Professional Documents

Culture Documents

Compresiune Excentrica - Cazul 1

Compresiune Excentrica - Cazul 1

Uploaded by

Puiu Ioan DanielOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Compresiune Excentrica - Cazul 1

Compresiune Excentrica - Cazul 1

Uploaded by

Puiu Ioan DanielCopyright:

Available Formats

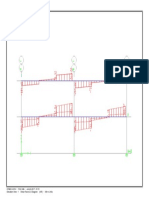

COMPRESIUNE EXCENTRICA - CAZUL 1

ARMARE STALP CENTRAL - PARTER

1. Date cunoscute

Eforturi: Nmin= 1552 kN

(IPOTEZA 2)

Mcoresp= 134 kNm

Ncoresp= 1552 kN

(IPOTEZA 2)

Mmax= 134 kNm

Caracteristici geometrice: b= 700 mm

h= 900 mm

2. Determinarea rezistentelor de calcul

C20/25 => fcd= 20/1.5 = 13.33 N/mm^2

fctm= 2.2 N/mm^2 (tabel 2.4. - EC2)

PC52 => fyd= 345/1.15 = 300 N/mm^2

3. Determinarea λx

λx=N/(b*fcd) => λx= 166.3 mm

λ=0.8 => xef= 207.9 mm

4. Verificarea conditiei de balans

εy=fyd/Es => εy= 1.43E-03

εc= 3.50E-03 (curbele caracteristice ale materialelor)

d=h-d1= 865 mm

xB=d*εc/(εy+εc) => xB= 614.28 mm

xB > xef => conditie verificata

5. Determinarea xmin

xmin=d1*εc/(εy+εc) => xmin= 59.14 => xmin < xef

6. Determinarea As

As2,nec= -1748 mm^2 => armare din procent minim

7. Armare din procent minim

ρmin=0.26*fctm/fyk => ρmin= 0.00166

ρef=As/(b(h-d1)) => As,min= 1004 mm^2

Propun 2φ18+4φ14 => As,ef= 1124 mm^2

As,min < Aef => conditie verificata

ARMARE STALP CENTRAL - ETAJ

1. Date cunoscute

Eforturi: Nmin= 665 kN

(IPOTEZA 1)

Mcoresp= 0 kNm

Caracteristici geometrice: b= 700 mm

h= 900 mm

2. Determinarea rezistentelor de calcul

C20/25 => fcd= 20/1.5 = 13.33 N/mm^2

fctm= 2.2 N/mm^2 (tabel 2.4. - EC2)

PC52 => fyd= 345/1.15 = 300 N/mm^2

3. Determinarea λx

λx=N/(b*fcd) => λx= 71.3 mm

λ=0.8 => xef= 89.1 mm

4. Verificarea conditiei de balans

εy=fyd/Es => ε y= 1.43E-03

εc= 3.50E-03 (curbele caracteristice ale materialelor)

d=h-d1= 865 mm

xB=d*εc/(εy+εc) => xB= 614.28 mm

xB > xef => conditie verificata

5. Determinarea xmin

xmin=d1*εc/(εy+εc) => xmin= 59.14 => xmin < xef

6. Determinarea As

As2,nec= -1107 mm^2 => armare din procent minim

7. Armare din procent minim

ρmin=0.26*fctm/fyk => ρmin= 0.00166

ρef=As/(b(h-d1)) => As,min= 1004 mm^2

Propun 2φ18+4φ14 => As,ef= 1124 mm^2

As,min < Aef => conditie verificata

ARMARE STALP CENTRAL - ETAJ

1. Date cunoscute

Eforturi: Ncoresp= 672 kN

(IPOTEZA 2)

Mmax= 185 kNm

Caracteristici geometrice: b= 700 mm

h= 900 mm

2. Determinarea rezistentelor de calcul

C20/25 => fcd= 20/1.5 = 13.33 N/mm^2

fctm= 2.2 N/mm^2 (tabel 2.4. - EC2)

