Professional Documents

Culture Documents

Design and Fabrication of Groundnut Pods and Shell Stripper: April 2018

Design and Fabrication of Groundnut Pods and Shell Stripper: April 2018

Uploaded by

Sanket WaradeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Fabrication of Groundnut Pods and Shell Stripper: April 2018

Design and Fabrication of Groundnut Pods and Shell Stripper: April 2018

Uploaded by

Sanket WaradeCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/326847516

Design and Fabrication of Groundnut Pods and Shell Stripper

Article · April 2018

CITATIONS READS

0 1,822

2 authors:

Gantyada Karthik A. Lakshumu Naidu

GMR Institute of Technology Centurion University of Technology and Management

4 PUBLICATIONS 0 CITATIONS 37 PUBLICATIONS 121 CITATIONS

SEE PROFILE SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Biofuels View project

A review on chemical and mechanical properties of natural fiber reinforced polymer composites View project

All content following this page was uploaded by A. Lakshumu Naidu on 07 August 2018.

The user has requested enhancement of the downloaded file.

International Journal of Engineering Trends and Technology (IJETT) – Volume 58 Issue 2 – April 2018

Design and Fabrication of Groundnut Pods

and Shell Stripper

G. Karthik#1, D. Balashankar#2, G. Rambabu#3, B. Nagabhushanam#4,

Lvs Akhil#5, A. Lakshumu Naidu*6

#

Research scholar& * Assistant professor & Department of mechanical engineering, GMR Institute of

technology,

Rajam, India.

Abstract:World is mostly concentrating on new Groundnuts has many pros such as food

inventions and running with updated technology. purpose (peanut oil, peanut butter, peanut flour,

Farmers are back bone for every country in the Boiled nuts etc.,) [3]. Malnutrition is reduced with the

world. Without farmer’s livelihood is difficult. help of groundnuts because it has more energy and

Groundnuts is grown on a small scale by farmer. The proteins. Groundnuts are useful for obtaining the oils.

major problem in groundnut production in country While extracting oil from the groundnut the waste

like India is the lack of groundnut processing produced is feed to the animals. It is used in many

machines available to farmers. In the beginning the industrial applications such as paints, lubrication oil,

peanuts were separated from its shells by the vanish, leather dressing and furniture polish. It is also

workers. The output from this method was very less used for cooking oil purpose [4].

and could not satisfy the market demand as it was Even though there are so many advantages,

very time-consuming process. This project is mainly groundnut shelling is a major problem in India [5]. In

about to remove the barriers while removing the this project, we designed and developed a small

groundnuts. In this rotational mechanism is used. machine to peel out the shell of groundnut so that

With the help this instrument the time gap reduces farmers can reduce their labour cost and processing

from removing of groundnut from plant and also the time and high profit by selling the groundnut.

labor required reduces. This project makes the The main motto of the design is to remove the pods

farmer to work easy and can save more time and from the roots of the plants and peel out the nuts from

investment. It is more efficient and can be available the shell. This equipment is eco-friendly and also

to all at minimum cost. With this mechanism the final have less maintenance cost. The cycle rim we used is

outcome is nut from the shell. to separate the pods from the plant and rotor to

remove the shell of the ground nut [6]. For the

Keywords: Groundnuts, time consumption, preparation rotor we used arc welding and mild steel

rotational mechanism material. Plywood in this project is used as a base and

also supports. Rotor is rotated with the help of the

electric motor [7].

