Professional Documents

Culture Documents

DM-PH&SD-P4-TG09 - (Guidelines For Personal Protective Equipment-Eye and Face Protection) PDF

DM-PH&SD-P4-TG09 - (Guidelines For Personal Protective Equipment-Eye and Face Protection) PDF

Uploaded by

demie figueroaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DM-PH&SD-P4-TG09 - (Guidelines For Personal Protective Equipment-Eye and Face Protection) PDF

DM-PH&SD-P4-TG09 - (Guidelines For Personal Protective Equipment-Eye and Face Protection) PDF

Uploaded by

demie figueroaCopyright:

Available Formats

Organization Unit Public Health & Safety Department

Guidelines for Personal Protective Equipment –

Form sheet title:

Eye and Face Protection

Doc Ref. DM-PH&SD-P4-TG09

Background: Protection of the eyes and face from injury by physical or chemical

agents or by radiation is vital in Occupational Safety programs, as 25

to 30% of injuries are on the eye or face. Proper selection and use of

eye and face protective equipment shall be adopted taking into

consideration the operation and hazard. Every employer shall provide

and the employee shall use the eye and face protective equipment for

the job. Eye and face protective equipment shall conform to

International Standards.

Dubai Occupational Health and Safety Regulations Local Order 61 of

1991 requires the use of personal protective equipment.

The appropriate eye and face protection should be selected against the risk of physical

and radiation injuries.

Examples of activities and the typical hazards are given in the Schedule A and B.

Schedule A

Processes with involve risk of injury to the eyes from particles or fragments thrown

off or splash of chemicals.

1. The breaking, cutting, dressing or carving of bricks, stones, concrete, slag or

similar material by means of a hammer, chisel, pick or similar handtool or by

means of a power tool and the dry grinding of surfaces of any such materials

by means of a wheel or disc driven by mechanical power.

2. The dividing into separate parts of metal, bricks, stones, concrete or similar

material by means of high speed of saw or abrasive cutting off wheel or disc

driven by mechanical power.

3. The turning of metal or articles.

4. Drilling by means of stationary or portable power tools.

5. The welding and cutting of metals by means of an electric, oxy-acetylene or

similar process.

6. The hot fettling of steel castings.

7. The fettling metal castings involving the removal of metal including runners,

gates and risers and the removal of any other material.

7/1:الصفحة 2010 أبريل:تاريخ اإلصدار 2 : رقم اإلصدار

Organization Unit Public Health & Safety Department

Guidelines for Personal Protective Equipment –

Form sheet title:

Eye and Face Protection

Doc Ref. DM-PH&SD-P4-TG09

8. The chipping of metal, knocking out or cutting out or cutting off cold rivets,

bolts, nuts, lugs, pins, collars etc. from any structure or plant, by means of a

hammer, chisel, punch or similar handtool or by means of a portable power

tool.

9. The cutting and scrufing of paint, scale, slag, rust or other corrosion from the

surface of metal or other materials by means of hand or power tools.

10. The breaking of scrap metal by means of hammer or by any other tool driven

by mechanical power.

11. The routing of metal.

12. Work with drop hammers and power hammers.

13. Work at a furnace where there is risk to the eyes from molten metal.

14. Pouring or skimming of molten metal.

15. Work involving risk to the eyes from hot sand being thrown off.

16. Truing or dressing of an abrasive wheel.

17. The handling in open vessel or manipulation of strong acids or dangerous

corrosive liquids/chemicals or materials, and the operation, maintenance or

dismantling of plant or any other part or plant which contains or contained

such substances.

18. Any other process where there is a risk of injury to eyes from particles or

fragments thrown off and splash of chemicals during the course of the process.

Schedule B

Process which involve risk of injury to the eyes by reason of exposure to excessive

light or infra-red or ultra-violet radiations.

1. Welding and cutting of metals by means of an electrical, oxy-acetylene or

similar process.

