Professional Documents

Culture Documents

Containersbascketsccus 151006185809 Lva1 App6891

Containersbascketsccus 151006185809 Lva1 App6891

Uploaded by

Nico Achmad Zulviansyah0 ratings0% found this document useful (0 votes)

8 views42 pagesokk

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentokk

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

8 views42 pagesContainersbascketsccus 151006185809 Lva1 App6891

Containersbascketsccus 151006185809 Lva1 App6891

Uploaded by

Nico Achmad Zulviansyahokk

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 42

LIFTING EQUIPMENT INSPECTOR

CERTIFICATION PROCEDURES

IVD COUN sccm coliee eta

er Pesaretes

Intellectual Ownership & Copyright

of NSL Training Products and Materials.

North Seating Lid (NSL) & NSL America have iste heavy inthe development of training products and

teri that ar tlsed wordwite

The creaton and manteance of these invohes ime, efor and expensa to ensure ncuson of the iatesteiation,

regulations, dens, industy practice and equipment

NS Safety and Tanng documents shoud tbe esl, nor use fo persona / commercial gain win 3rd pany

raning cogans traning courses. Thisinclues any reference, he use of NS's Handbooks, Posts, Videos!

(Dis, Side Presentatons, et, unless unde spetic wren anrement or cane wth NS

SL customise products unr agreement, NSLallows cles adapt products and materials or ero real

use with ameneimens approved by NSL but ownership an copyright aways remains with NSL

‘To maltain te qualty of NSL products and metas, NSL vigaously maintain thar copyright NSL wi actly

pursue trough te courts, ey company or inva found in breech ofthis opt.

NSL

——

INDEX

Introduction

Section 8.01 Standards

Section 6.02 857072: Design and Construction

Section 6.03 BS7072 Inspection

{6.03.1 Primary load bearing structure

16.032 Socondary structure

6033 Doors

6.034 Markings

6.035 Pad eyes

6.036 Sings / shackles

6.087 Data plate

Section 6.04 BS7072 Certification

Section 05 BS7072NOT

Section 6.06 857072 Testing

Section 6.07 857072 Inspection and Testing Periods

Section 6.08 BS EN12079 Design and Construction

Section 6.09 BS EN12079 Inspection

6.09.1 Primary load bearing structure

6.092 Secondary structure

6.00.3 Fork pockets

6.094 Doors

6.005 Markings

6.096 Pad eyes

6.097 Stings and Shackies

6.098 Data plate

Section 6.10 BS EN12079 Gertfction

Section 6.11. BS EN12079 NOT

Section 6.12 BS EN12079 Testing

Section 6.13 8S EN12079 inspection and Testing Periods:

Section 6.14 Blank Reports

NSL

a

Introduction

‘The testing and inspection of iting equipment shall ony be cared cut by competent person, is essential hat

«competent person engaged ins werk must be avare of curent regulating, standards, best indus practice

and clean company procedures

Competence canon be achieved and recorded trough rng, experince and assesment nthe workplace

Theinspecor must act withthe necessary degre of party be re fom any exter pressures or inflances,

make decisions regarding the extent of testing requrenents ad iss caiicate tating tat he iting equipment

issuable, anit used correct, safe to use ding a spect period of ine.

For he most pa, tis unikely that anyone person o even company, wil be able to provide the krawedge and

npetie required to test and inspect, the vast range offing equsment use in today's dss. The rspecor

vill eed toute information rom standards, equations and manutscurss quidenes to ensure an inferred

econ s mate

‘The inspection of iting equbment by the competent person, wil determin if is for pupose. Te eta

used to determin his, mast be app to new and wsed equipment ake, he inspector must never assume new

‘qupment ise of patent defo.

‘The purpose ofthe overaador pron ad ts to prove the design, rater used, and the workmanship during

assemtly ofthe equipment. The sole use of cacao o xo the itty of equipment may ot accomplish

‘hs. shoud be tome in mind that ting equprent undergoing an overload est, might not withstand the aplod

loadings.

‘Al persone! no essen tothe test must be kept lar fhe area, wi he inspector also postoned, woe ha

Is uke tobe ijured if equipment fas

601 Standards

BS 7072: 89

ish Standard Code of Pract for specton and Repair of Ofshore Containers

Note: This standart has ben withcrawn fom publication, however many offshore containers curenty in use

nat meet te requirements of BS EN 12079, Contains ult pit the rocuctn ofthis andar

shouldbe ispoctod and tested in accordance wih BS 7072: 1980,

{BS EN 12079-1: 2006 oishore Conisiners and Associa Ling Sets

Part 1: Ofshore Containers: Desqn, Manufacture and Marking

‘BS EN 12079-2: 2006 Oshore Container and Associated Ling Ses

Part 2: Ling Sos: Design, Menufecture and Marking

BBS EN 12079-3: 2006 shore Consiners and Associated Ling Sets

Part 3: Pedic ispecon, Examinaton and Testing

DET NORSKE VERTAS (NN)

Standard fr Certification No.2.7-1 Oshore Containers Ail 2008

Noe: For practic purposes DNV CN 2. 7-1 and BS EN 12079 ae equivalent

NsL EE

es

6.01 Standards

Sample of Sting Containers fread)

