Professional Documents

Culture Documents

Pressure Relief Valve Inspection and Maintenance

Pressure Relief Valve Inspection and Maintenance

Uploaded by

@@ngOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pressure Relief Valve Inspection and Maintenance

Pressure Relief Valve Inspection and Maintenance

Uploaded by

@@ngCopyright:

Available Formats

Pressure Relief Valve Inspection and Maintenance

“Relief valves should be inspected each time the container is filled but no less than once a year. If there is any doubt

about the condition of the relief valve, it must be replaced.”

Major Factors to determine “Life” of Relief Valves

• Water/Ice Accumulation

• Corrosion

• Dirt – Debris

• Damage

• Normal Aging

Eye protection must be worn when performing inspection on relief valves under pressure. Never look directly into a

relief valve under pressure or place any part of your body where the relief vale discharge could impact it. In some

cases, a flashlight and a small mirror are suggested to assist when making visual inspections.

1. Rain cap. Check protective cap located in valve or at end of pipe away for a secure fit. Protective caps help

protect the pressure relief valve against possible malfunction caused by rain, sleet, snow, ice, sand, dirt,

pebbles, insects, other debris and contamination. REPLACE DAMAGED OR MISSING CAPS AT ONCE AND KEEP A

CAP IN PLACE AT ALL TIMES.

2. Open weep holes. Dirt, ice, paint and other foreign particles can prevent proper drainage from the valve body.

IF THE WEEP HOLES CANNOT BE CLEARED, REPLACE THE PRESSURE RELIEF VALVE.

3. Deterioration and corrosion on pressure relief valve spring. Exposure to high concentrations of water, salt,

industrial pollutants, chemicals and roadway contaminates could cause metal parts to fail. IF THE COATING ON

THE SPRING IS CRACKED OR CHIPPED, REPLACE THE PRESSURE RELIEF VALVE.

4. Physical damage. Ice accumulations and improper installation could cause mechanical damage. IF THERE ARE

ANY INDICATIONS OF DAMAGE, REPLACE THE PRESSURE RELIEF VALVE.

5. Tampering or readjustment. Pressure relief valves are factory set to discharge at specified pressure. IF THERE

ARE ANY INDICATIONS OT TAMPERING OR READJUSTMENT, RELPACE THE PRESSURE RELIEF VALVE.

6. Seat leakage. Check for leaks in the seating area using a non-corrosive leak detection solution. REPLACE THE

PRESSURE RELIEF VALVE IF THERE ARE ANY INDICATION OF LEAKAGE. Never force a pressure relief valve closed

and continue to leave it in service. This could result in damage to the valve and possible rupture of the

container or piping on which the pressure relief valve is installed.

7. Corrosion and contamination. REPLACE THE PRESSURE RELIEF VALVE IF THERE ARE ANY SIGNS OF CORROSION

OR CONTAMINATION.

8. Moisture, foreign particles or contaminates in the pressure relief valve. Foreign material such as paint, tar or

ice in pressure relief valve parts can impair the proper functioning on the valves. Grease placed in the valve

body may harden over time or collect contaminates, thereby impairing the proper operation of the pressure

relief valve. DO NOT PLACE GREASE IN THE VALVE BODY. REPLACE THE PRESSURE RELIEF VALVE IF THERE ARE

ANY INDICATIONS OF MOISTURE OR FOREIGH MATTER.

9. Corrosion or leakage at the container connection. Check container to pressure relief valve connection with a

non-corrosive leak detection solution. REPLACE THE PRESSURE RELIEF VALVE IF THERE IS ANY INDICATION OF

CORROSION OR LEAKAGE AT THE CONNECTION AND CONTAINER.

Caution: Never plug the outlet of a pressure relief valve. Any device used to stop the flow of a properly operating

pressure relief valve that is venting an overfilled or over pressurized container – raises serious safety concerns.

