and other

D

instruments like thermo wells which may interfere with flushing instrument shall not be

N

included in flushing circuit

E

Required pressure for water flushing shall meet the fire hydrant pressure or utility water

T

pressure.

R

For air flushing the line / system will be pressurized by compressed air at the required

FO

pressure but to a maximum of 50 psig. The pressure shall then be released by quick

opening of a valve, already in line or installed temporarily for this purpose. This procedure

shall be repeated as many times till inside of the pipe are fully cleaned.

During flushing temporary strainers shall be retained. These shall be removed, cleaned

and reinstalled after flushing but before testing.

From all permanent strainers the screens / meshes shall be removed before flushing.

Screen / meshes shall be reinstalled after flushing out and before testing.

In case equipment such as column, vessel, exchanger etc. forms part of a piping circuit

during flushing, this shall be done with the approval of Engineer-in-Charge. However

equipments thus included in the circuit, shall be completely drained and dried with

compressed air, after flushing is completed.

During flushing discharged water / air shall be drained to the places directed by the

Engineer-in-Charge. If necessary, proper temporary drainage shall be provided by the

contractor.

The contractor shall carry out all the activities required before, during and after the flushing

operation, arising because of flushing requirements, such as but not limited to the

Page 1073 of 2248

ENGINEERING & PROJECT MANAGEMENT CONSULTANCY FOR

CREATION OF FIELD GAS GATHERING STATION (FGGS) AT

BAGHJAN IN UPPER ASSAM FOR OIL INDIA LTD

SPECIFICATION FOR INSPECTION, FLUSHING AND TESTING OF

PIPING

OIL INDIA

JPEC DOC.NO.:FGGS-BJN-PIP-SPC-5002 REV.0 DATE:20-06-19 Page 4 of 8

LIMITED

following:

Dropping of valves, specials, distance pieces, inline instruments and any other piping parts

as may be necessary before flushing. The flanges to be disengaged for this purpose shall

be envisaged by the contractor and approved by the Engineer-in-Charge. These flanges

shall be provided with temporary gaskets at the time of flushing.

Care shall be taken during flushing so as not to damage / spoil work of other agencies.

Precautions shall also be taken to prevent entry of water, foreign matter into equipments,

electric motors, instruments electrical installations etc.in the vicinity of lines being flushed.

LY

Records in triplicate shall be prepared and submitted by the contractor for each piping

N

system for the flushing done.

O

4.0 TESTING

E

4.1 Extent of Testing:-

S

O

With the exclusion of instrumentation, piping systems fabricated or assembled in the field

P

shall be tested irrespective of whether or not they have been pressure tested prior to site

R

welding of fabrication.

U

To facilitate the testing of piping systems, vessels and other equipments may be included

P

in the system with the prior approval of Engineer-in-Charge if the test pressure specified is

R

equal to or less than that for the vessels and other equipments.

E

Pumps, compressors and other rotary equipments shall not be subjected to field test

D

pressure.

N

E

Lines which are directly open to atmosphere such as vents, drains, safety valves

T

discharge need not be pressure tested, but all joints shall be visually inspected. Such line

shall be tested by continuous flow of fluid to eliminate the possibility of blockade.

R

However, such lines if provided with block valve shall be pressure tested up to the first

FO

block valve.

Seats of all valves shall not be subjected to a pressure in excess of the maximum cold

working pressure of the valve. Test pressure applied to valves shall not be greater than

the manufacturer’s recommendation nor less than that required by the applicable code.

Where allowable seat pressure is less than test pressure, test shall be made through an

open valve.

Instruments in the system to be tested shall be excluded from the test by isolation or

removals, unless approved otherwise by the Engineer-in-Charge.

Restrictions, which interfere with filling, venting and draining such as orifice plates etc.

shall not be installed unless testing is complete.

Control valves shall not be included in the test system. Where bypasses are provided test

shall be performed through the bypass end / or necessary spool shall be used in place of

control valve.

Pressure gauges, which are part of the finished system, but cannot withstand test pressure

shall not be installed until the system has been tested. Where piping systems to be tested

are directly connected at the battery limits to piping for which the responsibility rests with

Page 1074 of 2248

ENGINEERING & PROJECT MANAGEMENT CONSULTANCY FOR

CREATION OF FIELD GAS GATHERING STATION (FGGS) AT

BAGHJAN IN UPPER ASSAM FOR OIL INDIA LTD

SPECIFICATION FOR INSPECTION, FLUSHING AND TESTING OF

PIPING

OIL INDIA

JPEC DOC.NO.:FGGS-BJN-PIP-SPC-5002 REV.0 DATE:20-06-19 Page 5 of 8

LIMITED

other agencies, the piping to be tested shall be isolated from such piping by physical

disconnection such as valve or blinds.

