Professional Documents

Culture Documents

Has Son 2006

Has Son 2006

Uploaded by

inejattOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Has Son 2006

Has Son 2006

Uploaded by

inejattCopyright:

Available Formats

Scale Control in Saline and Wastewater Desalination

David Hasson* and Raphael Semiat

GWRI Rabin Desalination Laboratory, Department of Chemical Engineering, Technion—Israel Institute of Technology,

Haifa 32000, Israel

(Received 28 November 2004 and in revised form 12 October 2005)

Abstract. This paper briefly reviews current understanding of basic phenomena

involved in scale formation, outlines current scale control techniques, and indicates

some promising research directions.

Introduction Scale Formation Mechanisms

Scale deposition is a difficulty encountered with water Scale deposition is a crystallization process involvi-

containing ions of sparingly soluble salts and is one of ing four stages:1–5

the obstacles hampering the further progress of desalinat-

• Attainment of supersaturation

tion. Scale precipitation occurs whenever process condit-

• Nucleation

tions lead to the creation of supersaturation with respect

• Crystal growth around the nucleus

to one or more of the sparingly soluble salts. This diffic-

• Growth of small crystals into larger ones; scale

culty is encountered in both evaporation and membrane

layer thickening

desalination processes. Unless preventive measures are

undertaken, the concentration effect involved in every Creation of a Supersaturation Potential

desalination process induces precipitation of sparingly The most important single factor determining the

soluble salts such as CaCO3 and CaSO4. intensity of scaling is the supersaturation level of the

Scale deposition cannot be tolerated because of its deposit-forming species. Supersaturation conditions are

highly deleterious effects on production capacity and achieved when a solution is concentrated beyond the

specific energy consumption. It is therefore essential to solubility limits of one or more of its constituents by

incorporate in every desalination process scale control evaporation (as in thermal desalination processes) or by

measures that can be rationally designed and are cost separation of pure water (as in membrane processes).

effective. The difficulties lie not in the lack of adequate Supersaturation conditions can also be achieved by

scale control techniques but in the constraint of a narr- a change in temperature. Most of the frequently enc-

row cost margin and in the frequently encountered situa- countered scaling salts—CaCO3, Mg(OH)2, CaSO4, and

ation of insufficient know-how. The aim of this paper Ca3(PO4)2—exhibit inverse solubility characteristics,

is to review current understanding of basic phenomena i.e., solubility decreases with increasing temperature.

involved in scale formation, to outline current scale cont- A solution of an inverted solubility salt in contact with

trol techniques, and to indicate some promising research *Author to whom correspondence should be addressed. E-mail:

directions. hasson@techunix.technion.ac.il

Israel Journal of Chemistry Vol. 46 2006 pp. 97–104

98

a hot surface can attain supersaturation by the inverted

solubility effect and deposit scale on the hot surface,

even when undersaturation conditions prevail in the

bulk of the solution.

Induction Period

A supersaturated solution is at an unstable equilibr-

rium and relieves its supersaturation by precipitating

a solid phase. Attainment of supersaturation alone is

not sufficient for a system to begin precipitation. At

relatively moderate supersaturations, the solution can

remain stable without precipitation for a certain time,

which is termed the delay or induction period. Only at

a sufficiently high supersaturation level is the induction

period virtually absent and precipitation instantaneous.

The induction period phenomenon is of utmost practic-

cal importance in scale control efforts. The widely used

technique discussed below, of scale control by dosage of

an anti-scalant, is based on the increase of the induction

period induced by the presence of the anti-scalant. Fig. 1. Linear correlation of induction time data for CaSO4

The physical mechanisms governing the induction deposition in the presence of anti-scalants.7 SRw denotes satur-

period are nucleation processes. To create a solid phase, ration ratio at the membrane wall.

an energy barrier has to be overcome. An embryo cons-

sisting of a cluster of molecular aggregates can survive at two levels.7 The inhibitory effect exerted by anti-scala-

as a stable solid nucleus only if it reaches a certain ants is also reflected in the increase in surface energy

critical size. Nuclei are of visually unobservable micros- for deposit formation in the presence of anti-scalants.

scopic dimensions. Their formation is facilitated by the Surface energy values extracted from data similar to

presence of a deposition surface so that in all practical those of Fig. 1 were around 15 mJ/m2 in the absence of

systems nucleation can be assumed to be of a heterogen- an anti-scalant, increasing to the range of 20–30 mJ/m2

neous nature. in the presence of anti-scalants dosed at concentrations

Induction time data may be correlated with the supers- of 6 to 12 ppm.

saturation level S by assuming that τ, the extent of the

Scale Layer Growth

induction period, is inversely proportional to the heterog-

Once an initial scale layer is formed, subsequent

geneous nucleation rate:6

deposition is facilitated. Growth of a crystal layer on a

(1) flow surface involves several consecutive processes:3

1. Diffusional transport of the crystal-forming ions

where T is the absolute temperature prevailing on the

towards the crystallizing layer;

deposition surface, σ is the scale crystal surface energy,

2. Incorporation of the ions on growth sites of the

θ is the contact angle of the crystallite on the surface,

crystal lattice;

and C1 and C2 are constants of the system. Induction

3. Adhesion and removal processes.

times are seen to be highly dependent on the supersatur-

ration level. A long induction period is induced by a low The interfacial process of crystallization (step 2) is

supersaturation level, a low surface temperature, and a viewed as a “surface reaction process”. In the absence

non-wettable surface (low contact angle θ). Induction of removal effects (to be discussed later), the deposition

periods can, therefore, be characterized by measuring flux r kg/s m2 (corresponding to a scale growth velocity

the slope of the straight line correlating lnτ with 1/(ln S)2 of dx/dt m/s) is obtained by equating the transport rate of

and extracting from the slope the value of the surface the scale constituents to the crystallization surface with

energy parameter σ. the rate of the crystallization reaction:1,6

Equation 1 can be used to evaluate the effectiveness

(2)

of anti-scalants in delaying scale precipitation. Figure 1

shows induction times for CaSO4 scale deposition meas- where x is the layer thickness, ρs is the scale bulk dens-

sured in a recycling membrane system at various supers- sity, kD is the mass transfer coefficient, kR is the surface

saturation levels in the presence of an anti-scalant dosed reaction kinetic coefficient, CB is the solution concent-

