Professional Documents

Culture Documents

Eng BD Fta380

Eng BD Fta380

Uploaded by

Gabriel PiticasCopyright:

Available Formats

You might also like

- ORIFICEDocument1 pageORIFICEhardavNo ratings yet

- Liebherr T264 SpecificationsDocument24 pagesLiebherr T264 Specificationsbas100% (1)

- RC Pile Cap Design (ACI318)Document4 pagesRC Pile Cap Design (ACI318)topukuet75% (4)

- S130 - Peças PDFDocument525 pagesS130 - Peças PDFtiago100% (1)

- Secrets of Exhaust and Intake DesignDocument26 pagesSecrets of Exhaust and Intake Designrudey1867% (3)

- Sorb Cu Clapeta 2Document11 pagesSorb Cu Clapeta 2Cosmin BonghezNo ratings yet

- F L A N G e D S T A I N L e S S S T e e L S T R A I N e R P N 1 6Document8 pagesF L A N G e D S T A I N L e S S S T e e L S T R A I N e R P N 1 6Miguel BentoNo ratings yet

- Eng BD Fta731Document19 pagesEng BD Fta731Lazar LilaNo ratings yet

- 731 Technical - Datasheet - 3 - Pieces - Ball - Valve - Stainless - Steel - Flanged - pn40Document8 pages731 Technical - Datasheet - 3 - Pieces - Ball - Valve - Stainless - Steel - Flanged - pn40ruiz sumarNo ratings yet

- Technical Datasheet 3 Pieces Ball Valve Adler fp3 Stainless Steel Fire SafeDocument12 pagesTechnical Datasheet 3 Pieces Ball Valve Adler fp3 Stainless Steel Fire SafeBenny 37No ratings yet

- Technical Datasheet Forged Carbon Steel A105n Gate Valve Trim16 Class800 NPTDocument5 pagesTechnical Datasheet Forged Carbon Steel A105n Gate Valve Trim16 Class800 NPTBenny 37No ratings yet

- Technical Datasheet 2 Pieces Forged Stainless Steel Ball Valve 1500lbsDocument8 pagesTechnical Datasheet 2 Pieces Forged Stainless Steel Ball Valve 1500lbsBenny 37No ratings yet

- Technical Datasheet Resilient Seat Gate Valve f5 Atc Epdm Acs Flanged pn10-16Document14 pagesTechnical Datasheet Resilient Seat Gate Valve f5 Atc Epdm Acs Flanged pn10-16Benny 37No ratings yet

- Technical Datasheet Resilient Seat Gate Valve f5 CTC Epdm Flanged pn10-16Document14 pagesTechnical Datasheet Resilient Seat Gate Valve f5 CTC Epdm Flanged pn10-16Benny 37No ratings yet

- Ref.744 790 791 792 - enDocument21 pagesRef.744 790 791 792 - enMikeNo ratings yet

- Technical Datasheet Forged Carbon Steel A105n Gate Valve Trim16 Class800 SWDocument5 pagesTechnical Datasheet Forged Carbon Steel A105n Gate Valve Trim16 Class800 SWBenny 37No ratings yet

- CompressorwashingstrainerDocument9 pagesCompressorwashingstraineraras aliNo ratings yet

- Technical Datasheet Forged Carbon Steel A105n Gate Valve Trim8 Class800 SWDocument5 pagesTechnical Datasheet Forged Carbon Steel A105n Gate Valve Trim8 Class800 SWBenny 37No ratings yet

- Technical Datasheet Resilient Seat Gate Valve f4 CTC Epdm Acs Flanged pn10-16Document18 pagesTechnical Datasheet Resilient Seat Gate Valve f4 CTC Epdm Acs Flanged pn10-16Benny 37No ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Technical Datasheet 2 Pieces Forged Carbon Steel Ball Valve 800lbs Wedling EndsDocument11 pagesTechnical Datasheet 2 Pieces Forged Carbon Steel Ball Valve 800lbs Wedling EndsBenny 37No ratings yet

- Technical Datasheet 2 Pieces High Pressure Ball Valve Carbon Steel Female BSPDocument8 pagesTechnical Datasheet 2 Pieces High Pressure Ball Valve Carbon Steel Female BSPBenny 37No ratings yet

- Technical Datasheet 2 Pieces Forged Carbon Steel Ball Valve 800lbsDocument7 pagesTechnical Datasheet 2 Pieces Forged Carbon Steel Ball Valve 800lbsBenny 37No ratings yet

- Technical Datasheet 2 Pieces Forged Stainless Steel Ball Valve 800lbsDocument7 pagesTechnical Datasheet 2 Pieces Forged Stainless Steel Ball Valve 800lbsBenny 37No ratings yet

- Technical Datasheet Forged Carbon Steel A105n Gate Valve Trim8 Class800 NPTDocument5 pagesTechnical Datasheet Forged Carbon Steel A105n Gate Valve Trim8 Class800 NPTBenny 37No ratings yet

- Technical Datasheet 2 Pieces Forged Carbon Steel Ball Valve 1500lbsDocument8 pagesTechnical Datasheet 2 Pieces Forged Carbon Steel Ball Valve 1500lbsBenny 37No ratings yet

- Technical Datasheet Forged Carbon Steel A105n Gate Valve Trim8 Class800 BSPDocument5 pagesTechnical Datasheet Forged Carbon Steel A105n Gate Valve Trim8 Class800 BSPBenny 37No ratings yet

- Resilient Seat Gate Valve Pn10/16 Short Pattern Din 3202-F4 CTC EpdmDocument18 pagesResilient Seat Gate Valve Pn10/16 Short Pattern Din 3202-F4 CTC EpdmG DilemaNo ratings yet