I. INTRODUCTION .

Agriculture is the back bone of the Indian economy. II. LITERATURE REVIEW

Many of the farmers work day and night for growing Santosh Mangave and Bhagyesh Deshmukh [8]

the crops [1]. According to the seasonal conditions designed the portable groundnut sheller machine.

farmers plant variety types of crops, in that They also fabricated it. The fabricated machine is

groundnuts is one of them. Arachishypogaea.L. is the manually operated. Sheller machine is used to shell

scientific name of groundnuts. It comes under the only dry pods and it can be used as a groundnut

family of fabaceae. The favorable condition for Sheller machine for domestic application.

growing this crop is dry climate. Around 7600 years Ashok. S. Andhale et.al [9] designed and developed a

onwards this crop is being cultivated. Earlier it was groundnut separator machine which runs with a

found in Peru because of its climatic conditions. This robotic arm. The main purpose of the robotic arm is

plant grows to a height of 30cm to 50cm [2]. The to pluck the ground nut from the plant and put into

main parts of the groundnut are shell, cotyledon, seed the rotor which has blades. With this the human effort

coat, radicle and plumule. is reduced and also efficiency is increased as it is

fully automatic.

ISSN: 2231 - 5381 www.ijettjournal.org Page 60

International Journal of Engineering Trends and Technology (IJETT) – Volume 58 Issue 2 – April 2018

Kulbhushan M. Shejole et.al [10] designed and control device, shelling unit, separating unit and

fabricated the pedal operated groundnut crusher. It is power system.

a manual process where the groundnuts are removed A. N. Gitau1 et.al [16] has done investigations on two

from shell. The pedal is used for the movement of the manually operated decorticators and were tested and

crusher. There will be no energy consumption and the modifications done on one of the decorticators to

cost of production is less. It has less maintenance optimize its technical performance.The performance

cost. tests showed that the requirements of the farmers

Ashish S. Raghtateet.al[11] designed and fabricated a including low kernel breakages and high shelling

groundnut sheller machine. It is very cheap and five efficiencies could be achieved by the modified

experiments were performed with peanuts. Since this decorticator.

machine is made for small businessman or for Pratima G. Mungase et.al [17] designed and

farmers, therefore the work carried out by this fabricated a machine where sprockets of a bicycle are

machine is less. The decocting process of groundnut rotated by pedaling action and this rotary motion is

by this machine is more economical and faster than used to rotate the shaft of a screw conveyor. The

manual process or any other processes. peanut gets crushed in between the flights around the

“GROUNDNUT SHELLER MACHINE” will save shaft and the casing of the conveyor.

the tremendous time, energy manpower and save By considering all these designs we designed our

financial input of the project, reducing the cost and own equipment which is of low cost and less

time considerably which is the backbone of the maintenance but higher efficiency.

present world economy.

Tushar Walke et.al [12] designed and fabricated the III. METHODS AND MATERIALS

groundnut machine which is electrically operated. The materials used for the preparation of the

The working of the machine is power supplied to equipment are:

motor it rotates the roller.Groundnuts are supplied in Ply wood (base of the equipment)

crushing chamber through hopper and they get (100cmx95cmx3cm)

crushed between Semicircular net and the roller. Cycle rim (20cm radius)

Thus, the ground nuts are removed from the shell. Sheet metal (2mm thickness)

Ikechukwu Celestine Ugwuoke et.al [13] designed an Hollow Rotor shaft (OD 4cm and

electrically powered groundnut shelling machine. The 1mm thickness)

machine was fabricated using materials that were Hollow drum (D6inches)

sourced locally. It can be used for both domestic and Electric Motor (1)

industrial purposes. The advantage to be derived from (1/4hp,1400rpm,220-240volts,50hz,

the use of this machine far outweighs its single phase)

shortcomings. The test result showed that the Blades (4 in number with length of

machine can shell a total of 400kg of groundnut in an 30cm)

hour. We have considered these materials because of the

Deshmukh Shubham et.al [14] designed and availability and also low cost.

fabricated the machine that has the capacity of The methods used for the fabrication of the

shelling 400kg of groundnut per hour with a shelling equipment are:

and separating efficiencies of 95.25% and 91.67% Welding for preparation of the

respectively. The machine was fabricated from rotor.

locally sourced materials, which makes it cheap and Wood work for finishing.

