Professional Documents

Culture Documents

Protect Your Fuel System

Protect Your Fuel System

Uploaded by

rezaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Protect Your Fuel System

Protect Your Fuel System

Uploaded by

rezaCopyright:

Available Formats

Cat Fuel Water Separators and

PrimeTime Priming Pumps ™

Manual Priming Pump

Cat Electronic PrimeTime Priming Pump

Protect your fuel system Caterpillar. The difference counts.™

Advanced High Efficiency Fuel Water Separator

Diesel fuel acts as a lubricant in unit injectors. The film strength of diesel fuel

prevents metal-to-metal contact between the plunger and barrel. Water can

Cat Dealers define world-class product

compromise film strength, resulting in scuffing and eventual seizure. Cat Fuel

support. We offer you the right parts

Water Separators have greater water removal capabilities essential for better

protection of unit injectors. Fuel Water Separators also deliver longer

and service solutions, when and where

secondary fuel filter life. you need them.

• Remove more than 98% of debris 10 microns and larger

• Virtually eliminate free water in fuel

The Cat Dealer network of highly

• Remove 87% of dissolved water trained experts keeps your entire fleet

PrimeTime Priming Pump up and running to maximize your

Cat PrimeTime Priming Pumps are easily installed on the frame or engine

as retrofits. They prime the filter and fuel system with a flip of the switch.

equipment investment.

• No need to pre-fill filter and risk debris reaching injectors

• Primes fuel filter in two to six minutes

• No time-consuming, difficult manual pumping

While these two products are available separately, you will get the best results

when they are used together.

Cat Fuel Water Separators and PrimeTime Priming Pumps

Easy to Install Pump

Extend the life of

Electric priming pump works with unit fuel injectors

the flip of a switch, priming in two to

six minutes.

Resilient mounting extends pump life

and absorbs some of the shock load.

Primary fuel filter removes more than

98% of debris 10 microns and larger.

Water separator removes virtually all

Undissolved water quantities greater

free water and 87% of dissolved water

than .1% can cause major damage.

from diesel fuel.

Excess water caused metal-to-metal

contact between the plunger and barrel

Reusable water collection bowl has in the fuel injector on the left. A Cat

capacity of 90ml, is transparent for easy Fuel Water Separator protected the

monitoring and drains in less than one injector on the right, preventing

minute. damage and extending its life.

Retrofit Information

Water removal efficiency*

Axial seal filters are designed to retrofit engines in the field while radial seal

97%

87%

PERCENT EFFICIENCY

filters have an exclusive Cat design for improved sealing performance on new

81%

engines. Both will upgrade the durability and water removal performance over

58% 56%

previous Caterpillar offerings and other brands.

45%

PrimeTime Pump Hand Priming Fuel Water** Separator

Engine Full Flow Configuration Configuration Basic Configuration Test 1 Test 2 Test 1 Test 2 Test 1 Test 2

Caterpillar Racor Stanadyne

Small Engines Kit 206-5756* - Base 128-8557 with - Base 195-1068 with

C12 & smaller 1R-0769 (axial seal) or 1R-0769 (axial seal) FWS or Cat Fuel Water Separators are much

- Base 202-9871 with - Base 177-9778 with

1R-0770 (radial seal) 1R-0770 (radial seal) FWS** more efficient than those produced by

other manufacturers. This efficiency

Medium Engines Kit 206-5756* - Base 128-8557 with - Base 195-1068 with

C15-C16, 3408 The 1R0770, included 1R-0781 (axial seal) or 1R-0781 (axial seal) FWS or minimizes barrel-to-plunger scuffing

in the kit, can be - Base 202-9871 with - Base 177-9778 with and significantly reduces the chance

replaced with the 1R0771 1R-0771 (radial seal) 1R-0771 (radial seal) FWS**

for additional capacity of fuel injector failure.

Check the collection bowl daily and

PrimeTime Pump Fuel Water** Separator

Engine Prime Only Configuration Basic Configuration drain as needed. In some applications

such as marine and underground

3508 Kit 206-5756* Base 175-7060 with

(for priming only) 200-4139 (axial seal) mining, a metal collection bowl is

a safety requirement.

3512-3516 Kit 206-5756* 232-5263 group, each include

(for priming only) (2) base 225-6404 with * Test procedures and results are on file and

(2) 200-4139 (axial seal) certified to represent the parts actually tested.

Caterpillar implies nothing further, and no one

3524 Kit 206-5756* 232-5263 group, each include should infer that these parts typify the maker’s

(for priming only) (3) base 225-6404 with overall production.