4.2 General Requirements / Test Preparation for Testing:-

Testing shall be carried out with permanent gaskets installed unless specified otherwise or

instructed by the Engineer-in-Charge.

No pressure test shall be carried out against close valve unless approved by the Engineer-

in-Charge.

LY

The Engineer-in-Charge shall be notified in advance by the contractor of the testing

sequence and programme, to enable him to be present for witnessing the test.

N

O

Before testing, all piping shall be cleaned by flushing to make it free from dirt, loose scale,

debris and other loose foreign materials.

E

S

All piping systems to be hydrostatically tested shall be vented at the high points and the

O

systems purged of air before the test pressure is applied.

P

Wherever in the line any void is existing due to any reasons, for absence of control valves,

R

safety valves, check valves etc. it shall be filled with temporary spools.

U

All joints welded, screwed or flanged shall be left exposed for examination during the test.

P

Before pressurizing the lines, each weld joints shall be cleaned by wire brush to free it from

R

rust and any other foreign matter.

E

Where a system is to be isolated at a pair of companion flanges, a blank shall be inserted

D

between the companion flanges. Minimum thickness of the blank shall be designed in

N

accordance with applicable design code.

E

T

Open ends of piping system where blanks cannot be used, such as pumps, compressors,

turbines or whenever equipment or pipe spool have been recovered or disconnected prior

R

to hydrostatic testing, shall be blinded-off by using standard blind flanges of same rating as

FO

the piping system being tested.

Pressure gauges used in testing shall be installed as close as possible to the lowest point

in the piping system to be tested, to avoid overstressing of any of the lower portion of the

system. For longer lines and vertical lines, two or more pressure gauges shall be installed

at locations decided by the Engineer-in-Charge.

For lines containing check valves any of the following alternatives shall be adopted for

pressure testing:

Whenever possible pressurize up-stream side of valve.

Replace the valve by temporary spools and reinstall the valve after testing.

Provide blind on valve flanges and test the upstream and downstream of the line

separately and remove the blind after testing. At these flanges, temporary gaskets shall

be provided during testing and shall be replaced by permanent gaskets subsequently.

For check valves in lines 1 ½” and below flapper or seat shall be removed during testing (if

possible). After completion of testing the flapper / seat shall be refitted.

Page 1075 of 2248

ENGINEERING & PROJECT MANAGEMENT CONSULTANCY FOR

CREATION OF FIELD GAS GATHERING STATION (FGGS) AT

BAGHJAN IN UPPER ASSAM FOR OIL INDIA LTD

SPECIFICATION FOR INSPECTION, FLUSHING AND TESTING OF

PIPING

OIL INDIA

JPEC DOC.NO.:FGGS-BJN-PIP-SPC-5002 REV.0 DATE:20-06-19 Page 6 of 8

LIMITED

Gas lines when hydrostatically tested shall be provided with additional temporary supports

during testing as directed by the Engineer-in-Charge.

Piping which is spring or counter – weight supported shall be temporarily supported, where

the weight of the fluid would overload the support. Retaining pins for spring supports shall

be removed only after testing is completed and test fluid is completely drained.

When testing any piping system, air or steam of approximately 2 Kg / Sq. cm (g) may be

used as preliminary test to detect missing gaskets etc. as this avoids the necessity of

draining the line to make repairs. However, steam shall not be used for this purpose, if the

LY

steam temperature is more than the design temperature of the line.

N

For jacketed pipes, testing of core pipes shall be done on individual pieces before welding

O

the closure joint of the outer jacket. The outer jacket shall be tested separately as

separate continuous system.

E

S

4.3 Testing Media, Test Pressure and Test Pressure Gauges:-

O

4.3.1 Testing Media:-

P

In general all pressure tests shall be hydrostatic using Iron free water, which is clean and

R

free of silt. Maximum Chlorine content in water for hydrostatic testing for SS piping shall be

U

10 – 20 ppm.

P

Air shall be used for testing only if water would cause corrosion of the system or

R

overloading of supports etc. in special cases as directed by Engineer-in-Charge.

E

D

Where air / water test are undesirable substitute fluid such as gas, oil, kerosene, methanol

N

etc. shall be used as the testing medium, with due consideration to the hazards involved.