150 668: 1995 Sores 1 Fgh Cotaers: hssicton Dimensions an Fats

10 668: 1995 ind 2 200545 Corsnes

1S0 1161: 1984 Sores 1 Fight Cotas: Cams Ftngs Spasticatn

150 1161: 1984 And 1: 200745 Contanrs

$80 1496-1: 1900 Series 1 Freight Cortaners:Spacfleaton and Testing, Pat 1: General Cargo Containers for

General Purposes

180 1496-2: 1996 Sere 1 Freight Corsines: Speciation and Testing Pat 2 Thrmal Containers

180 1496-3: 1996 Series 1 Freight Corsines: Speciation and esting, Pat 3 Tank Contains for Liquids,

Gases and Pressured Dry Buk

180 1496-4: 1901 Sars 1 Freight Cotzners Spectcaon and Testing, Part : Non Pressused Canines for

Dry Buk

180 1496-5: 1991 Sees 1 Freight Cozies: Speciation and Testing, Pat: Platorm and Patorn- Based

Contaers

180-3874: 1997 / nd 2: 2002:Vertea Tandem ing

180 3874: 1987 Amd 4: 2007: 45 f Containers

$80 8323: 1905 Fright Containers: Al Sarace (otermoda) General Purpose Containers, Speciation and

Tests

180 / TR 16070: 1906 And 1: 2008: Gudanco on Structural rtagity

6.02 857072 Design and Construction

Prieto a OCU elng tken Into service forthe ft time, te competent person shoud ensure hat has been

signed and manufactured in azcrdance wih the standards guidance,

‘ue ote harsh working condtions and erronmentffsor the folowing structural factor of sft

‘maximum goss weight fhe OU, shouldbe adopted, as @ minimum, wtendesgring OCU,

5 tines the

‘Thetetore, the designer sould ensure that all materials used are suitable forthe intended purpose and equipment

shouldbe of good constuction ard manufactured ram sound material using recognizes standards

Auminium materia that may rest in high-energy soark when stuck should not be used and cast iron, (ass

re, wood and simlar mates shoul ot be used or anal bearing components,

In actin, the manufacturer should ensure tat the CCU Is fabricated to recagnised welding tardards andthe

entre process contol by an eetve documenied quay assurance system.

NSL

=

6.03 BS7072 Inspection

he competent person shal carryout thorough visual

of the CCU to ensure tat tft forts intended use

ono the exter, en the Hn

The ispecton shouldbe cai ut in adequsteighting and include a suitable means of ting and soparting the

CU, alow he compete person to inspect the unde he

NSL

=

6.03: Primary load bearing structure

‘The structure shal be vsualyispocted for consion, mechanical damage and deformatn,

‘Ay reais /alteratons tothe pxnary or seenrdary structure shoul be cared outingccorance wth acceptable

cares of practoe and ecrdes bythe anne ol the COL,

Noe: ited, one inten upper ants should be skid-sted oer an even concrete suave. A pro lead of ice

‘he gross weight minus he tare weight shal be applied

NSL

a

6.082 Secondary structure

Fors, was an roots shal be vsualynepectd to check they ae predominant fat wih no Sgr of excessive

lamage. Drainage hoes n fox, where ited, tal be eared of debs.

internal cargo te-down cleats rings soul be provided and itis esse the hey ere secure anchored Their

tating shoul be assessed in rat fo he lacs tat may be imped on hen.

NSL

e.

6.033 Doors

Doors, frames, seals, hinges and cts shall be visual Inspected o ensure tat they operate in a satstactary

manne witout the errton of udu foc,

oor and removabie panels should be cigs oasis postive dosing, have ainimum of one lckg bar per

oor and be grote to prevent coding by accidental inact

“

8.08.4 Markings

NSL

°.

‘Theos of dosed 04's and theo al of pen COU sho beard o cary day or orn

8S7072 ao sugges te fofowing markings:

Abana osalicontasting elo nt ss than 100 men we oud the ol permet csed CEU

+ _Conastatching onthe op as of open and framed COU

+ CH eos shou cated wh a prmane rans mau

‘+ The CCU identification number staud be prominent displayed onal sides in carecers of @ contrasting

cour, rot shan 75 mn tigh

Note: For open sided COU, panels maybe wsed to cay te ietiicatin

‘COU identticaton number should be cspayed onthe fot characters not les han SOD mv high. The

‘marking shoud be appl toad increctirterretation

‘© On each COU a mat black square not less than 400 mm x 400 mm shoud be provide fo ifort

markings such 28 destination, cargo hazard et

Marked below the matt black square, the tare weight, the SWL/paload, andthe maximum gross weight

shld he slay in horas ass han Sf en Fgh

ad eyes ing points shal be visual inspeced fo distortion, mechanical damage, excessive wear and

covered

Four titing pons are sormaly recommended wth each iting point bing designe to bear the maimurn gross

Weight of he CCU. Hwee, for smaller CCU, wo or tee fag pints may be acceptable.