2. All work on furnaces where there is risk of exposure to excessive light or

infra-red radiations.

3. Process such as rolling, casting or forging of metals where there is risk of

exposure to excessive light or infra-red radiation.

4. Any other process wherein there is a risk of injury to the eyes from exposure

to excessive light or ultra-violet or infra-red radiations.

7/2:الصفحة 2010 أبريل:تاريخ اإلصدار 2 : رقم اإلصدار

Organization Unit Public Health & Safety Department

Guidelines for Personal Protective Equipment –

Form sheet title:

Eye and Face Protection

Doc Ref. DM-PH&SD-P4-TG09

Guidelines:

1. Equipment for the protection of the eyes and face are divided into two groups.

i. Goggles/Spectacles ii. Visors/Faceshields

The equipment shall be designed to protect the wearer from chemical and

physical hazards such as splashes, vapours, foreign bodies and radiations from

sources emitting ultra-violet, infra-red etc.

2. Table - 1 should be used as a guide in the selection of eye and face protection

for certain operations.

3. Spectacles fitted with impact resistant lenses shall be used.

4. Spectacles without side shield are not acceptable since they provide only

frontal protection. Spectacles must have side shield to restrict the entry of

flying particles from the side of the wearer.

5. Goggles of the type suitable for the risk shall be worn.

i. Goggles with mesh or perforated ventilation sides - General hazards

ii. Goggles with shield and anti-fogging coating - chemical liquid or vapour

hazards.

6. Goggles shall be worn over corrective lenses spectacles without disturbing the

adjustment of the spectacle.

7. Spectacles - Toughened material:

For those employees with sight defects, prescribed lenses shall be in

toughened materials to withstand impacts from flying particles, etc.

8. Visors or Face shield:

i. Visors or face shield fitted to head harness or safety helmets shall be

worn in chemical process areas or chemical handling operations.

ii. Hood made of chemical resistant materials with frontal plastic window

and rear shielded ventilation ports should be preferred while handling

acid and other corrosive liquids and vapours requiring higher degree of

protection. If air is not respirable, use of air-fed hoods are

recommended.

7/3:الصفحة 2010 أبريل:تاريخ اإلصدار 2 : رقم اإلصدار

Organization Unit Public Health & Safety Department

Guidelines for Personal Protective Equipment –

Form sheet title:

Eye and Face Protection

Doc Ref. DM-PH&SD-P4-TG09

9. Filters:

Welding glasses or lenses shall be used to protect the eyes from visible and

infra-red as well as ultra-violet radiations.

Recommended filters for welding wre given in the Table - 2.

10. Showers and eye wash fountains shall be provided for areas where there is risk

of eye injuries due to chemicals handled. Eye wash bottles are generally kept

in first aid kits.

11. Further References:

American National Standard ANSI Z 87.1 - Eye and face protection

British Standard Specification BS: 679 Filters for use during welding

BS: 2092 Specification for industrial eye

protection

BS:1542 Equipment for eye and face

protection against radiation

arising during welding.

EN Standard Specifications

FURTHER INFORMATION IS AVAILABLE FROM

PUBLIC HEALTH AND SAFETY DEPARTMENT

Tel: 2064244 FAX: 2270160

7/4:الصفحة 2010 أبريل:تاريخ اإلصدار 2 : رقم اإلصدار

Organization Unit Public Health & Safety Department

Guidelines for Personal Protective Equipment –

Form sheet title:

Eye and Face Protection

Doc Ref. DM-PH&SD-P4-TG09

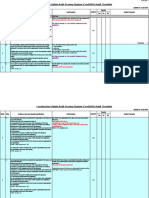

TABLE 1

a b c d e f g h I j k l mn o p q r s t u

EYE AND FACE

PROTECTION

= SUITABLE

Suitable for -

Bitumen spraying

Boiler/furnace operations *

Chipping concrete, stone etc.