(3) 200-4139 (axial seal)

* 270-5320 Water Collection Bowl—220-8678 Bowl/Can Seal

** Install the kit 206-5756 per Special Instruction media# REHS1037-01

Model Specific Electric Priming Pump Kits: For more information, visit us

on the Web site at www.cat.com

Model Part No.

D11 205-6452

777 205-6453

793 205-6454

PEHJ0082-01 www.cat.com Printed in USA © 2006 Caterpillar All Rights Reserved

CAT, CATERPILLAR, ACERT, their respective logos and "Caterpillar Yellow," as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without

permission.

You might also like

- Astm Astm d2887 PDFDocument20 pagesAstm Astm d2887 PDFharNo ratings yet

- ESPECIFICACIONES D12C Motor VolvoDocument44 pagesESPECIFICACIONES D12C Motor VolvoErika Salinas100% (4)

- Filtro Racor 1000 PDFDocument12 pagesFiltro Racor 1000 PDFCarlos RinconNo ratings yet

- C10467212 PDFDocument4 pagesC10467212 PDFKeron TrotzNo ratings yet

- Hydraulics IOEDocument169 pagesHydraulics IOEEr. Satya Narayan ShahNo ratings yet

- Engine Oil and Fuel Filters - c134986Document1 pageEngine Oil and Fuel Filters - c134986Marsha Citra MauriscaNo ratings yet

- Groman PumpsDocument38 pagesGroman PumpsEL Yonke MontyNo ratings yet

- Retail PDFDocument3 pagesRetail PDFGago MaldonadoNo ratings yet

- Promotion Berco1 PDFDocument5 pagesPromotion Berco1 PDFJas SumNo ratings yet

- CM20190228 43314 16908 PDFDocument325 pagesCM20190228 43314 16908 PDFEduardo Ariel Bernal100% (1)

- Oferta Piese Discount 40Document31 pagesOferta Piese Discount 40ionvasile2010No ratings yet

- 31.2003 Cat Replacement Catalog MergedDocument4 pages31.2003 Cat Replacement Catalog MergedHerlan GarciaNo ratings yet

- Total Solution For Heavy Equipment: Description Size Oem No. Material WeightDocument7 pagesTotal Solution For Heavy Equipment: Description Size Oem No. Material WeightAlexander RuizNo ratings yet

- 01 Motor Engine ADocument67 pages01 Motor Engine AFranky FernandezNo ratings yet

- Lista PerkinsDocument21 pagesLista PerkinsandrelovisiNo ratings yet

- Kubota PartsDocument1 pageKubota PartssermatectractoreirlNo ratings yet

- Maxon GP 42 CDocument2 pagesMaxon GP 42 CElectromateNo ratings yet

- Orient Price List NewDocument3 pagesOrient Price List Newrohan12345670% (1)

- Service Jobcards Details 2018Document72 pagesService Jobcards Details 2018Rohit Om TiwariNo ratings yet

- POLARIS Gear PumpsDocument88 pagesPOLARIS Gear PumpsSasko DimitrovNo ratings yet

- Catalog Grauvell-2014 PDFDocument370 pagesCatalog Grauvell-2014 PDFOscar SpinningaliciaNo ratings yet

- 019-Oil Filter PDFDocument2 pages019-Oil Filter PDFبهية عمرNo ratings yet

- Paque InstaladoDocument310 pagesPaque InstaladoBernardo EscorciaNo ratings yet

- Catalogo Maxgear PDFDocument31 pagesCatalogo Maxgear PDFGeovane NogueiraNo ratings yet

- Parfit Hydraulic Elements: Customer Value PropositionDocument4 pagesParfit Hydraulic Elements: Customer Value PropositionGianna FrolaNo ratings yet

- Dic Trading Company: #104-1004,65-14 Shinhyon-Ro, Gwangju City, Kyunggido, KoreaDocument1 pageDic Trading Company: #104-1004,65-14 Shinhyon-Ro, Gwangju City, Kyunggido, KoreaRidha AbbassiNo ratings yet

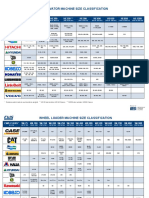

- CWS Machine Classes PDFDocument2 pagesCWS Machine Classes PDFtvwrightNo ratings yet

- OEM - Fuel Manager Brand Cross Reference P/Ns For Service Filter Elements 99642 - January 2006Document6 pagesOEM - Fuel Manager Brand Cross Reference P/Ns For Service Filter Elements 99642 - January 2006Miguel RojasNo ratings yet