The tng oits may be of any design suitable for the purpose butts essen ta they ar ited ina manner

‘and aligned inthe decton ofthe ine of it. They should be accurately positoned wit a mixenum devon not

exceeding 5 mn,

Bute fing should be s-eckng or be proved witha means to prevent oserin, Where eebots ar ited

the manufacturer shoul provide a cetficte conforming to BS 4278, Eyal for Ling Purposes

Pa eyes /fting pons shall be capable of aceping a shackle or connector wthat ning the movement ot

the sing termination

NSL PME COHPUER NEETCR Heo rene

o—

{6038 Slings / shackles,

Te inepection shal be cared aun locaton proving adequate hing and facies necessary to allow iio

be cae ut safely and fective

Inspect each ndviual eg ofthe sing lng its entire length and check for

Wear

Coresion

Abrasion

Mechanical Damage

Broken Wes

Internal Deterioration

Intemal detroaton should be checked forby using two special designed dams to cpen yp the ope to

expse the wie tre core

The ope ameter should be messed fr any educon ram is orginal se that could indicate wear onthe outer

ites, partial colape ofthe career stretch duet vera

Inspect each ele for excessive demape and ensue the corec siz of ele has bean ted

Check thatthe en of the loop doesnot terminate inside the ful (ete ope end shoul be fh osghity

protrucing but no more tan 1/3 of th da) unless the feu iso the longer tered desi, whch hasan

intemal ste

Inspect each thimble and check fr coect fing, snaging damage and etongaton (Stretched thimble / eyes

‘could indeate posse overload)

Inspect wie rope round thimble as itis often abraded oto the stng beng dragged over ough src.

ified spect maser nk qua assembly and check for wea, coreson and cracking

Mult ig sing asombles shout berated at 1.3 tes the speci MGW ofthe COU to wbich is tobe fited

(actor of safety should be 65:1

‘ing lags stould be constructs rom wre ope of at ast 18 mn dameter

Maso Inks, ited, shoud ae a minimum intral dimension of 270 mm x 140 mm,

‘Shackle inspection:

erovestacl pin and examine or wear, deformation and cracking

Ensue isthe coet pin forthe shackle (NOT a higher tensile pn in an aly shack)

Check pin breeds for wear! detarsation

amine stackle body and check for wearin the crown and in hes, deformation and cracking

In the caseot safety pin shacls, ensue pit pin re fited

‘Mutt singsal be atiached to the COU pa eyes without tistng ofthe legs athe master ink

[Al sings and stacks shouldbe cetied in accordance with relevant standards. The unique ition ofthe

‘ing, and ofeach stark sal be noted onthe certificate.

Tho ownor sta maintain coi records fr each set of sings and shackles in accordance ith SI 1998 No

2207 Ling Orato and itegEqupmant Regus,

aching setsal be marked on a prominent cation withthe folowing ifrmatn:

‘Unig idenieation atch numbering tal nat be used)

‘SUL and te maximum pei incuted ange ott

The date othe ast test inspection

Shackles sabe marke with a urique ienfcation ach nanberng should rat bo used)

NSL c

Ee

6037 Data pate

Dat plats shal be mase fa corasion resistant mateal and secuelystached in a maner to avoid

unautoried or accidental eval

The plate shoul bef othe doa, oF on CCU with no dors, n¢ prominent paste

‘Aluniiun ts sould at be use,

‘The plat stould beheaded “Data Pate" with information pemanery an egy marked onthe pate tis shal

ince

(Owner's nae

(Cu identicaton

“are weight (n tones)

‘SL pay fi tonnes)

Mam gross weight terns)

‘Date fast test /exanation shal be iertiled using the follwing ters:

+ Tor prot loa tet, non-destructive examination and visual examination

‘© WNfernon-destucive examination ae visual exzinain

‘© Vior visual examination ony

ching, engraving or stamping sale in characters of nat ess tha 4 mm in hgh.

‘The plat should not cary the dat ofthe net test /exarinain

“The plat te shal be sunt ocr a inoue examinations

6.04 BS70T2 certification

‘A certeate of examination shal shaw te folonng minimum information:

ccUldentcaton,

Coarse

Date and rumber fas corcatec examination or tst and examination

“The name o the company, whch cei out the examination estan the name ofthe competent person

vhost

Certicate number

Design ofthe OCU

Number and poston of ting points

Manufacturer (tknoan)

Date of manufacture known)

Date is gut into use ot kno

Tare weight in tonnes

Safe working lad / payed in tonnes

Maxerum goss weight interes

Detale of NE cad out

Name of company caring ou the earnaon

Name of te competent person caring out the examination

‘statement tat the COU described as toughy inspected and that he particuars are cmect

Signature of inspector and dat of ezrin

‘Acericate of test and examination sal stow te fllng minimum orton

cu dentaten

(Ouners name, or delogated pomings

Date and number fst cortical of aination or st and examination and the name of person who issued

land of is employer

Corticate nunber,

Design ofthe OU including:

Number and poston of ting points,

Manutacturr knoe)

Date of manulacture kon)

Date fs put into use (kno

Taro sight in tomas

Safe working lad /paoad in ones

Maximum goss weight in ores.

