Professional Documents

Culture Documents

Lifting Plan PDF

Lifting Plan PDF

Uploaded by

frog150 ratings0% found this document useful (0 votes)

78 views12 pagesOriginal Title

LIFTING PLAN.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

78 views12 pagesLifting Plan PDF

Lifting Plan PDF

Uploaded by

frog15Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 12

Revision: 0

“0" ANMOL PILING « sText srrucrurEsLLc, bate 1410-2019

v Page Page 1of 12

LIFTING PLAN FOR KING POST

SHORING

PROJECT NAME:

HUNGARIAN NATIONAL PAVILION

EXPO 2020

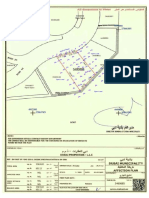

LOCATION:

PLOT NO.: C.47 MADINAT AL MATAAR, DUBAI - U.A.E.

CLIENT:

M/s MAGYAR TURISZTIKAI UGYNOKSEG

PROJECT REFERENCE : P-136/19/DXB

PREPARED BY ‘APPROVED BY

ae: | ARVE CRUZ name: | ARve Ceuz

DESIGNATION: |-TEERINICAL MANGER DESIGNATION: | APPONWTED LIFT PERS

Paes} r10 2015 Me pate: | 161-2015

«(po mv

Re ROR 3) oe

MODIFICATION

ANMOL Revision: 0

= | ANMOL PILING esteex structurEsitc vate; 1410-2019

7 Page + Page 2 of 12

INDEX

1. Lifting Plan for King Post Shoring

2. Specification of Piling Rig Machine

Lifting Schedule

4. Quality Control

5. Attachment

=

ANMOL Revision: 0

‘= ANMOL PILING ssreetstRUCTURESLLC.| pate: 14-10-2019

¥ Page Page 3 of 12

1.0 LIFTING PLAN FOR KING POST SHORING

Rig Operator _: Rambeer Shish Paljat ~ Certified Drill Rig Operator

{Star Safety & Security Consultancy)

Lifting Supervisor: Barkat Ali Khan Shahid Ali - Heavy Tractor License (RTA)

- Certified Crawler Crane Operator

(Star Safety & Security Consultancy)

Lifting Equipment _: MAIT HR 180 Piling Rig Machine

spected by Star Safety & Security Consultancy

Inspection Dated : 22-06-2019 and Inspection Due Date is 21-06-2020

Lifting Accessories. = Chains and Slings

Using the rig machine pile hoist rope the steel beam shall be lifted into @ near vertical position and.

placed to the pre-bored shaft by minimum distortion,

2.0 SPECIFICATION OF PILING RIG MACHINE

Maximum Height: 20.50mm from ground

‘Maximum width: 4000mm wide

Aunillary Winch: 80 KN. or 8.0 ton Aunillary Hoist Rope Maximum Pull Force

3.0 LIFTING SCHEDULE

SCHEDULE OF STANDARD LIFTS

DEscRIPTION OF | APROX | LOAD merwooor | CNTF | urring poits/ on

LoaD ftom] | CHARACTERISTIC | LIFTING greumy | METHOD OF SLINGING

Steel Beams UB Rig

0.888 | steel Beam hoisted by Piling Rig using

457x191074 ‘ Lifting point on | Central iY

a ton, | L=32.00m ea lifting shackles and sling

Steel Beams UB Rig ,

457x199 feral eoee Lifting point on | central_| Posted BY Piling Rig using

ke/m. = |e top (hole on web) S al

Rig 7

35107. | « attength = | Single choke for | 2 leg chains (horizontal lift by

bring Auger | oom | SRHalLensth= | vericatttt to. | Cental | Excavator) Wie Sling by

diameter ue connect auger to Piling Rig,

rig

cylindrical, with | Rig

35ton. | pairoflifting | Single choke for

Wego) 600mm | holes for lifting | vertical lift to Central ‘Wire Sling by Piling Rig