E

These test fluids shall be specified in the line list given to the contractor.

T

4.3.2 Test Pressure:-

R

The hydrostatic / pneumatic test pressure shall be as indicated in the line list or as per the

FO

instruction of Engineer-in-Charge.

The selection of the piping system for one individual test shall be based on the following:

Test pressure required as per line list.

Maximum allowable pressure for the material of construction of piping.

Depending upon the above requirements and based on construction progress, maximum

length of piping shall be included in each test.

4.3.3 Test Pressure Gauge:-

All gauges used for field-testing shall have suitable range so that the test pressure of the

various systems falls in 40% to 80% of gauge scale range. Gauge shall be of a good

quality and in first class working condition.

Prior to the start of any test or periodically during the field test program, all test gauges

shall be calibrated using a standard dead weight gauge tester or other suitable approved

testing apparatus. Any gauge showing an incorrect zero reading or error of more than

± 2% of full-scale range shall be discarded. The Engineer-in-Charge shall check the

accuracy of master pressure gauge used for calibration.

Page 1076 of 2248

ENGINEERING & PROJECT MANAGEMENT CONSULTANCY FOR

CREATION OF FIELD GAS GATHERING STATION (FGGS) AT

BAGHJAN IN UPPER ASSAM FOR OIL INDIA LTD

SPECIFICATION FOR INSPECTION, FLUSHING AND TESTING OF

PIPING

OIL INDIA

JPEC DOC.NO.:FGGS-BJN-PIP-SPC-5002 REV.0 DATE:20-06-19 Page 7 of 8

LIMITED

4.4 Testing Procedure:-

4.4.1 Hydrostatic Test:-

All vents and other connections used as vents shall be left open while filling the line with

test fluid for complete removal of air. In all lines for pressurizing and depressurizing the

system, temporary isolating valves shall be provided if valve vents, drains do not exist in

the system.

Pressure shall be applied only after the system / line is ready and approved by the

LY

Engineer-in-Charge.

Pressure shall be applied by means of suitable test pump or other pressure source which

N

shall be isolated from the system as soon as test pressure is reached and stabilized.

O

A pressure gauge shall be provided at the pump discharge for guidance in bringing the

E

system to the required pressure.

S

O

The pump shall be attended constantly during the test by an authorized person. The pump

shall be isolated from the system whenever the pump is to be left unattended.

P

R

Test pressure shall be maintained for a sufficient length of time to permit through

U

inspection of all joints for leakage or signs of failure. Any joint found leaking during a

P

pressure test should be retested to the specified pressure after repair. Test period shall be

maintained for a minimum of three hours.

R

E

The pumps and the piping system to be tested are to be provided with separate pressure

D

indicating test gauges. These gauges are to be checked by the standard test gauge

N

before each pressure test.

E

Care shall be taken to avoid increase in the pressure due to temperature variation during

T

the test.

R

4.4.2 Air Test:-

FO

When testing with air, pressure shall be supplied by means of a compressor. The

compressor shall be portable type with receiver, after cooler and oil separator.

Piping to be tested by air shall have joints covered with a soap and water solution so that

the joints can be examined for leaks.

All other details shall be same as per hydro testing procedure (specified above).

4.5 Completion of Testing:-

After the hydrostatic test has been completed, pressure shall be released in a manner and

at a rate so as not to endanger personnel or damage equipments.

All vents and drains shall be opened before the system is to be drained and shall remain

open till all draining is complete, so as to prevent formation of vacuum in the system. After

draining, lines / systems shall be dried by air.

After testing is completed the test blinds shall be removed and equipment / piping isolated

during testing shall be connected using the specified gaskets, bolts and nuts. This

connection shall be checked for lightness in subsequent pneumatic tests to be carried out

by the contractor for complete loop / circuit including equipments (except rotary

Page 1077 of 2248

ENGINEERING & PROJECT MANAGEMENT CONSULTANCY FOR

CREATION OF FIELD GAS GATHERING STATION (FGGS) AT

BAGHJAN IN UPPER ASSAM FOR OIL INDIA LTD

SPECIFICATION FOR INSPECTION, FLUSHING AND TESTING OF

PIPING

OIL INDIA

JPEC DOC.NO.:FGGS-BJN-PIP-SPC-5002 REV.0 DATE:20-06-19 Page 8 of 8

LIMITED

equipments).

Pressure test shall be considered complete only after approval by the Engineer-in Charge.

Defects, if any, noticed during testing shall be rectified immediately and retesting of the

system / line shall be done by the contractor at his cost.