Prot oad apple in tonnes

Detals of NDT cared out

Name of company caring ou the waminaton;

Name of te competent person caring ou the examination

‘statement that the COU descrived was thoroughly inspected and tat he parca ere cre

Signature of inspector and date of examination

2

[NOT must be care out on he ting pont welds below and ater the aoiation of he poo load tes This sto

ensure the weling i suitable for esting and ate to ensue testing has not exposed any detect,

Whe cometent person dacs that an aematve method of non-destucte tesng is mare appropiate then

ferromagnet matels shoddbe inspected by nagetpartcleinspecton (MP) and ron-feomagnet materials

shouldbe nspcte by de pentant inspect (OP

Pant Removed

Contest Api

The COU must be inspected beloe anda the apication ofthe poof iad test. This is to ensure that tis eutabe

tor testing and the CCU snot damage or deformedin anyway afer te application of the pot ad,

Testing imives toot by sings wth an inclded angle of SO degrees. Ihe COU is normaly fied wth sing,

ths sing shold nat be used to cary cut the rot ad test

The prot lead app othe CCU shal be vice themarimum gross Weigh

* Gisthe maximum gross weight fn tonnes)

isthe tes oad fs tones)

‘Tis the tare weight noone

Tocaleaite the ook (Hand test ad)

‘+H (Hook) = Twice the maximum goss wolht hiss the fur record onthe crate

‘© Les ozs = Tice the maximum grass weit () minus te tare weight (1)

Tho test oad () shal be unflomiy dstrbutes verte Yoo and she, appa.

Ut he CCU careful by its iting pons n such away tan sigifcantaccleration or deceleration forces are

apple

ithe CCU canot be cel loaded because fs constuction, te compen person should determine a

_sulabe tes fo example suspending weight ome ame

Te proot oad shal be hel for a minimum o i

Note:The tare weight includes any tem pemanenty tached tothe CCU.

“The oad maybe anped using calibrated weighs ten ited by a cane or by means of sulabl test i, however

any typeof test equipment, ich can carryout the above procedure, maybe used

‘Al weights, gauges, oad ces, which may afc the accurate determination ofthe poo lad shal be altated

‘annual anda record retained by he test carga,

“Test weghs shoud be ceri as accurate o beter than 1% of he nonal eight,

Mechanical test equipment should be veiled and oerfied using a ten testing machine which meets the

requirements of BS 1610-1: 1992, Materials testing machines and force verifcatenequpment.

6.07 _BS7072 Inspection andTestng Periods

CU's shal be inspected, tested and NOT cared ou at regular intervals in acordane wth the sche

elo.

ited

SS eee

Time / interval Test / Inspection

an ry a

)

Before being used forthe

first ime Yes Yes Yes i

‘AL intervats of 6 months Discretion ot

No Inspector Yes Vor

AL Intervals of 12 months a 7 au: is

At intervals of 24 months

Yes Yes Yes T

‘After substantial repair oF

alteration Yes Yes Yes T

Gis the symbol forthe maximum gross weight

6.08 BSEN 12079 Design and Construction

Symbols

A stands forthe rag i.e. te asian ges eit heCCUbut exuding the tng st ecrddin ko.

7 stand fot, Lhe weigh of CU empty exclu cargo andthe ting se, rate ink.

P stands forthe pay, ete mann weht of cargo, ich nay be safe anspor by he COU, recoded

inka

Praducian shal be pertored according to approved doings, spesiaons and proces prepared ard

proved before poccion sats

The CCU manufac sal ens quay assurance in rordanca what last EN SO S001

‘ay eas tat are cari ou nse be acres wth he requrament fr the desig and mands of

(cts set out in EN 120791 Foowing ay repairs, the OU sal be spect and where rears bya

campeent peer

‘COL used in the offstore enirnment shal have suticentstengt to aw lading and nioaing am upp

‘vessels operatingin sea states wih significant wave heights of 6 mand withstand inpct rom heavy seas.

To prevent the CCU’ om overturing on a moving deck, they sal be designed to wthstan ting at 99 degrees

In any seston without overturing when loaded ats maximum gos wet

¥ OCU’ are designe tobe tack, the sings and shackles shal be protected ram damage, for exarpe te CCU

shouldbe fed th aso comers

(CU's shal be designed as structural frames (my structure) wth none bearing adding where weessary

(Secondary structure). However, on vatsin pes of CU's the whole structure may be consgered a a primary

sual,

6.09. BSEN 12079 Inspection

The equcerents of is stardrd mors hat of th ros but to a greater degree, detain

ers sal carry cut rough visual inspection ofthe eer, near and the

ere that is it forts nerfed use

hat ne camgtent

oases of he

inspection should be cared aun adequate Ighing and nude a sultable means of tng and supporting the

COU, alow he competent et ect he underside.

