Professional Documents

Culture Documents

Subgrade Soil Stabilization Using Stone Dust and Coarse Aggregate Project 2019

Subgrade Soil Stabilization Using Stone Dust and Coarse Aggregate Project 2019

Uploaded by

VANI KRISHNA PSOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Subgrade Soil Stabilization Using Stone Dust and Coarse Aggregate Project 2019

Subgrade Soil Stabilization Using Stone Dust and Coarse Aggregate Project 2019

Uploaded by

VANI KRISHNA PSCopyright:

Available Formats

Subgrade soil stabilization using stone dust and coarse aggregate project 2019

1.INTRODUCTION

The rapid urban and industrial developments pose an increasing demand for the

construction of highway embankments and other civil engineering works.Sometimes the

existing soil may not be sufficiently strong to withstand the load of pavement and traffic.

To overcome the this problem,ground improvement methods such as soil stabilization can

be used.Stabilization can increase the shear strength of soil and control the shrink-swell

properties of a soil, thus improving the load bearing capacity of subgrade to support

pavements and foundations.The most common improvements achieved through

stabilization include better soil gradation, reduction fo plasticity index or swelling

potential,and increases in durability and strength.In wet weather , stabilization may also be

used to provide a working platform for construction operations. These types of soil quality

improvement are refered to as soil modification. Benefits of soil stabilization are higher

resistance values, reduction in plasticity, lower permeability, reduction of pavement

thickness, elimination of excavation, material hauling and handling,and base importation,

aids compaction, provides all-weather accessonto and within project sites. The

determining factors associated with soil stabilization may be the existing moisture content

,the end use of the soil structureand ultimatelynthe cost benefit provided.As a good soil

becomes scarcer and their location becomes more difficult,costly,the need to improve

quality of soil using soil stabilization is becoming more important. Soil stabilization usig

stone dust or coarse aggregate is an alternative method for improvement of subgrade soil

of pavement. It can significantly enhance the properties of soil used in the costruction of

road infrastructure.

2.SOIL STABILIZATION

The process of soil stabilization refers to changing the physical properties of soil in order

to improve its strength, durability, or other qualities. Typically, this is important for road

construction, and other concerns related to the building and maintenance of infrastructure.

Soil that has been stabilized will have a vastly improved weight bearing capability, and

will also be significantly more resistant to being damaged by water, frost, or inclement

conditions.

Dept. of civil engineering 1 MITS,Varikoli

Subgrade soil stabilization using stone dust and coarse aggregate project 2019

2.1 MECHANICAL SOIL STABILIZATION

The oldest types of soil stabilization are mechanical in nature. Mechanical solutions

involve physically changing the property of the soil somehow, in order to affect its

gradation, solidity, and other characteristics. Dynamic compaction is one of the major

types of soil stabilization; in this procedure, a heavyweight is dropped repeatedly onto the

ground at regular intervals to quite literally pound out deformities and ensure a uniformly

packed surface. Vibro compaction is another technique that works on similar principles,

though it relies on vibration rather than deformation through kinetic force to achieve its

goals.

2.2 CHEMICAL SOIL STABILIZATION

Chemical solutions are another of the major types of soil stabilization. All of these

techniques rely on adding additional material to the soil that will physically interact with it

and change its properties. There are a number of different types of soil stabilization that

rely on chemical additives of one sort or another; you will frequently encounter

compounds that utilize cement, lime, fly ash, or kiln dust. Most of the reactions sought are

either cementitious or pozzolanic in nature, depending on the nature of the soil present at

the particular site you are investigating.

2.3 POLYMER/ALTERNATIVE SOIL STABILIZATION

Both of the previous types have been around for hundreds of years, if not more; only in

the past several decades has technology opened up new types of soil stabilization for

companies to explore. Most of the newer discoveries and techniques developed thus far

are polymer based in nature, such as those developed by Global Road Technology. These

new polymers and substances have a number of significant advantages over traditional

mechanical and chemical solutions; they are cheaper and more effective in general than

mechanical solutions, and significantly less dangerous for the environment than many

chemical solutions tend to be.

Dept. of civil engineering 1 MITS,Varikoli

Subgrade soil stabilization using stone dust and coarse aggregate project 2019

3 MATERIALS

3.1 Subgrade Soil

The subgrade soil and its properties are important in the design of pavement

structure.Subgrade soil is an integrated part of the road pavement structure as it provides

the support to the pavement from beneath.The main function of the subgrade is ti give

adequate support to the pavement and for the subgrade shouild prossess sufficient stability

under adverse climate and loading conditions.