Israel Journal of Chemistry 46 2006

99

tration of the scaling salt, Ci is its concentration at the lowered due to partial removal of the deposit by the

solution–scale crystal interface, and CS is the solubility shear force acting on the flow surface.

of the scaling salt. For most crystallizing salts, the value The deposition rate of a scale layer composed of

of the power coefficient is p = 2. a pure crystalline substance such as pure calcite will

When the scaling rate is relatively high, the deposit- usually be governed by the rate of diffusional transport

tion process is governed by the diffusional transport discussed above. The layer thickness will grow linearly

process. In this case the increase in scaling rate with with time and an increase in flow velocity will augment

temperature is moderate and the main effect is exerted the rate of scaling. On the other hand, a weakly adhere-

by the flow velocity. Since the mass transfer coefficient ent scale deposit formed in the presence of impurities

kD increases with the velocity V (kD ~ V 0.33 in laminar usually experiences a decrease in the scaling rate with

flow and kD ~ V 0.8–0.9 in turbulent flow), an increased time due to effects such as removal of weakly adherent

velocity facilitates transport of the scaling species to the crystals, accumulation of adsorbed impurities on act-

flow surface, thus acting to augment the scaling rate. tive crystal sites, or buildup of a repelling electrostatic

In most industrial systems (notably in anti-scalant charge.

treated feeds), the scaling rate is relatively low and scali- The above phenomena are illustrated in Fig. 2, which

ing is governed by the rate of the crystallization surface shows the effect of an anti-scalant on the growth of a

reaction. In this case the velocity effect is secondary. calcite scale layer depositing from a falling film of a

An increase in temperature sharply increases the scali- supersaturated hot Ca(HCO3)2 solution flowing down

ing rate, since the crystallization rate coefficient kR foll- the outer surface of a vertical tube.8 As discussed below,

lows an exponential dependence given by the Arrehnius anti-scalants are in effect impurities that adsorb on act-

relationship: tive crystal sites and hinder the crystallization process.

Figure 2 shows that a dosage of 0.5 ppm of a polyp-

(3)

phosphate anti-scalant (SHMP) results in an increase

where E is the crystallization reaction activation energy in the induction period and suppression of further layer

and R is the universal gas constant. growth after an asymptotic thickness is reached.

Data on the kinetic coefficient are scant, but since

Metal Impurities

values of kD can be readily estimated, it is possible to

A literature review focusing on the effect of Zn+2

evaluate an upper limit of the scaling rate from the exp-

ions on CaCO3 precipitation provides credible evidence

pression:

that Zn+2 and other ions can generate a useful scale supp-

(4) pression effect. The experimental findings of various

researchers (e.g., refs 9–11) indicate that various metal

The mass transfer coefficient kD for typical flow cond-

ions can exert retarding effects on nucleation and crystal

ditions in spiral-wound modules is of the order of 10–5

growth and can also affect the crystal habit. It is evident

to 10–6 m/s. With this mass transport coefficient and a

that both Zn+2 and Cu+2 ions can exert an inhibitory act-

scale density of about 2000 kg/m3, the maximum posss

tion on scale formation and that their full potential for

sible scaling rate that can occur with a supersaturation

scale suppression has been very scantily explored. The

driving force of ∆C ppm is:

(5)

with M having a value in the range of 0.04 to 0.4.

Impurity Effects

A tenacious well-bonded scale deposit can form only

when the water precipitates a pure crystalline deposit.

Fortunately, most practical systems contain impurities

to some extent. Impurities tend to adsorb on active sites

of a crystallizing deposit and interfere with the format-

tion of a well-ordered solid structure. Such processes

can induce a significant decrease in both the nucleation

rate and the crystal growth rate, often accompanied by

a change in precipitate morphology. Deposits formed

from mixed salts and in the presence of impurities have Fig. 2. Asymptotic fouling induced by the presence of an anti-

a weakened adherence and the net scaling rate will be scalant.8

Hasson and Semiat / Scale Control

100

Ion exchange columns can readily remove scale-

forming ions. However, attempts to develop an ion

exchange process based on cheap regenerating chemic-

cals have so far been unsuccessful.13 Lime softening

processes, which are widely used for hardness removal

in water supply systems, are too expensive for desalin-

nation processes. Water hardness can also be reduced

by nanofiltration (NF) membranes. Because of their

negative charge, NF membranes preferentially retain

divalent ions and thus reduce the concentration of the

ions involved in the precipitation of CaCO3 and CaSO4.

Nanofiltration softening is constrained by economic

considerations, but has potential in integrated memb-

brane systems.