een) diameter | shackles and connect auger to

slings tig |

ANMOL ne °

= | ANMOL PILING asreet stRucTURESLLC,| pate 14.10.2019

¥ Page Page 4of 12

4.0 QUALITY CONTROL

QUALITY CONTROL

SR. 7

Na ACTIVES RESPONSIBILITY

1 | BorEHoLe

The steel beam and pile location willbe marked by a steel pin

44

driven into the ground, using co-ordinate system. uel

checking of steel beam ‘center to cen

fe ore cca en coe Site Engineer/ Foreman

‘Two reference pins willbe driven into the ground to subtend an

| angle of approximately 80° with the setting out pin as the origin. Bs

13 | the pins willl be accurately fixed at approximately 2 meters from Riasse/tocernan)

the setting out pin,

‘The rig will set up over the pin and the mast ofthe machine

14. | checked for vertically using a hand held spirit level. Verticality nee

will be checked during the drilling operation and final check will es

be carried out ater reaching the final depth.

Installation of temporary casing, min 2.50m. to length concentric

15 | tothe steel beam center. Bases

1.6 | Checking of top level of casing. site Engineer

1.7. Boring will then continue up to required level Site Engineer/ Foreman

xa | Messurng te dent orboreungan end weigted messing | Se egner/ Foreman

tape.

2_| INSTALLATION oF STEEL BEAM |

a | The steel beam willbe lifted by hoist frig machine and placed | 5 engineer/ Foreman

with minimum distortion

‘After aligning the beam to the string line indicating the shoring

2.2 _| line and checking the verticality, the hole will be backfilled by Site Engineer/ Foreman

road base up to existing ground surface

5.0. ATTACHEMENT

SKETCH OF STEEL BEAM LIFTING

MAIT HR 180 RIG MACHINE TECHNICAL SPECIFICATION

REGISTERED CERTIFICATE OF TEST & EXAMINIATION (MAIT HR 180 RIG MACHINE)

CERTIFICATE OF DRILL RIG OPERATOR

CERTIFICATE OF CRAWLER CRANE OPERATIOR

HEAVY TRACTOR LICENCE RTA

ANMOL PILING sTEex stRUCTURES LLC.

Revision

Date

Page

°

2 1410-2019

+ Pages of 12

SK EEL BE/

ANMOL,

ANMOL PILING «steer sreucruxestic. os

Date 14102019

Page Page Gof 12

DIMENSIONS POR TRANSPORT DIMENSIONS POUR LE TRANSPORT

[MAIT HR 180 RIG MACHINE TECHNICAL SPECIFICATION

PAGE 1/2

ANMOL

ANMOL PILING « sTeet stRUCTURES LLC,

Revision: 0

Date 1410-2019

Page Page 7 of 12

WORKING CHARACTERISTICS

‘Works with anger and bucket

‘TECHNICAL DATA

shang ge

Nee plik ee et

MAIT HR 180 RIG MACHINE TECHNICAL SPECIFICATION

(CARACTERISTIQUE DE TRAVAIL

Travaux ave tarire et bucket

PAGE 2/2

sine Nt

Revision: 0

ANMOL PILING &sreet stRUCTURES LLC, pete; 14.10.2019

Page age 8 of 12

APPROVED OY MINISTRY OF LABOUR

# STARSAFETY & SECURITY CONSULTANCY Qa Sludly 4{fi GiyLiciuld Cow

ase

Registered Certificate of Test and Examination

DRILL RIG

Certente Nox $85C0110/20237

= [ANMOL PILING & STEEL STRUCTURES LLC

aoe ams

‘ALsaRAny DUBAD

cee i

Retoene Sant eS 2622842505,6720%4, 05 17584, 2218

(corona:

we Mandiacired oe

Trainee nos ‘| Yer of Merce a 7

Fazesz,ousar | Moseliee: G

i fing Pree:

Hwr809K0823 [oie ten am =

Tere ent nspeaion Dae

SAFE TO USE 21-06-2020

1 cane eet ay sn aon ee nai ma

‘sts in nuns nan aren

a oupmon emer nt tid

‘ce ren aa ay ey oan gE eo omg my pen orgy mat

Serta ee mimo oe fos meas a

SS ae ve

a \s

sea re

a

nase © OS en oman

REGISTERED CERTIFICATE OF TEST & EXAMINIATION (MAIT HR 180 RIG MACHINE)

PAGE 1/2

ANMOL Revision o

‘= ANMOL PILING &sTEEL sTRUCTURESLLC.| cate 14-10-2019

7 Poge + Page of 12

Corttnte Nos soscoitoza7

sm "secon : ewan

[a [eremerr aie =

[5 [everter conse : :

