Professional Documents

Culture Documents

User Manual: and Technical Description

User Manual: and Technical Description

Uploaded by

Youness Ben TibariCopyright:

Available Formats

You might also like

- 04 Installation Instructions VALiA Spring Arms 1563740 06Document128 pages04 Installation Instructions VALiA Spring Arms 1563740 06lasiw91100% (1)

- Oec 9600imaging Workstation Illustrated Parts ManualDocument95 pagesOec 9600imaging Workstation Illustrated Parts ManualJoe B BestialNo ratings yet

- KARL STORZ OR1™ PresentationDocument83 pagesKARL STORZ OR1™ PresentationLemayian Lemah Bonnke100% (9)

- AXIOM Luminos TF With Mobile Flat Detector: Answers For LifeDocument20 pagesAXIOM Luminos TF With Mobile Flat Detector: Answers For Lifeuriel vazquezNo ratings yet

- vf1000l Manual enDocument79 pagesvf1000l Manual enCompuWan PolancoNo ratings yet

- AMX Periodic MaintenanceDocument26 pagesAMX Periodic MaintenancejustinNo ratings yet

- Syngo - Plaza: Software Version VA20B and Higher Operator and Administrator Manual - AddendumDocument87 pagesSyngo - Plaza: Software Version VA20B and Higher Operator and Administrator Manual - AddendumNikcola KrylovNo ratings yet

- Planet PDFDocument3 pagesPlanet PDFMohammed SadhikNo ratings yet

- Check List CeretomDocument2 pagesCheck List CeretomSalim AloneNo ratings yet

- PDFDocument24 pagesPDFousmaneNo ratings yet

- CAM-14 Acquisition Module: Field Service ManualDocument88 pagesCAM-14 Acquisition Module: Field Service ManualLászló BaloghNo ratings yet

- Service Manual: Single and Combination Lights Chromophare E 778, E 668, E 558Document112 pagesService Manual: Single and Combination Lights Chromophare E 778, E 668, E 558hluevano100% (1)

- GE Healthcare Aespire 7900 SmartVent BrochureDocument6 pagesGE Healthcare Aespire 7900 SmartVent BrochureVladimir OsunaNo ratings yet

- CT-HPL Aserie FWDocument138 pagesCT-HPL Aserie FWDemis MuratNo ratings yet

- COROMETRICSDocument440 pagesCOROMETRICSANELYNo ratings yet

- Operating Manual Ergometrics ER 900 (English) PDFDocument84 pagesOperating Manual Ergometrics ER 900 (English) PDFmiryangelNo ratings yet

- Philips NSN 6525-01-514-9962 User Manual PDFDocument1 pagePhilips NSN 6525-01-514-9962 User Manual PDFAnonymous KKSGFIZP7PNo ratings yet

- 2F201-059E - E - Asteion4 PartsDocument414 pages2F201-059E - E - Asteion4 Partsmedical serviceNo ratings yet

- Artromot K3 Knee CPM Service Manual SN Over 10000 PDFDocument17 pagesArtromot K3 Knee CPM Service Manual SN Over 10000 PDFمركز ريلاكس للعلاج الطبيعيNo ratings yet

- Shimadzu How To Connect Room Light For Radspeed PDFDocument3 pagesShimadzu How To Connect Room Light For Radspeed PDFRichard GomezNo ratings yet

- Mac 1200 ServiceDocument150 pagesMac 1200 Servicesoso loloNo ratings yet

- AA3426 - SPT1 User Guide - 2013-04-08 - enDocument26 pagesAA3426 - SPT1 User Guide - 2013-04-08 - enJose Quisca100% (1)

- Trumpf Ts 7500 Brochure enDocument26 pagesTrumpf Ts 7500 Brochure enPablo Botero BermúdezNo ratings yet

- Belmont Belray 096 Dental X-Ray - Installation Manual PDFDocument32 pagesBelmont Belray 096 Dental X-Ray - Installation Manual PDFIsmael CassiNo ratings yet

- Technical Information (General Radiography / XTV)Document4 pagesTechnical Information (General Radiography / XTV)Janet WaldeNo ratings yet

- T20-A Parts ListDocument28 pagesT20-A Parts ListVladimir OsunaNo ratings yet

- Uroview 8K Table Uroview 8K System: Pausch Medical GMBHDocument60 pagesUroview 8K Table Uroview 8K System: Pausch Medical GMBHmohadeseNo ratings yet

- Digitaldiagnost 2: Philips HealthcareDocument165 pagesDigitaldiagnost 2: Philips HealthcareJavier PayáNo ratings yet

- Rev4 (User's Manual)Document119 pagesRev4 (User's Manual)Павел ЗагудалинNo ratings yet

- Electrocardiografo IVY BIOMEDICAL 7800 (Manual)Document53 pagesElectrocardiografo IVY BIOMEDICAL 7800 (Manual)Kaira Romero VivancoNo ratings yet

- Q Stress User ManualDocument268 pagesQ Stress User ManualMade YastawaNo ratings yet

- Somatom: Hiq/ Plus/ ArDocument18 pagesSomatom: Hiq/ Plus/ ArHernan PerezNo ratings yet

- ENG - 6984924503 - Rev2 (Service Manual)Document440 pagesENG - 6984924503 - Rev2 (Service Manual)l.n.a.92100% (1)

- Chromophare Surgical and Examination Light: Pre-Installation InformationDocument23 pagesChromophare Surgical and Examination Light: Pre-Installation InformationCesar AlfaroNo ratings yet

- Surgical C-Arm Tables: Service ManualDocument80 pagesSurgical C-Arm Tables: Service ManualArt Messick100% (1)

- Horus 4Document6 pagesHorus 4Juan carlos100% (1)

- Eschmann RX-500 Operation Table - Service Manual PDFDocument40 pagesEschmann RX-500 Operation Table - Service Manual PDFimran maani100% (1)

- Comparison Mobilis Maquet Steris TrumpfDocument361 pagesComparison Mobilis Maquet Steris TrumpfOscar Daniel Q B100% (1)

- PLD8000 User Manual-V2.0Document128 pagesPLD8000 User Manual-V2.0abdulkader8dawalibiNo ratings yet

- Gendex 765DC Dental X-Ray - User Manual (En, Es, FR, Por)Document87 pagesGendex 765DC Dental X-Ray - User Manual (En, Es, FR, Por)henry olivares sotoNo ratings yet

- Victoreen 8000: Users ManualDocument98 pagesVictoreen 8000: Users ManualmariaNo ratings yet

- 2120900-100 Advantx Single Partes CpuDocument14 pages2120900-100 Advantx Single Partes CpuCarlos FloresNo ratings yet

- Regulatory Requirement: S8/S8 Pro Portable Digital Color Doppler Ultrasound SystemDocument132 pagesRegulatory Requirement: S8/S8 Pro Portable Digital Color Doppler Ultrasound SystemЮрий ДмитриевNo ratings yet

- ZEN-7000 - Consolidated Manual - ENG - 20130207Document164 pagesZEN-7000 - Consolidated Manual - ENG - 20130207Benjamin Gonzalez100% (1)

- DRX-Revolution Mobile X-Ray System: Safety and Regulatory InformationDocument44 pagesDRX-Revolution Mobile X-Ray System: Safety and Regulatory InformationDoaà SsalamNo ratings yet

- CR30 C11 Install Planning 7.0Document28 pagesCR30 C11 Install Planning 7.0suny1982No ratings yet

- GE Tonoport V Blood Pressure Monitor - Service ManualDocument52 pagesGE Tonoport V Blood Pressure Monitor - Service ManualManuel SaenzNo ratings yet

- Polydoros SX 50/80: SIRECON 2 ConnectionDocument50 pagesPolydoros SX 50/80: SIRECON 2 Connectionkhawar mukhtarNo ratings yet

- BC-11 BrochureDocument2 pagesBC-11 BrochureKopeNo ratings yet

- Soering MBC 200-BCC 140 - SM - enDocument101 pagesSoering MBC 200-BCC 140 - SM - enГригорийNo ratings yet

- Chapter 5 - Electrical DrawingsDocument68 pagesChapter 5 - Electrical DrawingsmazighiNo ratings yet