3.2 Coarse aggragates

The coarse aggregate is also known as mechanical stabilizer as they help to stabilize the

soil mainly by improving its gradation, plasticity and compaction characteristics. Coarse

aggregates as stabilizer for expansive soil are very effective for improving the engineering

properties in all aspects and also reduce the settlement problem. These are universally

used as mechanical stabilizer to increase the bearing capac-ity, strength and tension

resistance of soils . The coarse aggregates used in the present study are crushed aggregates

of 10 mm nominal size. In the present study, untreated soil types have been mixed with

coarse aggregates of 10 mm size in proportion of 10% and 20% by mass of dry soil.

Size of Aggregates(mm) 10-12

Density of 20.9

Aggregate(kN/m3)

Impact Strength(%) 10-20

Specification of aggregate Strong

Specific gravity 1.02

Table 1. Properties of aggregate

Figure 1 Coarse aggragate

Dept. of civil engineering 1 MITS,Varikoli

Subgrade soil stabilization using stone dust and coarse aggregate project 2019

3.3 Stone Dust

Stone dust or crusher sand is a type of fine aggregate obtained from stone crushers. Each

crusher unit is estimated to produce 15%–20% of stone dust. The stone dust can be used as

a soil stabilizer to enhance the geotechnical properties of local soil by replacing the soil

with stone dust at various mix proportion . It is known as a mechanical stabilizer as it

helps to stabilize the soil mainly by improving its gradation, plasticity and compaction

characteristics.Stone dust has lesser fraction of soil passing 0.075 mm sieve and is non-

plastic in nature. This helps to improve the gradation and plasticity of the soil when mixed

with stone dust. Stone Dust consists of angular particles having more interlocking strength

which improves the density of the soil when mixed with stone dust. Stone dust has been

identified to have high shear resistance and is beneficial to use it as a stabilizing material.

Stone dust, also known as stone screenings, is the finest of the types of crushed stone. It is

made of the same type of stone as the other types but is crushed into a powder. When used

by itself stone dust forms a hard surface that is water resistant. When used with a larger

stone it acts as a binding agent. Because of its ability to form a strong, non-porous surface,

stone dust is often used in between the stones or bricks in patios and walkways. In this

application, it not only protects the base of the area from moisture, thus preventing

heaving or mold growth, but it also effectively keeps weeds and grass from growing up

between the pavers. It serves the same purpose when used in horse arenas, biking and

hiking trails and walkways. Stone dust is also used as a binding agent in cement or asphalt

for roads, driveways and sidewalks. crushed stone dust is a product of stone crushing

industry, every crusher unit produced 15%-20% stone dust. So it’s easily available.

Component Weight (%)

Cao 3.5 – 40

Al203 0.5-40

Mgo 2.5-25

Si02 1-12

S03 0.23-3

Available Alkalis 0-4

Dept. of civil engineering 1 MITS,Varikoli

Subgrade soil stabilization using stone dust and coarse aggregate project 2019

Table 2 . Chemical properties of stone dust source

Property Value

Natural Moisture

Content 9.11

(%)

Particle Size

distribution

Sand (%) 97.1

Silt (%) 2.9

Specific Gravity 2.76

Liquid Limit (%) NP

Plastic Limit (%) NP

Plasticity Index (%) NP

OMC (%) 11.5

MDD (g/cm3) 1.97

Angle of internal friction 35

(degree)

Cohesion (kN/m2) 0.07

CBR Soaked (%) 11.5

CBR Unsoaked (%) 26.28

Table 3. Index properties of stone dust source

4.Different forms of stone

4.1 Sedimentary stone

Sedimenary stone came from organic elements such as glaciers, rivers, wind, oceans, and

plants. Tiny sedimentary pieces broke off form these elements and accumulated to form

rock beds. They were bonded through millions of years of heat and pressure.

4.1.1 Limestone

Mainly consists of calcite. It does not show such graining or crystalline structure. It has a

smooth granular surface. Varies in hardness. Some dense limestone can be polished.

Common colors are black, grey, white, yellow or brown. It is more likely to stain than

marble. Limestone is known to contain lime from sea water.

4.1.2 Sandstone

Dept. of civil engineering 1 MITS,Varikoli

Subgrade soil stabilization using stone dust and coarse aggregate project 2019

Is a very durable formation of quartz grains (sand). Usually formed in light brown or red

colors. Categorized by the most popular sandstone bonding agents such as silica, calcium,

clay, and iron oxide.