4.6 Test Records:-

Records in quadruplicate shall be prepared and submitted by the contractor for each piping

system, for the pressure test done.

LY

N

O

E

S

O

P

R

U

P

R

E

D

N

E

T

R

FO

Page 1078 of 2248

ENGINEERING & PROJECT MANAGEMENT CONSULTANCY FOR

CREATION OF FIELD GAS GATHERING STATION (FGGS) AT

BAGHJAN IN UPPER ASSAM FOR OIL INDIA LTD

SPECIFICATION FOR PAINTING

OIL INDIA

JPEC DOC.NO.:FGGS-BJN-PIP-SPC-5004 REV.0 DATE:20-06-19 Page 1 of 51

LIMITED

LY

N

O

E

S

O

P

R

SPECIFICATION FOR PAINTING

U

P

R

E

D

N

E

T

R

FO

0 Issued for ITB 20-06-19 AF RD KPM

Issued for

A 10-04-19 AF RD KPM

Review/Approval

REV. DESCRIPTION DATE BY CHECKED APPROVED CLIENT

Page 1079 of 2248

ENGINEERING & PROJECT MANAGEMENT CONSULTANCY FOR

CREATION OF FIELD GAS GATHERING STATION (FGGS) AT

BAGHJAN IN UPPER ASSAM FOR OIL INDIA LTD

SPECIFICATION FOR PAINTING

OIL INDIA

JPEC DOC.NO.:FGGS-BJN-PIP-SPC-5004 REV.0 DATE:20-06-19 Page 2 of 51

LIMITED

TABLE OF CONTENTS

1.0 GENERAL .......................................................................................................................3

2.0 SCOPE............................................................................................................................3

3.0 REFERENCE CODES & STANDARDS ..........................................................................5

LY

4.0 EQUIPMENT ...................................................................................................................6

N

5.0 SURFACE PREPARATION, SHOP PRIMER / COATING APPLICATION, REPAIR AND

O

DOCUMENTATION.........................................................................................................6

E

S

6.0 PAINT MATERIALS ......................................................................................................14

O

P

7.0 COATING SYSTEMS ....................................................................................................19

R

8.0 STORAGE .....................................................................................................................37

U

P

9.0 COLOUR CODE ...........................................................................................................37

R

E

10.0 IDENTIFICATION OF VESSELS, PIPING ETC. ............................................................46

D

N

11.0 PAINTING FOR CIVIL DEFENCE REQUIREMENTS ...................................................47

E

T

12.0 QUALITY CONTROL, INSPECTION AND TESTING....................................................47

R

13.0 GUARANTEE................................................................................................................51

FO

Page 1080 of 2248

You might also like

- Sid Su 5106 CDocument13 pagesSid Su 5106 ColalekanNo ratings yet

- STS Qac Sop 002 Heat Exchanger Retubing ProcedureDocument4 pagesSTS Qac Sop 002 Heat Exchanger Retubing Proceduremohd as shahiddin jafri50% (2)

- B24-Fabircaition and Erection of PipingDocument12 pagesB24-Fabircaition and Erection of PipingRajNo ratings yet

- Itp For All MaterialsDocument59 pagesItp For All MaterialsTauqueerAhmad100% (2)

- A286 GIGLM 1004 PJ DOC QAR R 0006 Welding ConsumableDocument8 pagesA286 GIGLM 1004 PJ DOC QAR R 0006 Welding ConsumableMahesh PanditNo ratings yet

- CT - PT MQPDocument12 pagesCT - PT MQPGnanavel GNo ratings yet

- PGRI-00-N1-PR-006 Painting Procedure Rev ADocument69 pagesPGRI-00-N1-PR-006 Painting Procedure Rev ASendy MaulanaNo ratings yet

- Approved ITP - RTN - VS215B-101-A-PLN-7001 - 05 - Code ADocument131 pagesApproved ITP - RTN - VS215B-101-A-PLN-7001 - 05 - Code ALionell Logesh0% (1)

- Generator Commissioning Procedure PDFDocument19 pagesGenerator Commissioning Procedure PDFkvrao44No ratings yet

- Weekly Report For Shutdown Valve - Rev 0 15 Jan 2023Document10 pagesWeekly Report For Shutdown Valve - Rev 0 15 Jan 2023Andy ArdianNo ratings yet

- Vedanta: Vedanta L Mited C O GasDocument13 pagesVedanta: Vedanta L Mited C O GasfirozNo ratings yet