NSL

—

6.08.1 BS EN 12079 Primary load bearing structure

7 primary structure can be deserved asthe mln structural members, which trates the cargo lad othe

‘ane ook, for example forming the loa path fro the payoad tothe ting ng

‘isha neue but not ite

Top and bot sie ras

* Top ard bottom end as

= Comer posts

+ Pa

The desin fre on the primary structure shale cacvated as 2.5 x maximum gross weight

This structure shal be visually inspected for coroson, mechanical

19@ and excessive deormaton,

Primary structural member sal be welded vith ul peneraton welds and sal be veal inspected to ensure

‘freedom from vise detects,

6.00.2 BSEN 12079 Secondary structure

“The secondary structure canbe descibed as pats, which arent considered as load beating,

“This shall inclu but nt ited to:

oos, was and root panels

Pana stoner and corugatons

Seta component used fr tank protection ony

Internal seuting points

‘Tis structre sal be vu inspected fr corosion, mechanical damage or excessive cefrmaton

Interment fit welding ofthe secondary structure is aoeptble, however care shal be kent vod corason,

“The loo sal be vsualy Inspected to chek that is nt excessively defomed and att shows no sgn of

stressor overiad,Drsrage faces, wher fitod, stall be inspected and car of deb

(CUS or goneral cargo sal be fted wth neal sacung pots ach shal be designed to wltstanda force of

at eas 10, wth a minima of 12, Pingod ype, being ecommended/ pear.

(cL rots, incuting thas costed rom cheque plate shal cnt wth parent no-spam,

NSL

—

6.08.3 BS EN 12079 Forklift pockets

When ted vt pockets shal be installed Inthe base structure and shal have a cle tp

The minimum ial cimensons ofthe frit pockets shal be 200 mm x 90mm.

They shal be visual inspected for cotsion, mechanical damage and exessive deformation.

hee

Moe

16094 65 EN 12079 Doors

Doos, rames sels, hngs and locks shal be visual inspected and checkad to ensue tat they operate

satisfactory thot undue force being requiod

Locking devies shal secure agains opening during transportation anliting, locking dec othe top and bom

Locking arrangements and hinges sal be protected aoans damage fom imgact

6.085 BS EN 12079 Markings

‘The tps of closed COU’ andthe np ras of open and framed COU shal be marked with a band of solid

conrstng colour notes than 100 me wie round the of perimeter the root ofthe CCU s recessed

elo the top perimeter ral least the top surface fhe top ral shal be marked,

‘When a OCU sited it or pockets, designed for handing he CCU only when ery, hen the words “Ey

Itony stall be clearly csplyed naar each et of fork pockets in characters ot less than 60 ma igh

Each CCU shalhave the fabrcat’s serial umber welded on In charactors at ast Om tgh. Iain, each

(CCU shale marked wth a nigue CCU numb, sued by the oer.

‘Tho COU nur stl be prainenty and indelby dspayed on al sides of he COU in characters of contrasting

our, not ss than 75mm high

Note: For open sided CCUS, panels may be use oct be detcation

Hf. COU as a ot, the COU wmber shal be displayed onthe oon charts no ess then 300 men igh

Noe: Were characte izes rstictd by the avalte space they shou be as large es rattle, The

raring shall be cared out in such @ ways to wo ncarect interpretation

Each COU shale clearly marked wih

elvan electical hazard classfcaton and zene marking

elvan dangerous gods ncetor

Maximum gross weight (aka)

Tae weight nk)

Paya nk)

Not: Gros, tare and payod shal be dspayd in characters ofa contrasting colour ot ss than SOmm high

‘Amat backpanel appropiate ize maybe provided on a or, forthe aplication of mprary information,

the COU sted wt an itemetiate decks payload shal be spayed onthe inside ofthe CCUin a poston

‘her tis Gleave at ames, n charactors ofa contesting colour not ss than SO mm igh

NSL

ws rose

6.096 BS EN 12079 Pad eyes

A pad eyes and leshing pons shall be sual inspected fr distort, mechanical damage, excessive wear or

cverons,

Inardero prevent itera bending moments on pad ees, hy shal be algned wth the sng tothe ne of i, wt

maximum manufacturing tolerance of + 2.5 depres

‘ry diference inthe diagonal measurements between ifig point centres shal not exood 0.2% of he length ot

‘he dlagonal or mm, whichever ste gear,

ad eyes sallbe designed fora total vertcal fore of 3x the maximum gross wag

Te camer of hols in pad eyes sal match the shackle used, clearance betwoen shackle pin and pad ye hole

stall not exceed 6% ofthe nominal stack pin dametr

The tolerance between pad ee thickness andthe Ise wish of shackle shall not exced 25

Pad yes shal be so designed as ope ree movement ofthe shackle and sng teminaton without fouling the

pad ee.

ad ees shal ot protde ouside the boundaries ofthe COU ater han vertical pad, and shall as fr as

pss be designed to avid damage rm other CCU'sandbepeitonedon he CCU to eit the skaf Ings

fouing during norma use.

Its recommended that pad eyes are sloted ino he primary stuctur and welded to he rae wit ul

penetration welds

Note 1: — Where S0-corners are moured in conjunction wih pad eyes, he comer igs ae not tended

{orting wih sings otshore

ote 2: iting offshore wih stacls fed tothe comer tings snot acceptable.

6.09.7 BS EN 12079 Sings and Shackles

Wire rope stings

‘Tha inspection of wire rope sings and shacks shal be cari out as pr theca lated in secon 6.02.6,

\Wire ope sings shall metal reqdrements of EN 124144, sabe 6-standed and of one ofthe yes sted, 6

119.0636

Wire ope grade 1770 or 1960 stale sed. Te vrkng kad lint shal be calculated onthe basis ofthe actual,

rope grade used

‘Thelin set shal be of sufclen ng allo easy handing by operators, The top Unk or master nk shall be

bet reach down oa height of no more tan 1.3m above the CCU base when the sing hangs over the eng se

ofthe COU

‘Sings conforming to this Standard shal be suppl wih acetate containing the folowng, as risimum

Manufacturers name, mark and catact loaton

Date of sue forthe ceria ea, manth anc dy)

Sing certificate uber

Description ofthe sing, ncung unique deeaton nur ox ark.