- Technical Datasheet 2 Pieces Ball Valve Carbon Steel BSP Din m3Document7 pagesTechnical Datasheet 2 Pieces Ball Valve Carbon Steel BSP Din m3Benny 37No ratings yet

- PP41 Rev.3Document1 pagePP41 Rev.3Ashish ChackoNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Karta Katalogowa Zawor Kulowy 789Document6 pagesKarta Katalogowa Zawor Kulowy 789Telmo EstrelaNo ratings yet

- Technical Datasheet 2 Pieces Ball Valve Stainless Steel Male Female BSPDocument6 pagesTechnical Datasheet 2 Pieces Ball Valve Stainless Steel Male Female BSPBenny 37No ratings yet

- Technical Datasheet 2 Pieces Ball Valve Stainless Steel NPT Din m3Document7 pagesTechnical Datasheet 2 Pieces Ball Valve Stainless Steel NPT Din m3Benny 37No ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Fig - 33 TI S60 03 ENDocument5 pagesFig - 33 TI S60 03 ENAditomo PutrantoNo ratings yet

- Technical Datasheet Carbon Steel Triple Offset Butterfly Valve Lug pn40Document13 pagesTechnical Datasheet Carbon Steel Triple Offset Butterfly Valve Lug pn40Benny 37No ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Technical Datasheet 2 Pieces Ball Valve Stainless Steel Solar High Temperature BSPDocument6 pagesTechnical Datasheet 2 Pieces Ball Valve Stainless Steel Solar High Temperature BSPBenny 37No ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- 2/2, 3/2 Manifold Mounting Compact Design High Flow Rate High Cycle Rate of Up To 1200 Cycles Per Minute Up To KV 14 (Orifice 8 MM)Document4 pages2/2, 3/2 Manifold Mounting Compact Design High Flow Rate High Cycle Rate of Up To 1200 Cycles Per Minute Up To KV 14 (Orifice 8 MM)Venkatesan ManikandanNo ratings yet

- Welding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1Document1 pageWelding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Spirax Sarco Fig 33Document2 pagesSpirax Sarco Fig 33Jacobus CalvelageNo ratings yet

- 7.1 ΒΑΝΕΣ ΕΛ.ΕΜΦΡΑΞΗΣ ΦΥΛΛΑΔΙΟ PDFDocument19 pages7.1 ΒΑΝΕΣ ΕΛ.ΕΜΦΡΑΞΗΣ ΦΥΛΛΑΔΙΟ PDFAthanasoulis KostasNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- AL-905-R-11208 Spec AS01 Rev.T02Document3 pagesAL-905-R-11208 Spec AS01 Rev.T02altipatlarNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Eng BD Tds1160-NaDocument19 pagesEng BD Tds1160-Naoussama fatihNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Y-Strainer - Data SheetDocument7 pagesY-Strainer - Data SheetŁukasz OlszewskiNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Technical Datasheet 2 Pieces Ball Valve Stainless Steel Male Male BSPDocument6 pagesTechnical Datasheet 2 Pieces Ball Valve Stainless Steel Male Male BSPBenny 37No ratings yet

- Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp06Document1 pageFormat No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp06S GoudaNo ratings yet

- Philips 22ah590 SMDocument4 pagesPhilips 22ah590 SMGabriel PiticasNo ratings yet

- Single Digit LED Numeric Display: LA-301 B / L SeriesDocument6 pagesSingle Digit LED Numeric Display: LA-301 B / L SeriesGabriel PiticasNo ratings yet

- MOSFET Audio AmplifierDocument38 pagesMOSFET Audio AmplifierGabriel PiticasNo ratings yet

- Kxe 300Document12 pagesKxe 300Gabriel PiticasNo ratings yet

- Scott 420aDocument2 pagesScott 420aGabriel PiticasNo ratings yet

- KLTX3 en User-ManualDocument2 pagesKLTX3 en User-ManualGabriel PiticasNo ratings yet

- PID + Fuzzy Logic Process Controller: C22/C62/C82/C83/C72/C42/R22 User ManualDocument153 pagesPID + Fuzzy Logic Process Controller: C22/C62/C82/C83/C72/C42/R22 User ManualGabriel PiticasNo ratings yet

- Danfoss EKC201CDocument16 pagesDanfoss EKC201CGabriel PiticasNo ratings yet

- Denon Dra-385rdDocument29 pagesDenon Dra-385rdGabriel PiticasNo ratings yet

- PID + Fuzzy Logic Process Controller: C22/C62/C82/C83/C72/C42/R22 User ManualDocument131 pagesPID + Fuzzy Logic Process Controller: C22/C62/C82/C83/C72/C42/R22 User ManualGabriel PiticasNo ratings yet

- Sansui Au-X111 SMDocument8 pagesSansui Au-X111 SMGabriel PiticasNo ratings yet

- Assembly Manual: In-Circuit LOPT/FBT Tester K 7205Document6 pagesAssembly Manual: In-Circuit LOPT/FBT Tester K 7205majanaam100% (1)

- Operating Instructions Smartec CLD18: Conductivity Measuring SystemDocument48 pagesOperating Instructions Smartec CLD18: Conductivity Measuring SystemGabriel PiticasNo ratings yet

- F1 UserManual ENDocument419 pagesF1 UserManual ENGabriel PiticasNo ratings yet

- Digital ThermostatDocument28 pagesDigital ThermostatGabriel PiticasNo ratings yet

- Brain ChildDocument8 pagesBrain ChildGabriel PiticasNo ratings yet

- Foundation Settlement ElasticDocument14 pagesFoundation Settlement Elasticxingze luNo ratings yet