[7a [ener conan ams

[Sesutifuctoy ‘R= Recommendation

‘THIS 8 TO CERTIFY THAT the sow ing appoce, was thorugh inspected, amine ud tested byte by

nsign competent peron in ordnce withthe cleat tans an sae fore onde we white

Tints speed ane ot the Une of person ta wae fund to be stsacery fr fst use under the above

enone SW) and vied ta here contour marcel ed ued opto

lye

Approved by

“ENG sD. Date Issued: 23-06-2019

Inspection Engineer te *

([Desmeat Ne Tieaisoar Ra —

——_[er-Na [OT[teswe Nes [02 [ese Date T1701

REGISTERED CERTIFICATE OF TEST & EXAMINIATION (MAIT HR 180 RIG MACHINE)

PAGE 2/2

|

Page 10 of 12

14-10-2019

20

| Date

Page

ANMOL PILING & sree structuRES LLC.

ANMOL

Ln

wS

SS OT SUMALOAUSS THES ONT TONNY 3A GBAOTEMTE

4 NVIGNT {ALrFFNOLIAN

sy ei By ov rivd HSIKS YaaGNeR “SW

| 4

fil

LVEL AXLLYD OL ST STALL

& 4 imam BS Ae RII RD Fiemery, AONVEINSNOD ALTUNDAS 8 ALZAVS UVLS

A. Cee

ASS SNEASS

i wy

8 gy F

Hel BS y E

2 iS)

2

2 Z Od NOLLVNINVX ¥ ONINIVUEL

Zz iS) Tiv_ GIHWYHS NYHM IT? LY ays SW

= BS VELL AALLYS) OF SI STELL

2 & HLYOLHLLYD aes

< = mmnin SP mye REID RP? Siemon AONUEINGNOD ALAMOS © ALIVE WLS

3 IG

fy QAAAAAAAAAAAAAAAA

=

a ANMOL PILING g sree structures 1c.

Revision

Date

Page

10

1410-2019

Page 12 of 12

ate Ah mn og

oe taome indy,

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Reinforced and Prestressed Concrete 3rd-Edition PDFDocument524 pagesReinforced and Prestressed Concrete 3rd-Edition PDFfrog1589% (9)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Behavior of Piles With Raft Foundation Using Safe Software: Reshma T.V, Bhavya B S, Rashmi Mishra, Sankalpasri S SDocument5 pagesBehavior of Piles With Raft Foundation Using Safe Software: Reshma T.V, Bhavya B S, Rashmi Mishra, Sankalpasri S Sfrog15No ratings yet

- SD19000067 Final Interpretative Report Rev 00 - 08.03.2020 PDFDocument1,103 pagesSD19000067 Final Interpretative Report Rev 00 - 08.03.2020 PDFfrog15No ratings yet

- Frame Foundation-RADocument97 pagesFrame Foundation-RAfrog15No ratings yet

- Mait - HR 180 CP: Technical SpecsDocument2 pagesMait - HR 180 CP: Technical Specsfrog15No ratings yet

- Soil Report - 0667Document34 pagesSoil Report - 0667frog15No ratings yet

- A - Soil Investigation ReportDocument43 pagesA - Soil Investigation Reportfrog15No ratings yet

- SPEC - Gen, Civil & StrucDocument156 pagesSPEC - Gen, Civil & Strucfrog15No ratings yet

- Soil ReportDocument42 pagesSoil Reportfrog15No ratings yet

- Affection Plan and Land UseDocument2 pagesAffection Plan and Land Usefrog15No ratings yet

- BS 47-1 - 1991 PDFDocument41 pagesBS 47-1 - 1991 PDFHafa Lab100% (1)

- Affection PlanDocument2 pagesAffection Planfrog15No ratings yet

- (CEDSR-37788) Technical ReportDocument1 page(CEDSR-37788) Technical Reportfrog15No ratings yet

- Soil ReportDocument103 pagesSoil Reportfrog15No ratings yet

- Key PlanDocument1 pageKey Planfrog15No ratings yet

- DMBLDP4F8Document8 pagesDMBLDP4F8frog15No ratings yet