PC52 => fyd= 345/1.15 = 300 N/mm^2

3. Determinarea λx

λx=N/(b*fcd) => λx= 72.0 mm

λ=0.8 => xef= 90.0 mm

4. Verificarea conditiei de balans

εy=fyd/Es => ε y= 1.43E-03

εc= 3.50E-03 (curbele caracteristice ale materialelor)

d=h-d1= 865 mm

xB=d*εc/(εy+εc) => xB= 614.28 mm

xB > xef => conditie verificata

5. Determinarea xmin

xmin=d1*εc/(εy+εc) => xmin= 59.14 => xmin < xef

6. Determinarea As

As2,nec= -374 mm^2 => armare din procent minim

7. Armare din procent minim

ρmin=0.26*fctm/fyk => ρmin= 0.00166

ρef=As/(b(h-d1)) => As,min= 1004 mm^2

Propun 2φ18+4φ14 => As,ef= 1124 mm^2

As,min < Aef => conditie verificata

ARMARE STALP MARGINAL - PARTER

1. Date cunoscute

Eforturi: Nmin= 550 kN

(IPOTEZA 3)

Mcoresp= 19 kNm

Caracteristici geometrice: b= 500 mm

h= 700 mm

2. Determinarea rezistentelor de calcul

C20/25 => fcd= 20/1.5 = 13.33 N/mm^2

fctm= 2.2 N/mm^2 (tabel 2.4. - EC2)

PC52 => fyd= 345/1.15 = 300 N/mm^2

3. Determinarea λx

λx=N/(b*fcd) => λx= 82.5 mm

λ=0.8 => xef= 103.2 mm

4. Verificarea conditiei de balans

εy=fyd/Es => ε y= 1.43E-03

εc= 3.50E-03 (curbele caracteristice ale materialelor)

d=h-d1= 665 mm

xB=d*εc/(εy+εc) => xB= 472.25 mm

xB > xef => conditie verificata

5. Determinarea xmin

xmin=d1*εc/(εy+εc) => xmin= 59.14 => xmin < xef

6. Determinarea As

As2,nec= -798 mm^2 => armare din procent minim

7. Armare din procent minim

ρmin=0.26*fctm/fyk => ρmin= 0.00166

ρef=As/(b(h-d1)) => As,min= 551 mm^2

Propun 4φ14 => As,ef= 615 mm^2

As,min < Aef => conditie verificata

ARMARE STALP MARGINAL - PARTER

1. Date cunoscute

Eforturi: Ncoresp= 932 kN

(IPOTEZA 2)

Mmax= 127 kNm

Caracteristici geometrice: b= 500 mm

h= 700 mm

2. Determinarea rezistentelor de calcul

C20/25 => fcd= 20/1.5 = 13.33 N/mm^2

fctm= 2.2 N/mm^2 (tabel 2.4. - EC2)

PC52 => fyd= 345/1.15 = 300 N/mm^2

3. Determinarea λx

λx=N/(b*fcd) => λx= 139.8 mm

λ=0.8 => xef= 174.8 mm

4. Verificarea conditiei de balans

εy=fyd/Es => ε y= 1.43E-03

εc= 3.50E-03 (curbele caracteristice ale materialelor)

d=h-d1= 665 mm

xB=d*εc/(εy+εc) => xB= 472.25 mm

xB > xef => conditie verificata

5. Determinarea xmin

xmin=d1*εc/(εy+εc) => xmin= 59.14 => xmin < xef

6. Determinarea As

As2,nec= -709 mm^2 => armare din procent minim

7. Armare din procent minim

ρmin=0.26*fctm/fyk => ρmin= 0.00166

ρef=As/(b(h-d1)) => As,min= 551 mm^2

Propun 4φ14 => As,ef= 615 mm^2

As,min < Aef => conditie verificata

ARMARE STALP MARGINAL - ETAJ

1. Date cunoscute

Eforturi: Nmin= 283 kN

(IPOTEZA 3)

Mcoresp= 76 kNm

Caracteristici geometrice: b= 500 mm

h= 700 mm

2. Determinarea rezistentelor de calcul

C20/25 => fcd= 20/1.5 = 13.33 N/mm^2

fctm= 2.2 N/mm^2 (tabel 2.4. - EC2)