Chipping paint *

Cleaning - high pressure water jets *

Cutting metal by hand (cold)

Dust laden atmospheres (non-toxic)

Electric Welding

Engineering workshops

Filling cylinders - LPG

Filling drums - chemicals

Filling drums - oil products

Filling gantries - chemicals

Fire - fighting

Gas welding /cutting

Grinding

Handling chemicals

Handling cryogenic materials

Laboratories - general

Metal machining

Mech. wood working

Paint spraying

Radiation heat

Spillages, oil - clean up etc.

Spillage, chemical - clean up

Steam cleaning

a. Goggles, Vent, Cup type, welding b. Safety Spectacles - with side shield

c. Goggles, full view, general purpose d. Goggles, full view, dust/chemical

e. f. Eye/face shields, swing back

g. Welders shields, with skull guard h. Welders shields, head gear

i. Welders shields, hand type j. Eye/Face shield, clip-on type

k. Reflective eye/face shield l.

m. n.

7/5:الصفحة 2010 أبريل:تاريخ اإلصدار 2 : رقم اإلصدار

Organization Unit Public Health & Safety Department

Guidelines for Personal Protective Equipment –

Form sheet title:

Eye and Face Protection

Doc Ref. DM-PH&SD-P4-TG09

TABLE 2

RECOMMENDED FILTERS FOR WELDING

SPECIFICATION

REF.: BS 679

RECOMMENDED FILTERS FOR GAS WELDING Filters required for:

Welding Process Welding Welding with

without flux

flux

Gas welding of aluminimum and aluminimum magnesium

alloys:

Lead welding or oxy-acetylene cutting 3/GW 3/GWF

Oxygen machine and hand cutting, oxygen gouging, flame

descaling, silver soldering, fusion welding of zinc base die

casting, bronze welding of light gauge copper pipe and

light gauge steel sheet. 4/GW 4/GWF

Fusion welding of copper and copper alloys, of nickel and

nickel alloys, of steel plate, all bronze welds in heavy

gauge steel and cast iron, except pre-heated work, re-

building work of relatively small parts and areas for fusion

welding, all hard surfacing operations, including rail-

surfacing 5/GW 5/GWF

Fusion welding of heavy steel, of heavy cast iron, fusion

welding and bronze welding of pre-heated cast iron and 6/GW 6/GWF

steel castings. and 7/GW and 7/GWF

Re-building large steel areas, e.g. large cams, etc.

RECOMMENDED FILTERS FOR ELECTRIC WELDING Approx. Filter(s)

Welding Process Range of required

welding

current

(in amps)

Metal-arc welding (coated electrodes), UP to 100 8/EW, 9/EW

Continuous covered - electrode welding, 100-300 10/EW, 11/EW

Carbon dioxide shielded continuous covered-electrode Over 300 12/EW, 13EW

welding. 14/EW

Metal-are welding (bare wire), Carbon-arc welding, Up to 200 10/EW, 13/EW

Inert-gas metal-arc welding, Over 200 12/EW, 11/EW

Atomic hydrogen welding 14/EW

Automatic CO2 shielded metal-arc welding (bare wire) Over 500 15/EW, 16/EW

7/6:الصفحة 2010 أبريل:تاريخ اإلصدار 2 : رقم اإلصدار

Organization Unit Public Health & Safety Department

Guidelines for Personal Protective Equipment –

Form sheet title:

Eye and Face Protection

Doc Ref. DM-PH&SD-P4-TG09

Inert-gas tungsten -arc welding Up to 15 8/EW

15-75 9/EW

75-100 10/EW

100-200 11/EW

200-250 12/EW

250-300 13/EW, 14/EW

7/7:الصفحة 2010 أبريل:تاريخ اإلصدار 2 : رقم اإلصدار

You might also like

- ENG - DM-PHSD-P6-WI-02 Health Requirements For Labor Accommodation PDFDocument7 pagesENG - DM-PHSD-P6-WI-02 Health Requirements For Labor Accommodation PDFdemie figueroaNo ratings yet