- Automation Chapter 6 PDFDocument240 pagesAutomation Chapter 6 PDFRaed Al Ma'aniNo ratings yet

- Book 14Document6 pagesBook 14ebuka okohNo ratings yet

- TE32 Full flow -measure points (điểm đo và vị trí solennoi)Document7 pagesTE32 Full flow -measure points (điểm đo và vị trí solennoi)Nguyễn Văn HùngNo ratings yet

- Turbo MachineDocument2 pagesTurbo MachinescribdkhatnNo ratings yet

- Chapter4 Allowable StresseDocument26 pagesChapter4 Allowable StresseDevendra BangarNo ratings yet

- Specs VC82ASEDocument1 pageSpecs VC82ASEyudi handokoNo ratings yet

- CrowerCat Master CatalogDocument222 pagesCrowerCat Master Cataloggigio GigioNo ratings yet

- Flyer Secondary EncoderDocument2 pagesFlyer Secondary EncoderSalvator Espinoza VallesNo ratings yet

- 5-2 The Laval Nozzle Choked Nozzle (Col Amorcé) : (Tuyère de Laval)Document8 pages5-2 The Laval Nozzle Choked Nozzle (Col Amorcé) : (Tuyère de Laval)hasan bishNo ratings yet

- .2.14 Stress-Strain Relations For Linear Elastic Transversely Isotropic MaterialDocument6 pages.2.14 Stress-Strain Relations For Linear Elastic Transversely Isotropic MaterialHanmant PhadatareNo ratings yet

- 1997 Design Axially Loaded Piles 1Document7 pages1997 Design Axially Loaded Piles 1erick velascoNo ratings yet

- What Is Flow?: Turbulent Flow Laminar FlowDocument3 pagesWhat Is Flow?: Turbulent Flow Laminar FlowAurelia AlexandraNo ratings yet

- CM 425 - Properties of Fresh Concrete PDFDocument14 pagesCM 425 - Properties of Fresh Concrete PDFTran Huynh NamNo ratings yet

- PC130-7 (YEAM200400) (OM Eng) (WM)Document300 pagesPC130-7 (YEAM200400) (OM Eng) (WM)Анатолий ЩербаковNo ratings yet

- Models - Cfd.turbulent BackstepDocument18 pagesModels - Cfd.turbulent BackstepRouaissi RidhaNo ratings yet

- Air - Conditioning and RefrigerationDocument4 pagesAir - Conditioning and RefrigerationsarmadNo ratings yet

- Catálogo StaubliDocument8 pagesCatálogo StaubliJackson BravosNo ratings yet

- USHTRD HighTempRefrigDryer 07-2020 67-37017Document2 pagesUSHTRD HighTempRefrigDryer 07-2020 67-37017Adan Serrano CaroNo ratings yet

- Last Service ReportDocument4 pagesLast Service ReportSandeep NikhilNo ratings yet

- Technical Data Master: GrippersDocument1 pageTechnical Data Master: Grippersnumber_25No ratings yet

- PHQS250SMCS Stoper ManualDocument39 pagesPHQS250SMCS Stoper ManualgeominambNo ratings yet

- Activity No.3 (Blade Section Forces)Document16 pagesActivity No.3 (Blade Section Forces)Jandrew TanNo ratings yet

- Grain Size Analysis: Axis TitleDocument4 pagesGrain Size Analysis: Axis Titleajit karandikar100% (1)

- Mathcad in Mechanical EngineeringDocument16 pagesMathcad in Mechanical Engineeringgato7777777100% (2)

- Presostatos KPI 1Document10 pagesPresostatos KPI 1Gamaliel QuiñonesNo ratings yet

Eng BD Fta380

Eng BD Fta380

Uploaded by

Gabriel PiticasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eng BD Fta380

Eng BD Fta380

Uploaded by

Gabriel PiticasCopyright:

Available Formats

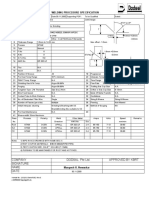

REF.

380-384

3 PIECES STAINLESS STEEL CHECK VALVE (380-384)

Certificate 3.1

Size : DN 8 to DN100

Ends : Female-Female BSP or NPT, SW or BW

Min Temperature : - 20°C

Max Temperature : + 200°C

Max Pressure : 63 Bars

Specifications : 3 pieces spring type

All positions

Metal / metal

Materials : Stainless steel ASTM A351 CF8M

Sferaco 90 rue du Ruisseau 38297 St Quentin Fallavier Tel: + 33 (0) 474.94.15.90 Fax: + 33 (0) 474.95.62.08 Internet: www.sferaco.fr E-mail : sferaco@sferaco.fr

Date : 12/18 Rev.09

Page 1 sur 11

Information provided as an indication and subject to possible modification

REF. 380-384

3 PIECES STAINLESS STEEL CHECK VALVE (380-384)

SPECIFICATIONS :

3 pieces spring type

All positions (respect the flow direction indicated by the arrow )

Metal / metal tightness

Stainless steel

USE :

Chemical and pharmaceutical industries, petrochemical industries, hydraulic installation, compressed air, potable water

Min Temperature Ts : - 20°C

Max Temperature Ts :+ 200°C

Max Pressure Ps : 63 bars ( see graph under )

Steam : 11 bars max

PRESSURE / TEMPERATURE GRAPH ( STEAM EXCLUDED ) :

FLOW COEFFICIENT Kvs ( M3 / h ) :

DN 8 10 15 20 25 32 40 50 65 80 100

Kvs ( m3/h ) 1.23 1.23 2.24 6.5 9.61 15.89 22.49 25.12 57.8 64.93 91.6

Sferaco 90 rue du Ruisseau 38297 St Quentin Fallavier Tel: + 33 (0) 474.94.15.90 Fax: + 33 (0) 474.95.62.08 Internet: www.sferaco.fr E-mail : sferaco@sferaco.fr