Electrolytic scale removal is a relatively new

technique4,14,15 that is mainly used for Ca hardness rem-

Fig. 3. Scale inhibition in a membrane system by low zinc ion moval from cooling tower waters. An electrolytic scale

dosage. Lp = membrane permeability; Lpo = initial membrane removal device consists of a stainless steel vessel acting

permeability; Tb = bulk temperature; TA = total alkalinity; as a cathode and a central rod acting as an anode. The

Qconc = concentrate flow rate. scale removal principle of the electrolytic technique is

the generation of a high pH environment around the

utilization of Zn+2 ions appears to be preferable to that of

cathode. Scale deposition is due to the alkaline environm-

Cu+2 ions, as the permissible Zn+2 level in drinking water

ment created by the cathodic reactions:

is 5 mg/L compared to 1 mg/L for Cu+2.12

Figure 3 shows results of exploratory experiments 2 H2O + 2e– ⇑ + 2OH– (6)

undertaken with scaling waters at two supersaturation

levels (LSI = 1.1 and 1.5) in a recycling membrane syst- O2 + 2H2O + 4e– ⇒ 4OH– (7)

tem. It is seen that the permeate flow decline of 25 to

The hydroxyl ions promote removal of the calcium

30% observed in 16 h in the untreated water could be

hardness by the precipitation of CaCO3 according to the

arrested by a dosage of 2 ppm Zn+2. We are studying the

reaction:

possibility of replacing all or part of the currently used

organic anti-scalants by trace Zn ion dosage. Ca2+ + HCO3– + OH– ⇒ CaCO3 ⇓ + H2O (8)

The scale precipitating on the cathodic walls of the

Scale Control Techniques electrolytic system is removed either by periodic piston

The severity of a potential scaling difficulty in a des- scraping or by periodic charge reversal, which loosens

salination process depends of course on the nature and the adhering scale deposit.

concentration of the scaling species present in the raw Electrolytic scale removal has been scantily treated

feed water. The main scale control strategies are:3,4 in the literature. Very little quantitative information is

available on mechanisms of the electrode reactions and

• Removal or reduction of scale-forming species;

on the influence of geometrical and hydrodynamic par-

• Inhibition of scale deposition by dosage of anti-

rameters.

scalants;

Figure 4 shows the effect of flow rate on scale rem-

• Controlled scale deposition with periodic cleaning

moval by deposition on the cathodic surface under lamin-

schedules.

nar flow conditions. The data show that the scaling rate

Prevention of Supersaturation Conditions increases roughly with Re1/3. As previously noted, the

The most effective way for eliminating a scaling mass transfer coefficient in laminar flow also increases

problem is by water treatment measures designed to with Re1/3, indicating that scale removal in an electrol-

eliminate the scaling constituents present in the feed lytic cell is mass transfer controlled.

water. For instance, acidifying the raw water and degass- The specific energy data displayed in Fig. 5 show that

sing the CO2 released by carbonate decomposition will the electrical energy consumption (kWh per kg CaCO3)

prevent alkaline scale formation. This technique is often in electrolytic scale removal can be significantly red-

adopted but usually in combination with anti-scalant duced by operating at high Reynolds numbers. Another

dosage at an economically optimized pH level. important parameter is the solution conductivity. Energy

Israel Journal of Chemistry 46 2006

101

Fig. 4. Effect of the Reynolds number on the scale removal Fig. 5. Effect of the flow rate on the specific energy consumpt-

rate in an electrolytic cell. tion in electrolytic scale removal

consumption is reduced at high salinities. The energy tal growth stage, the inhibitor molecules can retard the

consumption in experiments carried out with solutions growth process in several ways. If the ions of the inhibi-

simulating desalination plant concentrates was as low as iting molecule are small and are preferentially adsorbed

2.2 kWh/kg CaCO3. on active sites, a relatively small crystal surface covera-

The exploratory data so far obtained indicate that age is sufficient for effective retardation of the growth

the electrolytic method holds considerable promise for process. Most inhibitor compounds possess large ions,

beneficial integration in reverse osmosis desalination and effective crystal growth retardation probably occurs

processes. through relatively large crystal surface coverage.

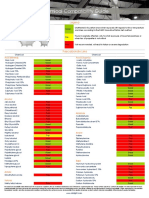

Suppression of Scale Precipitation by Anti-scalants Anti-scalant compounds

The most widely used technique for scale control is Commonly used anti-scalants are derived from three

by dosage of an anti-scalant. This technique is cost eff- chemical families: condensed polyphosphates, organop-

fective because in many cases scaling can be suppressed phosphonates, and polyelectrolytes. Polyphosphates,

with only a few ppm of the anti-scalant, typically less the cheapest anti-scalants, can display effective thresho-

than 10 ppm. Since such low dosages are only a small old effects as well as dispersive and corrosion protection

fraction of the stoichiometric concentration of the aff- properties. Organophosphonates are superior to the ino-

fected species, the inhibition phenomena do not involve organic polyphosphates in their marked thermal and hyd-

chemical reactions. The inhibition is by physical rather drolytic stabilities over a wide range of pH and temperat-

than chemical mechanisms and involves adsorption ture conditions. Effective polyelectrolyte inhibitors are

processes.2, 16 mostly polycarboxylic acids. Some of the more familiar

polycarboxylates are polyacrylic acid, polymethacrylic

Inhibition mechanisms acid, and polymaleic acid. A noteworthy development

Adsorption of the inhibitor on the crystallization is the trend for designing copolymers having different

surface acts to delay nucleation, reduce the precipitat- functionalities to achieve specific goals and for blendi-

tion rate, and distort the crystal structure such that the ing different polymers so as to extend their anti-scaling

deposit tenacity to the flow surface is weakened, as was capabilities.2

illustrated in Fig. 2. By adsorbing on embryos, inhibitor Numerous studies have shown that all inhibitor polym-

molecules prohibit their growth beyond the critical size mers are effective only within a relatively narrow range

and thereby retard the rate of nucleation. Since low-mol- of molecular weights, typically around 1000 to 5000 Da.

lecular-weight inhibitor molecules are more mobile, the Howie-Meyers et al.17 investigated the role of calcium

extension of the induction period is more pronounced and polymer MW on the crystal growth inhibition of

with the lower molecular weight molecules. In the cryst- hydroxyapatite by polycarboxylates. Maximum inhibit-

Hasson and Semiat / Scale Control

102

tion activity occurred in a narrow MW range—around excellent service for most but not all scaling species.