- Radiographic Testing ProcedureDocument28 pagesRadiographic Testing ProcedureAbdulrahman TahaNo ratings yet

- 1922A691OO ANG 52 CI CCS 1002 - VariousPitCalculationSP998 - Rev0Document90 pages1922A691OO ANG 52 CI CCS 1002 - VariousPitCalculationSP998 - Rev0Didi Hadi RiantoNo ratings yet

- PC-6 Pim 01820 R08 PDFDocument80 pagesPC-6 Pim 01820 R08 PDFfrancescosalsa100% (2)

- ITP For Injection Work of Basement Walls: King Abdullah Financial District (KAFD) Cluster J1Document5 pagesITP For Injection Work of Basement Walls: King Abdullah Financial District (KAFD) Cluster J1amirskbkbk0% (1)

- ภาคผนวก ข-26 Tie-In ProcedureDocument47 pagesภาคผนวก ข-26 Tie-In ProcedureOPAZOSCNo ratings yet

- U2004-015-JUV-JQ01-T0676 - MS For Field Instrument Ins. Rev.1FDocument79 pagesU2004-015-JUV-JQ01-T0676 - MS For Field Instrument Ins. Rev.1FTenri DimitriNo ratings yet

- Ione-Aa00-Ms-In-0003 Method Statement For Instrument Loop Test - Rev. 2Document35 pagesIone-Aa00-Ms-In-0003 Method Statement For Instrument Loop Test - Rev. 2Sazzad Ahmad SiddiqueNo ratings yet

- 8.product Characteristics Matrix 4482 - 370 - 016 - DES001Document1 page8.product Characteristics Matrix 4482 - 370 - 016 - DES001BHUSHANNo ratings yet

- PR For BV - NON-METALLIC - R0 - DIGHADocument6 pagesPR For BV - NON-METALLIC - R0 - DIGHADipali DaveNo ratings yet

- 6-44-0016mmmmmmrev 4Document1 page6-44-0016mmmmmmrev 4Sumantrra ChattopadhyayNo ratings yet

- Technical Specification For Foam Pump - Panki - 29082020 1599141527Document157 pagesTechnical Specification For Foam Pump - Panki - 29082020 1599141527irshadNo ratings yet

- Expansion Tank Data SheetDocument5 pagesExpansion Tank Data Sheetabdul azizNo ratings yet

- Api 0011PGTDocument75 pagesApi 0011PGTjuniorferrari06No ratings yet

- Instrument CableDocument29 pagesInstrument Cablegalih santoso100% (1)

- SNO-P-ES-009 Specification For Precomm Cleaning of Piping System Rev - 0Document11 pagesSNO-P-ES-009 Specification For Precomm Cleaning of Piping System Rev - 0Langit GanjarNo ratings yet

- Attach Information On Compliance of Emissions WitDocument3 pagesAttach Information On Compliance of Emissions WitroyalepalacekaraikalNo ratings yet

- Ione VP 14 P 102ab 001 - 1Document8 pagesIone VP 14 P 102ab 001 - 1ضياء محمدNo ratings yet

- NPK 000 Q2 in 6001 K Rev 3 Field Inspection and Test Procedure ADocument15 pagesNPK 000 Q2 in 6001 K Rev 3 Field Inspection and Test Procedure ADangolNo ratings yet

- 27964E00Document14 pages27964E00Ua AnyanhunNo ratings yet

- SGBP-P1-CAL-003 Test Package Assignment - Rev 0-19-10-2023 SignDocument18 pagesSGBP-P1-CAL-003 Test Package Assignment - Rev 0-19-10-2023 Signanis.fuad2501No ratings yet

- Technical Guideline For Coating Selection For Line Pipes, Bends and RisersDocument23 pagesTechnical Guideline For Coating Selection For Line Pipes, Bends and RisersMohamed GhonaimNo ratings yet

- FCPG-00000-CPP143-00-QA-6050-00011-002 - RT ProcedureDocument19 pagesFCPG-00000-CPP143-00-QA-6050-00011-002 - RT Procedurem.rasheed400010No ratings yet

- PJ-0231-004-IMA-6002-22-0 (Restriction Orifice Plates)Document2 pagesPJ-0231-004-IMA-6002-22-0 (Restriction Orifice Plates)Construction Projects100% (1)

- PRGR 00 Ins Cal 002Document10 pagesPRGR 00 Ins Cal 002sugeng wahyudiNo ratings yet