Date : 12/18 Rev.09

Page 2 sur 11

Information provided as an indication and subject to possible modification

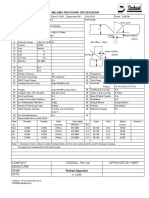

REF. 380-384

3 PIECES STAINLESS STEEL CHECK VALVE (380-384)

HEAD LOSS GRAPH :

Flow (m3/h) Flow (l/s)

Head loss ( Bar )

Sferaco 90 rue du Ruisseau 38297 St Quentin Fallavier Tel: + 33 (0) 474.94.15.90 Fax: + 33 (0) 474.95.62.08 Internet: www.sferaco.fr E-mail : sferaco@sferaco.fr

Date : 12/18 Rev.09

Page 3 sur 11

Information provided as an indication and subject to possible modification

REF. 380-384

3 PIECES STAINLESS STEEL CHECK VALVE (380-384)

LEAKAGE RATE ACCORDING TO API 598 (DURING 60s):

DN 8 10 15 20 25 32 40 50 65 80 100

Liquid Test ( cc/min ) 6 7.5 9 12

Gas Test (m3/h) 0.08 0.11 0.13 0.17

OPENING PRESSURE ( in mbar ) :

Vertical Position

DN Horizontal Position

ascending fluid

DN 08 25 23

DN 10 25 23

DN 15 25 23

DN 20 25 23

DN 25 25 23

DN 32 27 24

DN 40 29 25

DN 50 29 25

DN 65 31 25

DN 80 32 26

DN100 33 27

RANGE :

Female / female threaded BSP cylindrical Ref. 380 from DN 1/4“ to DN 4“

Butt Welding ends Ref. 381 from DN 8 to DN 100

Socket Welding ends Ref. 382 from DN 8 to DN100

Female threaded BSP cylindrical with SS316 strainer Ref. 383 from DN 3/8“ to DN 4“ ( Ref. 380 + Ref. 391 )

Female / female threaded NPT Ref. 384 from DN 1/4“ to DN 2“

Sferaco 90 rue du Ruisseau 38297 St Quentin Fallavier Tel: + 33 (0) 474.94.15.90 Fax: + 33 (0) 474.95.62.08 Internet: www.sferaco.fr E-mail : sferaco@sferaco.fr

Date : 12/18 Rev.09

Page 4 sur 11

Information provided as an indication and subject to possible modification

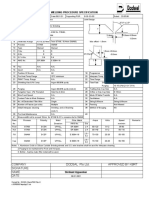

REF. 380-384

3 PIECES STAINLESS STEEL CHECK VALVE (380-384)

MATERIALS :

Item Designation Materials

1 Body ASTM A351 CF8M

2 Disc ASTM A240-316

3 Spring AISI 316

4 Gasket PTFE

5 Ends ASTM A351 CF8M

6 Spring holder ASTM A240-316

7 Screw AISI 304

8 Washer AISI 304

9 Nut AISI 304

Sferaco 90 rue du Ruisseau 38297 St Quentin Fallavier Tel: + 33 (0) 474.94.15.90 Fax: + 33 (0) 474.95.62.08 Internet: www.sferaco.fr E-mail : sferaco@sferaco.fr

Date : 12/18 Rev.09

Page 5 sur 11

Information provided as an indication and subject to possible modification

REF. 380-384

3 PIECES STAINLESS STEEL CHECK VALVE (380-384)

SIZE THREADED TYPES ( in mm ) :

DN 8–50 :

DN 65-80 : DN 100 :

Ref. DN 1/4" 3/8“ 1/2“ 3/4“ 1“ 1“1/4 1“1/2 2“ 2“1/2 3“ 4“

ØP 10 10 14 19 25 31 39 49 64 78 97

L 60 60 63 71 81.5 91 97.5 117 131.5 143.5 174.5

L1 16 16 18 20 20 23 23 27 33 35 45

L2 21 21 22 23.5 26 29 30 35 42 44 52

380/384 B 18 18 19 24 29.5 33 37.5 47 47.5 55.5 70.5

ØD 12 12 14 16 16 18 18 18 18 18 18

ØT 36.5 36.5 42.7 51.7 58.7 72.7 83.7 98.7 129 153.5 186.5

W 22 22 26 32 39 49 56 69 83 100 122.5

Weight ( Kg ) 0.3 0.2 0.4 0.5 0.7 1.3 1.7 2.5 4.3 6.2 11

Sferaco 90 rue du Ruisseau 38297 St Quentin Fallavier Tel: + 33 (0) 474.94.15.90 Fax: + 33 (0) 474.95.62.08 Internet: www.sferaco.fr E-mail : sferaco@sferaco.fr

Date : 12/18 Rev.09

Page 6 sur 11

Information provided as an indication and subject to possible modification

REF. 380-384

3 PIECES STAINLESS STEEL CHECK VALVE (380-384)

SIZE B.W. TYPE ( in mm ) :

DN 8–80 :

DN 100 :