- DM-PH&SD-P4-TG21 - (Guidelines For Examination and Certification of Cranes, Hoists, Lifts and Other Lifting Appliances) PDFDocument2 pagesDM-PH&SD-P4-TG21 - (Guidelines For Examination and Certification of Cranes, Hoists, Lifts and Other Lifting Appliances) PDFdemie figueroaNo ratings yet

- DM PHSD P7 TG6 Emergency+Preparedness+GuidelineEN1 PDFDocument10 pagesDM PHSD P7 TG6 Emergency+Preparedness+GuidelineEN1 PDFdemie figueroaNo ratings yet

- DM-PH&SD-P4-TG04 - (Guidelines For Entry Into Confined Spaces) PDFDocument3 pagesDM-PH&SD-P4-TG04 - (Guidelines For Entry Into Confined Spaces) PDFdemie figueroa100% (1)

- S3EMIA - 315 - PR1 - Working On and Near WaterDocument7 pagesS3EMIA - 315 - PR1 - Working On and Near WaterSiwaNo ratings yet

- Victor Propane LPG Natural Gas Cutting Tip ChartDocument2 pagesVictor Propane LPG Natural Gas Cutting Tip ChartYhamil La Madrid0% (1)

- Benzene: 1. Purpose 2. ScopeDocument8 pagesBenzene: 1. Purpose 2. ScopeKandhasamy888No ratings yet

- Safety Data Sheet: Masterseal P 101Document10 pagesSafety Data Sheet: Masterseal P 101Sam Malik100% (1)

- Development of Emergency Response Procedure For Accidents Involving Dangerous GoodsDocument5 pagesDevelopment of Emergency Response Procedure For Accidents Involving Dangerous GoodsMuhammad Faheem100% (1)

- DM-PH&SD-P4-TG04 - (Guidelines For Entry Into Confined Spaces)Document3 pagesDM-PH&SD-P4-TG04 - (Guidelines For Entry Into Confined Spaces)kevinNo ratings yet

- Fire Code 2013 PDFDocument1,033 pagesFire Code 2013 PDFKo PaukNo ratings yet

- DM-PH&SD-P4-TG18 - (Guidelines For Safety in Vehicle Repair and Servicing Shops) PDFDocument6 pagesDM-PH&SD-P4-TG18 - (Guidelines For Safety in Vehicle Repair and Servicing Shops) PDFdemie figueroaNo ratings yet

- DM-PH&SD-P4-TG14 - (Guidelines For Personal Protective Equipment-Fall Protection-Safety Lines) PDFDocument3 pagesDM-PH&SD-P4-TG14 - (Guidelines For Personal Protective Equipment-Fall Protection-Safety Lines) PDFdemie figueroaNo ratings yet

- ME 2207 - Manufacturing Technology 1 - Lab ManualDocument57 pagesME 2207 - Manufacturing Technology 1 - Lab ManualMohan Prasad.M71% (17)

- Plasma Cutting PDFDocument35 pagesPlasma Cutting PDFahmed100% (2)

- DM-PH&SD-P4-TG08 - (Guidelines For Personal Protective Equipment-Head Protection)Document3 pagesDM-PH&SD-P4-TG08 - (Guidelines For Personal Protective Equipment-Head Protection)narma143No ratings yet

- DM-PH&SD-P4-TG23 - (Guidelines For Safety Procedures in Metal Finishing Industries) PDFDocument3 pagesDM-PH&SD-P4-TG23 - (Guidelines For Safety Procedures in Metal Finishing Industries) PDFdemie figueroaNo ratings yet

- DM-PH&SD-P4-TG10 - (Guidelines For Personal Protective Equipment-Hearing Protection) PDFDocument3 pagesDM-PH&SD-P4-TG10 - (Guidelines For Personal Protective Equipment-Hearing Protection) PDFdemie figueroaNo ratings yet