- 000-A-JD-801400-231 - Rev B SOW - Part-1Document5 pages000-A-JD-801400-231 - Rev B SOW - Part-1Senthil KumarNo ratings yet

- IONE-AA00-PE-QA-0002 Project Quality Audit Procedure Rev.1Document21 pagesIONE-AA00-PE-QA-0002 Project Quality Audit Procedure Rev.1YusufNo ratings yet

- Tendernotice 1 37 Compressed 301 377Document77 pagesTendernotice 1 37 Compressed 301 377p m yadavNo ratings yet

- Design Basis: Supply of Condensate Stabilization Unit For Mehar GPF Project No. 7005Document22 pagesDesign Basis: Supply of Condensate Stabilization Unit For Mehar GPF Project No. 7005Muhammad.SaimNo ratings yet

- ITT - Sample of ITPDocument3 pagesITT - Sample of ITPajiNo ratings yet

- FCPG-00000-CPP143-00-QA-6050-00012-001 - UT ProcedureDocument19 pagesFCPG-00000-CPP143-00-QA-6050-00012-001 - UT Procedurem.rasheed400010No ratings yet

- SPECIFICATION FOR PIPING FABRICATION, WELDING, INSPECTION AND TESTING Rev. ADocument15 pagesSPECIFICATION FOR PIPING FABRICATION, WELDING, INSPECTION AND TESTING Rev. AAgus SupriadiNo ratings yet

- Res Tr-2925-Method Statement For Piping Tie in Tank 3 AreaDocument29 pagesRes Tr-2925-Method Statement For Piping Tie in Tank 3 AreaKhouloud Hadj SassiNo ratings yet

- Specification For Piping NDE - IFADocument9 pagesSpecification For Piping NDE - IFAAndreas Schlager100% (1)

- Itp STR Slpg-Q-0000-24001-032-001-4-ADocument11 pagesItp STR Slpg-Q-0000-24001-032-001-4-AsivagnanamNo ratings yet

- PSI ProcedureDocument10 pagesPSI ProcedureDion Alfred EucogcoNo ratings yet

- Painting ProcedureDocument14 pagesPainting ProcedureSuresh KrishnanNo ratings yet

- IDBC-TS-MTTDS-FGR623304 Rev 50 Production Flowline Pig ReceiverDocument18 pagesIDBC-TS-MTTDS-FGR623304 Rev 50 Production Flowline Pig ReceiverTifano KhristiyantoNo ratings yet

- S 000 3130 001 - 00a - 0010 (Steel Structures Shop Fabrication)Document60 pagesS 000 3130 001 - 00a - 0010 (Steel Structures Shop Fabrication)LinoNo ratings yet

- 000 SP Pi02 0218Document33 pages000 SP Pi02 0218Samuel ValbuenaNo ratings yet

- MS. General Pipes Rev.0Document19 pagesMS. General Pipes Rev.0arsilanisNo ratings yet

- Imir 246Document15 pagesImir 246onshorequalitykclNo ratings yet

- 6206 Qap R0 DT 30.01.24Document3 pages6206 Qap R0 DT 30.01.24PRASHANTNo ratings yet

- Apf PPL PCD 004 - Rev 0 Procedure WrappingDocument8 pagesApf PPL PCD 004 - Rev 0 Procedure WrappingRamdanWahyuNugrohoNo ratings yet

- Pi-135-0007-Spc - 00a - Insulation Additional NotesDocument11 pagesPi-135-0007-Spc - 00a - Insulation Additional NotesRoberthappylandNo ratings yet

- AEPCOM-QAP-3281-58548 Rev 1Document3 pagesAEPCOM-QAP-3281-58548 Rev 1VIVEK TIWARINo ratings yet

- Ffio$pc @: Procedure FOR Material Identification & ControlDocument11 pagesFfio$pc @: Procedure FOR Material Identification & ControlAvijit DebnathNo ratings yet

- FCPG-00000-CPP143-00-QA-6050-00009-001 PT ProcedureDocument23 pagesFCPG-00000-CPP143-00-QA-6050-00009-001 PT Procedurem.rasheed400010No ratings yet

- Weekly Report For Control Valve - REV 0 15 January 2023Document12 pagesWeekly Report For Control Valve - REV 0 15 January 2023Andy ArdianNo ratings yet

- f1 R&M Condensor Pipe-Iso (After)Document1 pagef1 R&M Condensor Pipe-Iso (After)Syach FirmNo ratings yet