- Rptinventory 2016Document121 pagesRptinventory 2016bt karachi Workshop E0% (1)

- Lubricant EsDocument82 pagesLubricant EsFelipe Alexis Aros SánchezNo ratings yet

- MaintenanceTechnology Mtapril2016Document61 pagesMaintenanceTechnology Mtapril2016Cristian Javier SierraNo ratings yet

- Perkins Filter Promo April2006 PDFDocument3 pagesPerkins Filter Promo April2006 PDFgliga vasileNo ratings yet

- Stanadyne FiltrosDocument16 pagesStanadyne FiltrosClaudia Collar GarciaNo ratings yet

- Equivalencias Filtros DonaldsonDocument4 pagesEquivalencias Filtros Donaldsonfredaster21No ratings yet

- BYG Teeth Cat Side Pin TeethDocument12 pagesBYG Teeth Cat Side Pin TeethteicooyNo ratings yet

- R800LC-9 MaintananceDocument33 pagesR800LC-9 MaintananceJorge RojasNo ratings yet

- Part Price ListDocument1 pagePart Price ListYusNo ratings yet

- Mining Supplies: Volvo L350FDocument2 pagesMining Supplies: Volvo L350FRyan Abubakar Obili PakayaNo ratings yet

- Parker Uk pgp500 PDFDocument20 pagesParker Uk pgp500 PDFAnonymous srN69mFENo ratings yet

- Generator FiltratDocument2 pagesGenerator FiltratArtin HykoNo ratings yet

- Anac Stock Li̇st 2020Document51 pagesAnac Stock Li̇st 2020CJ TradersNo ratings yet

- MRP Selesai Plus UploadDocument46 pagesMRP Selesai Plus UploadTyler GoodwinNo ratings yet

- Caterpillar PDFDocument47 pagesCaterpillar PDFMarianaCataRomeroNo ratings yet

- 61 PDF FR PDFDocument4 pages61 PDF FR PDFRyan Abubakar Obili PakayaNo ratings yet

- Maestro FiltrosDocument13 pagesMaestro Filtrosrjan7peNo ratings yet

- Indic AdoresDocument4 pagesIndic AdoresRicardo BarretoNo ratings yet

- BombasDocument6 pagesBombasEdgar Rojas EspejoNo ratings yet

- BrochureDocument34 pagesBrochurejadiNo ratings yet

- Item Found Secnd TimeDocument73 pagesItem Found Secnd TimejunaidssNo ratings yet

- Hydraulic Filter - Wheel Loader Komatsu Wa20-1 - Work Equipment Control System 777partsDocument2 pagesHydraulic Filter - Wheel Loader Komatsu Wa20-1 - Work Equipment Control System 777partsashraf elsayedNo ratings yet

- BL Spherical Plain BearingsDocument16 pagesBL Spherical Plain BearingsAgus YulfizarNo ratings yet

- 19501Document21 pages19501Szilárd SNo ratings yet

- Owning Operating Cost To 9000hrs: Working Hours (HM) Component Part Number DescriptionDocument2 pagesOwning Operating Cost To 9000hrs: Working Hours (HM) Component Part Number DescriptionAnonymous Xei7J6qJyNo ratings yet

- 2 PH Camión 793 F PDFDocument2 pages2 PH Camión 793 F PDFAnonymous HhjNxRCS6ANo ratings yet

- ZX-5G Large+Fuel+ConsumptionDocument1 pageZX-5G Large+Fuel+Consumptionosmaini sutraNo ratings yet

- Cat® Bulk Fuel Filtration SystemsDocument4 pagesCat® Bulk Fuel Filtration Systemsdoncia100% (1)

- Fuel FiltersDocument1 pageFuel FiltersalpanakaurNo ratings yet

- Cleanawater DEOIL3 - 5 - 10 Hydrocyclone Oil Separators BrochureDocument5 pagesCleanawater DEOIL3 - 5 - 10 Hydrocyclone Oil Separators BrochureAnonymous a4Jwz14WNo ratings yet

- SEP Catalog SWK2000 EmailDocument4 pagesSEP Catalog SWK2000 Emailகோவி கோபால் ஆர்ட்ஸ்No ratings yet

- 50,000 Hour Off-Highway Diesel Engine RebuildsDocument2 pages50,000 Hour Off-Highway Diesel Engine RebuildsOscar IngaNo ratings yet

- Applications of Oil CentrifugeDocument2 pagesApplications of Oil CentrifugeZack A. HaqNo ratings yet

