Professional Documents

Culture Documents

74FE1D4E.msg: TCL 12.06.2019

74FE1D4E.msg: TCL 12.06.2019

Uploaded by

Ajay PrajapatiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

74FE1D4E.msg: TCL 12.06.2019

74FE1D4E.msg: TCL 12.06.2019

Uploaded by

Ajay PrajapatiCopyright:

Available Formats

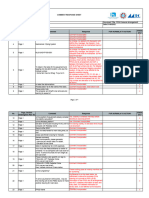

design team. Our drawing are as per first angle projection.

FS12: Specify Dimension consider minimum Incorporated Noted & closed Closed Closed Closed

Emerson provided major dimension in drawing, Hence no need to this

FS13: Specify Dimension Incorporated Not found in Reived GAD Open Closed

dimension.

Will check the same during assembly. If

FS4 : Kindly ensure the space for fixing nut. This is standerd design hence no issue for fitmnet found problem will involve you for Open Noted Closed

necessary correction.

Model no. not match with attahced sizing

Actutor Model no. is already updated in drawing which is

FS5 : Model no. not match with attached sizing sheet. kindly update model no. in drawing. sheet please send updated sizing sheet or Open Automation Engineering to ignore this point TCL Closed

inline as per data sheet and TCL. 12.06.2019.xlsx

1 Open PUN2000011-01-A1 drawing for further approval.

FS6 : Specify Ball valve body & Seat MOC Those details are mentioned in automation GAD. Kindly provide the same Open Please refer attached bare stem GADs Closed

FS7 : Specify body MOC for all Items. Those details are mentioned in bare stem GAD. Kindly provide the same Open Please refer attached bare stem GADs Closed

FS8 : Please mention following notes in drawing:

1. PMI, Material Test Certificate, Non destructive exam (RT/PT)

as per ASME, Hydrotest, Seat Leakage (Zero leakage (E-seat) to Kindly mention below notes in drawing as 74FE1D4E.msg

ISO 5208 Rate A and API 598), Functional and Performance Test per client requirement and accordingly

certificate, FET type test certificate (ISO-15848-1 Class B) shall update in TCL & provide the same for

be provided. further approval from client.

2. Ball Valve, Actuator, Solenoid Valve and Limit Switch shall be 8. "Ball Valve Body shall be painted

SIL-2 and shall be provided with SIL-2 certificate. according to Supplier's painting standarad

3. Air filter regulators shall be a self-reducing relief valve type selected based on a refinery ambient

with an output gauge, auto-draining facilities and adjustment We cant able to mention all comments in GADs, But we exposure with minimum corrosive category We ensure Painting activitees will proceed as per point no. 8 and 9, but due

Open Closed

with locking facilities. ensure All comments we have considered. C5-M as per ISO 12944 minimum 380 DFT. to space constrint we cant able to mention those comments in GADs.

4. Ball valve shall be Fire-Safe (as per API 607 5th edition and Finish painting shall be Aluminum (RAL

ISO 10497), Anti-Static design. 9006). provide paint details (i.e. type of

5. Actuator torque shall include 1.5 times safety factor in paint, no. of coat & total DFT)." Refer

addition to minimum torque requirement. attahced your mail.

6. SOV supply voltage shall be 24V DC & Lowest voltage shall be - 9. Actuator Color shall as per below.

15% from the rated voltage. For Fail to Open - Red

7. Limit Switch shall be proximity, Contact rating 24V DC, 2A, SIL- For Fail to Close - Green.

2.