- DM HSD GU97 PPEFP2 - Technical Guideline On PPE Foot ProtectionDocument17 pagesDM HSD GU97 PPEFP2 - Technical Guideline On PPE Foot ProtectionNatalie Blackmore100% (1)

- DM-PH&SD-P4-TG02 - (Guidelines For Safety Audit Reports)Document5 pagesDM-PH&SD-P4-TG02 - (Guidelines For Safety Audit Reports)kevinNo ratings yet

- DM-PH&SD-P4-TG13 - (Guidelines For Personal Protective Equipment-Foot Protection) PDFDocument5 pagesDM-PH&SD-P4-TG13 - (Guidelines For Personal Protective Equipment-Foot Protection) PDFdemie figueroaNo ratings yet

- DM-PH&SD-P4-TG06 - (Guidelines For Guarding of Dangerous Machinery)Document7 pagesDM-PH&SD-P4-TG06 - (Guidelines For Guarding of Dangerous Machinery)kevinNo ratings yet

- DM-PH&SD-P4-TG11 - (Guidelines For Personal Protective Equipment-Protective Clothing) PDFDocument4 pagesDM-PH&SD-P4-TG11 - (Guidelines For Personal Protective Equipment-Protective Clothing) PDFdemie figueroaNo ratings yet

- Personal Protective Equipment ProceduresDocument3 pagesPersonal Protective Equipment ProceduresLwandziso DlaminiNo ratings yet

- ESH&S Plan Semi - Mobile Coal WashingDocument76 pagesESH&S Plan Semi - Mobile Coal WashingWahyu NugrahaNo ratings yet

- DM-PH&SD-GU93-LAP - E - Work Permit and Precautionary Measures For Labor Acc PDFDocument14 pagesDM-PH&SD-GU93-LAP - E - Work Permit and Precautionary Measures For Labor Acc PDFMuhammad JahangirNo ratings yet

- COSHH FOR Sodium Metabisulfite (Food Grade) - BASF - MSDSDocument3 pagesCOSHH FOR Sodium Metabisulfite (Food Grade) - BASF - MSDSAhmad OmarNo ratings yet

- A Review of Radioactive Waste ManagementDocument5 pagesA Review of Radioactive Waste ManagementVIVA-TECH IJRI100% (1)

- Details Required For ESIADocument2 pagesDetails Required For ESIAbhaskarNo ratings yet

- Afcons Infrastructure LTD.: Job. No. 6152 (Environment, Health & Safety Department) Excavation ChecklistDocument1 pageAfcons Infrastructure LTD.: Job. No. 6152 (Environment, Health & Safety Department) Excavation ChecklistSravanPolepalliNo ratings yet

- Sample Ppe ProgramDocument4 pagesSample Ppe ProgramRizal DaudNo ratings yet

- HSE Practice No 5 - Personal Protective Equipment (PPE)Document21 pagesHSE Practice No 5 - Personal Protective Equipment (PPE)Leda DaleNo ratings yet

- DM-PH&SD-P4-TG15 - (Guidelines For Personal Protective Equipment-Respiratory Protection) PDFDocument9 pagesDM-PH&SD-P4-TG15 - (Guidelines For Personal Protective Equipment-Respiratory Protection) PDFdemie figueroaNo ratings yet

- F007C Fire Alarm Record of TestingDocument2 pagesF007C Fire Alarm Record of TestingShahlaNo ratings yet

- OSHAD-SF - TG - Dealing With Adverse Weather Conditions For School Transportaiton v3.0 EnglishDocument10 pagesOSHAD-SF - TG - Dealing With Adverse Weather Conditions For School Transportaiton v3.0 EnglishNiel Brian VillarazoNo ratings yet