PC52 => fyd= 345/1.15 = 300 N/mm^2

3. Determinarea λx

λx=N/(b*fcd) => λx= 42.5 mm

λ=0.8 => xef= 53.1 mm

4. Verificarea conditiei de balans

εy=fyd/Es => εy= 1.43E-03

εc= 3.50E-03 (curbele caracteristice ale materialelor)

d=h-d1= 665 mm

xB=d*εc/(εy+εc) => x B= 472.25 mm

xB > xef => conditie verificata

5. Determinarea xmin

xmin=d1*εc/(εy+εc) => xmin= 59.14 => xmin < xef

6. Determinarea As

As2,nec= -90 mm^2 => armare din procent minim

7. Armare din procent minim

ρmin=0.26*fctm/fyk => ρmin= 0.00166

ρef=As/(b(h-d1)) => As,min= 551 mm^2

Propun 4φ14 => As,ef= 615 mm^2

As,min < Aef => conditie verificata

ARMARE STALP MARGINAL - ETAJ

1. Date cunoscute

Eforturi: Ncoresp= 286 kN

(IPOTEZA 2)

Mmax= 243 kNm

Caracteristici geometrice: b= 500 mm

h= 700 mm

2. Determinarea rezistentelor de calcul

C20/25 => fcd= 20/1.5 = 13.33 N/mm^2

fctm= 2.2 N/mm^2 (tabel 2.4. - EC2)

PC52 => fyd= 345/1.15 = 300 N/mm^2

3. Determinarea λx

λx=N/(b*fcd) => λx= 42.9 mm

λ=0.8 => xef= 53.6 mm

4. Verificarea conditiei de balans

εy=fyd/Es => ε y= 1.43E-03

εc= 3.50E-03 (curbele caracteristice ale materialelor)

d=h-d1= 665 mm

xB=d*εc/(εy+εc) => xB= 472.25 mm

xB > xef => conditie verificata

5. Determinarea xmin

xmin=d1*εc/(εy+εc) => xmin= 59.14 => xmin < xef

6. Determinarea As

As2,nec= 789 mm^2

Propun 2φ18+2φ14 As,ef= 816 mm^2

As,min < Aef => conditie verificata

7. Verificare procent minim

ρmin=0.26*fctm/fyk => ρmin= 0.00166

ρef=As/(b(h-d1)) => ρef= 0.00245

ρmin < ρef => conditie verificata

TABEL CENTRALIZATOR AL ARMARILOR STALPILOR

STALP NIVEL EFORTURI ARMARE ARMARE FINALA

Nmin

2φ18+4φ14

Mcoresp

P

Ncoresp

2φ18+4φ14

Mmax

SC 2φ18+4φ14

Nmin

2φ18+4φ14

Mcoresp

E

Ncoresp

2φ18+4φ14

Mmax

Nmin

4φ14

Mcoresp

P

Ncoresp

4φ14

Mmax

Sm 2φ18+2φ14

Nmin

4φ14

Mcoresp

E

Ncoresp

2φ18+2φ14

Mmax

VERIFICAREA COEFICIENTULUI DE ARMARE PE INTREAGA SECTIUNE A STALPULUI

ρs=As,total/b/h ≥ 0.1*Ned/fyd

≥ 0.002

Distanta maxima intre 2 armaturi: 300 mm

Pentru verificarea armaturii, se alege Ned,max pe fiecare stalp pentru a

rezulta cea mai mare arie de armatura necesara

STALP CENTRAL b= 700 mm

h= 900 mm

NEd,max= 1552 kN

ρs=As,total/b/h ≥ 0.1*Ned/fyd => As,total = 517 mm^2

ρs=As,total/b/h ≥ 0.002 => As,total = 1260 mm^2

Armare b: 2φ18+4φ14 => As,ef = 816 mm^2 (din calcul sectional)

Armare h: 4φ18 => As,ef = 1017 mm^2 (din procent minim)