8. Valve Body shall be painted according to Supplier's painting

Please consider all comments as per page no. 1 of 9. Incorporated Not found in Reived GAD Open Agreed point are incoporated in GA drawing Closed

FS15 : Specify Dimension L X W of plate Incorporated Noted & closed Closed Closed Closed

2 Open PUN2000011-02-A1 Will check the same during assembly. If

FS16: Kindly ensure the space for fixing nut. This is standerd design hence no issue for fitmnet found problem will involve you for Open Noted Closed

necessary correction

You might also like

- Certified Solidworks Professional Advanced Weldments Exam PreparationFrom EverandCertified Solidworks Professional Advanced Weldments Exam PreparationRating: 5 out of 5 stars5/5 (1)

- FalkDocument4 pagesFalknoviyanthyNo ratings yet

- Jis G3141 PDFDocument28 pagesJis G3141 PDFjorgesalgNo ratings yet

- ME417 Final Project PacketDocument40 pagesME417 Final Project PacketTAYYABA AMJAD L1F16MBAM0221No ratings yet

- Westfalia Control Unit C7-623 PDFDocument148 pagesWestfalia Control Unit C7-623 PDFAamir100% (2)

- PV 2505 enDocument9 pagesPV 2505 enKmilo VinaTea ChavezNo ratings yet

- Sr. No. Comment/ Observation Resolution/ Action: GeneralDocument9 pagesSr. No. Comment/ Observation Resolution/ Action: GeneralmahipalNo ratings yet

- CRS - 2018SNE2714601103 Mechanical Seal CRSDocument9 pagesCRS - 2018SNE2714601103 Mechanical Seal CRSsalman1111aNo ratings yet

- Crs - b390 Jnki056 PC DG 0618 - r0 (Zeeco Reply 20 Sep 22)Document1 pageCrs - b390 Jnki056 PC DG 0618 - r0 (Zeeco Reply 20 Sep 22)daniel perezNo ratings yet

- Dps 1 2581 137 Efcp 03 - P&i Diagam Rev 3 Crs - by VendorDocument518 pagesDps 1 2581 137 Efcp 03 - P&i Diagam Rev 3 Crs - by VendorswarnamaliniNo ratings yet

- Service Manual: DSC-F828Document29 pagesService Manual: DSC-F828Anonymous Lfgk6vygNo ratings yet

- Visual-003 SL BossDocument2 pagesVisual-003 SL BossCong BuiNo ratings yet

- DSC-T1 Level 3Document33 pagesDSC-T1 Level 3Anonymous Lfgk6vygNo ratings yet

- RANS S21 Outbound BuilderDocument11 pagesRANS S21 Outbound BuilderneovondorfmamNo ratings yet

- Vedanta Limited: Cairn Oil & GasDocument21 pagesVedanta Limited: Cairn Oil & GasBALASUBRAMANIAM MEGHANADHNo ratings yet

- MGP1 Pomj0s0047 D07 0005Document4 pagesMGP1 Pomj0s0047 D07 0005Massimo FumarolaNo ratings yet

- 14 August, 2020: Comment Reference: DatedDocument3 pages14 August, 2020: Comment Reference: DatedFarhan KhanNo ratings yet

- 10-01764-1030-1381-21-Rev-02 - Revised Shop Drawings With Design Calculation From Designer KBR-AMCDE For Handrail Platform All Around MDC Modules - Part1Document53 pages10-01764-1030-1381-21-Rev-02 - Revised Shop Drawings With Design Calculation From Designer KBR-AMCDE For Handrail Platform All Around MDC Modules - Part1Pappu Kishore KumarNo ratings yet

- Service Manual: DPS-V55/V55MDocument32 pagesService Manual: DPS-V55/V55MQuiruNo ratings yet

- Data SheetDocument8 pagesData SheetElzkenuszNo ratings yet

- Hexagon Head Screw ISO 4017 - M8 X 10 - 5.6Document1 pageHexagon Head Screw ISO 4017 - M8 X 10 - 5.6Cbh FastenersNo ratings yet

- 163-130 - Falk Drive One Type DH3, Sizes M1130-M1210 Shaft Drives - Parts ManualDocument4 pages163-130 - Falk Drive One Type DH3, Sizes M1130-M1210 Shaft Drives - Parts ManualCagNo ratings yet

- TDH 0500 SS RP 0107 - R1Document3 pagesTDH 0500 SS RP 0107 - R1waquarshaiNo ratings yet