- Contractor Safety Proceduresv1 1Document27 pagesContractor Safety Proceduresv1 1Bambang Setyo Utomo100% (1)

- The American University in Cairo Environmental Health & Safety DepartmentDocument91 pagesThe American University in Cairo Environmental Health & Safety DepartmentBabbooNo ratings yet

- Confined Space PlanDocument25 pagesConfined Space PlanPokiko MikotoNo ratings yet

- 3340-Sds-Petromin Atf Dexron Ii e V#2Document6 pages3340-Sds-Petromin Atf Dexron Ii e V#2SICIM SAUDI ARABIANo ratings yet

- SS ISO 45001-2018 (2023) PreviewDocument14 pagesSS ISO 45001-2018 (2023) PreviewSelva RajNo ratings yet

- Qcs 2010 Section 11 Part 1.5 Regulatory Document - OTHER HAZARDOUS A PDFDocument124 pagesQcs 2010 Section 11 Part 1.5 Regulatory Document - OTHER HAZARDOUS A PDFbryanpastor106100% (1)

- HDPE Plastic PIPE FUSION WELDING WORK METHOD STATEMENT 01 PDFDocument11 pagesHDPE Plastic PIPE FUSION WELDING WORK METHOD STATEMENT 01 PDFSuryakant Suraj100% (1)

- Fall Protection Program: Reviewed: May 2011Document20 pagesFall Protection Program: Reviewed: May 2011Marvin ReggieNo ratings yet

- Health Requirements For Permanent Labour Accommodation: Organization Unit Form Sheet Title: Doc RefDocument6 pagesHealth Requirements For Permanent Labour Accommodation: Organization Unit Form Sheet Title: Doc RefManikandan BmNo ratings yet

- Consass ChecklistDocument62 pagesConsass Checklistmohamed Abo-EwishaNo ratings yet

- Risk Assessment TrainingDocument10 pagesRisk Assessment TrainingAlok SinghNo ratings yet

- Contractor Safety and Health StandardDocument15 pagesContractor Safety and Health StandardJonathan KaratoNo ratings yet

- Chemicals Can: Safe Handling of ChemicalsDocument1 pageChemicals Can: Safe Handling of ChemicalsJavier Quintero SaavedraNo ratings yet

- 1 Million ManhoursDocument8 pages1 Million ManhoursAina AnditaNo ratings yet

- ExcavationDocument9 pagesExcavationabidNo ratings yet

- 2014 Contractor Safety Training - Contractor OrientationDocument68 pages2014 Contractor Safety Training - Contractor OrientationdethscrimNo ratings yet

- DM-PH&SD-P4-TG12 (Guidelines For Personal Protective Equipment-Hand Protection) PDFDocument5 pagesDM-PH&SD-P4-TG12 (Guidelines For Personal Protective Equipment-Hand Protection) PDFdemie figueroaNo ratings yet

- 01-11 QCS 2014Document11 pages01-11 QCS 2014Raja Ahmed HassanNo ratings yet

- Personal Protective Equipment: Helmet MaskDocument52 pagesPersonal Protective Equipment: Helmet MaskANSHUL HIKER100% (1)

- DM HSD GU99 SSW2 - Technical Guideline On Safety Signs at WorkDocument30 pagesDM HSD GU99 SSW2 - Technical Guideline On Safety Signs at WorkNatalie BlackmoreNo ratings yet

- Jsa Ndt-BuildingDocument5 pagesJsa Ndt-BuildingFirdaus RidzuanNo ratings yet

- Contractor Risk AssessmentDocument5 pagesContractor Risk Assessmentrnp2007123No ratings yet

- OSHA 511 Sub I PPEDocument33 pagesOSHA 511 Sub I PPEAhmed Hassan SabryNo ratings yet

- Workers' Participation in ManagementDocument37 pagesWorkers' Participation in ManagementPiyush ParmarNo ratings yet