ρef= As,ef /900/665= 0.00170 > ρmin= 0.00166

ARMARE SC: 8*18+8*14 => As,ef = 3266 mm^2 > ρs

STALP MARGINAL b= 500 mm

h= 700 mm

NEd,max= 932 kN

ρs=As,total/b/h ≥ 0.1*Ned/fyd => As,total = 311 mm^2

ρs=As,total/b/h ≥ 0.002 => As,total = 700 mm^2

Armare b: 2φ18+2φ14 => As,ef = 816 mm^2 (din calcul sectional)

Armare h: 2φ18+2φ8 => As,ef = 609 mm^2 (din procent minim)

ρef= As,ef /700/465= 0.00187 > ρmin= 0.00166

ARMARE SC: 4*18+4*14+4*8 => As,ef = 1834 mm^2 > ρs

You might also like

- Calcul Buloane Ancoraj HalaDocument6 pagesCalcul Buloane Ancoraj Halagherman_cld7549No ratings yet

- Armare Diafragme A4Document11 pagesArmare Diafragme A4Kalauz EdmondNo ratings yet

- Structural Dynamics & Earthquake EngineeringDocument34 pagesStructural Dynamics & Earthquake EngineeringHema Chandra Reddy Karimireddy100% (1)

- Nikolaus Pevsner - An Outline of European ArchitectureDocument48 pagesNikolaus Pevsner - An Outline of European ArchitecturePuiu Ioan DanielNo ratings yet

- Dimensionare Perete P7Document5 pagesDimensionare Perete P7Ionuț ScrobNo ratings yet

- Bending - Single Reinforcement For Bending Only Rectangular Sections, Parabolic Stressblock Concrete Grade C50/60Document3 pagesBending - Single Reinforcement For Bending Only Rectangular Sections, Parabolic Stressblock Concrete Grade C50/60Dong LINo ratings yet

- Dimensionare Si Armare Diafragma DT3: Montant 3Document5 pagesDimensionare Si Armare Diafragma DT3: Montant 3Eliseo JohnsonNo ratings yet

- EC2-BE-deflection Rev3Document6 pagesEC2-BE-deflection Rev3Dong LINo ratings yet

- RC Column DesignDocument11 pagesRC Column Designa.b.a.c.u.sNo ratings yet

- Beam Design EC2Document62 pagesBeam Design EC2Khac Hoang PhamNo ratings yet

- Spectru ProiectareDocument27 pagesSpectru ProiectareHoria Ionut MihneaNo ratings yet

- Wood Beam Bending Capacity EC5Document2 pagesWood Beam Bending Capacity EC5kissistvanNo ratings yet

- Common Rafters: Job No: Job Name: Date: Drawing Ref: Prepared By: Checked By: Site Ref: OtherDocument8 pagesCommon Rafters: Job No: Job Name: Date: Drawing Ref: Prepared By: Checked By: Site Ref: Otherstarsplesh100% (1)

- 2015-0075 1 5 KH Tann 3/20/2018 Dawson Deep Beam Formworks: 149b Selegie Road Singapore 188314Document6 pages2015-0075 1 5 KH Tann 3/20/2018 Dawson Deep Beam Formworks: 149b Selegie Road Singapore 188314jasekan.dcNo ratings yet

- Xtras Lemn SarpantaDocument4 pagesXtras Lemn SarpantaHussenuNo ratings yet

- Windload Analysis V ModelDocument4 pagesWindload Analysis V ModelMirsad Daidza CorbadzicNo ratings yet

- Mathcad - 4stalp13-17Document3 pagesMathcad - 4stalp13-17cypydymy100% (1)

- Template Armare PeretiDocument21 pagesTemplate Armare PeretiMarinoiu MarianNo ratings yet

- Mathcad - Fundatii Continue RigideDocument3 pagesMathcad - Fundatii Continue RigideGîlea ȘtefanNo ratings yet

- Model SpectruDocument10 pagesModel SpectruLaurentiu Flaviu DarabanNo ratings yet

- Cap.8 - Calculul Si Armarea ScarilorDocument2 pagesCap.8 - Calculul Si Armarea ScarilorStefania OlareanuNo ratings yet