7/9/18

You might also like

- Daily Chainsaw ChecklistDocument2 pagesDaily Chainsaw ChecklistMunaku TafadzwaNo ratings yet

- Asm Vr115hvDocument104 pagesAsm Vr115hvDaniel Alex Sánchez75% (8)

- Mobile Elevating Work Platform (MEWP) Pre-Use Inspection: Power Off Checks Power On ChecksDocument1 pageMobile Elevating Work Platform (MEWP) Pre-Use Inspection: Power Off Checks Power On Checksfaisal nadeemNo ratings yet

- Care and Use Guide Rig Mate Creeper WinchDocument8 pagesCare and Use Guide Rig Mate Creeper Winchmoha19841No ratings yet

- Telehandler Forklift Pre-Use Inspection ChecklistDocument1 pageTelehandler Forklift Pre-Use Inspection Checklistsanjay ohriNo ratings yet

- Please Write Yes or No in The Given Box and If Some Comments Write in Remarks ColumnDocument1 pagePlease Write Yes or No in The Given Box and If Some Comments Write in Remarks ColumnmurthyNo ratings yet

- Form-067-Weekly Crane Inspection ChecklistDocument2 pagesForm-067-Weekly Crane Inspection Checklistshamroz khanNo ratings yet

- SMOOTH OR PAD FOOT ROLLER Daily Inspection ChecklistDocument1 pageSMOOTH OR PAD FOOT ROLLER Daily Inspection ChecklistBorislav VulićNo ratings yet

- Towed Scraper Checklist V0810.1 PDFDocument1 pageTowed Scraper Checklist V0810.1 PDFcherifNo ratings yet

- JHA No D0011 "Rust/Paint Chipping": Job Hazard Analysis and Tool Box Discussion FormDocument3 pagesJHA No D0011 "Rust/Paint Chipping": Job Hazard Analysis and Tool Box Discussion Formtjeng syuwenNo ratings yet

- Loadcell User ManualDocument20 pagesLoadcell User ManualTonyNo ratings yet

- Hansen p4 Qvrc2 Cun 9Document21 pagesHansen p4 Qvrc2 Cun 9lcazac100% (1)

- Borang Pemeriksaan Air KompressorDocument1 pageBorang Pemeriksaan Air KompressorAndara Asifa YudianaNo ratings yet

- Engine Presentation 3Document134 pagesEngine Presentation 3Mekonnen AyalNo ratings yet

- Excavator Daily Inspection ChecklistDocument2 pagesExcavator Daily Inspection ChecklistFira KurniatyNo ratings yet

- DailyCranePre OpChecklist PDFDocument1 pageDailyCranePre OpChecklist PDFPablo Hidalgo ValenzuelaNo ratings yet

- Breathing Apparatus ChecklistDocument6 pagesBreathing Apparatus ChecklistJhun AquinoNo ratings yet

- Movable Tower Light-Monthly Inspection Checklist: Acceptable Not Acceptable N/ADocument1 pageMovable Tower Light-Monthly Inspection Checklist: Acceptable Not Acceptable N/Amunna yadav100% (1)

- Inspection Checklist Overhead CraneDocument2 pagesInspection Checklist Overhead CraneMohammad Safdar SadatNo ratings yet

- Crane Inspection Checklist RevDocument1 pageCrane Inspection Checklist RevMuhammadHaziqHaiqalNo ratings yet

- Safety Audit Format Gs ManmadDocument3 pagesSafety Audit Format Gs ManmadsunilNo ratings yet

- UTA AST-Fall Protection SafetyDocument72 pagesUTA AST-Fall Protection SafetyNyoman SaktiNo ratings yet

- Warehouse Cleaning Checklist Daily TasksDocument6 pagesWarehouse Cleaning Checklist Daily TasksDanaNo ratings yet

- Building Works at Hougang Town: Daily Housekeeping ChecklistDocument4 pagesBuilding Works at Hougang Town: Daily Housekeeping ChecklistALFREDO JR. ARIOS CLARONo ratings yet

- Fall Protection Equipment Inspection Checklist - GL-HAL-HSE-0604Document2 pagesFall Protection Equipment Inspection Checklist - GL-HAL-HSE-0604Lijo JohnNo ratings yet

- Earth Compactor Daily Check ListDocument2 pagesEarth Compactor Daily Check ListpjosesmNo ratings yet

- Inspection Rigging EquipmentDocument1 pageInspection Rigging Equipmentwahyu haryadiNo ratings yet