- Fosroc - Nitocote PE 135Document8 pagesFosroc - Nitocote PE 135guru sathya bharathyNo ratings yet

- New Osha - Ansi Safety Sign Systems For Today's WorkplacesDocument18 pagesNew Osha - Ansi Safety Sign Systems For Today's WorkplacesElif Oztrk100% (1)

- Bitustick - XL-Material Safety Data SheetDocument2 pagesBitustick - XL-Material Safety Data Sheetaldred_chezka100% (1)

- 1.1 Buildings and FloorsDocument4 pages1.1 Buildings and FloorsMohamed Mouner100% (1)

- EHS AgreementDocument37 pagesEHS AgreementSantosh KumarNo ratings yet

- Jha Region7 GeoprobeDocument10 pagesJha Region7 Geoprobewasif ahmedNo ratings yet

- Compressed Gas Cylinder SafetyDocument38 pagesCompressed Gas Cylinder SafetyFarhat SetharNo ratings yet

- CSTS - Toolbox Talks - Barrier Management (Final)Document2 pagesCSTS - Toolbox Talks - Barrier Management (Final)herlambangNo ratings yet

- OETC-HSE-O-COP-F-010 Daily HSE Report PDFDocument1 pageOETC-HSE-O-COP-F-010 Daily HSE Report PDFKing_of_SenseNo ratings yet

- DM-PH&SD-P4-TG23 - (Guidelines For Safety Procedures in Metal Finishing Industries) PDFDocument3 pagesDM-PH&SD-P4-TG23 - (Guidelines For Safety Procedures in Metal Finishing Industries) PDFdemie figueroaNo ratings yet

- DM-PHSD-P7-A-TG - (Guidelines For Rope Access Work) English PDFDocument11 pagesDM-PHSD-P7-A-TG - (Guidelines For Rope Access Work) English PDFdemie figueroaNo ratings yet

- Dubai Municipality Codes ListDocument8 pagesDubai Municipality Codes Listdemie figueroaNo ratings yet

- DM PH&SD P4 TG22 (Guidelines+for+Acetylene+Generators) PDFDocument2 pagesDM PH&SD P4 TG22 (Guidelines+for+Acetylene+Generators) PDFdemie figueroaNo ratings yet

- DM-PH&SD-P7-WI18 - (Health Requirements For The Services Provided Inside Labours Accommodations) PDFDocument4 pagesDM-PH&SD-P7-WI18 - (Health Requirements For The Services Provided Inside Labours Accommodations) PDFdemie figueroaNo ratings yet

- DM-PH&SD-P4-TG15 - (Guidelines For Personal Protective Equipment-Respiratory Protection) PDFDocument9 pagesDM-PH&SD-P4-TG15 - (Guidelines For Personal Protective Equipment-Respiratory Protection) PDFdemie figueroaNo ratings yet

- DM-PH&SD-P4-TG11 - (Guidelines For Personal Protective Equipment-Protective Clothing) PDFDocument4 pagesDM-PH&SD-P4-TG11 - (Guidelines For Personal Protective Equipment-Protective Clothing) PDFdemie figueroaNo ratings yet

- DM-PH&SD-P4-TG10 - (Guidelines For Personal Protective Equipment-Hearing Protection) PDFDocument3 pagesDM-PH&SD-P4-TG10 - (Guidelines For Personal Protective Equipment-Hearing Protection) PDFdemie figueroaNo ratings yet

- DM-PH&SD-P4-TG13 - (Guidelines For Personal Protective Equipment-Foot Protection) PDFDocument5 pagesDM-PH&SD-P4-TG13 - (Guidelines For Personal Protective Equipment-Foot Protection) PDFdemie figueroaNo ratings yet

- DM-PH&SD-P4-TG06 - (Guidelines For Guarding of Dangerous Machinery) PDFDocument7 pagesDM-PH&SD-P4-TG06 - (Guidelines For Guarding of Dangerous Machinery) PDFdemie figueroaNo ratings yet