Reference to each single components unique itetcaton mark (fnew crmponents stale before

re-ceficaton reference oprevous cata number and the new components unique dentition ark)

Nominal size an length ofthe sing

Working lad iit LL ogee ith the appreite angle othe vertical for muleg sings and he method

of rating

* Dale of sting manuiactur or re-certicaton

‘A staerment hat the sing described has been designed, menulactred and tested in accordance with this

European Standard

‘+ Manutetuers authored snatre

‘+ Forrre ope sings, he grade of ein its end the rope tog

‘anor to EN 134141

‘© Far chai sings, the grade mark 8 ada statenent confirming thatthe sing conforms to EN 818-4 and

roving cross reference othe resus of any fal tesng of mechani properties after hat reatmant

vith statement that the sing

‘Sings sal be marked wth anieniication tap permanent attached to the tp assembly ofthe sing. The ag

shale made of metal wth markings pemanentty embossed or stanped. The tag sal be sided for can Ings

a round or ie rope sings.

8 ee

=

The martng on as for chain and te oe sigs sal ce:

"Number ofthis stand

Unique idenificaton nur ofthe sing

Nurnerofegs

Diameter of chain or wite rope sed cuting the top lag where ited

Working od iit (WLL in tonnes

Maximum ange ofthe sng legs fom the vertical

Wight ofthe ting set in Kg

if sastactory after Inspection / test a ep shal be lsued to the cuner, containing he flowing intrmaton fs

amsimu

‘Sing and shackle dentfcaton numbers

(Owners name

Cericate number

‘statement tat he iting equipment described was thoroughly inspectod or tested

roo ina applied aplable

Is safe to operat and atthe parts are correct

Dati of any NOT cared cut

Confmaton that he sing dentiication tag was marked

Date of inspection

Name of organization

"Name and signature ofthe person who cated out he inspection or test

Noe: The CCU certtcate may also contain the inspection ep forthe lifteg set

(n stistectory completion of te inepection / test the sting detfcaton ap sal be permanent mated with

Date yea, month and ayo the inspection / test,

Uniue identification mark and when apocable

Tinian lod tet non-destructive examination, and visual inspection

\incating visual inspection only

{We inscatng NO and visual inepectin

‘logs shal be aed forte itendad angle fuse. Te sling shal note ate fran ange ofthe sing leg to the

vertical in excess of 45°

1 the tng sets damaged it shal ot be used unl itis repaired or replace, and inspected, Reps shal be

cated ot in accordance withthe requirements of EN 120792

‘Tho owner stall ean the curentcaticatn for each iting set and mainan adequate recoris to ensure

tracoabiy,

Iisrecommerded that the mast nk tobe atached to he cane hack shal have tase minimum censions 270

mm 140 mm teal

NSL G

—

Chain slings

‘© Sightthe agin test carta and oban te dae the sing went into sence, chain ameter an length rom

‘beating to beairg (measure chai length to check or stretch)

‘+ Layout chan sing on foo or suspend, ere al vss rom legs

4 Match up gs techeck for sins of stetch / defomaton in india egs

\Vsualy examine the chan ing along its entre length and check for:

‘Distortion in chan Inks rcs, bends, wists, elongated inks}

‘+ Wear betieen cui inks

‘© Woar between cx rks and componants

‘+ Moat damage

“© Chemical damage

Woah tistng on end terminations

*Coectdeticaton nunber and SWL

Chain sings shal be tstd wth a load equal o 25 x WL ofa single leg rated in accordance wth EN 818

41906 +/-2 %, ple o each fg without shock. Tho lad shale applied fora minimum of 5 ites before

measurements fake,

Hinge type couplirg components Le. connectors shall NOT be used.

‘Shackles

‘Shacks shal be of bot pep ted witha st cotter i

‘Shacks ited toasting, without being assembly (mechanical secure Le. capt stl be marked with a nique

idecaton. This marking shoul be applied using ‘low stress sta, the eight of wich shou be a inénun

of 5mm and poston away from areas of highest esl stress |, anid to the stag econ of the dy,

minimum shackle Working Load Limit

4 eg sing end

WLL minimum divided by (2 | WLLminimum divided by (2. | WLL minimum LL mirimum

Xosine of sling angle) WLL | x cosine of sling angle) WLL

minimum divided by (3x cosine | minimum divided by (2x cosine

‘of sing ange) ‘ot sing angle)

eer eran

Cet Ce ee ee

Cn reer an)

7

1000 7

1500 z

2000 35 7

2500) 288 72

3000) 26 78

3500) 2.408, a.

4000) 2207 883

4500 1.962 883

5000) 1768 883

5500 1766 ait

6000 1.766 1059

6500) 1738, 11.26

47 ing

11666, 125

1638, 1307,

16 136.