easily affordable and also easy and cheaper to IV. DESIGN CALCULATION

maintain. It is also of light weight and comprises of According to the motor specifications: voltage: 220-

the hopper, crushing chamber, separation chamber 260 volts

and the blower unit. Current

Arjun Vishwakarma et .al [15] has designed and (amp): 2 amps

fabricated a machine whose production capacity is RPM: 1400

more & machine gets operated on 1 H.P. electric. The Capacity:1/4

fresher and small farmer or business man can start HP

business by investing less capital. groundnut Power:

decorticator consists of feed hopper with a flow rate P=VI

ISSN: 2231 - 5381 www.ijettjournal.org Page 61

International Journal of Engineering Trends and Technology (IJETT) – Volume 58 Issue 2 – April 2018

P = 240 X2 Design of rim:

= 480 Watt We considered the cycle rim of diameter of 20mm

We know that P = 2ℼNT/60 and we kept shield around it so that the groundnut

T = P X60 /2ℼN pods which move in random direction does not go

T SHAFT = 480X60/2ℼ out. The complete design can be viewed in fig.1.

(1400)

= 3.27 N-m

Energy consumption:

E IN KWH = P X TIME

= 480 X 24

= 11520 W-hour/ day

= 11.52 kw- hour/day

For month,

= 11.52x 30 kw-hour/month

= 345.6 kw-hour/month

1-unit cost is 8.5 rupees

= 345.6 x 8.5 = 2937.6 /- per

month. Fig-1: Design of cycle rim

Shaft calculations: We have diameter of hollow Design of rotor and shaft:

shaft as follows We designed a rotor with the help of hollow shaft of

Outer diameter= 40mm diameter 4 cm and length of 48 cm. We also kept flat

Inner diameter = 38mm mild steel plate on four sides of the hollow shaft. The

The shaft experienced with two moments bending flat plat which we considered is of length 30 cm and

moment as well as twisting moment. thickness of 5mm. Curved plates are welded on the

T/J= τ/R flat plates with the help of arc welding. This rotor

We know that T = 3.27 N-m= 3270 N-mm helps to break the ground nut pods. Due to shear

J = ℼ/32 ((D0)4-(DI)4) force between rotor and ground nut pods the shell of

= ℼ/32 ((40)4- (38)4) = 46619.7 mm4 the pods breaks. The figure 2 shows the design of

=3270/46619.7 = τ/20 shaft and figure 3 shows the rotor complete design.

τ shaft = 3270x20/46619.7 = 1.4 N/mm2

Bending stress = M/I = σ/Y

Bending stress due to self-weight = 5kg

Weight = 5x9.81 = 49.1 N

Stress(σ) = P/A

= 49.1/ (ℼ/4) ((40)2-(38)2)

= 0.4 N/mm2

For circular shaft: I= ℼ/64 ((D0)4-(DI)4)

= ℼ/64 ((40)4-(38)4) = 23309.83 Fig 2: Design of the shaft

4

mm

Bending moment (M) = (σ X I)/Y

= (0.4X 23309.83)/20 =

466.197 N-mm

Shaft subjected to combined torsion and bending:

τ max = (16 x d0 / ℼ((d0)4- (di)4))

(M)2 + (T)2

= (16X40X3303.1)/ ℼ((40)4-(38)4) = 1.41N/mm2

σ max = (16 x d0 / ℼ((d0)4- (di)4)) (M+

(M)2 + (T)2 )

= 16X40 X (3769.3)/ ℼ ((40)4-(38)4) =

2

1.62 N/mm Fig 3: Design of the rotor

V. DESIGN OF THE EQUIPMENT Design of complete equipment:

ISSN: 2231 - 5381 www.ijettjournal.org Page 62

International Journal of Engineering Trends and Technology (IJETT) – Volume 58 Issue 2 – April 2018

The complete equipment is shown in the figure 4. We (1) Shelling efficiency (%) = [Qs / Qt] x 100 =

assembled the rotor and cycle rim and a slope which (228.5/250) x100 = 91.2 %

can been seen in the figure. The slope is of at an (2) Material efficiency (%) = [Qu / (Qu +Qd)] x 100

inclination of 45 degrees. = 66.1 %

(3) Mechanical damage (%) = [Qd / (Qu +Qd)] x 100

= 33.9 %

(4)Throughput capacity(kg/h)=[Qs/Tm] =

228.5/209.75=1.089 kg/hrs

Fig-4Assembly of complete equipment

Fig-5: Production rate different countries

The above fig.5 shows that the production rate of

groundnuts is more in chain compared to the

remaining countries in the world. India ranks 2nd in

the world.