- Sirona Orthophos XG Dental X-Ray - Maintenance Instructions PDFDocument58 pagesSirona Orthophos XG Dental X-Ray - Maintenance Instructions PDFomar kassarNo ratings yet

- Lampi DragerDocument68 pagesLampi DragerAlin Mircea PatrascuNo ratings yet

- XG AC DC Annual Maint ScheduleDocument28 pagesXG AC DC Annual Maint ScheduleAnonymous YPx8ss48No ratings yet

- Remoute Maitenance Safari 17 DAR-8000Document178 pagesRemoute Maitenance Safari 17 DAR-8000drakonNo ratings yet

- Rayos X Odont Preva PDFDocument135 pagesRayos X Odont Preva PDFDaniel Parada VanegasNo ratings yet

- X-Frame DR-2T: Dual Detector System For Chest, General Radiography and TraumaDocument24 pagesX-Frame DR-2T: Dual Detector System For Chest, General Radiography and TraumaNassima BELILNo ratings yet

- Airis 2Document253 pagesAiris 2Ma DamasNo ratings yet

- VIVIX-S 3643VW SpecificationsDocument14 pagesVIVIX-S 3643VW Specificationstejerinaefrain100% (1)

- Jungheinrich SLH 200 Service ManualDocument30 pagesJungheinrich SLH 200 Service ManualNhàn Nguyễn ThanhNo ratings yet

- Em1 01 0 en 2110 MaDocument80 pagesEm1 01 0 en 2110 Macrmaster213No ratings yet

- RLC Circuits and ResonanceDocument15 pagesRLC Circuits and ResonanceYouness Ben TibariNo ratings yet

- The Complete List of MS-DOS CommandsDocument3 pagesThe Complete List of MS-DOS CommandsYouness Ben TibariNo ratings yet

- Barrier-Free Power Exam Table 625: Service and Parts ManualDocument133 pagesBarrier-Free Power Exam Table 625: Service and Parts ManualYouness Ben TibariNo ratings yet

- PR Shimadzu Opescope Acteno PDFDocument3 pagesPR Shimadzu Opescope Acteno PDFYouness Ben TibariNo ratings yet

- ULN2068BDocument1 pageULN2068BYouness Ben TibariNo ratings yet

- Digital Radiography Artifacts PDFDocument9 pagesDigital Radiography Artifacts PDFYouness Ben TibariNo ratings yet

- High Surge Energy Non-Inductive Compact Size: U Series ResistorsDocument2 pagesHigh Surge Energy Non-Inductive Compact Size: U Series ResistorsYouness Ben TibariNo ratings yet

- Tcg057vglaaann-Gn20 PDFDocument20 pagesTcg057vglaaann-Gn20 PDFYouness Ben TibariNo ratings yet

- Tcg057vglaaann-Gn20 PDFDocument20 pagesTcg057vglaaann-Gn20 PDFYouness Ben TibariNo ratings yet

- KG057QV1CA G00 Kyocera PDFDocument26 pagesKG057QV1CA G00 Kyocera PDFYouness Ben TibariNo ratings yet

- Agfa CR 85-X: Specification Fuji FCR Xg5000 Kodak CR 975Document3 pagesAgfa CR 85-X: Specification Fuji FCR Xg5000 Kodak CR 975Youness Ben TibariNo ratings yet

- Formtiles Brochures 2Document2 pagesFormtiles Brochures 2Joseph ValenciaNo ratings yet

- Technical Rider Alcatraz Sound-Light Requirements PDFDocument3 pagesTechnical Rider Alcatraz Sound-Light Requirements PDFvijesh sutharNo ratings yet

- FD Fan ID Fan ControlDocument4 pagesFD Fan ID Fan ControlAbhishek Kumar100% (2)

- Range Rover Velar Spec Sheet Tcm297 736053Document2 pagesRange Rover Velar Spec Sheet Tcm297 736053Shovon MajumderNo ratings yet

- End Yoke PDFDocument96 pagesEnd Yoke PDFadamtuongNo ratings yet

- Gluckman, Max - Malinowski's Contribution To Social AnthropologyDocument7 pagesGluckman, Max - Malinowski's Contribution To Social Anthropologyernestostudio74No ratings yet

- ASAL Economics Workbook AnswersDocument111 pagesASAL Economics Workbook AnswersMatej Milosavljevic100% (1)

- The Nature and Goals of Anthropology SociologyDocument27 pagesThe Nature and Goals of Anthropology SociologyBea Angela Esteban100% (2)

- Vintage Airplane - Jun 1979Document28 pagesVintage Airplane - Jun 1979Aviation/Space History LibraryNo ratings yet

- Generator Protection Realy Test FormDocument6 pagesGenerator Protection Realy Test Formwaheed bassamiNo ratings yet

- TestDocument19 pagesTestSkipper SkyNo ratings yet

- Bios116-Drosophila Eye PigmentDocument3 pagesBios116-Drosophila Eye PigmentJulio SubagioNo ratings yet

- Business Plan 1710775998500Document3 pagesBusiness Plan 1710775998500clintwaleNo ratings yet

- 31 Questions To Define A CultureDocument2 pages31 Questions To Define A Cultureexoduschj9858No ratings yet

- Joint Seat Allocation Authority 2019: Filled Choice (S)Document11 pagesJoint Seat Allocation Authority 2019: Filled Choice (S)v pathakNo ratings yet

- Technical AnalysisDocument4 pagesTechnical AnalysisShikha ShuklaNo ratings yet

- Belt Conveyor Idler: Read These Instructions Carefully Before Starting InstallationDocument8 pagesBelt Conveyor Idler: Read These Instructions Carefully Before Starting InstallationKenji LacambraNo ratings yet

- Ga-G31m-S2l (Rev 1.2)Document33 pagesGa-G31m-S2l (Rev 1.2)Richard Hernandez RuizNo ratings yet

- The Restoration of Degraded Lands by Local Communities and Indigenous Peoples.Document8 pagesThe Restoration of Degraded Lands by Local Communities and Indigenous Peoples.Nadia SantiniNo ratings yet

- Datasheet 3L2Document6 pagesDatasheet 3L2juan carlos diaz cardozoNo ratings yet

- Adopted Nymtc Ffy 2020-2024 TipDocument349 pagesAdopted Nymtc Ffy 2020-2024 TipShu YUNo ratings yet

- Problemario 2Document2 pagesProblemario 2Frank Hurtado0% (1)

- 4.1 Data CenterDocument26 pages4.1 Data CenterPramod PawarNo ratings yet

- Curs 11. Sistemul ExcretorDocument66 pagesCurs 11. Sistemul ExcretorDobrincu MirelaNo ratings yet

- AirValves 2013 PDFDocument268 pagesAirValves 2013 PDFSergio Sebastian Ramirez GamiñoNo ratings yet

- ATR100 Owners Manual PDFDocument20 pagesATR100 Owners Manual PDFHernan Alberto Orozco CastañoNo ratings yet

- Open Elective List 2020-21 - 5 AprilDocument2 pagesOpen Elective List 2020-21 - 5 AprilDharmendra SharmaNo ratings yet

- Perangkat Penunjang Pembuatan Studio MetaverseDocument2 pagesPerangkat Penunjang Pembuatan Studio MetaverseMaulana JamaludinNo ratings yet

- Reading Comprehension Tests - 83653Document2 pagesReading Comprehension Tests - 83653Henry Rojas VasquezNo ratings yet

User Manual: and Technical Description

User Manual: and Technical Description

Uploaded by

Youness Ben TibariOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

User Manual: and Technical Description

User Manual: and Technical Description

Uploaded by

Youness Ben TibariCopyright:

Available Formats

User manual and technical

description

Image 3 B

Bariatric hospital bed for acute care

D9U001AM2-0101

Version: 04

Publication date: 2018-08

Downloaded from www.Manualslib.com manuals search engine

Manufacturer:

LINET spol. s r. o.

Želevčice 5

274 01 Slaný

Czech Republic

Tel.: +420 312 576 111

Fax: +420 312 522 668

E-mail: info@linet.cz

http://www.linet.cz

Image 3 B

Bariatric hospital bed for acute care

Author: LINET, s.r.o.