1.567, 141

1534 1457

1.501 1501

1479 15.53

1457 16.02

1435) 165

1419) 18.95,

1.391 17.38

1.908) 1779

1.346 1a18

224 1854

1.302 1888

ion of Working Load Limit

COU Maximum Gross Weight Enhancement Factor Minimum required WEL ofthe

co) rete)

15000 28 1920

5500 1267 19.64

1600) 1254 2008

16500 1.24 2087

17000 1227 20.86

17500 1214 2124

18000 1201 2181

18600) 1188) 217

19000 174 231

19600 161 22.84

20000) 1.148 2296

20500) 148 23.88

21000) 1139 23.2

21600) 1136 2439

22000 113 24.86

22500 1128 BH

23000 1321 278

73500 1a, 2625

24000) 112 25:70

24500) 1.108 27.15

25000) 1104 2758

Toalw forthe aynaic arptcaton shock loading that wi be experienced n fsbo Itng in adverse weather

and sa stats, the working oad mt ofthe tng sets for ofsore CCU stall be deterined using the tables

ov,

xcept for CCU wih maximum gos weights aw 2000 kg, he COU maximum gros wight shal be muti

by the entancerent fect to ge the minimurn WLL ofthe iting set

The minum working loa eit rom the tables above shal be used for determining the rial sizeof the ting

sat

NSL Co

eS

6.098 BSN 12079 Data plate

Data plates shal be made ofa corasion resistant material and securely tach ina manne avd urauhoised

or accel removal

The plat shoul be ited othe doa or en US with no doors, ina ronan tin.

‘Aurion eves shld ot bo use,

Infomation tal be permanent and legty marked onthe plas characters of tess tan 4mm igh

The plate shal be headed "OFFSHORE CONTANER INSPECTION PLATE -EN 120703: 2006"

The dat inspectn plate talc he oowing rit:

(Owners COU number

(Owners nae

Fabreator’ seal number

Month and year of manufacture

Maximum gross weghtn kilograms exccing iting st

Tae weigh in kograms

Pyad in klogras and intermediate dock payload (f applicable)

Conat of contormty nan

Desig temperature

ldentcaton of body issuing the cacao conformity

Date ys; month an yo the nt inpecon and test

‘Unique identtiation mark ofthe competent person

indcating prot oad test non-destructive exaination, and visual inspection:

\Windicatng non-destructive examination and vial inspection; or

Vinca sual inspacton only

‘ote: The dt plate may be cained wih the spect plate.

NSL

—_

‘OFFSHORE CONTAINER DATA PLATE

EN 12079-12006

Fabrcabon na:

Monn and year of manutacture

Masri goss nass excluding Ming eat Wat "i Dogies ran Vere

Tare as oat

Pao hat

Container hot

Intomedate deck gat

entcate ro:

Design epee 7

Inspection Data Plato -Ofshore Carano (00)

onan TDS

Fe Woah

Sele Waking Lod

Gross Welt

Bs7072 wart O BEN TAOS O

spect ats Sing Ane:

rr Vv w

iv Tr Vv

cy iv

NSL

=

6.10 BS EN 12079 Certitication

‘A catfcte of examination / inspection / test shal how he foloning minimum iteration:

COU identification ncuting omnes CCU number)

Name of onrer

Report nuber|

Siatoment ha the COU issuable for service

Tol gross welght nig

Payload weight in kg

Tare weight kg

Detals of tests cried cut

Detals of NOT cared cut

Salome tat he OU described was inspected and thatthe parclars are caret

Aferece, where apropite, 1 ary report sue othe one arising from the ress

Confimaton atte inpecton pat was marked

Name of company and name of he person caring out the ispection

Signatur fhe person wo cai out the nspection

‘omnmentson any its othe scape of inspection.

Detlef the cxarinatin ofthe ting set maya be gv e te repection ropa forthe CO

REPORT OF THOROUGH EXAMINATION AND / OR TEST OF LIFTING

‘APPLIANCE OR ACCESSORY

NSL seg re oS aoc ta

i =

Sea recast te

nr etn

Poy ug st

‘TiscteeCo es bean ese ap an

pce nd tl azarae wh nts tom

We bry cart at nn» 8 he Noms dotnet opr masvee rosy esl, 0 ar

‘ ozeabl adhe ov parle caret ntl ralea, he equpment chaste nd oad ae

Simo Pew ame Poson

(Grating Bata: (Ging e

Oa Deemer Rene Mamba NSL.C ODS

611 BSEN12079 NDT

‘The NDT of wos on pad eyes ana

craminaton and tess

atoning st

shal be cated out in acordance vith the schedule of

ca

Category of Member

Primary Structure

‘No Essential Primary Structure

Essential/ Non-redundant

Sree

Type of Examination

Utrasonic | Radiographic

100% 100% Pad eyes!

20% tall

others

Secondary Structure

NOT operators shal he atin a

eanoa wth FHA73, oa minimum of lve 2

SS]

pe

bie ssc eg

vet

‘This total weit canbe achieved by puting na tst weight equal o 2.5 x the maxinum gross welght minus the

tae weg.