1000–2000 Da for acrylate–maleate copolymers and The striking inhibitory effectiveness that an anti-scalant

around 5000–6000 Da for polyacrylates. can provide is illustrated in Fig. 6. The figure shows

It is presumed that the size of the inhibiting molecule the change with time of the ion concentration product

should be sufficiently large so that when adsorbed on the .

[Ca2+] [CO32–] of a highly supersaturated CaCO3 solut-

scaling species, it occupies a sufficient area for exerting tion, simulating the concentrate composition of the Gat

its effects, but it should not be so large that it lacks suff- desalination pilot plant (near Kiryat Gat, Israel) at 88%

ficient mobility and that its adsorption rate is too slow. recovery. In this beaker experiment, the solution had an

A low-molecular-weight fraction of a given inhibitor initial LSI of 2.5 and was dosed with the anti-scalant

is adsorbed on the scaling species more rapidly than a Permatreat 191 at three concentration levels: 5, 10, and

high-molecular-weight fraction, but the adsorbed quant- 25 ppm. The high stability imparted to this highly sup-

tity is larger with the high-molecular-weight fraction. persaturated solution is reflected by the extremely long

Adsorption increases with the degree of dissociation induction times, exceeding two months, required for

of phosphonic and polycarboxylic acids. The enhanced reaching the equilibrium value of the calcite solubility

scale suppression activity encountered at high pH is att- product.

tributed to the increase in the degree of deprotonation

Anti-scalant problems

with increasing pH.

Some of the problems associated with the use of anti-

Anti-scalant performance scalants are that they can induce fouling under certain

Since the fundamentals of inhibition mechanisms, conditions. For instance, in the presence of calcium,

particularly from their quantitative aspects, are poorly calcium phosphonates can precipitate.23 Virtually all

understood, the effects of operating parameters on inh- anti-scalants tend to promote biofouling in the presence

hibition effectiveness are largely unpredictable. The of assimilable organic carbon.24

useful guidance available from anti-scalant companies, Currently, the major uncertainties are in the control

based on service experience of their products, must of silica scales and calcium phosphates by available

often be complemented by extensive field tests. Labor- anti-scalants. The difficulty in inhibiting silica scales

ratory procedures we have developed can serve to red- stems from its protean nature. We have applied a fundam-

duce the laborious and costly efforts involved in field mentally based procedure for assessing the relative eff-

tests.7,18–22 fectiveness of various silica anti-scalants at comparable

When properly applied, anti-scalants can provide supersaturation conditions prevailing on the membrane

surface.22

Comparative tests of four commercial anti-scalants

tested, dosed at recommended dosage levels, revealed

that there was no significant difference in their inhibit-

tory effectiveness. Data similar to those illustrated in

Figs. 7 and 8 indicated that the mitigating effect prov-

vided by all anti-scalants tested was to increase the

threshold limit for the onset of scaling from a membrane

surface supersaturation level of 1.7–1.9 in the absence

of an anti-scalant, to the level of 2.1–2.3 in the presence

of the anti-scalant. In all cases, the degree of inhibition

achieved was below that indicated in the commercial

literature. Scale precipitation occurred below the limiti-

ing solution bulk concentration of 250–300 ppm silica

suggested in the product manuals.

The calcium phosphate scaling difficulty imposes a

severe limitation on water recovery from wastewaters.

The increasing water scarcity can be alleviated by usi-

ing treated sewage effluents for irrigation purposes.

Secondary treated wastewater purified by an MF/UF

(microfiltration/ultrafiltration) process has restricted irr-

Fig. 6. Illustration of the stability imparted by an anti-scalant rigation usages. Unrestricted irrigation usage requires

to a highly supersaturated CaCO3 solution. further purification by an RO process.

Israel Journal of Chemistry 46 2006

Au: Need permission for figs 7 and 8. 103

EXP. No. Ca+2 ppm PO4–3 ppm Cl– ppm log(s/s)bulk

60 321 26.2 587 1.48

61 324 26.6 587 1.46

Fig. 7. Permeability decline as a function of water recovery.22 62 318 27.2 587 1.49

Fig. 9. Flux decline as function of time in the presence of a

calcium-phosphate anti-scalant. Ex60 = experiment 60; log(s/s

wall) = log of the supersaturation ratio at the wall.

difficulty. Figure 9 shows the flux decline occurring in

the presence of an anti-scalant recommended by a well-

known company. Scale prevention under such situat-

tions calls for a lowered pH and a reduction in permeate

flux.