Related links: www.linet.cz

D9U001AM2-0101

Version: 04

Publication date: 2018-08

Copyright © LINET, s.r.o., 2018

Translation © LINET, 2018

All rights reserved. All trademarks and brands are the property of the appropriate owners. The manufacturer

reserves the right to changes in the contents of this manual that relate to the product´s technical regulations. It is

for this reason that the contents of this manual may indicate differences from the current manufacture of the

product.

D9U001AM2-0101_04 2

Downloaded from www.Manualslib.com manuals search engine

Table of content

1 Symbols ........................................................................................................................... 5

1.1 Warning Notices ..................................................................................................................................5

1.2 Other symbols .....................................................................................................................................5

1.3 Symbols and Labels on the Product ...................................................................................................6

1.4 Serial label with UDI ............................................................................................................................7

2 Safety and Dangers ......................................................................................................... 8

2.1 Safety instructions ...............................................................................................................................9

2.2 Conditions of Use ..............................................................................................................................11

2.3 Specifications of Use.........................................................................................................................11

3 Standards and Regulations .......................................................................................... 11

4 Functioning .................................................................................................................... 12

4.1 Correct use ........................................................................................................................................12

4.2 Incorrect Use .....................................................................................................................................12

5 Scope of Delivery and Bed Variants............................................................................. 13

5.1 Scope of Delivery ..............................................................................................................................13

5.2 Bed Variants ......................................................................................................................................13

5.3 Applied parts type B ..........................................................................................................................14

6 Setup .............................................................................................................................. 15

6.1 Transport ...........................................................................................................................................15

6.2 Setup ...............................................................................................................................................15

7 Battery Activation .......................................................................................................... 16

7.1 Placement of Control Section ..........................................................................................................16

7.2 Removing the Isolating Foil ..............................................................................................................16

7.3 Isolating Foil ......................................................................................................................................16

8 Assembly ....................................................................................................................... 17

8.1 Potential Equalisation........................................................................................................................17

8.2 Mattress platform ..............................................................................................................................18

8.3 Image 3 B (1AM2) - Single Collapsible Side Rails and Powder Coated Bed Ends ..........................19

8.4 Bed Ends ...........................................................................................................................................20

9 Operation ....................................................................................................................... 22

9.1 Initial Operation .................................................................................................................................22

9.2 Battery ...............................................................................................................................................22

9.3 Battery charging ................................................................................................................................23

9.4 Status Faulty Battery .........................................................................................................................24

9.5 Status Discharged Battery ................................................................................................................24

9.6 Removing the Bed from Service .......................................................................................................24

9.7 Deactivating the Battery ....................................................................................................................24

10 Manipulation .................................................................................................................. 25

10.1 Supervisor control panel (nurse controller) .................................................................................26

10.2 Handset .......................................................................................................................................29

10.3 Night Bed Lightning .....................................................................................................................30

10.4 Bed Illumination ...........................................................................................................................30

D9U001AM2-0101_04 3

Downloaded from www.Manualslib.com manuals search engine

10.5 CPR backrest release ..................................................................................................................31

10.6 Side rails ......................................................................................................................................32

10.7 Castor Control and Bed Transport ...............................................................................................33

11 Accessories ................................................................................................................... 34

12 Cleaning and Disinfection ............................................................................................. 39

12.1 Safety Instructions for Cleaning and Disinfection of the Bed ......................................................39

12.2 General Instructions for Cleaning and Disinfection .....................................................................40

12.3 Choosing of Detergents or Disinfections .....................................................................................41

13 Troubleshooting ............................................................................................................ 42

14 Maintenance................................................................................................................... 43

14.1 Maintenance Work .......................................................................................................................43

14.2 Functioning ..................................................................................................................................44

15 Disposal ......................................................................................................................... 46

15.1 Environmental Protection ............................................................................................................46

15.2 Disposal .......................................................................................................................................46

16 Warranty ......................................................................................................................... 47

17 EC Declaration of Conformity ....................................................................................... 48

18 Technical Specifications ................................................................................................ 49

18.1 Mechanical Specifications ............................................................................................................49

18.2 Environment Conditions ..............................................................................................................49

18.3 Electrical Specification .................................................................................................................50

18.4 PB 4X Electronic System of Image 3 B .......................................................................................51

D9U001AM2-0101_04 4

Downloaded from www.Manualslib.com manuals search engine

1 Symbols

1.1 Warning Notices

1.1.1 Types of Warning Notices

Warning notices are differentiated by the type of danger using the following key words:

Caution - risk of material damage.

Warning - risk of physical injury.

Danger - risk of fatal injury.

1.1.2 Structure of Warning Notices

SIGNAL WORDS!

Type and source of danger!

Measures to avoid the danger.

1.2 Other symbols

1.2.1 Instructions

Structure of instructions:

Perform this step.

Result, if necessary.

1.2.2 Lists

Structure of bulleted lists:

List level 1

List level 2

Structure of numbered lists:

a. List level 1

b. List level 1

1. List level 2

2. List level 2

D9U001AM2-0101_04 5

Downloaded from www.Manualslib.com manuals search engine

1.3 Symbols and Labels on the Product

Read user manual.

Attention

Thermal protection of transformer

Only suitable for indoor use

Protection against accidents due to electrical current

– Type B instruments

Safety isolation transformer, general

CE mark of conformity with EU regulation

Jack for attachment of conductor for potential

equalisation

Safe Working Load

Warning against crushing or trapping

Maximum weight of patient

Use mattress recommended by manufacturer

Weight of bed

D9U001AM2-0101_04 6

Downloaded from www.Manualslib.com manuals search engine

Do not put any objects here

WEEE symbol (recycle as electronic waste, do not put

into the household waste)

1.4 Serial label with UDI

1 2 3

4 5 6 7 8 9 10

Fig. Serial Label with UDI (Image 3 B)

1 Address of Distributor

2 Manufacturing Date (Year-Month-Day)

3 DI (Device Identifier) / GTIN (Global Trade Item Number)

4 1D Bar code GS1-128 (Serial Number)

5 Symbols

6 Configuration number

7 Electrical Specification

8 Serial Number

9 PI (Product Identifier)

10 2D Bar Code (GS1 DataMatrix) DI+PI=UDI

D9U001AM2-0101_04 7

Downloaded from www.Manualslib.com manuals search engine

2 Safety and Dangers

WARNING!

Image 3 B bed should be left in its lowest position when the patient is unattended in order to reduce

risk of injury due to falls!

WARNING!

Siderails of Image 3 B should be located in the „up“ position to reduce the risk of the patient

accidentally slipping or rolling off the mattress!

WARNING!

Incompatible siderails and mattresses can cause an entrapment hazard!

WARNING!

Inappropriate handling of the power supply cord, e. g. by kinking, shearing or other mechanical

damages is hazardous!

WARNING!

When routing cables from other equipment in the Image 3 B bed avoid squeezing those between parts

of the Image 3 B bed!

WARNING!

Image 3 B bed should not be used with bed hoists and bed lifts!

WARNING!

The bed is intended for adults.

Follow chapter Intended use.

WARNING!

Incompatible mattresses can create hazards.

WARNING!

To avoid the risk of electric shock, this equipment must only be connected

to a supply mains with protective earth.

WARNING!

No modification of this equipment is allowed.

D9U001AM2-0101_04 8

Downloaded from www.Manualslib.com manuals search engine

WARNING!

Do not modify this equipment without authorization of the manufacturer.

WARNING!

If this equipment is modified, appropriate inspection and testing must be

conducted to ensure continued safe use of the equipment.

WARNING!

An additional MULTIPLE SOCKET-OUTLET or extension cord shall not be

connected to the MEDICAL ELECTRICAL SYSTEM.

WARNING!

During specific investigations or treatments the significant risks of reciprocal interference posed by

ME equipment may occur.

2.1 Safety instructions

Follow the instructions carefully.

Any non-observance of this manual may lead to injuries or material damage.

Exclusively use the bed if it is in perfect working order.

If necessary, check the bed functions daily or at each shift change.

Use the bed exclusively in its original condition.

Use the bed exclusively with the correct mains supply.

Ensure that the bed is exclusively operated by qualified personnel .

Ensure that the patient (health permitting) has been informed about the operation of the bed and all

applicable safety instructions.