- ATTACH 3 LOG SHEET UpdatedDocument12 pagesATTACH 3 LOG SHEET UpdatedHedi Ben MohamedNo ratings yet

- Risk Assessment - PPE - FirefighterDocument2 pagesRisk Assessment - PPE - Firefighterbearingworks123No ratings yet

- MJ164 RIP SAW Operation ManualDocument36 pagesMJ164 RIP SAW Operation ManualEduardo Lopez CastilloNo ratings yet

- GD380A-L ListDocument6 pagesGD380A-L ListNam Won HongNo ratings yet

- M/S Kapoor Enterprises Vendor Code: K635: Mechanized Rock Breaker ChecklistDocument2 pagesM/S Kapoor Enterprises Vendor Code: K635: Mechanized Rock Breaker Checklistprojit basu100% (1)

- Boom Concrete Pump ChecklistDocument2 pagesBoom Concrete Pump ChecklistVilky VargheseNo ratings yet

- Sample: Excavator Inspection & Maintenance RecordDocument3 pagesSample: Excavator Inspection & Maintenance RecordbangladragosNo ratings yet

- PB Waste Management FormDocument3 pagesPB Waste Management Formslamet4riadiNo ratings yet

- Form-I-010 Welding Machine Inspection Form: Carry-In CertificateDocument1 pageForm-I-010 Welding Machine Inspection Form: Carry-In CertificateAdhy DarmawanNo ratings yet

- HSE 05-011a Daily Inspection Register For Forklift TrucksDocument1 pageHSE 05-011a Daily Inspection Register For Forklift TrucksQuentin KlynsmithNo ratings yet

- Monthly Crane Inspection ChecklistDocument2 pagesMonthly Crane Inspection Checklistslamet4riadiNo ratings yet

- Boom Truck Daily InspectionDocument1 pageBoom Truck Daily InspectionMartine OtienoNo ratings yet

- Control of Construction Plant and MachineryDocument38 pagesControl of Construction Plant and MachineryThiyagarajan kNo ratings yet

- F0556 Crane Weekly Check (Offshore)Document2 pagesF0556 Crane Weekly Check (Offshore)Vimal Singh0% (1)

- Form Inspection Premob - Quarterly (1) - 2Document26 pagesForm Inspection Premob - Quarterly (1) - 2Ryan Rhamdhani100% (1)

- Fork Lift Daily Check: (Only For FL Operated by Batery)Document1 pageFork Lift Daily Check: (Only For FL Operated by Batery)Martin CabelloNo ratings yet

- Weekly Lift Truck Pre-Use Check Sheet: Operator Signature: Supervisor SignatureDocument2 pagesWeekly Lift Truck Pre-Use Check Sheet: Operator Signature: Supervisor Signaturetemter gandaNo ratings yet

- Ladder-Safety-Inspection-Form-Editable - TemplateDocument2 pagesLadder-Safety-Inspection-Form-Editable - TemplateWayne McnaughtNo ratings yet

- 5 Weekly Check List JCBDocument4 pages5 Weekly Check List JCBsamiran RouthNo ratings yet

- Index: Cv. Dira Utama SejahteraDocument12 pagesIndex: Cv. Dira Utama SejahteraFreshop SurabayaNo ratings yet

- Forklift Daily Inspection F005Document1 pageForklift Daily Inspection F005mohammedNo ratings yet

- 26 - Welding Machine ChecklistDocument1 page26 - Welding Machine ChecklistZeeshan AbbasiNo ratings yet

- First Aid Kid ListDocument4 pagesFirst Aid Kid ListHairul Nizam Bin Mohd SalimNo ratings yet

- Lull Telehandler 944-E42Document200 pagesLull Telehandler 944-E42Allan DelormeNo ratings yet

- Crane Inspection Checklist: General InformationDocument7 pagesCrane Inspection Checklist: General InformationArunachu ArunachuNo ratings yet

- Fire EXTINGUISHER MAINTENANCE INSPECTION CHECKLISTDocument2 pagesFire EXTINGUISHER MAINTENANCE INSPECTION CHECKLISTJahaziNo ratings yet

- Forklift Daily Checklist ElectricDocument2 pagesForklift Daily Checklist Electricmikel derrickNo ratings yet