- RCCe11 Element DesignDocument9 pagesRCCe11 Element Designrelu59No ratings yet

- Fixed Column Base DesignDocument24 pagesFixed Column Base DesignMayuresh KudveNo ratings yet

- Mathcad - Stalp CentralDocument3 pagesMathcad - Stalp Centralagent206No ratings yet

- Zid de SprijinDocument4 pagesZid de SprijinAnonymous W6WPVDkeNo ratings yet

- Calculul La Forta Taiatoare Pereti Mulati + Dimensionare SpraituriDocument4 pagesCalculul La Forta Taiatoare Pereti Mulati + Dimensionare SpraituriBza ZaBugNo ratings yet

- Pre Dimension AreDocument6 pagesPre Dimension AreNeagu DragosNo ratings yet

- Bejan Gabriel - Proiect MetalDocument6 pagesBejan Gabriel - Proiect MetalGabriel BejanNo ratings yet

- Incovoiere: B Ho RC Ra MDocument58 pagesIncovoiere: B Ho RC Ra MConstantin OvidiuNo ratings yet

- RCC12 Bending and Axial ForceDocument4 pagesRCC12 Bending and Axial ForceAbdul KarimNo ratings yet

- Danh Gia Lien Ket Ban de Chan Cot ThepDocument2 pagesDanh Gia Lien Ket Ban de Chan Cot ThepNguyen Duc CuongNo ratings yet

- Calcule Rezistenta SarpantaDocument5 pagesCalcule Rezistenta SarpantaIulia Dumitrescu100% (1)

- 1.1 Other: 2 SteelDocument2 pages1.1 Other: 2 SteelashishNo ratings yet

- Breviar Calcul Fundatie IzolataDocument2 pagesBreviar Calcul Fundatie IzolataVirginia Elena IordacheNo ratings yet

- Sagging Med+ (KNM) Hogging Med - (KNM)Document13 pagesSagging Med+ (KNM) Hogging Med - (KNM)nagasabaNo ratings yet

- Breviar Armare-RadierDocument4 pagesBreviar Armare-RadierMoldovan Adrian NeluNo ratings yet

- Calcul Grinda BETONDocument12 pagesCalcul Grinda BETONrelu59No ratings yet

- Book 1Document80 pagesBook 1khaledmegahedNo ratings yet

- Calcul de Alpha CritiqueDocument20 pagesCalcul de Alpha Critiquelahlou_d9216No ratings yet

- Armare RadierDocument5 pagesArmare RadierRepanovici Alexandru100% (1)

- Valori Incarcari: PCF Utila A Aferenta LDocument3 pagesValori Incarcari: PCF Utila A Aferenta Lichim DragosNo ratings yet

- WWW Colegulperfect Ro-CalculeDocument98 pagesWWW Colegulperfect Ro-CalculeDragos-Catalin ChiritaNo ratings yet

- Proiect FundatiiDocument42 pagesProiect FundatiiFlorin Florinell100% (1)

- Slab Design6 Edj ROOFDocument2 pagesSlab Design6 Edj ROOFhedayatullahNo ratings yet

- 148841505-Verificare-StalpDocument50 pages148841505-Verificare-StalpkrmeenNo ratings yet

- Calcul Structural Planseu de LemnDocument13 pagesCalcul Structural Planseu de LemnLumezeanuDNo ratings yet

- Table of Concrete Design Properties (FCD, FCTM, Ecm, FCTD) - Eurocode 2Document3 pagesTable of Concrete Design Properties (FCD, FCTM, Ecm, FCTD) - Eurocode 2Cheng JiangNo ratings yet

- TCC11 Element DesignDocument8 pagesTCC11 Element DesignMelinda GordonNo ratings yet

- Connessione Controvento 2UPN EC3 IngleseDocument15 pagesConnessione Controvento 2UPN EC3 Inglesemihai_serban13No ratings yet

- BetonDocument7 pagesBetonBriscan RalucaNo ratings yet

- CompressDocument12 pagesCompressWataNo ratings yet

- Calcul Aria Armatura Longitudinala Perete Mulat Fata InterioaraDocument2 pagesCalcul Aria Armatura Longitudinala Perete Mulat Fata InterioaraBza ZaBugNo ratings yet