4.1.3 Soapstone

A very soft stone made of a variety of talc. It is a dense mineral that wears well and is

often resistant to oxide.

4.1.4 Fossilstone:

Considered a limestone that contains natural fossils such as sea-shells and plants.

4.1.5 Travertine

Usually a cream or reddish color. It is formed through the accumulation of calcite from hot

springs. It contains holes that were formed from water flowing through the stone. These

holes are often filled with synthetic resins or cements. Requires a lot of maintenance if the

holes are not filled. Classified as a limestone and a marble.

4.2 Metamorphic stones

Metamorphic stones originate from a natural form of one type of stone to another type

through the mixture of heat, pressure, and minerals. The change may be a development of

a crystalline formation, a texture change, or a color change.

4.2.1 Marble

A recrystallized limestone that formed when the limestone softened from heat and

pressure and recrystallized into marble where a mineral change occurred. The main

consistency is calcium and dolomite. Ranges in many colors and is usually heavily veined

and shows grains. Hardness rates from 2.5 to 5 on the MOH Scale.

Marble is classified into three categories:

1. Dolomite: If it has more than 40% magnesium carbonates.

2. Magnesium: If it has between 5% and 40% magnesium

3. Calcite: If it has less than 5% magnesium carbonate.

Dept. of civil engineering 1 MITS,Varikoli

Subgrade soil stabilization using stone dust and coarse aggregate project 2019

4.2.2 Slate

Fine grained metamorphic stone that is formed from clay, sedimentary rock shale, and

sometimes quartz. Very thin and can break easily. Usually in black, gray or green.

4.2.3 Serpentine

Identified by its marks, which look like the skin of a serpent. Most popular colors are

green and brown. Hardness rates from 2.5 to 4 on the MOH scale. Contains serpentine

minerals and magnesium, and has an igneous origin. Does not always react well to

recrystallization or diamond polishing.

4.3 Igneous stones

Igneous stones are mainly formed through volcanic material such as magma. Underneath

the Earth's surface, liquid magma cooled and solidified. Mineral gases and liquids

penetrated into the stone and created new crystalline formations with various colors.

4.3.1 Granite

Primarily made of Quartz (35%), Feldspar (45%) and Potassium. Usually comes in dark

colors and contains very little calcite, if any. Provides a heavy crystalline and granular

appearance with mineral grains. It is a very hard material and easier to maintain than

marble. Yet, it is still porous and will stain. There are different types of granite depending

on the percentage mix of quartz, mica and feldspar. Black granite is known as an

Anorthosite. It contains very little quartz and feldspar and has a different composition than

true granite

4.4 Quartz Stones

Quartz stone is a composite material made of crushed stone bound together by an

adhesive, (most commonly polymer resin, with some newer versions using cement mix).

The two common stones used in producing these products are marble and quartz. rial or

screenings falls through the screen.

5. TEST PERFORMED

Preliminary tests such as sieve analysis, liquid limit test and plastic limit test were

performed. Sieve analysis of 10 mm aggregate and stone dust showed zero percent and

7.2% passing from 0.075 mm sieve respectively. Both these stabilizing materi-als were

Dept. of civil engineering 1 MITS,Varikoli

Subgrade soil stabilization using stone dust and coarse aggregate project 2019

found to be non-plastic. Further, strength tests were carried out that are (1) compaction test

to obtain maximum

5.1 Sieve analysis

A sieve analysis (or gradation test) is a practice or procedure used (commonly used in civil

engineering) to assess the particle size distribution (also called gradation) of a granular

material by allowing the material to pass through a series of sieves of progressively

smaller mesh size and weighing the amount of material that is stopped by each sieve as a

fraction of the whole mass.The size distribution is often of critical importance to the way

the material performs in use. A sieve analysis can be performed on any type of non-

organic or organic granular materials including sands, crushed rock, clays, granite,

feldspars, coal, soil, a wide range of manufactured powders, grain and seeds, down to a

minimum size depending on the exact method. Being such a simple technique of particle

sizing, it is probably the most common.

5.3 Plastic limit test

Determination of Plastic Limit is as important as Liquid Limit so as to ascertain Plasticity

Index, Ip of the soil. The plastic limit of a soil is the moisture content, expressed as a

percentage of the weight of the oven-dry soil, at the boundary between the plastic and

semi-solid states of consistency. It is the moisture content at which a soil will just begin to

crumble when rolled into a thread ⅛ inch (3 mm) in diameter using a ground glass plate or

other acceptable surface.