- Machinery Inspection ChecklistDocument3 pagesMachinery Inspection ChecklistIvan Dave TorrecampoNo ratings yet

- Aerial Lifts FactsheetDocument2 pagesAerial Lifts FactsheetJafar KhanNo ratings yet

- Daily Angle Grinder Pre - Use Checklist - 2024 (Copy)Document1 pageDaily Angle Grinder Pre - Use Checklist - 2024 (Copy)papisdieng282No ratings yet

- Radiography Work Permit (OGF-HSE-23)Document3 pagesRadiography Work Permit (OGF-HSE-23)Mock ProjectNo ratings yet

- Excavator Daily Inspection Check List Rev 0Document1 pageExcavator Daily Inspection Check List Rev 0Zhafran diniyNo ratings yet

- Presentation PRV - Pressure Relive ValveDocument17 pagesPresentation PRV - Pressure Relive ValveZain SallehNo ratings yet

- Warning: Safety Warning - LP-Gas Pressure Re Lief ValvesDocument13 pagesWarning: Safety Warning - LP-Gas Pressure Re Lief ValvesJOSE BARONNo ratings yet

- Pressure Relief Valve InspectionDocument18 pagesPressure Relief Valve InspectionZain SallehNo ratings yet

- Turbine Flow Meter Coefficient and Scaling FactorDocument2 pagesTurbine Flow Meter Coefficient and Scaling Factor@@ngNo ratings yet

- How To Calculate Measurement Uncertainty: PurposeDocument7 pagesHow To Calculate Measurement Uncertainty: Purpose@@ngNo ratings yet

- Haskel Liquid Pumps BookletDocument28 pagesHaskel Liquid Pumps Booklet@@ngNo ratings yet

- Bell BP BrochureDocument4 pagesBell BP Brochure@@ngNo ratings yet

- Tutorial 1 - Basic Engineering Science: Instrumentation and ControlDocument6 pagesTutorial 1 - Basic Engineering Science: Instrumentation and Control@@ngNo ratings yet

- Brosure Wall Mountedv Ada LogoDocument2 pagesBrosure Wall Mountedv Ada Logo@@ngNo ratings yet

- 130 Series Pneumatic Indicating Controllers: Product SpecificationsDocument4 pages130 Series Pneumatic Indicating Controllers: Product Specifications@@ngNo ratings yet

- Rundown Published PPSDM Migas 2019Document22 pagesRundown Published PPSDM Migas 2019@@ngNo ratings yet

- Click To Edit Master Title StyleDocument4 pagesClick To Edit Master Title Style@@ngNo ratings yet

- Pt. Indocal Laboratori Sistem: Revision Date:24 September 2004 Expiry Date:23 September 2008Document2 pagesPt. Indocal Laboratori Sistem: Revision Date:24 September 2004 Expiry Date:23 September 2008@@ngNo ratings yet

- Comparison Table For Flowmeter PDFDocument1 pageComparison Table For Flowmeter PDF@@ngNo ratings yet

- List of IEC Standards - Wikipedia, The Free EncyclopediaDocument7 pagesList of IEC Standards - Wikipedia, The Free Encyclopedia@@ng0% (1)

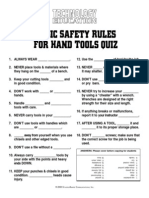

- Basic Safety Rules For Hand Tools Quiz: © 2000 S A C, IDocument1 pageBasic Safety Rules For Hand Tools Quiz: © 2000 S A C, I@@ngNo ratings yet

- Gallus 2000Document2 pagesGallus 2000@@ngNo ratings yet

- Xciting R 500I - SBA0BB (FR) - 2009.11.02.Document164 pagesXciting R 500I - SBA0BB (FR) - 2009.11.02.AndreiMirceaNo ratings yet

- Tvs Motor Company: Parts CatalogueDocument56 pagesTvs Motor Company: Parts Cataloguetvsparavattani75% (8)

- Aerospace Parts 2 Quick Disconnect CouplingsDocument104 pagesAerospace Parts 2 Quick Disconnect CouplingsSohail100% (1)

- GX 7, GX 11: Instruction BookDocument76 pagesGX 7, GX 11: Instruction Book754812No ratings yet