- Wiley Practitioner's Guide to GAAS 2023: Covering All SASs, SSAEs, SSARSs, and InterpretationsFrom EverandWiley Practitioner's Guide to GAAS 2023: Covering All SASs, SSAEs, SSARSs, and InterpretationsNo ratings yet

- S/N QTY Description Cost /unit Total: 2NR 2NR 2NR 3NR 3NRDocument1 pageS/N QTY Description Cost /unit Total: 2NR 2NR 2NR 3NR 3NRRajNo ratings yet

- Price. Bid: Ce For Pump S Sub.: Pri Pare and PartsDocument2 pagesPrice. Bid: Ce For Pump S Sub.: Pri Pare and PartsRajNo ratings yet

- Alacrity Production Systems Limited, Nigeria: Doc No: Rev: R0 Page: 1 of 2Document2 pagesAlacrity Production Systems Limited, Nigeria: Doc No: Rev: R0 Page: 1 of 2RajNo ratings yet

- PW610 PWM BB3 PDFDocument6 pagesPW610 PWM BB3 PDFRajNo ratings yet

- WETGFDZSR 27Y英文技术规格书Document28 pagesWETGFDZSR 27Y英文技术规格书RajNo ratings yet

- Saturn Home Appliances: 271b Ajose Adeogun Street, Victoria IslandDocument1 pageSaturn Home Appliances: 271b Ajose Adeogun Street, Victoria IslandRajNo ratings yet

- Jining Xunda Pipe Coating Materials Co.,Ltd: Test Report No. XD191014-03Document1 pageJining Xunda Pipe Coating Materials Co.,Ltd: Test Report No. XD191014-03RajNo ratings yet

- Product Certificate (Registered) : Standards Organisation of Nigeria Conformity Assessment ProgrammeDocument1 pageProduct Certificate (Registered) : Standards Organisation of Nigeria Conformity Assessment ProgrammeRajNo ratings yet

- Jining Xunda Pipe Coating Materials Co.,Ltd: Test Report No. XD191014-01Document2 pagesJining Xunda Pipe Coating Materials Co.,Ltd: Test Report No. XD191014-01RajNo ratings yet

- Technical Specifications: Zoomlion Ztc800V Truck CraneDocument27 pagesTechnical Specifications: Zoomlion Ztc800V Truck CraneRajNo ratings yet

- RWHRESFHGGRVDocument1 pageRWHRESFHGGRVRajNo ratings yet

- Jining Xunda Pipe Coating Materials Co.,Ltd: Test Report No. XD191014-02Document2 pagesJining Xunda Pipe Coating Materials Co.,Ltd: Test Report No. XD191014-02RajNo ratings yet

- ZTC250H431 27CSzxFDGHAWERS4GSZDTQ78JHYY英文技术规格书Document17 pagesZTC250H431 27CSzxFDGHAWERS4GSZDTQ78JHYY英文技术规格书RajNo ratings yet

- QWETWEFEWDocument1 pageQWETWEFEWRajNo ratings yet

- NO. Document No. Title of Document / DrawingDocument15 pagesNO. Document No. Title of Document / DrawingRajNo ratings yet

- 200 2BB6R V3 C40 3N662-Model PDFDocument1 page200 2BB6R V3 C40 3N662-Model PDFRajNo ratings yet

- THW444DRTFGHDocument1 pageTHW444DRTFGHRajNo ratings yet

- 360 6S3R, C00 8 (-NRD3-VY1,) - ModelDocument1 page360 6S3R, C00 8 (-NRD3-VY1,) - ModelRajNo ratings yet

- Luoyang Runcheng Petrochemical Equipment Co., Ltd. Painting ProcedureDocument10 pagesLuoyang Runcheng Petrochemical Equipment Co., Ltd. Painting ProcedureRajNo ratings yet

- Valve / Actuator Sizing Summary: Quotation No: FEQ-20-60010-A-1 Customer: 纽威 Project Name: 尼日利亚项目Document6 pagesValve / Actuator Sizing Summary: Quotation No: FEQ-20-60010-A-1 Customer: 纽威 Project Name: 尼日利亚项目RajNo ratings yet

- QCP of Q235B Steel Structural PDFDocument2 pagesQCP of Q235B Steel Structural PDFRajNo ratings yet

- Air Intake System: Systems DataDocument2 pagesAir Intake System: Systems DataRajNo ratings yet

- QCP of Api5lgr.b PDFDocument8 pagesQCP of Api5lgr.b PDFRajNo ratings yet

- Henan Bebon Iron & Steel Co., LTDDocument6 pagesHenan Bebon Iron & Steel Co., LTDRajNo ratings yet