- To Replace Existing Door Grilles & Remove Termites at Block 4 Level 1Document3 pagesTo Replace Existing Door Grilles & Remove Termites at Block 4 Level 1atienzajury24No ratings yet

- MS Balustrade and Wall Mounting Handrail Report Stair 1&2Document59 pagesMS Balustrade and Wall Mounting Handrail Report Stair 1&2noorgggggNo ratings yet

- Service Manual: DSC-T500Document35 pagesService Manual: DSC-T500Juan PerezNo ratings yet

- FalkGearbox FBDocument4 pagesFalkGearbox FBsaqargeloNo ratings yet

- SVDN-WHP-M-0010-D01-0003-Rev.02-HVAC General Arrangement Drawings - Ventilation FanDocument6 pagesSVDN-WHP-M-0010-D01-0003-Rev.02-HVAC General Arrangement Drawings - Ventilation FanTung Bui ThanhNo ratings yet

- Comment Response Sheet SVDN CPP M 0002 D01 0003 (r01)Document2 pagesComment Response Sheet SVDN CPP M 0002 D01 0003 (r01)Tuấn Vũ0% (1)

- Odpl Comments - On Etabs Model (Block B) - 4!1!23Document57 pagesOdpl Comments - On Etabs Model (Block B) - 4!1!23mustafazahmedNo ratings yet

- Relay Setting Comments - Commented - Updated-commented-Updated - RFRDocument8 pagesRelay Setting Comments - Commented - Updated-commented-Updated - RFRSARAVANAN ANo ratings yet

- Sony dsc-h55 Level-3 Ver-1.0 SMDocument18 pagesSony dsc-h55 Level-3 Ver-1.0 SMsouravsonar1997No ratings yet

- Ds071n Im e GeorgiaDocument12 pagesDs071n Im e GeorgiaGiorgi KurtsikidzeNo ratings yet

- TBC Fender PDFDocument3 pagesTBC Fender PDFmuhammad amanyNo ratings yet

- HDR As50Document29 pagesHDR As50Nerta NaturaNo ratings yet

- Service Manual: DCR-SR15E/SR20/SR20EDocument22 pagesService Manual: DCR-SR15E/SR20/SR20EForest NottinghamNo ratings yet

- GeniE UM Vol4 APP C2 AISC9thDocument11 pagesGeniE UM Vol4 APP C2 AISC9thBRIJITHNo ratings yet

- Supplier Offer - LV SWGR Observations-3Jun-20210609Document1 pageSupplier Offer - LV SWGR Observations-3Jun-20210609sudhirguduruNo ratings yet

- 4000046273-PGCA-EA-C09-004 - 5.2 - 1 - Control NarrativeDocument47 pages4000046273-PGCA-EA-C09-004 - 5.2 - 1 - Control Narrativerajindo1No ratings yet

- 6 Dorado 40xs EFI - 50 EFI - 60 EFI-2008Document53 pages6 Dorado 40xs EFI - 50 EFI - 60 EFI-2008ZeeNo ratings yet

- Mgad IpsDocument8 pagesMgad IpsSuvranil BanerjeeNo ratings yet

- Corporation Local Operating Procedure: TitleDocument11 pagesCorporation Local Operating Procedure: TitleJeevanandham MNo ratings yet

- MSS SP-06 (2001)Document6 pagesMSS SP-06 (2001)Allan SousaNo ratings yet

- Mat Cscec 17 Me HP 0014 01 PDFDocument199 pagesMat Cscec 17 Me HP 0014 01 PDFLi LiuNo ratings yet

- Design Guide - Users Guide - Design and Load Rating PDFDocument206 pagesDesign Guide - Users Guide - Design and Load Rating PDFGustavo Solar100% (2)

- BS 2151.01, 2151.011-U Manual de ManttoDocument28 pagesBS 2151.01, 2151.011-U Manual de ManttoAndrés Rivera MartínezNo ratings yet

- Pin-050-Mmd-Pc1-In35-0003 - 01 DCS SpecificationsDocument86 pagesPin-050-Mmd-Pc1-In35-0003 - 01 DCS SpecificationsZulfequar R. Ali KhanNo ratings yet