5.4 Compaction test

Compaction test of soil is carried out using Proctor's test to understand compaction

characteristics of different soils with change in moisture content. Compaction of soil is the

optimal moisture content at which a given soil type becomes most dense and achieve its

maximum dry density by removal of air voids. mpaction is the process of densification of

soil by reducing air voids. The degree of compaction of a given soil is measured in terms

of its dry density. The dry density is maximum at the optimum water content. A curve is

drawn between the water content and the dry density to obtain the maximum dry density

and the optimum water content.

Dept. of civil engineering 1 MITS,Varikoli

Subgrade soil stabilization using stone dust and coarse aggregate project 2019

Dry density of soil:

Where M = total mass of the soil, V= volume of soil, w= water content.

5.4.1 Test Procedure

Take about 20kg of air-dried soil. Sieve it through 20mm and 4.7mm sieve.Calculate the

percentage retained on 20mm sieve and 4.75mm sieve, and the percentage passing

4.75mm sieve.If the percentage retained on 4.75mm sieve is greater than 20, use the large

mould of 150mm diameter. If it is less than 20%, the standard mould of 100mm diameter

can be used. The following procedure is for the standard mould.Mix the soil retained on

4.75mm sieve and that passing 4.75mm sieve in proportions determined in step (2) to

obtain about 16 to 18 kg of soil specimen.Clean and dry the mould and the base plate.

Grease them lightly.Weigh the mould with the base plate to the nearest 1 gram.Take about

16 – 18 kg of soil specimen. Add water to it to bring the water content to about 4% if the

soil is sandy and to about 8% if the soil is clayey.Keep the soil in an air-tight container for

about 18 to 20 hours for maturing. Mix the soil thoroughly. Divide the processed soil into

6 to 8 parts.Attach the collar to the mould. Place the mould on a solid base.Take about

2.5kg of the processed soil, and hence place it in the mould in 3 equal layers. Take about

one-third the quantity first, and compact it by giving 25 blows of the rammer. The blows

should be uniformly distributed over the surface of each layer.The top surface of the first

layer be scratched with spatula before placing the second layer. The second layer should

also be compacted by 25 blows of rammer. Likewise, place the third layer and compact

it.The amount of the soil used should be just sufficient to fill the mould ad leaving about 5

mm above the top of the mould to be struck off when the collar is removedRemove the

collar and trim off the excess soil projecting above the mould using a straight edge.Clean

the base plate and the mould from outside. Weigh it to the nearest gram.Remove the soil

from the mould. The soil may also be ejected out.Take the soil samples for the water

content determination from the top, middle and bottom portions. Determine the water

content.Add about 3% of the water to a fresh portion of the processed soil, and repeat the

steps 10 to 14.

Dept. of civil engineering 1 MITS,Varikoli

Subgrade soil stabilization using stone dust and coarse aggregate project 2019

5.5 Calofornia Bearing Ratio Test

t is the ratio of force per unit area required to penetrate a soil mass with standard circular

piston at the rate of 1.25 mm/min. to that required for the corresponding penetration of a

standard material. The California Bearing Ratio Test (CBR Test) is a penetration test

developed by California State Highway Department (U.S.A.) for evaluating the bearing

capacity of subgrade soil for design of flexible pavement.

5.5.1 Test Procedure

Normally 3 specimens each of about 7 kg must be compacted so that their compacted

densities range from 95% to 100% generally with 10, 30 and 65 blows. Weigh of empty

mouldAdd water to the first specimen (compact it in five layer by giving 10 blows per

layer)After compaction, remove the collar and level the surface.Take sample for

determination of moisture content.Weight of mould + compacted specimen. Place the

mold in the soaking tank for four days (ignore this step in case of unsoaked CBR.Take

other samples and apply different blows and repeat the whole process.After four days,

measure the swell reading and find %age swell.Remove the mould from the tank and

allow water to drain.Then place the specimen under the penetration piston and place

Dept. of civil engineering 1 MITS,Varikoli

Subgrade soil stabilization using stone dust and coarse aggregate project 2019

surcharge load of 10lb.Apply the load and note the penetration load values. Draw the

graphs between the penetration (in) and penetration load (in) and find the value of

CBR.Draw the graph between the %age CBR and Dry Density, and find CBR at required

degree of compaction.

