Professional Documents

Culture Documents

Saudi Aramco Inspection Checklist: Inspect Assembly of Air-Cooled Heat Exchanger Components

Saudi Aramco Inspection Checklist: Inspect Assembly of Air-Cooled Heat Exchanger Components

Uploaded by

mominOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Inspection Checklist: Inspect Assembly of Air-Cooled Heat Exchanger Components

Saudi Aramco Inspection Checklist: Inspect Assembly of Air-Cooled Heat Exchanger Components

Uploaded by

mominCopyright:

Available Formats

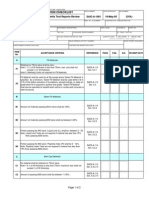

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.

00 30-Jun-16

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Inspect Assembly of Air-Cooled Heat Exchanger Components SAIC-E-2006 15-Nov-17 MECH-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A Driver Installation (API 661 & 32-SAMSS-011 apply as req'd by SAES-E-007, Para. 7.1.1)

Motor frames are made of cast steel or corrosion-resistant cast iron

SAES-E-007,

A1 (unless otherwise agreed by the purchaser), with integrally cast

Para. 7.1.1

support feet. (API 661, Para. 7.2.7.2.3)

32-SAMSS-011,

A2 Electric motors are manufactured in accordance with 17-SAMSS-503

Para. 7.2.7.2.10

32-SAMSS-011,

A3 All drives are mounted beneath the tube bundles

Para. 7.2.7.1.3

For vertically mounted motors, the bearing lubrication system and

SAES-E-007,

A4 seals are suitable for a vertically mounted motor.

Para. 7.1.1

(API 661, Para. 7.2.7.2.5)

If the motor is mounted in the shaft-up position, the belt sheave has a

shield to prevent water from accumulating and being directed down SAES-E-007,

A5

the motor shaft while the motor is either idling or running. (API 661, Para. 7.1.1

Para. 7.2.7.2.6)

32-SAMSS-011,

A6 Belt drives are provided with Removeable guards.

Para. 7.2.8.2.14

32-SAMSS-011,

Belt drives are synchronous high torque (toothed) type and Belt

A7 Para. 7.2.8.2.1 &

tensioning adjustment is possible without removal of fan guards.

Para. 7.2.8.2.14

Gaps between guards & equipment is 13 mm (1/2 in). (API 661, SAES-E-007,

A8

Para. 7.2.8.4.3) Para. 7.1.1

Grade mounted exchangers, headroom clearance below unit,

excluding driver arrangement, is not less than 2150 mm between fan 32-SAMSS-011,

A9

ring and grade for forced draft units, and between tube bundle and Para. 7.3.1.9

grade for induced draft units.

Hot-air re-circulation motors and the drivers are not exposed to 32-SAMSS-011,

A10

heated re-circulated air temperature higher than their design temp. Para. 7.2.1.9

Belt drives are provided with jack screws or an equivalent means of

SAES-E-007,

A11 initial belt-tensioning and/or retensioning.

Para. 7.1.1

(API 661, Para. 7.2.8.2.4)

The drive-belt jacket confirms to oil resistant. SAES-E-007,

A12

(API 661, Para. 7.2.8.2.12) Para. 7.1.1

Gear boxes are provided with an external oil level indicator visible SAES-E-007,

A13

from the maintenance platform. (API 661, Para. 7.2.8.3.6) Para. 7.1.1

B Fan Shaft

Gear- box vents, oil filters, sight glasses and lubrication connections 32-SAMSS-011,

B1

are located outside the plenums. Para. 7.2.1.10

Stainless steel tubing with an outside diameter of at least 6 mm (1/4 SAES-E-007,

B2

inch) are used for grease lines. (API 661, Para. 7.2.5) Para. 7.1.1

Saudi Aramco: Company General Use

Thrust bearings are mounted so as to allow removal without 32-SAMSS-011,

B3

dismantling shaft or hub and located at the lower end of shafts. Para. 7.2.4.8

Bearings are re-greasable type. Grease supply tubing are at 32-SAMSS-011,

B4

accessible location. Bearing housing are dust and drip proof. Para. 7.2.4.9

Actuators for auto-variable pitch fans are provided with maximum

32-SAMSS-011,

B5 pitch stops. NOTE: The design blade setting shall be marked on the

Para. 7.2.3.17

hub nameplate.

Saudi Aramco: Company General Use

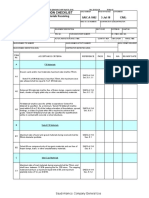

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.00 30-Jun-16

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Inspect Assembly of Air-Cooled Heat Exchanger Components SAIC-E-2006 15-Nov-17 MECH-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

C Louvres (See Attachment 2)

The thickness of louvre blades manufactured from plain sheets shall

be at least 1.5mm (16 gauge USS, 0.060 inch) for carbon steel and

SAES-E-007,

C1 2.3 mm (0.090 inch) for aluminium.

Para. 7.1.1

(NOTE: The thickness of extruded hollow-shaped aluminium blades

shall be at least 1.5 mm (0.060 inch). (API 661, Para. 7.2.10.1)

Steel louvre blades and frames are galvanized all cut and punched

SAES-E-007,

C2 edges shall be protected by a zinc-rich coating and Louvre blade

Para. 7.1.1

pivot pins are made of austenitic stainless steel. (API 661,Para. 8.3.)