- DM-PH&SD-P4-TG12 (Guidelines For Personal Protective Equipment-Hand Protection) PDFDocument5 pagesDM-PH&SD-P4-TG12 (Guidelines For Personal Protective Equipment-Hand Protection) PDFdemie figueroaNo ratings yet

- Jj104 - Workshop Technology 1Document5 pagesJj104 - Workshop Technology 1Nina Mazuin100% (1)

- Welding TechnologyDocument35 pagesWelding TechnologyAlejandro Cano100% (1)

- Welding TerminologiesDocument5 pagesWelding Terminologiescharlesbryan.martinezNo ratings yet

- HVAC CatalogDocument47 pagesHVAC CatalogJoel BecherNo ratings yet

- Student ReferenceDocument188 pagesStudent Referencepapipapii94% (18)

- Projetos de Normas Iso - Set - OutDocument23 pagesProjetos de Normas Iso - Set - OutRaphael AugustoNo ratings yet

- TB38 Hot WorkDocument2 pagesTB38 Hot WorkAndrei KrivdaNo ratings yet

- Fabrication Erection and Installation Procedure For PipingDocument60 pagesFabrication Erection and Installation Procedure For Pipinghasan_676489616No ratings yet

- Welding WorkshopDocument43 pagesWelding WorkshopJasmeet KaurNo ratings yet

- Ice 1.1 Steam Welding PrincipleDocument82 pagesIce 1.1 Steam Welding PrincipleThilagavathy SethuramahNo ratings yet

- Beginner's Guide To Welding 101 - All You Need To Know PDFDocument60 pagesBeginner's Guide To Welding 101 - All You Need To Know PDFisaias.prestesNo ratings yet

- 2011 Nov-1Document24 pages2011 Nov-1ratheesh1981No ratings yet

- Valve Glossary - Tom KirkmanDocument323 pagesValve Glossary - Tom KirkmanBogdan StanciuNo ratings yet

- Arc Welding ReportDocument24 pagesArc Welding ReportMuhammad HidayaturrahmanNo ratings yet

- UTIDocument5 pagesUTIYoko Dwi SNo ratings yet

- Welding CBCDocument77 pagesWelding CBCpolly agkisNo ratings yet

- Daily House Keeping ChecklistDocument290 pagesDaily House Keeping ChecklistJafar AliNo ratings yet

- Annexure-VIID Syllabus For Mechanical & Allied Engineering Exam Group - JEDocument2 pagesAnnexure-VIID Syllabus For Mechanical & Allied Engineering Exam Group - JEVishal KumarNo ratings yet

- Imp Lab ManualDocument36 pagesImp Lab ManualAnas MuhammedNo ratings yet

- Brazing Copper To SteelDocument3 pagesBrazing Copper To SteelathulpcucekNo ratings yet

- Gas Cutting - by KiranDocument40 pagesGas Cutting - by KiransridharchebroluNo ratings yet

- Oxy-Acetylene Welding and Related ProcessesDocument28 pagesOxy-Acetylene Welding and Related ProcessesMohammad Sobhan RajabiNo ratings yet

- Joining MethodsDocument15 pagesJoining MethodsAliyu Ibrahim SalihuNo ratings yet

- Bharat Metal Cutting GasDocument5 pagesBharat Metal Cutting GasGitanjaliNo ratings yet

- Prescribed Units General Plumbing Main Classes 2021Document24 pagesPrescribed Units General Plumbing Main Classes 2021pradip barasiyaNo ratings yet

- General Method Statement R1.Document21 pagesGeneral Method Statement R1.Ganjar Dreadlocks NugrahaNo ratings yet

- Bajaj Electricals Limited: Summer Training ReportDocument30 pagesBajaj Electricals Limited: Summer Training Reportसंकेत संभाजीराजे पवारNo ratings yet