VI. RESULTS AND DISCUSSIONS

The sample is brought from market. It is sun dried for

one day to remove moisture contend. Sample

contains unshelled groundnut and some soil adhered

to shell. In testing table following parameters are

mention like, wt. of sample, wt. of shelled nuts and

time required to shelled groundnut. The testing of the

system was done and the following results were

observed:

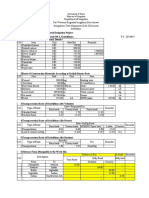

1: Testing Table

Sr. Total Wt. Of Wt. Of Wt. Of Time

Fig.6: Efficiency of different machines

No Wt. Of Shelle Undam Dama To The above fig: 6 shows the efficiency of the different

Groun d aged ge Shelli processes where the manual process shows the lowest

dnut Groun Ground Groun ng efficiency compared to all and robotic shows the

In dnut nut dnut Opera highest efficiency. Powered has the efficiency of 82%

gms. In Seed In Seed tion nearly.

(Qt) gms. gms. In In

(Qs) (Qu) gms. Sec.

(Qd)

1 250 220 132 88 190

2 250 230 149.5 80.5 220

3 250 239 164.91 74.09 232

4 250 225 157.5 67.5 197

TOT 1000 914 603.91 310.09 839

AL

ME 250 228.5 150.97 77.52 209.7 Fig.7 Throughput capacity of different machines

AN 5 The above fig.7 shows the throughput capacity

different machines in that the robotic has high

throughput compared to remaining machines.

Powered machine has a throughput of 130 kg/hr.

ISSN: 2231 - 5381 www.ijettjournal.org Page 63

International Journal of Engineering Trends and Technology (IJETT) – Volume 58 Issue 2 – April 2018

The below flowcharts show the process of making the 4. It was also observed that groundnut with one seed

equipment. The main part in the equipment is electric per pod and those with two small seeds in their pods

motor, if the motor is not suitable again check the were the ones that came out unshelled or partially

design calculation and take suitable electric motor. If shelled.

the electric motor is suitable then proceed for theVIII. ACKNOWLEDGEMENTS: We are very much

fabrication. grateful to our faculty Mr. A. LAKSHUMU

NAIDU (assistant professor) for providing the

support and guidance towards this work.

IX. REFERENCES:

[1]. Pande, S., et al. "Disease management factors influencing yield

and quality of sorghum and groundnut crop residues." Field Crops

Research 84.1-2 (2003): 89-103.

[2]. Wijnands, J. H. M., Jaap Biersteker, and E. N. Van Loo.

Oilseeds business opportunities in Ethiopia 2009. PPP, 2009.

[3].Geleta, Tarekegn, et al. "Integrated management of groundnut

root rot using seed quality." International Journal of Pest

Management 4 (2007): 53-57.

[4].Kebede Desta, 1997. Attaining small holder household food

security through promotion of mechanization technology: The

experience of ministry of Agriculture. Proceed of the first

conference of the ESAE, 1(1): 62-73.

[6]. Nathan Trujillo. Lowrider Bicycle Magazine. laced up a pair of

144-spoke Phoenix wheels.

[7].Hughes, Thomas Parke. Networks of power: electrification in

Western society, 1880- 1930. JHU Press, 1993.

[8].Mangave, Santosh, and Bhagyesh Deshmukh. "Design of

Portable Groundnut Sheller Machine." Department of mechanical

The fig.8 is the final equipment which fabricated after engineering, WIT, Solapur. International Journal of Mechanical

Engineering and Information Technology 3: 1125-1129.

considering the design and design calculations. The [9]. Ashok. S. Andhale, Sayed Wajahat, Pranav Lawhale, Kunal

Mendhe. “Design and Development of Groundnut Pod Separating

1/4HP electric motor rotates the rotor shaft. Machine”.