Concluding remarks

The scaling problem poses a unique challenge in desalin-

nation, due to the severe economic constraints imposed

by the very low cost of the water-product. Scale control

has been and continues to be one of the overriding cons-

siderations in the development of improved desalination

processes. Further reductions in the cost of desalinated

Fig. 8. Silica supersaturation level on the membrane.22 water can be expected from R & D efforts oriented tow-

wards better understanding of currently practiced scale

control techniques (notably the anti-scalant dosage

method) and by the development of novel techniques

Since wastewaters usually contain phosphate and (such as the electrolytic scale removal method).

calcium ions, they are prone to precipitate sparingly-

soluble calcium phosphate salts. At the present time

there are no known reliable anti-scalants that can inhibit References and notes

calcium phosphate scale deposition. The literature ind- (1) Hasson, D. Precipitation Fouling—A Review. In Foulis

dicates increasing efforts of anti-scalant manufacturers ing of Heat Transfer Equipment; Somerscales, E.F.C.;

Knudsen, J.G., Eds.; Hemisphere Publishing Corporat-

to develop more effective calcium phosphate inhibit-

tion: Bristol, PA, 1981; pp 527–568.

tors.25,26 (2) Hasson, D. In Understanding Heat Exchanger Fouling

Experiments carried out with simple model solut- and its Mitigation; Bott, T.R. Ed.; Begell House: New

tions containing only CaCl2 and KH2PO4 at a NaOH- York, 1999; pp 67–90.

controlled pH illustrate the calcium phosphate scaling (3) Hasson, D. In Scaling in Seawater Desalination; Glade,

Hasson and Semiat / Scale Control

104

H.; Ulrich, J., Eds.; Shaker Verlag: Aachen, 2001; pp Electrochemical System for Scale Precipitation and

49–68. Removal; POB 13390, Netanya, Israel.

(4) Sorber, C.A.; Valenzuela, S.R. Evaluation of an Elects (16) Sangwall, K. Prog. Cryst. Growth Charact. Mater.

trolytic Water Conditioning Device for the Elimination 1996, 32, 3–43.

of Water-Formed Scale Deposits in Domestic Water (17) Howie-Meyers, C.L.; Yu, K.; Eilliott, D.; Vasudevan,

Systems; Tech. Rep.—Univ. Texas, Austin, Cent. Res. T.; Aronson, M.P.; Ananthapadmanabhan, K.P.; Somas-

Water Resources, 1982, CRWR 186. sundaran, P. In Mineral Scale Formation and Inhibits

(5) Perez, L.A. In Calcium Phosphates in Biological and tion; Amjad, Z., Ed.; Plenum press: New York, 1995;

Industrial Systems; Amjad, Z., Ed.; Kluwer Academic: pp 169–182.

Norwell, MA, 1998; pp 395–415. (18) Semiat, R.; Hasson, D.; Bramson, D. Proceedings of

(6) Mullin, J.W. Crystallization. 3rd ed.; Butterworth- AWWA Membrane Technology Conference; New Orl-

Heinemann: Oxford, 1997. leans, Louisiana, 1997; pp 1013–1027.

(7) Hasson, D.; Drak, A.; Semiat, R. Desalination 2003, (19) Drak, A.; Glucina, K.; Busch, M.; Hasson, D.; Laine,

157, 193–207. J.M.; Semiat, R. Desalination 2000, 132, 233–242.

(8) Hasson, D.; Semiat, R.; Bramson, D.; Busch, M.; Lim- (20) Hasson, D.; Drak, A.; Semiat, R. Desalination 2001,

moni-Relis, B. Desalination 1998, 118, 285–296. 139, 73–81.

(9) Wada, N.; Yamashita, K.; Umegaki, T. J. Cryst. Growth (21) Semiat, R.; Sutzcover, I.; Hasson, D. Desalination

1995, 148, 297–304. 2001, 140, 181–193.

(10) Pernot, B.; Euvrard, M.; Remy, F.; Simon, P.J. Water (22) Semiat, R.; Sutzkover, I.; Hasson, D. Desalination

SRT—Aqua 1999, 48 (1), 16–23. 2003, 159, 11–19.

(11) Abouali, E.; Jean, O.; Lédion, J. J. Européen d’Hydro (23) Jasbir, S.G. Desalination 1999, 124, 43–50.

logie 1996, 27, 109–126. (24) Vrouwenvelder, J.S.; Manolarakis, S.A.; Veenendaal, H.

(12) De Juane, J. Drinking Water Quality, 2nd ed.; John R.; van der Kooij, D. Desalination 2000, 132, 1–10.

Wiley: New York, 1997. (25) Betz, G.E. Betz Dearborn Australia Pty. Kwinana Water

(13) Harris, A. In Desalination Technology: Developments Recycling Project: Solutions for Biofouling, Organic

and Practice; Porteous, A., Ed.; Applied Science Publ.: Fouling and Calcium Phosphate Scaling on Wastewater

1983, pp 31–55. Recycling Membrane Plants. Report GENTD001, July

(14) Nair, M.K.V.; Misra, B.M. Desalination 1978, 27, 2002.

59–64. (26) Hendel, R.; Bandick, K. IDA Desalination Conference;

(15) Elgressy Engineering Services, Commercial Catalogue. Bahamas, September 2003, Paper BAH03-091.