5.6 RESULTS

5.6.1 Effect of Mechanical Stabilization on Compaction Characteristics

The effect of the addition of stone dust and coarse aggre-gate to the soil on maximum dry

density and optimum moisture content of the soils was determined by conduct-ing a series

of modified proctor tests on various soil sam-ples in di fferent mix proportions. the

addition of stabilizers whereas optimum moisture con-tent decreases for all soil-aggregate

mixes. As both stone dust and 10 mm size aggregate are comparatively coarser, more

angular and non-plastic material than untreated soil, their addition to the soil leads to

increase in MDD and decrease in the OMC of the soil samples . With the addi-tion of

stabilizers MDD increases from 0.5 to 6.9%.

Dept. of civil engineering 1 MITS,Varikoli

Subgrade soil stabilization using stone dust and coarse aggregate project 2019

5.6.2 Efect of Mechanical Stabilization on Strength Characteristics

The load penetration curves obtained from the CBR tests for various stabilized soil

samples with varying mix proportions , that CBR value under soaked condition increases

with addition of stone dust (10%, 20%, and 30% by mass of dry soil) and coarse aggregate

(10% and 20% by mass of dry soil) and mix proportions (10% stone dust + 10% coarse

aggregate and 10% stone dust + 20% coarse aggregate). IRC: 37-2012, the standard for the

thickness design of flexible pavements in India , specifies the use of select soil of

minimum CBR 8.0% when trafc on the road is 450 commercial vehicles per day or higher.

This desired value of 8% CBR under soaked condition is obtained with the addition of

30% stone dust by mass of dry soil to the untreated soil. Similarly, other soil-aggregate

mixes comprising,in addition to soil, 20% coarse aggregate, or 10% stone dust + 10%

coarse aggregate, or 10% stone dust + 20% coarse aggregate by mass of dry soil for all six

type of soil samples, were able to meet the desired value of CBR. Increase in MDD with

the addition of angular, non-plastic stone dust and 10 mm aggregate leads to increasing the

CBR value of the soil samples. This is in conformity with the results reported earlier also

[37, 38 ]. With the addition of stabilizers CBR increases from 32.4 to 194.7% for three

types of fine-grained soils considered in the study.

Dept. of civil engineering 1 MITS,Varikoli

Subgrade soil stabilization using stone dust and coarse aggregate project 2019

Dept. of civil engineering 1 MITS,Varikoli

Subgrade soil stabilization using stone dust and coarse aggregate project 2019

6. CONCLUSION

With the addition of stone dust and coarse aggregate, the MDD value of the soil types

increased while the OMC decreased. Stone dust (10%, 20% and 30% by mass of dry soil),

10 mm size coarse aggregates (10% and 20% by mass of dry soil) and both together (10%

stone dust + 10% coarse aggregates and 10% stone dust + 20% coarse aggregates)

increased the CBR value of the soil types considered in the study.The CBR value

increased significantly and the desired value of minimum CBR of 8% under soaked

condition was obtained by adding to the soil 30% of stone dust, or 20% of 10 mm size

coarse aggregates, or with both 10% stone dust + 10% coarse aggregates and 10% stone

dust + 20% coarse aggregates. It has been observed that on addition of stabilizers, MDD

and CBR increases from 0.5 to 6.9% and 32.4 to 194.7%, respectively.Stone dust a

product from crusher unit consists of mainly sand size particles and is having good CBR

value. Thus, the stone dust itself can be considered as agood sub base material . Hence it

can be used for construction of road embankment.Stone dust has high specific gravity and

the soaked CBR value for stantard compaction is more. This indicates that stone dust can

be used as an embankment material, backfill material for the lower layer of subbase.Also

reuse of this waste material is economically advantage and does not bring any economical

advateges and does not bring any environmental hazards.As the CBR value of stone dust

is more , the crush thickness of flexible pavement is less and it is economical in

construction of road,highways.

Dept. of civil engineering 1 MITS,Varikoli

You might also like

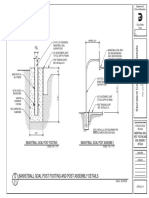

- D-11 Basketball Goal Post Footing and Goal Assembly Details - 201407301802167813 PDFDocument1 pageD-11 Basketball Goal Post Footing and Goal Assembly Details - 201407301802167813 PDFJAYNo ratings yet

- Business NegotiationDocument10 pagesBusiness NegotiationJasneet Singh AnandNo ratings yet

- Lime Stabilization of Expansive SoilDocument14 pagesLime Stabilization of Expansive Soilعبدالرحمن العليميNo ratings yet

- ChaptersDocument79 pagesChaptersMay JangkumNo ratings yet

- Use of Waste Foundry Sand As Fine Aggregates For Structural Concrete - A ReviewDocument14 pagesUse of Waste Foundry Sand As Fine Aggregates For Structural Concrete - A ReviewJanak RaazzNo ratings yet