- Gas Transmission and Distribution Piping Systems ASME B31.12 Hydrogen Piping and PipelinesDocument5 pagesGas Transmission and Distribution Piping Systems ASME B31.12 Hydrogen Piping and PipelinesnasrNo ratings yet

- For Restricted Circulation Only: Inspection OF Loading and Unloading Hoses FOR Petroleum ProductsDocument26 pagesFor Restricted Circulation Only: Inspection OF Loading and Unloading Hoses FOR Petroleum ProductsPandhu Arief Lakshana0% (1)

- Igat6 D PL Me SPC 0007 01 Spec For Barred TeeDocument9 pagesIgat6 D PL Me SPC 0007 01 Spec For Barred Teeamini_mohi100% (1)

- A Vapour Cloud ExplosionDocument4 pagesA Vapour Cloud ExplosionTeererai KaguraNo ratings yet

- Tis-Gti-Aosi-Epf-Itp-001 Inspection Test Plan (Itp)Document10 pagesTis-Gti-Aosi-Epf-Itp-001 Inspection Test Plan (Itp)Raka PriaNo ratings yet

- Approval Standard For Explosionproof Electrical Equipment General RequirementsDocument33 pagesApproval Standard For Explosionproof Electrical Equipment General RequirementsEduardo_77No ratings yet

- Reinforcement Pad CalculationDocument5 pagesReinforcement Pad Calculationsada siva100% (1)

- Section 3 - Scope of WorkDocument14 pagesSection 3 - Scope of Worktrung nguyen tranNo ratings yet

- Preiss Core Standards in The Pressure Equipment Area 4668Document42 pagesPreiss Core Standards in The Pressure Equipment Area 4668ZoranNo ratings yet

- Leak - Testing Asme 31.3Document7 pagesLeak - Testing Asme 31.3Tran Trungtt100% (1)

- TDI33 Tank Inspection Suitaility For Service API 653 Sec 4Document29 pagesTDI33 Tank Inspection Suitaility For Service API 653 Sec 4Faizal SattuNo ratings yet

- Inspection of Unfired Pressure Vessel Std-128Document34 pagesInspection of Unfired Pressure Vessel Std-128dyke_engg100% (1)

- Appendix E - Drawings & Data SheetDocument21 pagesAppendix E - Drawings & Data SheetsajanchaudhariNo ratings yet

- HSE ProcedureDocument5 pagesHSE ProcedureAndreas Schlager100% (1)

- Ressure Test Procedure For Piping SystemDocument5 pagesRessure Test Procedure For Piping SystemKyaw Kyaw AungNo ratings yet

- Standard Specification For: Designation: B167 11Document9 pagesStandard Specification For: Designation: B167 11Allan DiasNo ratings yet

- JI2048-974-MS-DAT-0036 - Rev001 (T-1001)Document9 pagesJI2048-974-MS-DAT-0036 - Rev001 (T-1001)Tech DesignNo ratings yet

- Typical Hydrostatic-Vents DrainsDocument1 pageTypical Hydrostatic-Vents Drainsrats182No ratings yet

- Presentation On Internal Inspection of Vessels TanksDocument39 pagesPresentation On Internal Inspection of Vessels TanksAbiram VSNo ratings yet

- Piping Hydro-Static Test ComprehensionDocument9 pagesPiping Hydro-Static Test ComprehensionViệt Đặng XuânNo ratings yet

- GM-NOC-LH-006 Rev.00Document10 pagesGM-NOC-LH-006 Rev.00le huyNo ratings yet

- ASME Code Section VIII Pressure TestsDocument3 pagesASME Code Section VIII Pressure TestsAngga100% (1)

- 1055 Attachment 9 - QP GRP Piping SpecifiDocument8 pages1055 Attachment 9 - QP GRP Piping SpecifikarunaNo ratings yet

- 1861B-MS-08-00002 Revision 2Document41 pages1861B-MS-08-00002 Revision 2Moh'd SameerNo ratings yet

- Bladder Tank ManualDocument19 pagesBladder Tank ManualRISHABH VERMANo ratings yet

- 32 Samss 004Document59 pages32 Samss 004israr khanNo ratings yet

- Extracted Pages From FOAM-SYSTEMDocument1 pageExtracted Pages From FOAM-SYSTEMAziz UllahNo ratings yet

- Curriculum Vitae: Vivek PatilDocument3 pagesCurriculum Vitae: Vivek PatilVivek PatilNo ratings yet