[10].Design and Fabrication of Pedal Operated Groundnut

Decorticator Machine” Kulbhushan M. Shejole, Nitin B. Borkar,

Abhijit M. Bobade.

[11].Raghtate, Ashish S., and Dr CC Handa. "Design and

fabrication of groundnut sheller machine." IJIRST–International

Journal for Innovative Research in Science & Technology 1.7

(2014).

[12].Walke, Tushar, et al. "Design & Fabrication of Groundnut

Sheller Machine." International Journal of Engineering Science

5997 (2017).

[13].Ugwuoke, Ikechukwu Celestine, Olawale James Okegbile,

and Ibukun Blessing Ikechukwu. "Design and Fabrication of

Groundnut Shelling and Separating Machine." Department of

Mechanical Engineering, Federal University of Technology Minna,

Niger State, Nigeria. International Journal of Engineering Science

Invention ISSN (Online) (2014): 2319-6734.

[14].Design and Fabrication of Groundnut Pod Separating Machine

Deshmukh Shubham, GiramkarHarshawardhan, Kadam Bharat,

JedheShubham,Adhapure D.U.

Fig-8: Final equipment

[15].Design And Fabrication Of Groundnut Decorticator Arjun

Vishwakarma, TejasTandale, Prof R.H.kekan

VII. CONCLUSIONS

[16].Gitau, A. N., et al. "Optimizing the Performance of a

1. This work presents the design of an electrically manually operated groundnut (Arachishypogaea) decorticator."

Open Journal of Optimization 2.01 (2013): 26.

powered groundnut pods stripper and shelling

[17].Mungase, Pratima G., et al. "Peanut Sheller using Screw

machine.

Conveyor." (2016).

2. It can be used for both domestic and industrial

purposes.

3. The advantage to be derived from the use of this

machine far outweighs its shortcomings.

ISSN: 2231 - 5381 www.ijettjournal.org Page 64

View publication stats

You might also like

- Δ Table 6.1.14.4.1 (a) Required Separation of Occupancies (hours) ,† Part 1Document2 pagesΔ Table 6.1.14.4.1 (a) Required Separation of Occupancies (hours) ,† Part 1JamesNo ratings yet

- Quiz 3Document8 pagesQuiz 3Dhruv Sahni100% (1)

- Physics Cheat SheetDocument1 pagePhysics Cheat Sheetjlvmrbd7770% (1)

- Design and Fabrication of Groundnut Pods and Shell StripperDocument5 pagesDesign and Fabrication of Groundnut Pods and Shell StripperSanket WaradeNo ratings yet

- Agricultural Shredder MachineDocument9 pagesAgricultural Shredder Machineahmad fauziNo ratings yet

- Groundnut ThrasherDocument27 pagesGroundnut ThrasherBoopathi KalaiNo ratings yet

- Multicrop Harvesting MachineDocument9 pagesMulticrop Harvesting MachineIJRASETPublicationsNo ratings yet

- Design and Development of Peanut Peeler MachineDocument7 pagesDesign and Development of Peanut Peeler MachineKristoffer SamsonNo ratings yet

- Design and Fabrication of Corn De-Seeding MachineDocument8 pagesDesign and Fabrication of Corn De-Seeding MachineAnonymous 1mMOyt9zNo ratings yet

- Groundnut Sheller Machine PDFDocument8 pagesGroundnut Sheller Machine PDFTanvi Khurana100% (5)

- Literature Review On Coconut Peeling MachineDocument8 pagesLiterature Review On Coconut Peeling MachineIJRASETPublications100% (1)

- Design and Fabrication of Sugarcane Cutting Machine For Cane-Can Industry, NagpurDocument2 pagesDesign and Fabrication of Sugarcane Cutting Machine For Cane-Can Industry, NagpurSaiNo ratings yet