Move the bed exclusively on even, hard-surfaced floors.

Replace any damaged parts immediately with original spare parts.

Ensure that maintenance and installation are performed exclusively by qualified personnel who have been

trained by the manufacturer.

Do not apply excess weight or loads to the bed according to SWL (safe working load).

During peak loads or unavoidable excess loads (CPR), place mattress platform in the lowest position.

Ensure that only one adult patient uses the bed at any time.

Take care to avoid injuries or squeezing when operating moving parts.

When using lifting poles or infusion stands, ensure that nothing will be damaged when you move or adjust

the bed.

Ensure that castors are braked when the bed not being moved, regardless of whether the bed is occupied

or empty

Keep the mattress platform in the lowest position at any time when the healthcare personnel are not

treating the patient in order to prevent the patient from falling or injuries.

Ensure that siderails are operated exclusively by healthcare personnel.

Never use the bed in areas where there is a hazard of explosion.

Enable or disable functions on the handset using the supervisor panel as appropriate for the patient’s

physical and mental state. Verify that the function is actually disabled.

Never handle the mains plug with wet hands.

Unplug the mains cable exclusively by pulling on the plug.

D9U001AM2-0101_04 9

Downloaded from www.Manualslib.com manuals search engine

Position the mains cable so that there are no loops or bends in the cable; protect the cable from

mechanical wear and tear.

Improper handling of mains cable can cause an electric shock hazard, other serious injuries or damage to

the bed.

Ensure that the stipulated duty cycle (on-time) is not exceeded (see INT. on product label).

Ensure that the moving parts of the bed are not blocked.

To prevent failures, use exclusively the manufacturer’s original accessories and mattresses.

Ensure that the stipulated safe working load is not exceeded.

If the patient's condition could lead to an entrapment, leave the mattress support platform in the flat

position while the patient is unattended.

Adjust bed height to approx. 20 cm below maximum height when transporting the bed in order to facilitate

overcoming possible obstacles.

Do not exceed maximum load of 75 kg for mattress platform extension.

Ensure that the bed and its components are exclusively modified with the manufacturer´s approval.

Ensure there is no risk of crushing or otherwise injuring the patient’s limbs (e.g. between siderails and

mattress platform, between movable parts etc.) before positioning the bed or folding down the siderails.

Close linen shelf before using the Reverse Trendelenburg position.

Do not put any objects (e.g. accessories, infusions, cables) between or on siderails and movable parts.

Use exclusively split plastic or split telescopic siderails for confused or disoriented patients.

Before setting the extra-low position, ensure there is no risk of any parts of the bed colliding with servers,

accessories or body parts.

Ensure there is no risk of damaging the cables of supervisor panel or handset when they are stored on

siderails or bed ends.

To prevent collisions, do not put oxygen bottle holders directly under mattress platform.

Always set mattress platform to its lowest position and single parts of mattress platform to horizontal

position in case the patient is left on the bed without supervision of personnel and if his health and mental

status may indicate increase risk of falling out of the bed or entrapment.

Personnel must consider overall adjustment of the bed and locking all of the positioning functions in

accordance to health and mental status of patient, especially if the patient is left without supervision (even

for short period of time) of the personnel.

Manual positioning of parts of the bed which are designed for electronic positioning (e.g. back rest) is

forbidden. Otherwise there is a risk of damaging and dysfunction of the back rest actuator or unprompted

fall of the back rest.

D9U001AM2-0101_04 10

Downloaded from www.Manualslib.com manuals search engine

2.2 Conditions of Use

The bed may not be used and stored in indoor environments:

Where there is a risk of explosion.

Containing inflammable anaesthetics.

The bed is designed for use in rooms for medical purposes. Electrical installations must therefore meet local stan-

dards laying down the necessary conditions for electrical installations.

Disconnect the bed from the mains in exceptional cases (i.e. a storm).

2.3 Specifications of Use

Medical purpose:

Hospital bed for acute care, support for patient in various positions (Horizonal position, Trendelenburg,

cardiac chair, etc.)

Patient:

For patiens older than 15 years. Weight of patient + mattress + accesories can not be higher than safe

working load (SWL). Condition of patient is not important.

Personnel:

Qualified medical staff (nurse, doctor) with medical school or university (EU). Any person familiar with the

manual. Patient if the condition permits.

Location:

The bed is determined for application environments 1, 2, 3 and 5 according to EN 60601-2-52:2010. The

stable undercarriage with 4 castors makes it possible for the bed to be handled by one person. However,

the manufacturer recommends that at least two persons handle the bed.

3 Standards and Regulations

The bed complies with the following standards and directives:

IEC 60601-1:2012

IEC 60601-1-2:2007 3.ED

IEC 60601-1-6:2010

IEC 60601-2-52:2010

ISO 15223-1:2012

ISO 10993-5:2009

ISO 10993-10:2010

93/42/EEC

2011/65/EU

The manufacturer adheres to a certified quality management system in compliance with the following

standards:

ISO 9001:2008

ISO 14001:2004

EN ISO 13485:2003

D9U001AM2-0101_04 11

Downloaded from www.Manualslib.com manuals search engine

4 Functioning

4.1 Correct use

DANGER!

Risk of injury or death due to use of incorrect equipment!

Always conduct the risk assessments required for the selection of suitable equipment.

Image 3 B is a standard care hospital bed. It is designed for supporting the bariatric patient in several positions

such as horizontal, Trendelenburg, Cardiac Chair etc.

The stable undercarriage with 4 castors makes it possible for the bed to be handled by one person. However, the

manufacturer recommends that at least two persons handle the bed.

Image 3 B is suitable for:

Patients

Older than 15 years

With a maximum weight of 285 kg

Whose weight (including mattress and accessories) does not exceed the SWL

Personnel

Qualified medical staff

Any person familiar with the manual

Patient (condition permitting)

Use

standard care

acute care

uninterrupted operation

Location

Application environments 1, 2, 3 and 5 according to EN 60601-2-52:2010

4.2 Incorrect Use

Image 3 B is not suitable for:

Patients

Younger than 15 years

Use

Other than described in the user manual

NOTE For information concerning uses other than those outlined in the “Correct Use” section above, please

contact LINET®.

LINET®’s efforts in research, design and manufacture ensure LINET® products are of the highest quality and fit

for their intended purpose. However, LINET® can take no responsibility for any damage to the products or any

harm to patients, staff or other individuals resulting from:

Not following the instructions in the manual, including warning notices.

Using the product for a purpose other than the intended purpose stated in the relevant documentation

provided by LINET® (see Correct Use).

D9U001AM2-0101_04 12

Downloaded from www.Manualslib.com manuals search engine

5 Scope of Delivery and Bed Variants

5.1 Scope of Delivery

Delivery:

Upon receipt, check that the shipment is complete as specified on the delivery note.

Notify the carrier and supplier of any deficiencies or damages immediately as well as in writing or make a

note on the delivery note.

The bed is delivered with deactivated battery. To activate battery see chapter “Battery activation”.

5.2 Bed Variants

CAUTION!

Damage to the bed due to incorrect use!

Use 125 mm castors exclusively on flat, even surfaces without any gaps.

Features – Image 3 B Model 1AM2 (model no. see product label):

Mattress Platform

mattress platform consisting of removable plastic segments

Bed Ends

powder coated with fixed, coloured HPL panels

aluminium bed ends with fixed coloured HPL panels

Side rails

Single collapsible side rails, powder coated

Castors

125 mm Tente Linea with individual braking system

150 mm Tente Linea, with central braking system

Control Elements

ACP Nurse control panel (supervisor control panel)

Handset with illuminated keyboard

Handset without illuminated keyboard

Other

Linen shelf

Vertical safety bumpers

One pair of universal accessory holders

One pair of urine bag holder

CPR emergency backrest release

Segufix holders

Colour concept

Powder-coated metal parts RAL 9006 (light grey) + RAL 7043 (dark grey)

Powder-coated metal parts RAL 9002 (white)

D9U001AM2-0101_04 13

Downloaded from www.Manualslib.com manuals search engine

5.3 Applied parts type B

All the accesories the patient can reach are type B applied parts.