- Effect of Stone Dust On Geotechnical Parameter of Fine Grained SoilDocument7 pagesEffect of Stone Dust On Geotechnical Parameter of Fine Grained SoilAmanulla KhanNo ratings yet

- Effect of Water Cement Ratio On The Work PDFDocument8 pagesEffect of Water Cement Ratio On The Work PDFMohamed HamdyNo ratings yet

- Effect of Replacement of Natural Sand byDocument4 pagesEffect of Replacement of Natural Sand byH SNo ratings yet

- Chapter 2 Aggregate PDFDocument17 pagesChapter 2 Aggregate PDFmoshilizaNo ratings yet

- SCMT4 Wol 123Document10 pagesSCMT4 Wol 123DivyaNo ratings yet

- Effect of Tire Buffings Addition On Compaction Properties of Bentonite-Sand, Bentonite-Rock Dust, and Bentonite-Sand-Rock Dust MixesDocument11 pagesEffect of Tire Buffings Addition On Compaction Properties of Bentonite-Sand, Bentonite-Rock Dust, and Bentonite-Sand-Rock Dust MixesIJRASETPublicationsNo ratings yet

- Note On Manfactured SandDocument6 pagesNote On Manfactured SandRamdas SurveNo ratings yet

- N0300100101. 21pdfDocument13 pagesN0300100101. 21pdfSara Pierina Santos DiazNo ratings yet

- Effects of Partial Replacement of Cement With Marble Dust Powder On Properties of ConcreteDocument9 pagesEffects of Partial Replacement of Cement With Marble Dust Powder On Properties of ConcreteAnkush ThakurNo ratings yet

- Stabilization of Dispersive Soil Using BiopolymerDocument16 pagesStabilization of Dispersive Soil Using BiopolymerwuhanbigtreeNo ratings yet

- Bekelcha Edited orDocument20 pagesBekelcha Edited orBeeka GMNo ratings yet

- IJEDR1802132Document5 pagesIJEDR1802132ayat arahmanNo ratings yet

- Paper 274Document9 pagesPaper 274FikeduNo ratings yet

- Ijs DR 2009016Document6 pagesIjs DR 2009016عبدالرحمن العليميNo ratings yet

- Partial Replacement of River Sand With Quarry Rock DustDocument8 pagesPartial Replacement of River Sand With Quarry Rock DustDharma banothuNo ratings yet

- 1.1 General: Study of Suitability of Manufactured Sand (M-Sand) As Fine Aggregate in ConcreteDocument62 pages1.1 General: Study of Suitability of Manufactured Sand (M-Sand) As Fine Aggregate in Concretebits computersNo ratings yet

- Project Report (Soil Stabilization)Document24 pagesProject Report (Soil Stabilization)ytsell30No ratings yet

- Chapter-1: 1.1 Soil ImprovementDocument28 pagesChapter-1: 1.1 Soil ImprovementNischal LgNo ratings yet

- Soil Stabilization Using Crumb RubberDocument36 pagesSoil Stabilization Using Crumb RubberPRETTY MARYNo ratings yet

- Study On Flyash Soil Stabilization: AbstractDocument8 pagesStudy On Flyash Soil Stabilization: AbstractNaingnine AungNo ratings yet

- 2 11 1637210758 8ijcseierddec20218Document12 pages2 11 1637210758 8ijcseierddec20218TJPRC PublicationsNo ratings yet

- 2745-Article Text-5065-1-10-20210723 (UTILIZATION OF STONE DUST FOR STABILIZATION OF BLACK COTTON SOIL)Document6 pages2745-Article Text-5065-1-10-20210723 (UTILIZATION OF STONE DUST FOR STABILIZATION OF BLACK COTTON SOIL)Amanulla KhanNo ratings yet

- Building Roads On Sabkha Soils With Geosynthetic Systems PDFDocument12 pagesBuilding Roads On Sabkha Soils With Geosynthetic Systems PDF류태하No ratings yet

- Stabilization of Expansive Soils Using Stone Waste Materials: A ReviewDocument7 pagesStabilization of Expansive Soils Using Stone Waste Materials: A Reviewal.baidhani7471No ratings yet

- Improvement of Subgrade Soil With Shredded Waste Tyre ChipsDocument4 pagesImprovement of Subgrade Soil With Shredded Waste Tyre ChipsRenugopalNo ratings yet

- Effect of Quarry Dust On Compaction Characteristics of ClayDocument23 pagesEffect of Quarry Dust On Compaction Characteristics of ClaywuhanbigtreeNo ratings yet