- PEHJ0156-02 (Low Res) Sistemas de Filtrado CATDocument4 pagesPEHJ0156-02 (Low Res) Sistemas de Filtrado CATjoseNo ratings yet

- Well IntegrityDocument2 pagesWell IntegrityhamadahutpNo ratings yet

- Fact Sheet: Engine D13A440, EU4SCR / EU5SCRDocument2 pagesFact Sheet: Engine D13A440, EU4SCR / EU5SCRDavid PomaNo ratings yet

- X30532Document84 pagesX30532FoxTheHunterNo ratings yet

- Lilin Downhole MotorDocument35 pagesLilin Downhole MotorIAN.SEMUT100% (2)

- Boomer S1: Single-Boom Face Drilling Rig For Small Drifts and Tunnels With Cross Sections Up To 33 MDocument8 pagesBoomer S1: Single-Boom Face Drilling Rig For Small Drifts and Tunnels With Cross Sections Up To 33 MHéctor MoralesNo ratings yet

- 07 - SynduroDocument14 pages07 - Syndurorobertoalfaro492023No ratings yet

- Comparative Study of Stand-Alone and Hybrid Solar Energy Systems Suitable For Off-Grid Rural Electrification: A ReviewDocument15 pagesComparative Study of Stand-Alone and Hybrid Solar Energy Systems Suitable For Off-Grid Rural Electrification: A Reviewel_ruso__83No ratings yet

- Starlet FaqDocument12 pagesStarlet Faqjavier.abraham100% (2)

- Industrial Training 1Document32 pagesIndustrial Training 1KumarShiveshNo ratings yet

- WeamcoMetric CatalogDocument83 pagesWeamcoMetric CatalogPustinjak SaharicNo ratings yet

- Filtration Products (Compressed Air)Document196 pagesFiltration Products (Compressed Air)Robert Cid de LeonNo ratings yet

- 4 LR Spotlight On Marine Fuel QualityDocument19 pages4 LR Spotlight On Marine Fuel Qualitymaneeshjha9368No ratings yet

- Repair Kit TXV 40 To 120 PumpDocument2 pagesRepair Kit TXV 40 To 120 PumpHorea Cordunianu100% (1)

- Hazard and Risk AssessmentDocument99 pagesHazard and Risk Assessment최재호83% (6)

- 3328 558 3500D Operator ManualDocument44 pages3328 558 3500D Operator ManualbbeisslerNo ratings yet

- Fuel Pressure Modeling in A Common Rail Injection SystemDocument63 pagesFuel Pressure Modeling in A Common Rail Injection SystemSundaraPandiyan100% (1)

- Process Industry Practices Piping: Pip Pndmv003 Gate Valve Data Sheet and Standard TermsDocument10 pagesProcess Industry Practices Piping: Pip Pndmv003 Gate Valve Data Sheet and Standard TermsermusatNo ratings yet

- PSODocument7 pagesPSOAshgar aliNo ratings yet

- Experimental Investigations On Mixing of Two Biodiesels Blended With Diesel As Alternative Fuel For Ci Engines - A ReviewDocument5 pagesExperimental Investigations On Mixing of Two Biodiesels Blended With Diesel As Alternative Fuel For Ci Engines - A ReviewSg_manikandanNo ratings yet

- GM 7000 Advanced Gasbag & Gas-LPG AnalysisDocument9 pagesGM 7000 Advanced Gasbag & Gas-LPG AnalysisAbdul MannanNo ratings yet

- APITECH 03 DecryptedDocument23 pagesAPITECH 03 Decryptedjokerveloz100% (2)

- Initial Survey Final Survey: #DIV/0! #DIV/0!Document1 pageInitial Survey Final Survey: #DIV/0! #DIV/0!merabNo ratings yet

- Engine Especifications G3520BDocument4 pagesEngine Especifications G3520BYaneth100% (1)

- Pipe FabricationDocument42 pagesPipe FabricationJanani M Janani67% (6)

- LIQUITOTE IBC Tanks PDFDocument2 pagesLIQUITOTE IBC Tanks PDFpramodtryNo ratings yet

- Hydraulics PneumaticsDocument168 pagesHydraulics PneumaticsVolety_Sarma_1703No ratings yet

- SLB COSL 223 Morning Report 11-Jul-2020) REV.01Document2 pagesSLB COSL 223 Morning Report 11-Jul-2020) REV.01Jusman Van Sitohang100% (1)

- Compresor Mobil Atlas Copco XAS 186 DDDocument4 pagesCompresor Mobil Atlas Copco XAS 186 DDdiconNo ratings yet