List of type B applied parts:

ACP Nurse control panel (supervisor control panel)

Handset

Satellite controller

Side rails

Bed ends

Mattress platform

D9U001AM2-0101_04 14

Downloaded from www.Manualslib.com manuals search engine

6 Setup

6.1 Transport

For safe transport, observe the following:

Ensure no cables are run over when moving a bed.

Ensure the mains cable is attached with a hook (at the head end of the bed).

Ensure the castors are unlocked before moving the bed during the loading/unloading process (see Castor

Control and Bed Transport).

Ensure the side rails are lifted and locked while the patient is on the bed during the transport.

Move the bed only on suitable floor surfaces.

Suitable surfaces:

Tile

Hard linoleum

Hard flooring

Unsuitable surfaces:

Soft, unsealed or defective flooring

Soft wooden flooring

Soft and porous stone floors

Carpeted floors with underlay

Soft linoleum

For longer distances, ensure the castor steering function (main control) is activated.

Ensure the brakes are released while moving the bed.

6.2 Setup

Set up the bed as follows:

Unpack the bed.

Check the delivery (see Scope of Delivery).

Remove isolating foil from mains control box (see Removing Isolating Foil).

Install equipment and accessories (see Assembly).

In case of delivery with dismounted bed ends, mount the head and foot ends (see Bed Ends).

Set-up the bed only on a suitable floor surface (see Transport).

Ensure the mains cable does not collide or get stretched when adjusting the bed. Check the plug is

inserted correctly.

Do not leave any extension cords or power strips loose on the floor.

Ensure all the required mechanical and electrical prevention mechanisms are available on site.

There is no mains switch on the bed, i.e. the mains cable is the only means to isolate the bed from the

mains.

Ensure the mains cable is always accessible.

The plug on the mains cable should only be changed and maintained by qualified and trained service

technicians authorised by the manufacturer.

D9U001AM2-0101_04 15

Downloaded from www.Manualslib.com manuals search engine

7 Battery Activation

7.1 Placement of Control Section

7.2 Removing the Isolating Foil

Pull

7.3 Isolating Foil

Check if isolating foil is complete and undamaged as shown:

If isolating foil is damaged, contact the manufacturer’s service department immediately.

NOTE: It is recommended to wear gloves when removing the isolating foil.

D9U001AM2-0101_04 16

Downloaded from www.Manualslib.com manuals search engine

8 Assembly

WARNING!

Risk of injury when working on the bed!

Ensure the bed is disconnected from the mains connection prior to assembly, disassembly and

maintenance.

Ensure the castors are locked prior to assembly, disassembly and maintenance.

CAUTION!

Material damage due to incorrect assembly!

Ensure the assembly is performed only by seller´s customer service or trained hospital personnel.

8.1 Potential Equalisation

The bed is equipped with a standard protective connector. This connector is used for potential equalisation

between the bed and any intravascular or intracardiac device connected to the patient to protect the patient from

static electric shocks.

Fig. 1 Potential equalisation connector – male Fig. 2 Potential equalisation connector – female

Use equalisation connector if:

The patient is connected to any intravascular or intracardiac device.

Before connecting the patient to an intravascular/intracardiac device:

Connect the ground wire of the device to the potential equalisation connector (Fig. 1) on the bed on which

the patient in question is lying.

Use a standard hospital connector (Fig. 2).

Make sure the connectors match.

Make sure there is no possibility of accidental disconnection.

Before moving the bed:

Disconnect the patient from the intravascular or intracardiac device.

Disconnect the potential equalisation connector.

D9U001AM2-0101_04 17

Downloaded from www.Manualslib.com manuals search engine

8.2 Mattress platform

The mattress platform consists of removable plastic sections.

To remove/install sections of the mattress platform:

Pull out mattress platform sections.

Install mattress platform section.

The correct fitting of section is signalized by hearable “click”.

Ensure that mattress platform sections are fitted correctly by trying pull the section up with little manpower.

Fig. 3 Label on Mattress Platform Parts

D9U001AM2-0101_04 18

Downloaded from www.Manualslib.com manuals search engine

8.3 Image 3 B (1AM2) - Single Collapsible Side Rails and Powder Coated Bed Ends

Fig. 4 Overview Image 3 B – Single Collapsible Side Rails

1. Foot end of the bed

2. Virtuoso II compressor

3. Side rail release mechanism

4. Side rail extension – Extender®

5. Virtuoso II active mattress for bariatrics

6. Head end of the bed

7. Single collapsible side rails

8. Handset

9. Castor control lever

10. Castor

11. CPR control lever – backrest release

12. Accessories rail

13. Fifth castor

14. Calf rest handle / Mattress holder

15. Housing for the Protector®

16. Bed end unlocking mechanism

17. Supervisor control panel

18. Protective bumper

NOTE For safe, easy handling, LINET® recommends that two technicians assemble the bed.

D9U001AM2-0101_04 19

Downloaded from www.Manualslib.com manuals search engine

8.4 Bed Ends

NOTE: The bed ends may be delivered in several decor colour variants.

WARNING!

Risk of injury when inserting the bed ends!

To insert bed ends into corner posts, hold them by the corner handles on top with both hands.

Install bed ends before the first use.

WARNING!

Risk of injury due to incorrectly installed bed ends!

Ensure bed ends are correctly inserted, especially when moving the bed.

Ensure bed ends locks are locked, especially when moving the bed.

WARNING!

Risk of injury when removing the bed ends!

Before removing bed ends, ensure side rails are folded down and there are no accessories attached to

the bed ends.

If a patient is lying in a bed with the head and/or foot board removed, supervise the bed at all times.

WARNING!

Material damage due to excess load!

Ensure nobody sits on the bed ends.

8.4.1 Aluminium bed ends

Fig. 5 Locking the bed end

1. Locked

2. Unlocked

D9U001AM2-0101_04 20

Downloaded from www.Manualslib.com manuals search engine

8.4.2 Powder coated bed ends

Fig. 7 Unlocked bed end Fig. 6 Locked bed end

1. Unlocked (the bed end can be removed)

2. Locked (bed end is locked)

8.4.3 Installation of bed ends

Install the bed ends as follows:

Unlock safety levers on corner posts (red arrow marks direction).

Slide bed end into slots on corner posts with coloured panel on the outside.

Lock safety levers on corner posts.

Remove the bed ends as follows:

Unlock safety levers on corner posts.

Pull bed end upward.

1. Right

2. Wrong

NOTE: It is possible to install bed

ends to the bushings with locked lock.

Fig. 8 Installing the bed ends

D9U001AM2-0101_04 21

Downloaded from www.Manualslib.com manuals search engine

9 Operation

9.1 Initial Operation

CAUTION!

Material damage due to temperature difference!

If there is a considerable temperature difference between the bed and the place of operation (after

transport/storage), leave bed unconnected for 24 hours to allo the temperature to equalise.

Prepare the bed for service as follows:

Dispose of all packaging (see Disposal).

Connect the bed to the mains.

Charge the battery.

Raise the mattress platform to the highest position.

Remove the isolating foil from control section.

Lower and tilt the mattress platform to the lowest position.

Check the castors and main brake work correctly.

Check the bed extension works correctly.

Check it is possible to remove the head and foot boards.

Check all of the functions on the control elements (supervisor control panel etc.).

Check the side rails function properly.

9.2 Battery

For declared lifetime period of leaded accumulators is recommended during storage:

1. To prevent accumulators from deep discharging (state-of-charge under 70%) and to keep accumulators

at least partly charged by regular recharging

2. To store accumulators on dry and cold places (from 10°C to 0°C)

3. To prevent accumulators from being in the sunshine

CAUTION!

Risk of reducing battery durability due to incorrect use!

Use bed on battery only in crisis situations(e.g. power blackout, patient complications during transport,

etc.).

After reconnecting bed to the mains charge battery to full capacity (see chart Battery charge status).

CAUTION!

Risk of damage or destruction of battery!

If the battery is faulty, degassing may occur. In rare cases this might cause deformations of the battery

case, control panel housing or cable.

If this occurs stop using the bed immediately (see Removing the Bed from Service).

Inform the manufacturer’s service department immediately.

The battery supplied with the bed is delivered uncharged. The battery serves as a backup during power failures or

while transporting the patient.

D9U001AM2-0101_04 22

Downloaded from www.Manualslib.com manuals search engine

Use only batteries approved by the manufacturer.