- Chapter - 1: 1.1 GeneralDocument13 pagesChapter - 1: 1.1 Generalshivanand hippargaNo ratings yet

- An Experimental Analysis As Replacement of Natural Sand With Bamboo Fibre and M-Sand in ConcreteDocument18 pagesAn Experimental Analysis As Replacement of Natural Sand With Bamboo Fibre and M-Sand in ConcreteIJRASETPublicationsNo ratings yet

- IGC-2015 Submission 293Document9 pagesIGC-2015 Submission 293mchetiaNo ratings yet

- Journal of Scientific and Engineering Research, 2017, 4 (9) :228-237Document10 pagesJournal of Scientific and Engineering Research, 2017, 4 (9) :228-237Basha FayissaNo ratings yet

- Stabilization of Gedebage Expansive Soil On Shear Strength Using Vermiculite and Emulsified AsphaltDocument7 pagesStabilization of Gedebage Expansive Soil On Shear Strength Using Vermiculite and Emulsified AsphaltDonoNo ratings yet

- Partial Replacement of Discarded Rubber Tyres With Coarse AggregateDocument18 pagesPartial Replacement of Discarded Rubber Tyres With Coarse AggregatePrasanna Gayathri VinnakotaNo ratings yet

- Stabilization of Black Cotton Soil Using Lime: Dept - of Civil Engineering, Suk KalburagiDocument27 pagesStabilization of Black Cotton Soil Using Lime: Dept - of Civil Engineering, Suk KalburagiAkash SiboNo ratings yet

- ProjectDocument33 pagesProjectSuresh BabuNo ratings yet

- Civil Engineering JournalDocument15 pagesCivil Engineering JournalHhowtobe YounesNo ratings yet

- Wutan Huatan Jisuan Jishu ISSN NO: 1001-1749: A E E S M-S & T A. Divya JyothiDocument8 pagesWutan Huatan Jisuan Jishu ISSN NO: 1001-1749: A E E S M-S & T A. Divya JyothiSurya Prakash Reddy KothapalliNo ratings yet

- Study On Fatigue and Rutting Response of FlexibleDocument5 pagesStudy On Fatigue and Rutting Response of FlexibleDeputy controller of examinationNo ratings yet

- I-Sand: Replacement of Natural SandDocument9 pagesI-Sand: Replacement of Natural SandVinay Kumar H SNo ratings yet

- Investigation To Improve The Sand Molding Formula of The Erg by Incorporating Local MaterialsDocument14 pagesInvestigation To Improve The Sand Molding Formula of The Erg by Incorporating Local MaterialsTJPRC PublicationsNo ratings yet

- Improving The Engineering Properties of Soil Using Sisal Fibre With Rice Husk AshDocument8 pagesImproving The Engineering Properties of Soil Using Sisal Fibre With Rice Husk AshIJRASETPublicationsNo ratings yet

- Investigation On Sustainable Concrete Using M-Sand and Rice Husk AshDocument4 pagesInvestigation On Sustainable Concrete Using M-Sand and Rice Husk AshjyothiNo ratings yet

- Chapter 1 - Concrete Material & MixtureDocument10 pagesChapter 1 - Concrete Material & MixtureNezrinNo ratings yet

- Sustainable Use of Industrial Waste As Partial Replacement of Fine Aggregate For Preparation of ConcreteDocument31 pagesSustainable Use of Industrial Waste As Partial Replacement of Fine Aggregate For Preparation of ConcreteISHIT GARGNo ratings yet

- M-Sand .: by Sneh Lata Mtech Structural EnggDocument24 pagesM-Sand .: by Sneh Lata Mtech Structural EnggAtul RaiNo ratings yet

- Nota Chapter 2 AggregatesDocument17 pagesNota Chapter 2 AggregatesnnsNo ratings yet

- Re 14Document6 pagesRe 14Alamgir kabirNo ratings yet

- An Experimental Study of Soil Stabilization Using Marble DustDocument6 pagesAn Experimental Study of Soil Stabilization Using Marble DustnidsNo ratings yet

- Effect of Sand Wall Stabilized With Different Percentages of Lime On Bearing Capacity of FoundationDocument4 pagesEffect of Sand Wall Stabilized With Different Percentages of Lime On Bearing Capacity of FoundationAhMed SaMeerNo ratings yet

- Ordinary and Encased Stone Columns at Two Different Relative DensitiesDocument12 pagesOrdinary and Encased Stone Columns at Two Different Relative DensitiesTiến Bách PhạmNo ratings yet