IF tis nt possible to evel distribute the test weght inside the CCU, a quarto! the tes iad may be placed

‘fideo: urder the COU, proved that tis duplicates loading onthe suture sila to the stron dung

ormal operating contons.

1 te CU hes an adatonlcargo dak. the test ad shal be evenly dvd bevesn the lor andthe addon

ek

Te COU sal be ted by ating set with an ange othe veal equal othe desgnangl and shal beeld clear

ofthe ground for 5 mints before measurements ae taken.

No detections during testing shal be reste than 1/300 of he spn ofthe mb

The OCU shal show no pernent deformation rather damage afte testing.

te iting st, ermal fad othe CCU, be used forthe Hfng tt, care shoud be taken to ensure that no

‘vereang, deformation or dtoton fs Induces and shale Wl inspected aft the lad testy competent

petson,

Test2

(CUS ited wth four pad eyes shal also be ited from wo pad eyes, stated aconaly opposite to each oe,

vith ota weight of 15 x he maximum gross weight

The CCU shal show no permanent deformation rather damage aft testing.

Tests

‘The COU, wih test weight coresponding tothe SNL / payload, tal be ether dropped or lowered onto a

werkshop flr of concrete ooher gd struc,

‘The test osc MUST be saely secured to ensure the load remains win the COL dng the chop est

‘The oor may be cored wth a sheathing of wenden parks wth hicknes nat exceeding 0 mm,

‘The OCU shale nctned that each ofthe baton side and and as conectd tthe mest come foms an angle

of not es than § degrees wit the lx. However the greatest height dlerence between the highest and lowest

Point of he undersige ofthe COU comers ned not be more than 400 mn.

‘The COU shat be suspended from a quick release hock, When leased, the GU shal drop feey fo at least 80

rm giv ita speed at intl impact fat east 1.

Meratvly

‘The COU shal be lowered tthe Foor at aconstant sped of no ess han 1.5 ms

the COU sonered rom a crane, te suspending wie and hock may dampen the impact compared tate al

‘rp test. Therefore the impact speed should be aes ia oven st is sed

‘Tho Impacting comer sal be the one expected o have the fest rigity. On closed cry cargo CCUS tis wil

normal bea the dor en.

‘No sionticant permanent caage sal cco

‘Cracks in welds and minor deformations maybe repaired.

Optional Test

(pen op OS wth an cer nat of 6 or mre wth ork pockets designed for lated iting shal be ated

{ntl uni cistbved test ad of 1.6 x the maximum goss weight pls the weight ofthe sr, and es

ear ofthe ground using te fark pockets,

No deletion during tis test shel be rater than 100 othe sano the mene.

The COU shal show no pemanest defomaton rather damape afer tsa,

(n compton ofthese tess a NOT inspecon and sual inspection ofthe ates and required sutra areas

shale cared out

“The st ads shal be vere using calbrated weights ora calibrated load cal and handset

alot oe and handsets used it shale calibrated annul in accordance wih EN S0 7500-1, tan accuracy

22%,

Where used, test weights stall be carted, as a minimum, every bwo.yers In accordance wih accept

internatonal or atonal standards. The measured wept, klograms, ofeach test welght shal be legby end

ural marked on

6.13 BSEN12079 Inspection and Testing Periods

COV’ and tng ses shal be perio inspected, examined andi necessary tested in accordance withthe

ule sted blow.

\When the schedule nudes aliting ts, the non-destructive examination and vu inspection shal ah be

cari tater te iting ts.

Tene tonal Test spacton|

ia set As equ by BS EN 12079-1

At ireral ot 12 monte WA wR vs v

ait of 8 months Wa ves ves 1

ter sustartal ep or ateaten | Yes Ye Ye T

eee ee

Time ner Applicable to Test pectin

eran ed

Test

Witt Craton completing Set is requted by 8 EN 2079-2

leterws f72 mets complete ig Set wa | wa] vs | v

Sing Congenens aan UNS | Eperaaiea | ves | Tar

orNOT

Pee cia Sig las tiernadtet | ves [Torn

ernOT

Sraces wa] wa | ves | wa

After substantal repat/alteation | Complete Lifting Set Yes | Yes | Yes T

SS. ES]

poo

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Summary - HaliburtonDocument3 pagesSummary - HaliburtonNico Achmad ZulviansyahNo ratings yet

- To: Human Resource Department PT Inspektindo Sinergi PersadaDocument2 pagesTo: Human Resource Department PT Inspektindo Sinergi PersadaNico Achmad ZulviansyahNo ratings yet

- 4-Lembar Pengesahan PengujiDocument163 pages4-Lembar Pengesahan PengujiNico Achmad ZulviansyahNo ratings yet

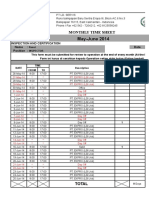

- Time Sheet Mei 2014Document32 pagesTime Sheet Mei 2014Nico Achmad ZulviansyahNo ratings yet

- Material Balance Equation: Kuliah 9 (24.05.2014)Document3 pagesMaterial Balance Equation: Kuliah 9 (24.05.2014)Nico Achmad ZulviansyahNo ratings yet

- English For Engineering-1regDocument30 pagesEnglish For Engineering-1regNico Achmad Zulviansyah100% (1)