Israel Journal of Chemistry 46 2006

You might also like

- Solubility Curve WorksheetDocument3 pagesSolubility Curve Worksheetapi-29824787350% (2)

- Chemical Engineering Calculations 1Document12 pagesChemical Engineering Calculations 1Kristien Mckay100% (2)

- 5% Hydrochloric Acid MsdsDocument7 pages5% Hydrochloric Acid MsdsNgoc Anh NguyenNo ratings yet

- Effect of Ore Size and Heap Porosity On Capillary Process Inside Leaching HeapDocument7 pagesEffect of Ore Size and Heap Porosity On Capillary Process Inside Leaching HeapPatricio Saldaña MirandaNo ratings yet

- ERT 313 Crystallization - 0Document28 pagesERT 313 Crystallization - 0Ambar AmKaNo ratings yet

- MBM362 3 PDFDocument17 pagesMBM362 3 PDFzeybek_144649143No ratings yet

- Isotope Effects Reveal The Template Influence On The Crystal Growth of A Metal-Halide NetworkDocument11 pagesIsotope Effects Reveal The Template Influence On The Crystal Growth of A Metal-Halide NetworkGold MochaNo ratings yet

- Chapter 8 CrystallizationDocument31 pagesChapter 8 CrystallizationarufatoNo ratings yet

- Lecture 13q 2Document46 pagesLecture 13q 2Aahil AleemNo ratings yet

- Nanowires and NanorodsDocument9 pagesNanowires and Nanorodsprakush_prakushNo ratings yet

- Evaporation With Sodium Chloride Crystallization in A Capillary TubeDocument10 pagesEvaporation With Sodium Chloride Crystallization in A Capillary TubeHamza FerkousNo ratings yet

- Soil Pulverization and Lime Migration Soil-Lime StabilizationDocument24 pagesSoil Pulverization and Lime Migration Soil-Lime StabilizationWAHEED JUBRILNo ratings yet

- Nanoparticles LecturesDocument67 pagesNanoparticles LecturesSunny RaoNo ratings yet

- Crystalization TypesDocument44 pagesCrystalization TypesLuis Olmos50% (2)

- Fluent UseCFDtoimprovecrystallizationDocument5 pagesFluent UseCFDtoimprovecrystallizationSi HamNo ratings yet

- 2008 LibDocument17 pages2008 LibTest Test2No ratings yet

- Reservoir ChachteristicDocument97 pagesReservoir ChachteristicTarek GanatNo ratings yet

- Sedimentation Is The Tendency ForDocument2 pagesSedimentation Is The Tendency ForRavi ShankarNo ratings yet

- 1 s2.0 S0894177715003441 MainDocument17 pages1 s2.0 S0894177715003441 MainTU NGO THIENNo ratings yet

- Mse121l TEMDocument12 pagesMse121l TEMstan_chunyunNo ratings yet

- SC Heuer Man 1990Document10 pagesSC Heuer Man 1990Jesus AlbertoNo ratings yet

- Modeling of Crystallization Processes FinalDocument18 pagesModeling of Crystallization Processes FinalSunil HansdaNo ratings yet

- Calcite Precipitation Instability UnderDocument13 pagesCalcite Precipitation Instability UnderEng-Mohamed HashiNo ratings yet

- 2016-How Surfactants Control Crystal Growth of Nanomaterials (Review)Document30 pages2016-How Surfactants Control Crystal Growth of Nanomaterials (Review)Mua ban linh tinhNo ratings yet

- C 13Document6 pagesC 13Phuppud Sii PutrysahidahNo ratings yet

- Mass Transfer Operation 1 (2150501) : Crystallization Concept, Techniques and ProcessesDocument18 pagesMass Transfer Operation 1 (2150501) : Crystallization Concept, Techniques and Processesvashu patelNo ratings yet

- Corrosion Inhibitors in The Oil and Gas Industry - 2020 - Saji - Antiscalants and Their Compatibility With CorrosionDocument23 pagesCorrosion Inhibitors in The Oil and Gas Industry - 2020 - Saji - Antiscalants and Their Compatibility With CorrosionNantawat KaekratokeNo ratings yet

- Journal of Membrane Science: Arezou Anvari, Kartikeya M. Kekre, Avner RonenDocument12 pagesJournal of Membrane Science: Arezou Anvari, Kartikeya M. Kekre, Avner RonenSuman DasNo ratings yet

- J.hydromet.2007.07.016Document10 pagesJ.hydromet.2007.07.016Apri LioNo ratings yet

- 1988 XiaDocument16 pages1988 XiaTest Test2No ratings yet

- Comparison of The Rotating Cylinder and Pipe FlowDocument16 pagesComparison of The Rotating Cylinder and Pipe FlowCalberttNo ratings yet

- PHCM223 - Lecture 11 - SS16 - 516Document31 pagesPHCM223 - Lecture 11 - SS16 - 516erorcrept100% (1)

- Carbonate Acidizing - A Review On Influencing Parameters of Wormholes Formation (2023)Document17 pagesCarbonate Acidizing - A Review On Influencing Parameters of Wormholes Formation (2023)Giovanna MassardiNo ratings yet

- General Dictionary of GeologyDocument20 pagesGeneral Dictionary of GeologySristi AgrawalNo ratings yet

- Chm221 Chapter 6Document31 pagesChm221 Chapter 6Badrudin JundailiNo ratings yet

- Answer 2Document31 pagesAnswer 2petitNo ratings yet

- SPE 16232 Understanding Formation Damage Processes: An Essential Ingredient For Improved Measurement and Interpretation of Relative Permeability DataDocument25 pagesSPE 16232 Understanding Formation Damage Processes: An Essential Ingredient For Improved Measurement and Interpretation of Relative Permeability DataAndres CaNo ratings yet

- Crystallization EASILY DESCRIBEDDocument4 pagesCrystallization EASILY DESCRIBEDFrancess Liene YagoNo ratings yet

- Factors Affecting Ore LeachingDocument9 pagesFactors Affecting Ore LeachingRodrigo GarcíaNo ratings yet