- Service Manual: Digital HD Video Camera RecorderDocument100 pagesService Manual: Digital HD Video Camera RecorderDanNo ratings yet

- REXTON новыйDocument422 pagesREXTON новыйЮра РудикNo ratings yet

- Winsmith R-A Reducer ManualDocument6 pagesWinsmith R-A Reducer ManualCesar Augusto Areinamo PerezNo ratings yet

- MBN10231 Eng+2008-09Document12 pagesMBN10231 Eng+2008-09gültekin gökNo ratings yet

- 711ART39K Repair Instruction, Rear Section Frame A35E A40EDocument10 pages711ART39K Repair Instruction, Rear Section Frame A35E A40EAwanNo ratings yet

- IFC Closure Approval ReportDocument12 pagesIFC Closure Approval ReportAjayNo ratings yet

- CRS R3 Drawing For Uf-Ro Building.Document1 pageCRS R3 Drawing For Uf-Ro Building.dineshNo ratings yet

- Id-F-Ft-Nn1-Gad-Fp-00-0001 - Rev 0C - Fpso Forel General ArrangementDocument5 pagesId-F-Ft-Nn1-Gad-Fp-00-0001 - Rev 0C - Fpso Forel General ArrangementaddypurnamaNo ratings yet

- 3.1 System CabinetDocument1 page3.1 System CabinetBoualem AisNo ratings yet

- Suzuki DT15 (1986-1988)Document39 pagesSuzuki DT15 (1986-1988)Suministros Lasser100% (1)

- Simatic c7623Document13 pagesSimatic c7623Jim KrerkNo ratings yet

- Guidelines For Filling Up The ChecklistDocument42 pagesGuidelines For Filling Up The ChecklistSunil UndarNo ratings yet

- Raf 917 10 36 P217 - Ret670 - F871 - CompDocument17 pagesRaf 917 10 36 P217 - Ret670 - F871 - CompSARAVANAN ANo ratings yet

- RTBNDocument1 pageRTBNAjay PrajapatiNo ratings yet

- Hmnjopl PDFDocument1 pageHmnjopl PDFAjay PrajapatiNo ratings yet

- Valve List - F-5001Document3 pagesValve List - F-5001Ajay PrajapatiNo ratings yet

- Valve List - F-5001Document3 pagesValve List - F-5001Ajay PrajapatiNo ratings yet

- Manual Valve List - FS-554!18!19Document1 pageManual Valve List - FS-554!18!19Ajay PrajapatiNo ratings yet

- Ar EntDocument7 pagesAr EntAjay PrajapatiNo ratings yet

- HC501, HC502: As NotedDocument2 pagesHC501, HC502: As NotedAjay PrajapatiNo ratings yet

- Astm A351 Cf3: Approved With CommentsDocument1 pageAstm A351 Cf3: Approved With CommentsAjay PrajapatiNo ratings yet

- By Ajay Prajapati at 5:56 PM, Oct 07, 2017Document2 pagesBy Ajay Prajapati at 5:56 PM, Oct 07, 2017Ajay PrajapatiNo ratings yet

- Stauff Hydraulic AccessoriesDocument67 pagesStauff Hydraulic AccessoriesAjay PrajapatiNo ratings yet

- Filter ConceptDocument2 pagesFilter ConceptAjay PrajapatiNo ratings yet

- 21 Oxygen Thunder, 29 Oxygen Thunder, 29 Oxygen 350, 29 True SlimDocument18 pages21 Oxygen Thunder, 29 Oxygen Thunder, 29 Oxygen 350, 29 True SlimSallauddin100% (1)

- Psa Ta Test 1Document4 pagesPsa Ta Test 1prajwal patilNo ratings yet

- R150 300 500 InterM ManualDocument16 pagesR150 300 500 InterM Manualastuck1No ratings yet

- Class 4 Introduction To Transfer Functions, Transfer Function Models.Document27 pagesClass 4 Introduction To Transfer Functions, Transfer Function Models.Acharya Mascara PlaudoNo ratings yet