The manufacturer provides a 6-month warranty for the full function of batteries.

Check the battery functionality at least once a month in accordance with the user and service manuals

and have the batteriy changed if necessary.

The manufacturer recommends to replace the battery by qualified service organization after 2 (two) years

of use. After this period the supposed service life of battery ends and the manufacturer cannot guarantee

the battery service life after this period.

The battery must be replaced with the new battery approved by manufacturer after maximum 5 (five)

years of use at the latest.

The manufacturer will assume no responsibility for any damage to the bed or the battery caused by:

o Non-observance of the manufacturer’s instructions in the user manual.

o Using batteries not approved by the manufacturer.

o Battery replacement non-qualified service organisation.

9.3 Battery charging

To charge the battery:

Connect the bed to the mains and check the yellow LED on the Supervisor control panel according to the

table 1.

NOTE: Some bed adjustment options are not available without a battery, for example, height adjustment under a

load of above 200 kg.

Charging and battery capacity is indicated by the yellow LED placed on the ACP control panel.

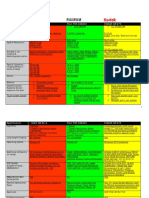

The LED indicates the battery’s charge status:

Yellow LED Battery charge status

Not lit Battery capacity is sufficient (charging completed)

Short flashing (short, intermittent illumination) Battery is charging - continue charging until the LED

(circa 1.8 sec.) is extinguished. In emer-gency cases, the battery can

be used as a backup power source for a short period.

If LED is still flashing after 12 hours of charging or

stops flashing, but you can not position with bed,

battery is defective or broken. Contact manufacturer.

Long flashing (long illumination) (circa 0.2 sec.) Low battery voltage - battery can not be used as a

backup power supply even for a short period; battery

is completely discharged or defective (if this type of

signalisation persists, it is necessary to replace the

battery - service action)

Long, intermittent illumination for several hours (circa Battery absence or failure condition (battery is

10 hours), when bed is connected to the mains. connected incorrectly, line between the power supply

and battery is broken or battery fuses are faulty);

contact service department of the manufacturer in

case of such signalisation.

Table 1 ACP control panel – battery signalization

To maintain maximum functionality of the battery:

Unplug the bed from the mains as least as possible.

In case the battery cover or control section is deformated by heat

Unplug the bed from the mains.

Do not use the bed (see. Removing the Bed from Service.

Contact service of the manufacturer.

D9U001AM2-0101_04 23

Downloaded from www.Manualslib.com manuals search engine

9.4 Status Faulty Battery

The battery is regarded as faulty if at least one of the following conditions applies:

Battery charging constantly

Low voltage on battery

Low charging current of battery

Status “faulty battery” is indicated:

By the battery status indicator being constantly lit.

A fault battery status can be cancelled by pressing the STOP button.

Battery status data is saved to the Linis system and written to the “Blackbox”.

9.5 Status Discharged Battery

The battery is regarded as discharged if the following condition is met:

Defined decrease of voltage depending on discharging current

Status “discharged battery” is:

Status is indicated by the battery status indicator flashing quickly.

The electric CPR position is the only possible position.

This status will be cancelled automatically when the bed switches to sleep mode.

9.6 Removing the Bed from Service

How to remove the bed from service:

Disconnect the bed from the mains.

Disconnect the ground wire.

Deactivate the battery (see Deactivating the Battery).

Remove accessories.

To prevent damage during storage:

Pack or cover the bed and accessories.

Ensure storage conditions are the same as the operating conditions.

9.7 Deactivating the Battery

To avoid damaging the bed and the environment during storage:

Deactivate the battery on the supervisor control panel.

To deactivate the battery on the supervisor control panel:

Disconnect the bed from the mains.

Disconnect the ground wire.

Activate the keypad by pressing the GO button on the supervisor control panel.

Press the Thigh Rest Up + Thigh Rest Down + Trendelenburg Position buttons at the same time and hold

them for three seconds.

The battery is deactivated.

NOTE: Try some functions to ensure the battery is deactivated.

D9U001AM2-0101_04 24

Downloaded from www.Manualslib.com manuals search engine

10 Manipulation

WARNING!

Risk of injury when adjusting the bed!

Ensure there are no body parts between the mattress platform elements and the mattress platform frame

when adjusting the bed.

Ensure there are no body parts below the mattress platform frame before adjusting the bed.

Secure or remove any items on the bed.

The bed is operated by different control elements.

Control elements:

ACP Nurse control panel (supervisor control panel)

Handset

Disabling individual functions on the supervisor control panel affects all of the control elements.

If the bed does not react to individual position settings:

Check whether the function is disabled on the supervisor control panel.

D9U001AM2-0101_04 25

Downloaded from www.Manualslib.com manuals search engine

10.1 Supervisor control panel (nurse controller)

Supervisor panel is main control panel of the bed. Nurse controller can be placed in the shelf. We recommend

placing ACP panel on the bed end of the bed or hold it in the hands while controlling the bed.

Fig. 9 Supervisor control panel

1. Lock indicators

2. Lock Buttons for respective functions

3. Thighrest Positioning Buttons

4. Backrest Positioning Buttons

5. Height Adjustment Buttons

6. Auto-Contour Buttons (simultaneous setting of back- and thighrest)

7. Central STOP button

8. Button Trendelenburg (mattress platform tilt only)

9. Button Reverse Trendelenburg (mattress platform tilt only)

10. Button Examination Position

11. Button Extra-low Position

12. Button CPR (Resuscitation) Position

13. Emergency Trendelenburg Button

14. Button Cardiac Chair Position

15. Button Mobilisation Position

16. LED Battery charge status (only for beds with backup battery)

17. LED Mains power

18. Activating GO Button

19. Bed Lights Control Button (ON/OFF)

NOTE: In case that the bed is not equipped with bed light control , button 19 is not on the controller.

D9U001AM2-0101_04 26

Downloaded from www.Manualslib.com manuals search engine

To set positions:

Activate the keypad by pressing the GO button.

Press and hold corresponding button until required position is reached.

10.1.1 Central STOP Button

The central STOP button 7 immediately interrupts all bed movements.

Pressing central STOP button 7 for at least 0.3 seconds immediately stops all electronic bed movements.

10.1.2 Activating GO Button

The GO button 18 activates the keypads on all control elements except the foot control.

A GO button is included on a number of different control elements. The function of the GO button is identical on

all control elements.

After pressing GO button 18, the keypad will remain active for 3 minutes. It is possible to control every function on

the bed except the locked functions.

Pressing a function button will keep the keypad active for another 3 minutes.

It is necessary to activate the keypad again if the 3 minute period without pressing any function is passed.

10.1.3 Function Buttons

Function buttons 3, 4, 5 and 6 allow the setting of different positions, for example the height and tilt of the

mattress plat-form, adjust individual mattress platform elements, etc.

NOTE: The bed can be stopped by pressing two different buttons even on two different controllers. If the press of

the buttons is longer than 0,5 second the bed will stop all the movements immediately.

To set a position:

Activate the keypad by pressing the GO button.

Press and hold the respective button until required position is reached.

10.1.4 Lock Buttons

Lock button 2 allows disabling individual functions on the supervisor control panel.

To disable functions:

Activate the keypad by pressing the GO button 18.

Press respective lock button.

The respective LED flashes to indicate the lock.

NOTE: The individual functions are locked in the central control panel, the satellite control and the handset.

To enable disabled functions:

Activate the keypad by pressing the GO button.

Press the respective lock button.

The respective LED goes out. The function is enabled.

D9U001AM2-0101_04 27

Downloaded from www.Manualslib.com manuals search engine

10.1.5 Position Buttons

WARNING!

Risk of injury due to moving parts!

Ensure no body parts are trapped between moving parts of the bed and mattress platform.

Ensure no persons or body parts are close to the bed or accessories (e.g. infusion stand, lifting pole)

when the mattress platform is moving.

CAUTION!

Material damage due to moving parts!

Ensure no objects (e.g. cables) are trapped between moving parts of the bed and mattress platform.

Ensure no objects are close to the bed or accessories (e.g. infusion stand, lifting pole) when the mattress

platform is moving.