Ref. DN 8 10 15 20 25 32 40 50 65 80 100

ØP 10 10 14 19 25 31 39 49 64 78 97

Ø P1 10 12.5 15 20 25 32 39 50 65 80 99.5

L 66 66 67 81 89.5 92 103.5 117 131.5 143.5 174.5

L2 24 24 24 28.5 30 29.5 33 35 42 44 52

B 18 18 19 24 29.5 33 37.5 47 47.5 55.5 70.5

381

ØD 12 12 14 16 16 18 18 18 18 18 18

Ø BW 18 20.5 22 28 31.5 40 46 60 78 91.5 116

Ø BW1 14 16.8 18 23.3 28.5 35.8 41.2 53.5 69.4 84.1 104

ØT 36.5 36.5 42.7 51.7 58.7 72.7 83.7 98.7 129 153.5 186.5

Weight ( Kg ) 0.3 0.2 0.4 0.5 0.7 1.3 1.7 2.5 4.3 6.2 11

Sferaco 90 rue du Ruisseau 38297 St Quentin Fallavier Tel: + 33 (0) 474.94.15.90 Fax: + 33 (0) 474.95.62.08 Internet: www.sferaco.fr E-mail : sferaco@sferaco.fr

Date : 12/18 Rev.09

Page 7 sur 11

Information provided as an indication and subject to possible modification

REF. 380-384

3 PIECES STAINLESS STEEL CHECK VALVE (380-384)

SIZE S.W. TYPE ( in mm ) :

DN 8–50 :

DN 65-80 : DN 100 :

Ref. DN 8 10 15 20 25 32 40 50 65 80 100

ØP 10 10 14 19 25 31 39 49 64 78 97

L 60 60 63 71 81.5 91 97.5 117 131.5 143.5 174.5

L1 15.5 16.5 12.5 14.1 15.7 17.7 19.5 22 26.3 28.7 37.5

L2 21 21 22 23.5 26 29 30 35 42 44 52

B 18 18 19 24 29.5 33 37.5 47 47.5 55.5 70.5

382

ØD 12 12 14 16 16 18 18 18 18 18 18

W 22 22 26 32 39 49 56 69 83 100 122.5

Ø SW 14.2 17.5 21.8 27.4 34.1 42.7 49 61 77 90.2 115.3

ØT 36.5 36.5 42.7 51.7 58.7 72.7 83.7 98.7 129 153.5 186.5

Weight ( Kg ) 0.3 0.2 0.4 0.5 0.7 1.3 1.7 2.5 4.3 6.2 11

Sferaco 90 rue du Ruisseau 38297 St Quentin Fallavier Tel: + 33 (0) 474.94.15.90 Fax: + 33 (0) 474.95.62.08 Internet: www.sferaco.fr E-mail : sferaco@sferaco.fr

Date : 12/18 Rev.09

Page 8 sur 11

Information provided as an indication and subject to possible modification

REF. 380-384

3 PIECES STAINLESS STEEL CHECK VALVE (380-384)

SIZE THREADED TYPE WITH STRAINER ( in mm ) :

DN 8–50 :

DN 65-80 : DN 100 :

Ref . DN 3/8“ 1/2“ 3/4“ 1“ 1“1/4 1“1/2 2“ 2“1/2 3“ 4“

ØP 10 14 19 25 31 39 49 64 78 97

L 60 63 71 81.5 91 97.5 117 131.5 143.5 174.5

L1 16 18 20 20 23 23 27 33 35 45

L2 21 22 23.5 26 29 30 35 42 44 52

B 18 19 24 29.5 33 37.5 47 47.5 55.5 70.5

Ø D1 21 23 29 37 44 49 61 80 86 116

383

H 51 55 62 69 80 89 101 114 126 144

ØD 12 14 16 16 18 18 18 18 18 18

T 36.5 42.7 51.7 58.7 72.7 83.7 98.7 129 153.5 186.5

W 22 26 32 39 49 56 69 83 100 122.5

Mesh 1.2 1.2 1.2 1.2 1.2 1.2 1.2 1.5 1.5 2

Weight ( Kg ) 0.211 0.415 0.525 0.737 1.355 1.767 2.584 4.435 6.369 11.243

Sferaco 90 rue du Ruisseau 38297 St Quentin Fallavier Tel: + 33 (0) 474.94.15.90 Fax: + 33 (0) 474.95.62.08 Internet: www.sferaco.fr E-mail : sferaco@sferaco.fr

Date : 12/18 Rev.09

Page 9 sur 11

Information provided as an indication and subject to possible modification

REF. 380-384

3 PIECES STAINLESS STEEL CHECK VALVE (380-384)

BOLT TIGHTENING TABLE ( in Nm):

DN 1/4" 3/8" 1/2" 3/4" 1" 1"1/4 1"1/2 2" 2"1/2 3" 4"

Torque ( Nm ) 30 30 30 30 45 45 45 60 75 90 105

STANDARDS :

Fabrication according to ISO 9001 : 2015

DIRECTIVE 2014/68/UE : CE N° 0035

Risk category III Module H

Certificate 3.1 on request

Construction according to EN 12516-1

Designing according to ASME B16.34

Pressure tests according to API 598, table 6

BSP threaded cylindrical ends according to ISO 228-1

NPT threaded ends according to ANSI B1.20.1

BW ends according to DIN 3239

SW ends according to DIN 3239-2

SW ends according to ASME B16.11 (excepted for DN65)

ATEX Group II Category 2 G/2D Zone 1 & 21 Zone 2 &22 ( optional marking )

French water agreement A.C.S. N° 17 ACC LY 341 from DN1/4“ to 2“

ADVICE : Our opinion and our advice are not guaranteed and SFERACO shall not be liable for the consequences of damages.

The customer must check the right choice of the products with the real service conditions.

Sferaco 90 rue du Ruisseau 38297 St Quentin Fallavier Tel: + 33 (0) 474.94.15.90 Fax: + 33 (0) 474.95.62.08 Internet: www.sferaco.fr E-mail : sferaco@sferaco.fr

Date : 12/18 Rev.09

Page 10 sur 11

Information provided as an indication and subject to possible modification

REF. 380-384

3 PIECES STAINLESS STEEL CHECK VALVE (380-384)

INSTALLATION INSTRUCTIONS

GENERAL GUIDELINES :

Ensure that the check valves to be used are appropriate for the conditions of the installation (type of

fluid,pressure and temperature).