- EVK NORA W1 - UserGuide - UBX 2431231323Document28 pagesEVK NORA W1 - UserGuide - UBX 2431231323comercialNo ratings yet

- Vonron Zdexp Clavijas y T de Corriente Fac Z 1Document4 pagesVonron Zdexp Clavijas y T de Corriente Fac Z 1Gerardo Orozco FloresNo ratings yet

- Mw61a Ti All Sv6.01a enDocument11 pagesMw61a Ti All Sv6.01a enpradeepNo ratings yet

- Remote Controlled AndroidDocument17 pagesRemote Controlled AndroidKathula ManikantaNo ratings yet

- Musical Siren Lab Project ReportDocument8 pagesMusical Siren Lab Project ReportMahipal_Singh_Deora100% (3)

- Ma202 Numerical Methods: L T P CDocument8 pagesMa202 Numerical Methods: L T P CVIGNESH L RNo ratings yet

- Spare Parts List: Electric PokerDocument20 pagesSpare Parts List: Electric PokeralmirNo ratings yet

- H12 111 Enu Hcia Iot V2.5 Exam With AnswersDocument93 pagesH12 111 Enu Hcia Iot V2.5 Exam With AnswersFATIMA-EZZAHRA HOUDNo ratings yet

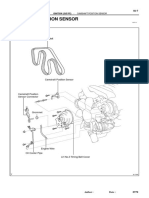

- Camshaft Position Sensor: ComponentsDocument13 pagesCamshaft Position Sensor: ComponentsNathan GabbottNo ratings yet

- Solar ALL in ONE 40W R3Document4 pagesSolar ALL in ONE 40W R3hendrikNo ratings yet

- LAN Design: LAN Switching and Wireless - Chapter 1Document30 pagesLAN Design: LAN Switching and Wireless - Chapter 1Degrace Ns100% (1)

- 485LDRC DRC-4003dsDocument3 pages485LDRC DRC-4003dslunatiko21No ratings yet

- SPR, RCS-9627CN, NoDocument5 pagesSPR, RCS-9627CN, NoAmaresh NayakNo ratings yet

- ICS Triplex-8000 SeriesDocument33 pagesICS Triplex-8000 SeriesSteve Carvalho100% (1)

- Presentation On Transformers and Its ApplicationsDocument27 pagesPresentation On Transformers and Its ApplicationsPRANAVNo ratings yet

- HBB 48 Brochure - 7.5 HPDocument2 pagesHBB 48 Brochure - 7.5 HPMuthia AstriNo ratings yet

- Witnessing Matrix SGP GEN 00 U PR 852061 001 - 2Document22 pagesWitnessing Matrix SGP GEN 00 U PR 852061 001 - 2odeinatusNo ratings yet

- Gyroscopic InstrumentsDocument4 pagesGyroscopic InstrumentsvinayNo ratings yet

- L&T PresentationDocument124 pagesL&T Presentationrajib ranjan panda100% (1)

- Lecture 5: Distance Measuring Equipment (DME)Document2 pagesLecture 5: Distance Measuring Equipment (DME)Anonymous cb2blyVKFrNo ratings yet

- 信號與系統Chap. 3 Class NotesDocument46 pages信號與系統Chap. 3 Class NoteswangliNo ratings yet

- Monarch Nice Catalogo Comercial InglesDocument12 pagesMonarch Nice Catalogo Comercial InglesBryan Dominguez Lopez100% (1)

- Service Manual: Surround CinemaDocument26 pagesService Manual: Surround CinemamyotezaNo ratings yet

- A Novel Facts Compensation Scheme For Power Quality Improvement in Wind Smart GridDocument4 pagesA Novel Facts Compensation Scheme For Power Quality Improvement in Wind Smart GridbarneypseNo ratings yet

- List of Malaysian Standards Prepared by MCMA SWO PDFDocument7 pagesList of Malaysian Standards Prepared by MCMA SWO PDFfisplNo ratings yet