- Design and Fabrication of Coconut Leaves ShredderDocument9 pagesDesign and Fabrication of Coconut Leaves ShredderRanjan SahooNo ratings yet

- Fabrication of Low-Cost Manualcrop Harvesting MachineDocument9 pagesFabrication of Low-Cost Manualcrop Harvesting Machinepratik g100% (1)

- Design and Development of Agriculture Multi-Crop CutterDocument8 pagesDesign and Development of Agriculture Multi-Crop CutterIJRASETPublicationsNo ratings yet

- Design and Fabrication of Multi-Purpose Sieving MachineDocument6 pagesDesign and Fabrication of Multi-Purpose Sieving MachineMICHEL RAJ MechNo ratings yet

- Design and Fabrication of Groundnut Plucking Machine: Amol Junnarkar, Pankaj Jain, Ramnewash NishadDocument5 pagesDesign and Fabrication of Groundnut Plucking Machine: Amol Junnarkar, Pankaj Jain, Ramnewash NishadFiraol GudisaNo ratings yet

- Development of Multipurpose Biowaste Shredder Machine-IJRASETDocument9 pagesDevelopment of Multipurpose Biowaste Shredder Machine-IJRASETIJRASETPublicationsNo ratings yet

- Design and Fabrication of A ShredderDocument9 pagesDesign and Fabrication of A ShredderEphraim MekonnenNo ratings yet

- Design and Fabrication of Crop ReaperDocument9 pagesDesign and Fabrication of Crop ReaperIJRASETPublicationsNo ratings yet

- Fin Irjmets1672122738Document13 pagesFin Irjmets1672122738Sharana basavaNo ratings yet

- 6 Tme011Document3 pages6 Tme011kapilrajNo ratings yet

- Prototype of The Chopping Machine For The Fronds and Leaves of Oil PalmsDocument6 pagesPrototype of The Chopping Machine For The Fronds and Leaves of Oil PalmsFachreza ArdianNo ratings yet

- (19-23) Sugarcane Research Paper-FormatDocument5 pages(19-23) Sugarcane Research Paper-FormatSubhash S SubbuNo ratings yet

- Design of Cutting Blade of Agricultural Harvester Using Bionic PrincipleDocument11 pagesDesign of Cutting Blade of Agricultural Harvester Using Bionic PrincipleIJRASETPublicationsNo ratings yet

- IJRPR2039Document4 pagesIJRPR2039Banana LoverNo ratings yet

- Thesis Final Proposal PresentationDocument25 pagesThesis Final Proposal Presentationkibromkb100% (1)

- FireeDocument7 pagesFireeBINIYAM ALAMREWNo ratings yet

- Design and Fabrication of Groundnut Separating MachineDocument2 pagesDesign and Fabrication of Groundnut Separating MachineBONFRINGNo ratings yet

- Journalnx DesignDocument3 pagesJournalnx DesignJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Design and Fabrication of Groundnut Shelling MachineDocument5 pagesDesign and Fabrication of Groundnut Shelling MachineGAMUCHIRAI MUGADZANo ratings yet

- Review On Pulverization MachineDocument7 pagesReview On Pulverization MachineIJRASETPublicationsNo ratings yet

- Design of An Innovative Coconut Grating Machine Using TinkercadDocument5 pagesDesign of An Innovative Coconut Grating Machine Using TinkercadChristopher Ysit100% (1)

- Design and Fabrication of Groundnut ShellerDocument7 pagesDesign and Fabrication of Groundnut ShellerIJRASETPublications100% (1)

- Design and Fabrication of Crop Cutting Machine IJERTV8IS060212 PDFDocument6 pagesDesign and Fabrication of Crop Cutting Machine IJERTV8IS060212 PDFHaritha ChowdaryNo ratings yet

- A Review On Design and Fabrication of GR PDFDocument4 pagesA Review On Design and Fabrication of GR PDFFiraol GudisaNo ratings yet

- Vinayak PDFDocument5 pagesVinayak PDFrajput sunilNo ratings yet

- FinalPaperAutomatic Coconut Dehusking Machine191390Document2 pagesFinalPaperAutomatic Coconut Dehusking Machine191390PRAJWALNo ratings yet