Be sure to have enough valves to be able to isolate the sections of piping as well as the appropriate

equipment for maintenance and repair.

Ensure that the check valves to be installed are of correct strenght to be able to support the capacity of

their usage.

Installation of all circuits should ensure that their function can be automatically tested on a regular

basis (at least two times a year).

INSTALLATION INSTRUCTIONS :

Before installing the check valves, clean and remove any objects from the pipes (in particular bits of

sealing and metal) which could obstruct and block the check valves.

Ensure that both connecting pipes either side of the check valve (upstream and downstream) are

aligned (if they’re not,the valves may not work correctly).

Make sure that the two sections of the pipe (upstream and downstream) match, the check valve unit

will not absorb any gaps. Any distortions in the pipes may affect the thightness of the connection,

the working of the check valve and can even cause a rupture. To be sure, place the kit in position to

ensure the assembling will work.

During welding operation, be sure to not exceed 200°C

If sections of piping do not have their final support in place, they should be temporarily fixed. This

is to avoid unnecessary strain on the check valve.

Fluids in the check valve must not contain solid objects ( it could damaged the seat ).

If there is a direction changing or if there’s another material, it’s better to take away the check valve so that

it is outside the turbulence area ( between 3 and 5 times the ND before and after ).

After a pump please refer to FD CEN/TR 13932 to install the check valve :

• If it is essential to keep priming the pump, a non-return check valve can be fitted to the suction

pipe at a distance L1 ( straight length suction ) > 10xD1 (diameter suction )

The check valve is designed to meet the maximum flow rate in service

In other cases, the non-return check valve is mounted on the discharge pipe at a distance of

L2 (straight length at discharge) > 3xD2 (diameter at discharge)

Sferaco 90 rue du Ruisseau 38297 St Quentin Fallavier Tel: + 33 (0) 474.94.15.90 Fax: + 33 (0) 474.95.62.08 Internet: www.sferaco.fr E-mail : sferaco@sferaco.fr

Date : 12/18 Rev.09

Page 11 sur 11

Information provided as an indication and subject to possible modification

You might also like

- ORIFICEDocument1 pageORIFICEhardavNo ratings yet

- Liebherr T264 SpecificationsDocument24 pagesLiebherr T264 Specificationsbas100% (1)

- RC Pile Cap Design (ACI318)Document4 pagesRC Pile Cap Design (ACI318)topukuet75% (4)

- S130 - Peças PDFDocument525 pagesS130 - Peças PDFtiago100% (1)

- Secrets of Exhaust and Intake DesignDocument26 pagesSecrets of Exhaust and Intake Designrudey1867% (3)

- Sorb Cu Clapeta 2Document11 pagesSorb Cu Clapeta 2Cosmin BonghezNo ratings yet

- F L A N G e D S T A I N L e S S S T e e L S T R A I N e R P N 1 6Document8 pagesF L A N G e D S T A I N L e S S S T e e L S T R A I N e R P N 1 6Miguel BentoNo ratings yet

- Eng BD Fta731Document19 pagesEng BD Fta731Lazar LilaNo ratings yet

- 731 Technical - Datasheet - 3 - Pieces - Ball - Valve - Stainless - Steel - Flanged - pn40Document8 pages731 Technical - Datasheet - 3 - Pieces - Ball - Valve - Stainless - Steel - Flanged - pn40ruiz sumarNo ratings yet

- Technical Datasheet 3 Pieces Ball Valve Adler fp3 Stainless Steel Fire SafeDocument12 pagesTechnical Datasheet 3 Pieces Ball Valve Adler fp3 Stainless Steel Fire SafeBenny 37No ratings yet

- Technical Datasheet Forged Carbon Steel A105n Gate Valve Trim16 Class800 NPTDocument5 pagesTechnical Datasheet Forged Carbon Steel A105n Gate Valve Trim16 Class800 NPTBenny 37No ratings yet

- Technical Datasheet 2 Pieces Forged Stainless Steel Ball Valve 1500lbsDocument8 pagesTechnical Datasheet 2 Pieces Forged Stainless Steel Ball Valve 1500lbsBenny 37No ratings yet

- Technical Datasheet Resilient Seat Gate Valve f5 Atc Epdm Acs Flanged pn10-16Document14 pagesTechnical Datasheet Resilient Seat Gate Valve f5 Atc Epdm Acs Flanged pn10-16Benny 37No ratings yet

- Technical Datasheet Resilient Seat Gate Valve f5 CTC Epdm Flanged pn10-16Document14 pagesTechnical Datasheet Resilient Seat Gate Valve f5 CTC Epdm Flanged pn10-16Benny 37No ratings yet

- Ref.744 790 791 792 - enDocument21 pagesRef.744 790 791 792 - enMikeNo ratings yet

- Technical Datasheet Forged Carbon Steel A105n Gate Valve Trim16 Class800 SWDocument5 pagesTechnical Datasheet Forged Carbon Steel A105n Gate Valve Trim16 Class800 SWBenny 37No ratings yet

- CompressorwashingstrainerDocument9 pagesCompressorwashingstraineraras aliNo ratings yet

- Technical Datasheet Forged Carbon Steel A105n Gate Valve Trim8 Class800 SWDocument5 pagesTechnical Datasheet Forged Carbon Steel A105n Gate Valve Trim8 Class800 SWBenny 37No ratings yet