- 867-42T-20 Pilot Operated, Pressure-Reducing Valve: WarningDocument8 pages867-42T-20 Pilot Operated, Pressure-Reducing Valve: WarningfernandoNo ratings yet

- Air DryerDocument14 pagesAir DryerIhsan Habib AbikNo ratings yet

- Santon Premier Plus pb150Document16 pagesSanton Premier Plus pb150salesman2009No ratings yet

- VM4C - VM4C1 Vm4Sc - Vm4Sc1 Single Vane Motor: Service InformationDocument4 pagesVM4C - VM4C1 Vm4Sc - Vm4Sc1 Single Vane Motor: Service Informationluisxxx1No ratings yet

- Directional Valve PneumaticDocument74 pagesDirectional Valve Pneumaticmajid fardniaNo ratings yet

- Wall Mounted Split Type Air Conditioner (J Series) : Installation ManualDocument20 pagesWall Mounted Split Type Air Conditioner (J Series) : Installation ManualcostelchelariuNo ratings yet

- Yanmar 6HAL2N Major OHDocument11 pagesYanmar 6HAL2N Major OHSafix Yazid100% (1)

- Maintenance: Contents PageDocument13 pagesMaintenance: Contents PageJorn StejnNo ratings yet

- Rivulis F3200 English Metric 20190508 Web-1Document10 pagesRivulis F3200 English Metric 20190508 Web-1Mehdi BassouNo ratings yet

- Guidelines On The Effects of Cycling Operation On Maintenance ActivitiesDocument97 pagesGuidelines On The Effects of Cycling Operation On Maintenance ActivitiesAndreaGentileNo ratings yet

- Aybey Alc HataDocument8 pagesAybey Alc HataerkanNo ratings yet

- Module 2Document4 pagesModule 2ShahrizatSmailKassimNo ratings yet

- Functional Test: FT-Packaged Boiler and Boiler System Including HW Pumps 1 & 2Document7 pagesFunctional Test: FT-Packaged Boiler and Boiler System Including HW Pumps 1 & 2vin ssNo ratings yet

- How To Order: FeaturesDocument4 pagesHow To Order: FeaturestauasiNo ratings yet

- Accumulator Selection: 3.1 Method of Selection 3.2 Gas Precharge PressureDocument12 pagesAccumulator Selection: 3.1 Method of Selection 3.2 Gas Precharge Pressurereincidentesk8No ratings yet

- Technical Manual Soft Serve Goshen ST16RELW ENDocument41 pagesTechnical Manual Soft Serve Goshen ST16RELW ENAkhmad Chairul LatiefNo ratings yet

- Cameron Fully Welded Ball Valves BrochureDocument36 pagesCameron Fully Welded Ball Valves BrochureBalderas Rosas WilibaldoNo ratings yet

- Cummins ISL CM554: Electrical Circuit DiagramDocument9 pagesCummins ISL CM554: Electrical Circuit DiagramElmer Tintaya Mamani100% (1)

- Piping Engineering Interview Questions Part 1Document4 pagesPiping Engineering Interview Questions Part 1smsunil12345No ratings yet

- 2.50 - Vol 2 Part 5 Particular Specifications Marafeq Specifications PDFDocument56 pages2.50 - Vol 2 Part 5 Particular Specifications Marafeq Specifications PDFIntergrity MediaNo ratings yet

- 660 MW Warm Startup Procedures Warm Start Up After 36 Hrs Shutdown and HPC Temperature 340 C and Ipc 320 C With Boiler PR 1 To 30 KSCDocument6 pages660 MW Warm Startup Procedures Warm Start Up After 36 Hrs Shutdown and HPC Temperature 340 C and Ipc 320 C With Boiler PR 1 To 30 KSCdjfffNo ratings yet

- Above Ground TanksDocument6 pagesAbove Ground TanksGyanendra Narayan NayakNo ratings yet

- DO - 005 - s2018 - Preventive Maintenance Manual For DPWH Equipment and Service VehiclesDocument231 pagesDO - 005 - s2018 - Preventive Maintenance Manual For DPWH Equipment and Service Vehiclesalterego1225100% (3)