- 639 1630 1 PBDocument6 pages639 1630 1 PBUNITED CADDNo ratings yet

- .Design and Fabrication of Groundnut Sheller MachineDocument3 pages.Design and Fabrication of Groundnut Sheller MachineTomorrowNo ratings yet

- Articleupload Article870.PDFDocument8 pagesArticleupload Article870.PDFKathryn Mae Caster GanNo ratings yet

- FinalPaperDESIGN AND FABRICATION OF SOLAR PADDY THRESHING MACHINE FOR AGRICULTURE PURPOSE191502 PDFDocument5 pagesFinalPaperDESIGN AND FABRICATION OF SOLAR PADDY THRESHING MACHINE FOR AGRICULTURE PURPOSE191502 PDFFachryan NaufalNo ratings yet

- Project Title:: Project Guide: Mr. Akshay Kumar Team MembersDocument29 pagesProject Title:: Project Guide: Mr. Akshay Kumar Team MembersAnonymous j0aO95fgNo ratings yet

- Pcadmmin, 46Document4 pagesPcadmmin, 46Bizuayehu ShibiruNo ratings yet

- 4-P Ijsrdv3i40185Document5 pages4-P Ijsrdv3i40185zyzerlyngNo ratings yet

- Maize Shller ThreshingDocument13 pagesMaize Shller ThreshingFrancisco ToroNo ratings yet

- M34 Research PaperDocument4 pagesM34 Research PaperHemant YadavNo ratings yet

- Untitled PDFDocument6 pagesUntitled PDFBemn BayuNo ratings yet

- Palm FruitDocument13 pagesPalm FruitTofunmi MatthewNo ratings yet

- Design of Crop Cutter Machine Ijariie5257Document6 pagesDesign of Crop Cutter Machine Ijariie5257Vijay PulavarthiNo ratings yet

- ICEMESM120Document3 pagesICEMESM120Raja ArifNo ratings yet

- Smart Solar Grass Cutter 2Document9 pagesSmart Solar Grass Cutter 2Larweh DanielNo ratings yet

- 8 Design of Robot Lawn MowerDocument40 pages8 Design of Robot Lawn MowerHanan ShayiboNo ratings yet

- Optimization and Development of Existing Corn Sheller MachineDocument5 pagesOptimization and Development of Existing Corn Sheller MachineIJRASETPublicationsNo ratings yet

- Design and Development of "Crop Cutter": September 2018Document7 pagesDesign and Development of "Crop Cutter": September 2018faiza_No ratings yet

- The Design and Fabrication Manually Operated Seed Planter MachineDocument6 pagesThe Design and Fabrication Manually Operated Seed Planter MachineTJPRC PublicationsNo ratings yet

- Fabrication of Automatic Sugercane Eye Bud Cutting and Coconut Water Extracting Machine FinalDocument9 pagesFabrication of Automatic Sugercane Eye Bud Cutting and Coconut Water Extracting Machine FinalPrajwal UtturNo ratings yet

- PD ReportDocument6 pagesPD Reportbitish commectNo ratings yet

- Design and Fabrication of Sand Filter MachineDocument4 pagesDesign and Fabrication of Sand Filter MachinerupeshNo ratings yet

- Design and Fabrication of Crop Cutter MachineDocument4 pagesDesign and Fabrication of Crop Cutter MachineDeepak GovardhaneNo ratings yet

- Design and Fabrication of Multi-Purpose Cutting Machine For Agricultural UsesDocument12 pagesDesign and Fabrication of Multi-Purpose Cutting Machine For Agricultural UsesIJRASETPublicationsNo ratings yet

- DEBRE BERHAN UNIVERSITY ThesisDocument27 pagesDEBRE BERHAN UNIVERSITY Thesishayliyesus100% (1)

- Farm Machinery and Equipment : Improving Productivity in the FieldFrom EverandFarm Machinery and Equipment : Improving Productivity in the FieldNo ratings yet