- Technical Datasheet Resilient Seat Gate Valve f4 CTC Epdm Acs Flanged pn10-16Document18 pagesTechnical Datasheet Resilient Seat Gate Valve f4 CTC Epdm Acs Flanged pn10-16Benny 37No ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Technical Datasheet 2 Pieces Forged Carbon Steel Ball Valve 800lbs Wedling EndsDocument11 pagesTechnical Datasheet 2 Pieces Forged Carbon Steel Ball Valve 800lbs Wedling EndsBenny 37No ratings yet

- Technical Datasheet 2 Pieces High Pressure Ball Valve Carbon Steel Female BSPDocument8 pagesTechnical Datasheet 2 Pieces High Pressure Ball Valve Carbon Steel Female BSPBenny 37No ratings yet

- Technical Datasheet 2 Pieces Forged Carbon Steel Ball Valve 800lbsDocument7 pagesTechnical Datasheet 2 Pieces Forged Carbon Steel Ball Valve 800lbsBenny 37No ratings yet

- Technical Datasheet 2 Pieces Forged Stainless Steel Ball Valve 800lbsDocument7 pagesTechnical Datasheet 2 Pieces Forged Stainless Steel Ball Valve 800lbsBenny 37No ratings yet

- Technical Datasheet Forged Carbon Steel A105n Gate Valve Trim8 Class800 NPTDocument5 pagesTechnical Datasheet Forged Carbon Steel A105n Gate Valve Trim8 Class800 NPTBenny 37No ratings yet

- Technical Datasheet 2 Pieces Forged Carbon Steel Ball Valve 1500lbsDocument8 pagesTechnical Datasheet 2 Pieces Forged Carbon Steel Ball Valve 1500lbsBenny 37No ratings yet

- Technical Datasheet Forged Carbon Steel A105n Gate Valve Trim8 Class800 BSPDocument5 pagesTechnical Datasheet Forged Carbon Steel A105n Gate Valve Trim8 Class800 BSPBenny 37No ratings yet

- Resilient Seat Gate Valve Pn10/16 Short Pattern Din 3202-F4 CTC EpdmDocument18 pagesResilient Seat Gate Valve Pn10/16 Short Pattern Din 3202-F4 CTC EpdmG DilemaNo ratings yet

- Technical Datasheet 2 Pieces Ball Valve Carbon Steel BSP Din m3Document7 pagesTechnical Datasheet 2 Pieces Ball Valve Carbon Steel BSP Din m3Benny 37No ratings yet

- PP41 Rev.3Document1 pagePP41 Rev.3Ashish ChackoNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Karta Katalogowa Zawor Kulowy 789Document6 pagesKarta Katalogowa Zawor Kulowy 789Telmo EstrelaNo ratings yet

- Technical Datasheet 2 Pieces Ball Valve Stainless Steel Male Female BSPDocument6 pagesTechnical Datasheet 2 Pieces Ball Valve Stainless Steel Male Female BSPBenny 37No ratings yet

- Technical Datasheet 2 Pieces Ball Valve Stainless Steel NPT Din m3Document7 pagesTechnical Datasheet 2 Pieces Ball Valve Stainless Steel NPT Din m3Benny 37No ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Fig - 33 TI S60 03 ENDocument5 pagesFig - 33 TI S60 03 ENAditomo PutrantoNo ratings yet

- Technical Datasheet Carbon Steel Triple Offset Butterfly Valve Lug pn40Document13 pagesTechnical Datasheet Carbon Steel Triple Offset Butterfly Valve Lug pn40Benny 37No ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Technical Datasheet 2 Pieces Ball Valve Stainless Steel Solar High Temperature BSPDocument6 pagesTechnical Datasheet 2 Pieces Ball Valve Stainless Steel Solar High Temperature BSPBenny 37No ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- 2/2, 3/2 Manifold Mounting Compact Design High Flow Rate High Cycle Rate of Up To 1200 Cycles Per Minute Up To KV 14 (Orifice 8 MM)Document4 pages2/2, 3/2 Manifold Mounting Compact Design High Flow Rate High Cycle Rate of Up To 1200 Cycles Per Minute Up To KV 14 (Orifice 8 MM)Venkatesan ManikandanNo ratings yet

- Welding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1Document1 pageWelding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Spirax Sarco Fig 33Document2 pagesSpirax Sarco Fig 33Jacobus CalvelageNo ratings yet

- 7.1 ΒΑΝΕΣ ΕΛ.ΕΜΦΡΑΞΗΣ ΦΥΛΛΑΔΙΟ PDFDocument19 pages7.1 ΒΑΝΕΣ ΕΛ.ΕΜΦΡΑΞΗΣ ΦΥΛΛΑΔΙΟ PDFAthanasoulis KostasNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- AL-905-R-11208 Spec AS01 Rev.T02Document3 pagesAL-905-R-11208 Spec AS01 Rev.T02altipatlarNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Eng BD Tds1160-NaDocument19 pagesEng BD Tds1160-Naoussama fatihNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Y-Strainer - Data SheetDocument7 pagesY-Strainer - Data SheetŁukasz OlszewskiNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Technical Datasheet 2 Pieces Ball Valve Stainless Steel Male Male BSPDocument6 pagesTechnical Datasheet 2 Pieces Ball Valve Stainless Steel Male Male BSPBenny 37No ratings yet

- Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp06Document1 pageFormat No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp06S GoudaNo ratings yet

- Philips 22ah590 SMDocument4 pagesPhilips 22ah590 SMGabriel PiticasNo ratings yet

- Single Digit LED Numeric Display: LA-301 B / L SeriesDocument6 pagesSingle Digit LED Numeric Display: LA-301 B / L SeriesGabriel PiticasNo ratings yet

- MOSFET Audio AmplifierDocument38 pagesMOSFET Audio AmplifierGabriel PiticasNo ratings yet