- PHT 432) ) Industrial Pharmacy: Dr. Fars AlanaziDocument48 pagesPHT 432) ) Industrial Pharmacy: Dr. Fars AlanaziMelisa JuradoNo ratings yet

- Current Topics Crystal GrowthDocument9 pagesCurrent Topics Crystal Growthmarcio_limaNo ratings yet

- Module 3Document10 pagesModule 3MelliyNo ratings yet

- 2004 Mathematical Modeling and Kinetic ParameterDocument11 pages2004 Mathematical Modeling and Kinetic ParameterRIcardoRaveloNo ratings yet

- Sca2023 025Document12 pagesSca2023 025kno.bodee.homeNo ratings yet

- Capillary Imbibition of Surfactant Solutions in Porous Media and Thin Capillaries: Partial Wetting CaseDocument7 pagesCapillary Imbibition of Surfactant Solutions in Porous Media and Thin Capillaries: Partial Wetting CasePatrick BelugaNo ratings yet

- Book1 PDFDocument18 pagesBook1 PDFDr . Sudipto BanerjeeNo ratings yet

- E Wisniewski: Sedimentation Tank Design For Rural Communities in The Hilly Regions of NepalDocument23 pagesE Wisniewski: Sedimentation Tank Design For Rural Communities in The Hilly Regions of NepalEshe2aNo ratings yet

- Salt Weathering Distress On Concrete by SulfatesDocument35 pagesSalt Weathering Distress On Concrete by SulfatesfaisalmfNo ratings yet

- Modelling The Overlap of Nucleation, Growth and Coarsening During PrecipitationDocument8 pagesModelling The Overlap of Nucleation, Growth and Coarsening During Precipitation奇峰束No ratings yet

- Balakotaiah e Kalia2009Document15 pagesBalakotaiah e Kalia2009David VieiraNo ratings yet

- Solvate: Extremely Pure FormDocument22 pagesSolvate: Extremely Pure FormNayan HalderNo ratings yet

- Facts at Your Fingertips-200706-Controlling Crystal GrowthDocument1 pageFacts at Your Fingertips-200706-Controlling Crystal Growthonizuka-t2263No ratings yet

- 16 Gourdon F PDFDocument8 pages16 Gourdon F PDFJoão AlvesNo ratings yet

- Deposition & Planarization: EE 311 Notes Prof SaraswatDocument28 pagesDeposition & Planarization: EE 311 Notes Prof SaraswatRIZA MELİH KÖKSALLINo ratings yet

- Fluid Partical Non Catalytic ReactionsDocument22 pagesFluid Partical Non Catalytic Reactionsعوض أمحمدNo ratings yet

- CrystallizationDocument29 pagesCrystallizationYawar QureshiNo ratings yet

- 2014 Mohammad Parvazdavani, Mohsen Masihi, Mohammad Hossein Ghazanfari, MonitoringDocument10 pages2014 Mohammad Parvazdavani, Mohsen Masihi, Mohammad Hossein Ghazanfari, Monitoring10_DAVID_10No ratings yet

- Gravimetric Methods of AnalysisDocument13 pagesGravimetric Methods of AnalysiscmarioagudeloNo ratings yet

- 2007 - T.G. Theofanous - The Physics of Aerobreakup. IV. Strain-Thickening LiquidsDocument11 pages2007 - T.G. Theofanous - The Physics of Aerobreakup. IV. Strain-Thickening LiquidsSurendra RatnuNo ratings yet

- Deep Marine Systems: Processes, Deposits, Environments, Tectonics and SedimentationFrom EverandDeep Marine Systems: Processes, Deposits, Environments, Tectonics and SedimentationNo ratings yet

- Lithospheric DiscontinuitiesFrom EverandLithospheric DiscontinuitiesHuaiyu YuanNo ratings yet

- Performance Evaluation of Technos Cleaning BallsDocument25 pagesPerformance Evaluation of Technos Cleaning BallsinejattNo ratings yet

- Lebkuchen Recipe - BBC Good FoodDocument3 pagesLebkuchen Recipe - BBC Good FoodinejattNo ratings yet

- Effect of Mixed Corrosion Inhibitors in Cooling Water SystemDocument12 pagesEffect of Mixed Corrosion Inhibitors in Cooling Water SysteminejattNo ratings yet

- Early Stages of Zinc Corrosion and Runoff Process Induced by Caribbean Sea WaterDocument10 pagesEarly Stages of Zinc Corrosion and Runoff Process Induced by Caribbean Sea WaterinejattNo ratings yet

- The Effect of PH Level On Corrosion Rate of Aluminium and CopperDocument4 pagesThe Effect of PH Level On Corrosion Rate of Aluminium and CopperinejattNo ratings yet

- Avista TB Scale Inhibitors RO NFDocument4 pagesAvista TB Scale Inhibitors RO NFinejattNo ratings yet

- Assessment of Calculation Methods For Calcium Carbonate Saturation in Drinking Water For DIN 38404-10 ComplianceDocument10 pagesAssessment of Calculation Methods For Calcium Carbonate Saturation in Drinking Water For DIN 38404-10 ComplianceinejattNo ratings yet

- BBC - GCSE Bitesize - Generating ElectricityDocument5 pagesBBC - GCSE Bitesize - Generating ElectricityinejattNo ratings yet

- Essential Users Guide Complete Booklet Rev 2015Document32 pagesEssential Users Guide Complete Booklet Rev 2015inejatt100% (1)