- Rate Analysis of AanatoliDocument59 pagesRate Analysis of Aanatoliujjwal sapkotaNo ratings yet

- GPCDocument39 pagesGPCRahul ChaudharyNo ratings yet

- Dmmpricelist Printable 010522ADocument4 pagesDmmpricelist Printable 010522AluisNo ratings yet

- Assignment 2 PDFDocument2 pagesAssignment 2 PDFamit_bs2002No ratings yet

- ZXSDR R8882 Product DescriptionDocument24 pagesZXSDR R8882 Product DescriptionJumongNo ratings yet

- Stability Problems of Emulsion and SuspensionDocument9 pagesStability Problems of Emulsion and SuspensionsyedtahaaliNo ratings yet

- tmp268D TMPDocument6 pagestmp268D TMPFrontiersNo ratings yet

- Manual 915 IsotechDocument26 pagesManual 915 IsotechErik ValterNo ratings yet

- TVET 1 Worksheet 8 Rivera, JomareDocument7 pagesTVET 1 Worksheet 8 Rivera, JomareJomare RiveraNo ratings yet

- Injection LockingDocument10 pagesInjection LockingKrishanu SadhuNo ratings yet

- Ships CertificatesDocument36 pagesShips CertificatesShalin Ilias100% (8)

- IE-112 Work SamplingDocument21 pagesIE-112 Work SamplingLahm NguyNo ratings yet

- C R R T: Ompressor OD ING EchnologiesDocument2 pagesC R R T: Ompressor OD ING EchnologiesJaadi 786No ratings yet

- International Graduate Studies in Mechatronics - University of Siegen - Siegen - DAAD - Deutscher Akademischer AustauschdienstDocument5 pagesInternational Graduate Studies in Mechatronics - University of Siegen - Siegen - DAAD - Deutscher Akademischer AustauschdienstDEVANo ratings yet

- Accident Manual PDFDocument263 pagesAccident Manual PDFsubhasish deyNo ratings yet

- Druck DPI 610/615 IS: Measurement & ControlDocument100 pagesDruck DPI 610/615 IS: Measurement & Controlenghemo89No ratings yet

- UserscriptDocument8 pagesUserscriptapi-289675854No ratings yet

- Old Code OLD R Number New Code NEW R Number Availability Phase Out Phase inDocument7 pagesOld Code OLD R Number New Code NEW R Number Availability Phase Out Phase intecnicomanelNo ratings yet

- ToyotomiDocument96 pagesToyotomikaraflocafeNo ratings yet

- V2 TubeFiring TFB030 Datasheet 310-1Document4 pagesV2 TubeFiring TFB030 Datasheet 310-1Anonymous ZalAqh6No ratings yet

- Cast Iron Manhole Cover & GratingsDocument4 pagesCast Iron Manhole Cover & GratingsttshareefNo ratings yet

- The Mechanism For The Esterification ReactionDocument5 pagesThe Mechanism For The Esterification Reactionuocmogiandi_aNo ratings yet

- M0114 - Mmaskinds - PPM - January-2022Document3 pagesM0114 - Mmaskinds - PPM - January-2022Praveen kumarNo ratings yet

- Documentation Checklist: FSAE and Baja SAE Tube Structures Sept 1 2017 Preparing and Submitting Documents To VR3 For Review and RFQDocument3 pagesDocumentation Checklist: FSAE and Baja SAE Tube Structures Sept 1 2017 Preparing and Submitting Documents To VR3 For Review and RFQpequeno_brotherNo ratings yet

- Eaton Pulsar Series Nova DatasheetDocument2 pagesEaton Pulsar Series Nova DatasheetVladimir StojicevicNo ratings yet

- Android Alarm Dump GuideDocument3 pagesAndroid Alarm Dump GuideIgnacio GarciaNo ratings yet

- PDB Saudi Split (Titan Gold Plus)Document45 pagesPDB Saudi Split (Titan Gold Plus)1969MAZHARNo ratings yet