- Kxe 300Document12 pagesKxe 300Gabriel PiticasNo ratings yet

- Scott 420aDocument2 pagesScott 420aGabriel PiticasNo ratings yet

- KLTX3 en User-ManualDocument2 pagesKLTX3 en User-ManualGabriel PiticasNo ratings yet

- PID + Fuzzy Logic Process Controller: C22/C62/C82/C83/C72/C42/R22 User ManualDocument153 pagesPID + Fuzzy Logic Process Controller: C22/C62/C82/C83/C72/C42/R22 User ManualGabriel PiticasNo ratings yet

- Danfoss EKC201CDocument16 pagesDanfoss EKC201CGabriel PiticasNo ratings yet

- Denon Dra-385rdDocument29 pagesDenon Dra-385rdGabriel PiticasNo ratings yet

- PID + Fuzzy Logic Process Controller: C22/C62/C82/C83/C72/C42/R22 User ManualDocument131 pagesPID + Fuzzy Logic Process Controller: C22/C62/C82/C83/C72/C42/R22 User ManualGabriel PiticasNo ratings yet

- Sansui Au-X111 SMDocument8 pagesSansui Au-X111 SMGabriel PiticasNo ratings yet

- Assembly Manual: In-Circuit LOPT/FBT Tester K 7205Document6 pagesAssembly Manual: In-Circuit LOPT/FBT Tester K 7205majanaam100% (1)

- Operating Instructions Smartec CLD18: Conductivity Measuring SystemDocument48 pagesOperating Instructions Smartec CLD18: Conductivity Measuring SystemGabriel PiticasNo ratings yet

- F1 UserManual ENDocument419 pagesF1 UserManual ENGabriel PiticasNo ratings yet

- Digital ThermostatDocument28 pagesDigital ThermostatGabriel PiticasNo ratings yet

- Brain ChildDocument8 pagesBrain ChildGabriel PiticasNo ratings yet

- Foundation Settlement ElasticDocument14 pagesFoundation Settlement Elasticxingze luNo ratings yet

- Automation Chapter 6 PDFDocument240 pagesAutomation Chapter 6 PDFRaed Al Ma'aniNo ratings yet

- Book 14Document6 pagesBook 14ebuka okohNo ratings yet

- TE32 Full flow -measure points (điểm đo và vị trí solennoi)Document7 pagesTE32 Full flow -measure points (điểm đo và vị trí solennoi)Nguyễn Văn HùngNo ratings yet

- Turbo MachineDocument2 pagesTurbo MachinescribdkhatnNo ratings yet

- Chapter4 Allowable StresseDocument26 pagesChapter4 Allowable StresseDevendra BangarNo ratings yet

- Specs VC82ASEDocument1 pageSpecs VC82ASEyudi handokoNo ratings yet

- CrowerCat Master CatalogDocument222 pagesCrowerCat Master Cataloggigio GigioNo ratings yet

- Flyer Secondary EncoderDocument2 pagesFlyer Secondary EncoderSalvator Espinoza VallesNo ratings yet

- 5-2 The Laval Nozzle Choked Nozzle (Col Amorcé) : (Tuyère de Laval)Document8 pages5-2 The Laval Nozzle Choked Nozzle (Col Amorcé) : (Tuyère de Laval)hasan bishNo ratings yet

- .2.14 Stress-Strain Relations For Linear Elastic Transversely Isotropic MaterialDocument6 pages.2.14 Stress-Strain Relations For Linear Elastic Transversely Isotropic MaterialHanmant PhadatareNo ratings yet

- 1997 Design Axially Loaded Piles 1Document7 pages1997 Design Axially Loaded Piles 1erick velascoNo ratings yet

- What Is Flow?: Turbulent Flow Laminar FlowDocument3 pagesWhat Is Flow?: Turbulent Flow Laminar FlowAurelia AlexandraNo ratings yet

- CM 425 - Properties of Fresh Concrete PDFDocument14 pagesCM 425 - Properties of Fresh Concrete PDFTran Huynh NamNo ratings yet

- PC130-7 (YEAM200400) (OM Eng) (WM)Document300 pagesPC130-7 (YEAM200400) (OM Eng) (WM)Анатолий ЩербаковNo ratings yet

- Models - Cfd.turbulent BackstepDocument18 pagesModels - Cfd.turbulent BackstepRouaissi RidhaNo ratings yet

- Air - Conditioning and RefrigerationDocument4 pagesAir - Conditioning and RefrigerationsarmadNo ratings yet

- Catálogo StaubliDocument8 pagesCatálogo StaubliJackson BravosNo ratings yet

- USHTRD HighTempRefrigDryer 07-2020 67-37017Document2 pagesUSHTRD HighTempRefrigDryer 07-2020 67-37017Adan Serrano CaroNo ratings yet

- Last Service ReportDocument4 pagesLast Service ReportSandeep NikhilNo ratings yet

- Technical Data Master: GrippersDocument1 pageTechnical Data Master: Grippersnumber_25No ratings yet

- PHQS250SMCS Stoper ManualDocument39 pagesPHQS250SMCS Stoper ManualgeominambNo ratings yet

- Activity No.3 (Blade Section Forces)Document16 pagesActivity No.3 (Blade Section Forces)Jandrew TanNo ratings yet

- Grain Size Analysis: Axis TitleDocument4 pagesGrain Size Analysis: Axis Titleajit karandikar100% (1)

- Mathcad in Mechanical EngineeringDocument16 pagesMathcad in Mechanical Engineeringgato7777777100% (2)

- Presostatos KPI 1Document10 pagesPresostatos KPI 1Gamaliel QuiñonesNo ratings yet