- Calcul SarpantaDocument3 pagesCalcul Sarpantacrmn_matNo ratings yet

- Calcul Ferma Curenta de Acoperis: Evaluarea IncarcarilorDocument32 pagesCalcul Ferma Curenta de Acoperis: Evaluarea IncarcarilorRoman Bentalo100% (1)

- Mathcad - Calcul Si Consolidare La Forta Taietoare (GRINDA)Document4 pagesMathcad - Calcul Si Consolidare La Forta Taietoare (GRINDA)agent206No ratings yet

- 2.armare Placa 1-Layout1Document1 page2.armare Placa 1-Layout1Cristina CojoceaNo ratings yet

- R - 08 Plan Cofraj Si Armare Fronton - A3Document1 pageR - 08 Plan Cofraj Si Armare Fronton - A3Adrian IstrateNo ratings yet

- TCC15 Resistance of Retaining MembersDocument9 pagesTCC15 Resistance of Retaining MembersMelinda GordonNo ratings yet

- Calcul Scara PisicaDocument18 pagesCalcul Scara PisicaVirginia Elena IordacheNo ratings yet

- Buloane de Ancoraj PDFDocument29 pagesBuloane de Ancoraj PDFAndrei Cretu100% (1)

- Calculations in The Main Direction: Lazareto Extension Stack Foundation Raft SlabDocument19 pagesCalculations in The Main Direction: Lazareto Extension Stack Foundation Raft Slabask.kulkarni KulkarniNo ratings yet

- VEd PDFDocument1 pageVEd PDFPuiu Ioan DanielNo ratings yet

- GL - CAMP - Corp C2 - Ax 1: Ef PL s1 Nec s1 Ef Min Ef B Ef RD 2 2Document6 pagesGL - CAMP - Corp C2 - Ax 1: Ef PL s1 Nec s1 Ef Min Ef B Ef RD 2 2Puiu Ioan DanielNo ratings yet

- GT Camp - Ax A: Ef PL s1 Nec s1 Ef Min Ef B Ef RD 2 2Document4 pagesGT Camp - Ax A: Ef PL s1 Nec s1 Ef Min Ef B Ef RD 2 2Puiu Ioan DanielNo ratings yet

- GL - CAMP - Corp C2 - Ax 1: Ef PL s1 Nec s1 Ef Min Ef B Ef RD 2 2Document6 pagesGL - CAMP - Corp C2 - Ax 1: Ef PL s1 Nec s1 Ef Min Ef B Ef RD 2 2Puiu Ioan DanielNo ratings yet

- ETABS v9.5.0 - File: 1 - March 9,2018 8:23 Elevation View - A Axial Force Diagram (ENVE) - KN-M UnitsDocument1 pageETABS v9.5.0 - File: 1 - March 9,2018 8:23 Elevation View - A Axial Force Diagram (ENVE) - KN-M UnitsPuiu Ioan DanielNo ratings yet

- ETABS v9.5.0 - File: Edb - June 8,2017 21:51 Elevation View - 1 Shear Force 2-2 Diagram (INF) - KN-M UnitsDocument1 pageETABS v9.5.0 - File: Edb - June 8,2017 21:51 Elevation View - 1 Shear Force 2-2 Diagram (INF) - KN-M UnitsPuiu Ioan DanielNo ratings yet

- Fundatie SC: 1. PredimensionareDocument5 pagesFundatie SC: 1. PredimensionarePuiu Ioan DanielNo ratings yet

- Soil MechanicsDocument35 pagesSoil MechanicsPuiu Ioan DanielNo ratings yet

- Calculul Buiandrugilor: 1. Calculul Buiandrugului Fereastra-Fereastra (B1 25x225)Document5 pagesCalculul Buiandrugilor: 1. Calculul Buiandrugului Fereastra-Fereastra (B1 25x225)Puiu Ioan DanielNo ratings yet

- DDP RTDocument2 pagesDDP RTPuiu Ioan DanielNo ratings yet