The therapeutic and safety-related positions are pre-programmed. When a position is set, several parts of the bed

and mattress platform will move simultaneously.

Programmed positions:

Cardiac chair position

Trendelenburg position

CPR (resuscitation) position

To set the programmed positions:

Activate the keypad by pressing the GO button.

Press and hold corresponding function button until the desired position is reached.

Trendelenburg position (8)

The Trendelenburg position serves as an anti-shock position. All parts of the mattress platform are flattened.

Mattress platform tilts head down.

Cardiac chair position (button 15)

The cardiac chair position is suitable for patients with cardiac arrhythmia and breathing difficulties.

Settings after pressing and holding the Cardiac chair button (15):

Calfrest tilts into lowest position, thighrest moves into the upright position (34°).

6 second after positioning calfrest and thighrest the backrest will move into an upright position (70°).

CPR (Resuscitation) Position

The CPR position is for resuscitating the patient in an emergency.

Settings after pressing and holding the CPR button (12):

Mattress platform moves into a horizontal position.

NOTE: For quick mechanical positioning, see CPR Backrest Release.

D9U001AM2-0101_04 28

Downloaded from www.Manualslib.com manuals search engine

10.2 Handset

The handset is included as a standard feature. The handset is available with and without button illumination. The

button illumination of the illuminated handset is active when the bed is connected to the mains. The functions of

both handsets are identical. Where the handset is to be stored on the bed depends on the patient’s condition.

Fig. 10 Handset

1. Thighrest Adjustment Button

2. Thighrest/Backrest Lock LED

3. Backrest Adjustment Button

4. Activating GO Button

5. Auto-Contour Button

6. Height Adjustment Button

7. Height Lock LED

8. Flashlight Button

9. Flashlight

To switch on the flashlight:

Press and hold flashlight button 8 and flashlight 9 on the top of the handset will light up.

Set the positions as follows:

Activate the keypad by pressing the GO button.

Press and hold the function button until the desired position is reached.

NOTE: Depending on the patient’s condition, the nursing staff decides whether the patient is allowed to adjust the

bed’s position.

If required, prevent the patient from adjusting the bed as follows:

Disable functions.

Unplug handset.

NOTE: The handset can be plugged into another LINET® hospital bed with the Plug and Play slot.

D9U001AM2-0101_04 29

Downloaded from www.Manualslib.com manuals search engine

10.3 Night Bed Lightning

It is possible to equip Image 3 B with undercarriage lightning. The lightning helps the patient or hospital personnel

to better orientate in room with lowered or turned off light. The lowered intensity of lightning is set up after turning

the bed on. For additional informations about bed lightning see chapter “Bed Illumination”.

10.4 Bed Illumination

The bed is equipped with three-phase illumination:

1. Full intensity of illumination

2. Lowered intensity of illumination

3. Illumination is turned off

The lowered intensity of illumination is set up after the bed is turned on.

After pressing the GO button:

The handset and bed illumination will light up at full intensity.

After elapsing the GO period:

The illumination intensity of handset will be lowered.

7 minutes after GO period has elapsed:

The intensity of bed illumination will be lowered.

In the event any button is pressed (supervisor, handset or side rail) outside of GO period:

The bed illumination will light up at full intensity for 10 minutes and after that, the illumination will be

lowered.

Simultaneously, the handset will light up at full intensity for 7 seconds. After that the illumination will

be lowered.

Turning off all illumination:

Press button (19) and all illumination on the bed (handset and bed illumination) will be turned off.

This function is not blocked by the activation GO button.

D9U001AM2-0101_04 30

Downloaded from www.Manualslib.com manuals search engine

10.5 CPR backrest release

WARNING!

Risk of injury due to lowering the backrest too quickly!

Ensure single collapsible side rails are in their lowest position.

or

Ensure split plastic side rails are in their highest position.

Ensure there are no body parts between side rails and backrest.

Press the backrest down only by the mattress guard handle or the side rail.

The bed permits quick mechanical lowering of the backrest for emergency resuscitation (CPR) procedures.

Fig. 11 Backrest release CPR

Set the position as follows:

Pull and hold CPR backrest release lever and simultaneously press backrest down by the mattress

guard handle.

NOTE: In some cases (e.g. with bed in Trendelenburg position without power supply) it is possible to use the

CPR lever to raise the backrest.

D9U001AM2-0101_04 31

Downloaded from www.Manualslib.com manuals search engine

10.6 Side rails

The single collapsible side rails are components of the bed. The side rails cannot be dismounted. Hospital

personnel are responsible for locking side rails in the highest position when the patient is on the bed.

To fold the siderail down:

Take hold of the release mechanism and push the side rail towards the head of the bed to unlock the

locking system 1.

Press button 2 to unlock.

Fold down side rail as required 3.

To raise the side rail push the side rail up. The side rail will click into place and lock automatically.

Fig. 12 Side rail release mechanism

D9U001AM2-0101_04 32

Downloaded from www.Manualslib.com manuals search engine

10.7 Castor Control and Bed Transport

CAUTION!

Material damage due to incorrect transport or involuntary movement!

Prior to assembly, disassembly and maintenance, ensure the castors are locked.

Ensure the castors are locked while the bed is occupied and/or not being transported.

Prior to transport, ensure that bed is disconnected from mains.

Put mains cable on hook provided for transport.

Have the bed transported only by nursing or trained personnel.

10.7.1 Bed with Castor Control Levers

The castor control levers are located on both sides of the foot end.

Fig. 12 Central braking system lever

The central braking system facilitates movement of the bed by a single person. The bed has a main lock control

lever for the four castors. The brakes are at the foot end of the undercarriage.

Castor control:

1. Forward Movement: The front left castor is locked. The bed moves straight ahead. If the bed is equipped with

a fifth castor, this castor determines the direction of movement.

2. Unrestricted Movement: All of the castors are unlocked.

3. Braked: All of the castors are locked.

To move the bed::

Adjust the bed height to at least 20cm below maximum height.

Push the bed using handles on head or foot end.

10.7.2 The Fifth Castor

th

The bed can be equipped with a 5 castor to make it easier to manoeuvre and control the bed. The standard

th

locking castor will automatically be excluded from the bed specification if the 5 castor is requested as this will

th

replace the need for this function. The control lever for the 5 castor is identical to the control lever for the

th

braking system. To activate the 5 castor, press the foot operated lever shown in Figure 12, position 1.

10.7.3 Brake Alarm – Signalization of Unbraked Bed

It is possible to equip Image 3 B with signalization of unbraked bed. The signalization of unbraked bed signalizes,

that bed is connected to the mains but is not braked. This status is signalized by acoustic signal. To shut down

acoustic signal brake the bed or unplug bed from the mains.

D9U001AM2-0101_04 33

Downloaded from www.Manualslib.com manuals search engine

11 Accessories

WARNING!

Risk of injury due to incompatible accessories!

Only the manufacturers original accessories can be used.

NOTE: The manufacturer assumes no responsibility for the use of accessories not approved by the

manufacturer.

NOTE: All accessories conform to IEC 60601-2-52:2010.

The following accessories are suitable for the Image 3 B:

Lifting pole

powder-coated

chrome-plated

Triangular holder, grey plastic

for lifting pole

for lifting pole, adjustable by retractor

IV holder

for lifting pole, 3 hooks, powder-coated

for lifting pole, 3 hooks, stainless steel

for lifting pole, 4 hooks, chrome-plated

Telescopic IV pole

4 plastic hooks, chrome-plated

4 plastic hooks, chrome-plated, S-shaped top part, with lock against unwanted rotation

4 metal hooks, chrome-plated, lock against unwanted rotation

4 metal hooks, stainless steel, S-shaped top part, lock against unwanted rotation

Infusion bottle basket

for IV pole, stainless steel

IV pump holder

cross-shaped, chrome-plated

Pole for devices and accessories

chrome-plated

Urine bag holder

self-adjusting level, powder-coated

Writing shelf

white, for plastic or metal bed ends

Name holder

plastic, for plastic bed ends

Chart holder

plastic, for plastic bed ends

D9U001AM2-0101_04 34

Downloaded from www.Manualslib.com manuals search engine

11.1.1 Lifting Pole

The lifting pole is an optional accessory. It is necessary to specify this feature in the order.