- Cement Stablize of SoilDocument10 pagesCement Stablize of Soilالزهور لخدمات الانترنيتNo ratings yet

- And Stone Dust PDFDocument7 pagesAnd Stone Dust PDFEmanoAceNo ratings yet

- Teleconnection Between The Low Index Phase of Southern Oscillation and Precipitation Patterns Over The Southeastern United StatesDocument14 pagesTeleconnection Between The Low Index Phase of Southern Oscillation and Precipitation Patterns Over The Southeastern United StatesEngr. Azunna Sunday UgochukwuNo ratings yet

- Stabilization of Clayey Soil Using Dunite Powder: K. Nikhilraaj, V.JananiDocument5 pagesStabilization of Clayey Soil Using Dunite Powder: K. Nikhilraaj, V.JananiAli Saleh Saad ALiSAWiNo ratings yet

- Rehabilitating Water and Wastewater Treatment Plants PDFDocument11 pagesRehabilitating Water and Wastewater Treatment Plants PDFArchana AcchuNo ratings yet

- Fine Grained PolicyDocument2 pagesFine Grained PolicyDarcy CaseyNo ratings yet

- Serial Communication 2Document31 pagesSerial Communication 2jaigodara100% (1)

- Thinking in Parametric PhenomenologyDocument10 pagesThinking in Parametric PhenomenologyAlexandre ChienNo ratings yet

- BS en 13139 PDFDocument10 pagesBS en 13139 PDFanilkumar_bojja97600% (1)

- Arcgis LabelsDocument53 pagesArcgis LabelsNeftali ChapiNo ratings yet

- Active Directory Migration To 2008 R2Document59 pagesActive Directory Migration To 2008 R2Rakesh PrashanthNo ratings yet

- Frequently Asked QuestionsDocument9 pagesFrequently Asked QuestionsJesus Rmz PeñaNo ratings yet

- 595215b455235 PDFDocument52 pages595215b455235 PDFStefan PalaghiaNo ratings yet

- Plastering PDFDocument6 pagesPlastering PDFTheOne YasirNo ratings yet

- Port NumbersDocument76 pagesPort NumberssophiaNo ratings yet

- Tutorial Elasticsearch - EnglishDocument166 pagesTutorial Elasticsearch - EnglishJohn CardNo ratings yet

- NJTA Design Manual Section 2 Structures DesignDocument120 pagesNJTA Design Manual Section 2 Structures DesignmorriatyNo ratings yet

- Protocols For Data Networks (Aka Advanced Computer Networks)Document17 pagesProtocols For Data Networks (Aka Advanced Computer Networks)Hedy PamungkasNo ratings yet

- Import An XML File Using The Deployment Manager in OIMDocument10 pagesImport An XML File Using The Deployment Manager in OIMsanjayid1980No ratings yet

- Cookie ManipulationDocument5 pagesCookie ManipulationJulianholgadoNo ratings yet

- Revit 2016 BIM Management-Template and Family Creation PDFDocument54 pagesRevit 2016 BIM Management-Template and Family Creation PDFYang LiNo ratings yet

- Area StatementDocument6 pagesArea StatementSougata DasNo ratings yet

- The Central AsiaDocument52 pagesThe Central AsiaSrashti singhNo ratings yet

- Final Calculation - 02Document26 pagesFinal Calculation - 02Muhammad irfan javaidNo ratings yet

- Vashi Mahaveer MarketDocument2 pagesVashi Mahaveer MarketumukundNo ratings yet

- 23-2 Design of Floor Diaphragms MoroderDocument9 pages23-2 Design of Floor Diaphragms Morodersbarwal9No ratings yet

- Ftth/Gpon Olt: FeaturesDocument2 pagesFtth/Gpon Olt: FeaturesTestgame GameonlyNo ratings yet

- Robatherm Medical EngDocument20 pagesRobatherm Medical Engtanbqtb030% (1)

- Link Tulisan2 Di Facebook - Annin HudayaDocument26 pagesLink Tulisan2 Di Facebook - Annin HudayaImran Rosidi SiregarNo ratings yet

- Summary - Phil HistoryDocument6 pagesSummary - Phil HistorySam AlvarezNo ratings yet

- Prefab Light Steel VillaDocument30 pagesPrefab Light Steel Villagunjan kandariNo ratings yet

- Sobinco Pentalock-Brave Za VrataDocument86 pagesSobinco Pentalock-Brave Za VrataSemsudin HabibovicNo ratings yet