- Legionnaires' Disease. The Control of Legionella Bacteria in Water SystemsDocument2 pagesLegionnaires' Disease. The Control of Legionella Bacteria in Water SystemsinejattNo ratings yet

- BBC - GCSE Bitesize - Types of RadiationDocument2 pagesBBC - GCSE Bitesize - Types of RadiationinejattNo ratings yet

- History - KelvionDocument7 pagesHistory - KelvioninejattNo ratings yet

- BBC - GCSE Bitesize - Heat Transfer and EfficiencyDocument13 pagesBBC - GCSE Bitesize - Heat Transfer and EfficiencyinejattNo ratings yet

- Hydration of AminesDocument4 pagesHydration of AminesinejattNo ratings yet

- Acetone Technical DocumentsDocument3 pagesAcetone Technical DocumentsinejattNo ratings yet

- Chi To SanDocument16 pagesChi To San638786No ratings yet

- JSA Example Final Year ProjectDocument33 pagesJSA Example Final Year ProjectnasuhaNo ratings yet

- Chemistry Project: Done by - Viral, Manan, Kush, Naitik, Parthiv, VirajDocument12 pagesChemistry Project: Done by - Viral, Manan, Kush, Naitik, Parthiv, VirajViraj PatelNo ratings yet

- Chem 33.1 Exp 1 Lab ReportDocument4 pagesChem 33.1 Exp 1 Lab ReportLucile BronzalNo ratings yet

- UntitledDocument368 pagesUntitledAgus TriyonoNo ratings yet

- GCSE Chemistry SpecDocument74 pagesGCSE Chemistry SpecAli Hasan MaherNo ratings yet

- Safety Data Sheet: Choline Chloride Solution 75%Document10 pagesSafety Data Sheet: Choline Chloride Solution 75%Daniel DíazNo ratings yet

- Material Safety Data Sheet: Hydrochloric Acid, 37% MSDSDocument8 pagesMaterial Safety Data Sheet: Hydrochloric Acid, 37% MSDSMuhNo ratings yet

- Gas Turbine Cleaning ChemicalsDocument9 pagesGas Turbine Cleaning ChemicalssarifinNo ratings yet

- Activity 7 LIPIDS PDFDocument3 pagesActivity 7 LIPIDS PDFPrincess Pilove GawongnaNo ratings yet

- Full download Solution Manual for the Law and Business Administration in Canada Plus Companion Website Without Pearson Etext Package 14 e j e Smyth Dan Soberman Alex Easson Shelley Mcgill pdf full chapterDocument35 pagesFull download Solution Manual for the Law and Business Administration in Canada Plus Companion Website Without Pearson Etext Package 14 e j e Smyth Dan Soberman Alex Easson Shelley Mcgill pdf full chapterimplumededgebonea3ny100% (23)

- Report CapsicumDocument105 pagesReport CapsicumRina WijayantiNo ratings yet

- Crystallization: MR Amar M. Raval Asst Professor Bmcper ModasaDocument39 pagesCrystallization: MR Amar M. Raval Asst Professor Bmcper Modasasowmya bandiNo ratings yet

- General Chemistry 1: Quarter 1 - Module 1Document21 pagesGeneral Chemistry 1: Quarter 1 - Module 1Kristine Joy MirabelNo ratings yet

- Dairy Products-The Calcium Challenge Jun02Document4 pagesDairy Products-The Calcium Challenge Jun02tarekscribdNo ratings yet

- EOC c20 Ionic EquilibriaDocument3 pagesEOC c20 Ionic EquilibriaKenneth KnightNo ratings yet

- Pharmaceutical Solutions For Oral Administration-2 PDFDocument31 pagesPharmaceutical Solutions For Oral Administration-2 PDFHanaa Abo Sweirh100% (1)

- Dialight Chemical CompatibilityDocument16 pagesDialight Chemical CompatibilityJuan AcuñaNo ratings yet

- Hydrochloric Acid VS: Methyl Red Solution Dissolve 50 MG ofDocument3 pagesHydrochloric Acid VS: Methyl Red Solution Dissolve 50 MG ofrina mediana100% (1)

- 4ch1 2c Que 20230119Document28 pages4ch1 2c Que 20230119LAITH ROBERT WADIE SWAIDANNo ratings yet

- Cooling Water Treatment Chlorination WorkoutDocument3 pagesCooling Water Treatment Chlorination WorkoutMohsin ModiNo ratings yet

- To The Student:: Box 42191, Lubbock, TX 79409 (806) 742-7200 FAX (806) 742-7222 WWW - Ode.ttu - EduDocument7 pagesTo The Student:: Box 42191, Lubbock, TX 79409 (806) 742-7200 FAX (806) 742-7222 WWW - Ode.ttu - EduDaynaLawsonGilmoreNo ratings yet

- An Improved Model For The Calculation of CO Solubility in Aqueous Solutions Containing Na, K, Ca, MG, CL, and SODocument9 pagesAn Improved Model For The Calculation of CO Solubility in Aqueous Solutions Containing Na, K, Ca, MG, CL, and SONumitor Tor Aten Jil100% (1)

- DissolvingDocument12 pagesDissolvingЈован ПродановићNo ratings yet

- Indian Standard: Methods of Sampling and Test For Resins For PaintsDocument10 pagesIndian Standard: Methods of Sampling and Test For Resins For PaintsB Kumar BNo ratings yet

- Fehling A and BDocument5 pagesFehling A and BXiao MieNo ratings yet

- Cover Geothermal Fluids (Introduction)Document8 pagesCover Geothermal Fluids (Introduction)Dhany RizkyNo ratings yet