Fig. 14 Placing the lifting pole Fig. 13 Image 3 B with bariatric lifting

pole

Lifting pole variants:

Bariatric lifting pole

To ensure safe use of the lifting pole:

Never exceed the maximum load of 100 kg of lifting pole.

Never use the lifting pole for rehabilitation exercises.

To prevent the bed from tipping over, ensure the lifting pole does not project out from the bed.

Replace plastic handle every 4 years.

Lifting pole positions:

Over the backrest (working position).

To install the lifting pole:

Attach plastic grab handle with an adjustable strap to the lifting pole.

Insert the lifting pole into both housings (Fig. 14) at the corners at the head of the bed with the help of a

second person

Ensure that both safety pins are locked into place

NOTE: The date of manufacture is marked on the grab handle. LINET® recommends replacing the plastic grab

handle every four years.

D9U001AM2-0101_04 35

Downloaded from www.Manualslib.com manuals search engine

11.1.2 Infusion Stand

WARNING!

Risk of injury due to incompatible accessories!

Use infusion stands exclusively for accessories listed in the instructions for use.

Do not use infusion stands for hanging infusion pumps, dosing devices etc. as this equipment might

collide with movable parts of the bed.

It is possible to insert infusion stands in the sockets at the head and foot ends of the bed.

Use exclusively infusion stands with 4 hooks for hanging IV bags or baskets for intravenous solutions.

Ensure that the infusion stand’s weight-bearing capacity is not exceeded.

Ensure that the weight-bearing capacity of the 4 hooks is not exceeded.

Capacity per hook: 2 kg

11.1.3 Accessory Rails

Fig. 15 Accessory Rail

Load capacity:

Maximum load of 5 kg without leverage.

Maximum load of hook pair 10 kg.

Accessories for hanging on the accessory rail:

Cannula holder

Urine bag holder

Urine bottle basket

DIN steel bar

D9U001AM2-0101_04 36

Downloaded from www.Manualslib.com manuals search engine

11.1.4 Side Rails Extension – Extender®

WARNING!

Risk of injury or collision due to incorrect use!

The Extender® can be used with single collapsible side rails only. The manufacturer will not be held

responsible for any consequences if the Extender® is used with other types of side rails.

Movement of the bed must be considered if the Extender® is installed.

Use of the Extender® in a manner other then stated in this user manual is on the responsibility of

personnel. The manufacturer shall not be held liable for incorrect use!

It is recommended the side rail extension – Extender® be used if a mattress higher than the recommended height

was placed on the bed. The Extender® is used to raise the height of the side rails and helps to secure patients

safety. The Extender® is designed for single collapsible side rails only.

It is recommended that the Extender® be used with the following mattresses:

Passive mattress: higher than 14 cm

o Virtuoso II

Active mattress: with maximum height 25 cm

o Virtuoso II - bariatric

Fig. 17 Installing the Extender® on the side rail Fig. 16 Inserting the screw

Fig. 19 Securing the Extender® Fig. 18 Image 3 B with installed Extender®

Install the Extender® as follows:

Place the Extender® on the upper edge of the side rail (Fig. 17). Side rails must be in the upper position.

Insert the screw from the inside of the bed thru the securing hole in the Extender® (Fig. 16). The square

hole is pointed into the mattress platform.

Secure the screw with the plastic rosette nut and tighten (Fig. 19). The rosette nut is pointed out from the

bed.

Check that the Extender® is secured correctly.

D9U001AM2-0101_04 37

Downloaded from www.Manualslib.com manuals search engine

11.1.5 Image 3 B Protector®

WARNING!

Risk of injury due to patient falling out of bed!

Ensure the Protector® is securely anchored to the housing.

To check stability, push the Protector up without touching the release button.

Always check that the side rail is properly locked.

WARNING!

Risk of damage to the bed or patient injury!

Do not attach the bed end to accessory housing (3).

Do not use the Protector with bed extension.

The Protector® can be used with powder coated bed ends only.

The Protector® is not a component of the bed. The Protector® is an optional accessory.

Fig. 21 Closed Protector® Fig. 20 Opened Protector®

Mount the Protector in the closed position as follows:

Put the tube of the Protector (2) into the housing near the foot of the bed (3), so that the Protector is facing

the side rail.

The safety pin must be locked in place.

Mount the Protector in the open position as follows:

Put the tube of the Protector (2) into the housing near the foot of the bed (3), so that the Protector is facing

out from bed.

The safety pin must be locked in place.

Dismount the Protector as follows:

Press and hold the release button (1).

Push the Protector up.

D9U001AM2-0101_04 38

Downloaded from www.Manualslib.com manuals search engine

12 Cleaning and Disinfection

WARNING!

Risk of injury when working on the bed!

Prior to assembly, disassembly, cleaning and maintenance, ensure that all adjustment functions are

locked.

Ensure the bed is disconnected from the mains during cleaning process.

Pay extra attention when cleaning any movable or controlling mechanisms of the bed to prevent

involuntary activation, entrapping or crushing.

Cleaning should be entrusted to the person who has been trained to control the bed.

WARNING!

Risk of damaging the bed due to use of incorrect cleaning detergents or cleaning processes!

The bed is not designed for machine washing.

The bed is not designed for cleaning by spraying, showering nor for pressure or steam cleaners.

The selection of cleaning detergents/disinfections and their correct concentration is responsibility of

responsible person in charge of cleaning/disinfection in accordance with the informations provided in this

manual.

Never use germicidal or other radiants for disinfection of the bed, if those radiants act directly on the bed.

Follow these instructions and follow the prescribed dosage by the manufacturer of cleaning detergents.

Not following recommended processes may result in damaging or deterioration of the bed condition.

12.1 Safety Instructions for Cleaning and Disinfection of the Bed

Preparation for cleaning:

Drive the bed on a place where the cleaning process will be performed and then brake the bed.

Position the mattress platform to its highest positions and also position the back rest and thigh rest parts

so the back side of those parts are accessible for cleaning.

Lock all adjustment functions of the bed to prevent involuntary adjustment of the bed or injuries during

cleaning.

Disconnect the bed from the mains.

Check if all connectors are properly fixed (controllers, actuators and control unit).

Recommendations for cleaning:

Only use detergents designed for cleaning the medical technologies.

Dilute the detergents in accordance with instructions from manufacturer of detergents.

Never use any strong acids or bases. Optimal pH range is 6-8.

Never use abrasive powders, steel wool or other materials and detergents that may damage the surface of

the bed.

Never use detergents with solvents that may affect the structure and consistency of the plastic parts

(benzene, toluene, acetone etc.).

Cleaning process:

Clean by wiping the bed with damp, well-wrung textile material.

The detergent can be applied by spraying on bed or on the textile material.

Perform cleaning and disinfection of the bed in the appropriate range. The range of cleaning and

disinfection should be distinguished according to the degree of contamination of the bed and the cleaning

mode (daily, before changing patient or complete).

Electronic parts that may be contaminated clean carefully and only their outer side. Never open those

connectors due to cleaning or disinfection. Those components should not be exposed to prolonged or

continuous exposure to moisture.

Let the bed dry completely after cleaning or disinfection process.

After drying the bed place the mattress back on the mattress platform.

After drying the bed check functions of the bed.

D9U001AM2-0101_04 39

Downloaded from www.Manualslib.com manuals search engine

12.2 General Instructions for Cleaning and Disinfection

12.2.1 Daily Cleaning

It is recommended to clean all parts of the bed which are touched by patient or personnel (e.g. side rails, bed

ends, handset, lifting pole etc.) and all handles, all control elements and accessory rails.

12.2.2 Cleaning before Changing Patients

It is recommended to completely clean and disinfects all parts of the bed which are touched by patient or

personnel (see Daily Cleaning), mattress platform, columns, undercarriage covers and mattress.

12.2.3 Complete Cleaning / Cleaning before First Use

It is recommended to clean the bed completely before the first use and then at least once in 4-8 weeks.

12.2.4 Cleaning of Spilled Fluids

Spilled fluids should be cleaned as soon as possible. Always disconnect the bed from mains before cleaning the

spilled fluids. Some fluids used in health care may cause permanent stains.

12.2.5 Damaged Foam Mattress