Unsupported louvre blade length not exceeded to 2.1 m (7 ft). (API SAES-E-007,

C3

661, Para. 7.2.10.3) . Deflection Tolerance - See Attachment 2 Para. 7.1.1

The gap between the louvre blade and the frame at the header ends SAES-E-007,

C4

not exceeded to 6 mm (1/4 inch). (API 661, Para. 7.2.10.6) Para. 7.1.1

The gap between the louvre blades and the frame at the louvre sides SAES-E-007,

C5

not exceeded to 3 mm (1/8 inch). (API 661, Para. 7.2.10.7) Para. 7.1.1

The measured gap between any two blades in closed position not SAES-E-007,

C6

exceeded to 3mm (1/8"). (API 661 Para. 7.2.10.10) Para. 7.1.1

32-SAMSS-011,

C7 All control louvers have side mounted hand wheels.

Para. 7.2.10.26

D Plenum, Fan Ring and Fan Guards (See Attachment 2)

The thickness of steel sheet material used in the construction of

SAES-E-007,

D1 plenums is at least 2.0mm (14 gauge USS, 0.075 inch) flat or 1.5 mm

Para. 7.1.1

(16 gauge USS, 0.060 inch) ribbed. (API 661 Para. 7.3.4.6)

Assembly of plenums and fan rings conform with the manufacturer's

D2 AFC Drawings

Construction drawing details.

The radial clearance between the fan tip and the fan ring is as shown SAES-E-007,

D3 in Att 1-Table 6. (API 661, Para. 7.2.3.6) Para. 7.1.1

Enclosed plenums with hot air re-circulation are equipped with fan 32-SAMSS-011,

D4

shaft bearing vibration transducers. Para. 7.2.4.7

Flattened expanded metal for fan guards not exceeded to SAES-E-007,

D5

50 mm (2 inch) nominal mesh size. (API 661, Para. 7.2.6.3) Para. 7.1.1

The distance from fan guard to fan blade at its maximum operating

SAES-E-007,

D6 pitch shall be at least 150 mm (6 inch) or six times the smaller of the

Para. 7.1.1

opening dimensions, whichever is less. (API 661, Para. 7.2.6.8)

E Structural Components

Header platforms have toeboard on the side next to the exchanger. SAES-E-007,

E1

(API 661, Para. 7.3.5.6) Para. 7.1.1

A knee rail is fitted where gap between the platform & exchanger is SAES-E-007,

E2

greater than 150 mm (6 inches) . (API 661, Para. 7.3.5.6) Para. 7.1.1

E3 If steel pipe railings are not galvanized, they shall be sealed to SAES-E-007,

prevent internal corrosion. (API 661, Para. 7.3.5.7) Para. 7.1.1

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.00 30-Jun-16

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Inspect Assembly of Air-Cooled Heat Exchanger Components SAIC-E-2006 15-Nov-17 MECH-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Shipping bolts between housing & both header boxes are removed. 32-SAIP-11,

E4

Note: Unit cells shall be allowed to expand freely if put in service. Para. 5.4.4

Structural supports, such as side frames and beams, that are part of

SAES-E-007,

E5 the tube bundle and not accessible for maintenance shall be

Para. 7.1.1

galvanized unless otherwise specified. (API 661, Para. 8.1.3)

Bolted connections for load-bearing members are inspected using SAES-E-007,

E6

SAIC-M-2009. (API 661, Para. 7.3.1.2) Para. 7.1.1

Structural Supports and access structures are inspected per 32-SAMSS-011,

E7

SATIP-M-001-01. For Ref see Att 2 Para.7.3.5

HARWARE RECEIVING INSPECTION & ISSUE CONTROL during APPROVED IFC

any field assembly is the most critical part of assembly to DRAWINGS &

E8

prevent rework. This is req'd for all Packaged Assemblies. HARDWARE

Verify that every type of hardware installed meets specs. SPECIFICATION

REMARKS:

NOTES: 1. API 661 & 32-SAMSS-011 apply for all Components Installed. Utilize a field copy of these docs & review reqmts before work.

ATTACHMENTS:

ATTACHMENT 1 - API 661 AIR-COOLED HEAT EXCHANGERS & COMPONENTS

ATTACHMENT 2 - COMPONENT ALIGNMENT, CLEARANCE & OTHER TOLERANCES, MECHANICAL ACCESS FACILITIES

REFERENCE DOCUMENTS:

1. 32-SAIP-11, Inspection of Air-Cooled Heat Exchangers, 15 September-2014

2. SAES-E-007, Design Criteria of Air-Cooled Heat Exchangers, (9 April 2015)

3. 32-SAMSS-011, Manufacture of Air-Cooled Heat Exchangers, (30 June 2014)

4. API Standard 661, Air-Cooled Heat Exchangers for General Refinery Service, SIXTH EDITION, FEBRUARY 2006

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.00 30-Jun-16

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Inspect Assembly of Air-Cooled Heat Exchanger Components SAIC-E-2006 15-Nov-17 MECH-

ATTACHMENT 1 - API 661 AIR-COOLED HEAT EXCHANGERS & COMPONENTS

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.00 30-Jun-16

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Inspect Assembly of Air-Cooled Heat Exchanger Components SAIC-E-2006 15-Nov-17 MECH-

ATTACHMENT 2 - COMPONENT ALIGNMENT, CLEARANCE & OTHER TOLERANCES

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

You might also like

- Victorian Case Study SolutionDocument3 pagesVictorian Case Study Solutionfaraz ahmad khan100% (2)

- Applicable Codes & Standards For Aramco Projects (Piping)Document107 pagesApplicable Codes & Standards For Aramco Projects (Piping)momin100% (11)

- Hydrostatic Testing ProcedureDocument7 pagesHydrostatic Testing Proceduremomin100% (2)

- Non-Conformance Control ProcedureDocument12 pagesNon-Conformance Control Proceduremomin100% (1)

- Saic Q 1002Document1 pageSaic Q 1002Hussain Nasser Al- NowiesserNo ratings yet

- 9852 3313 01a Maintenance Instructions PowerROC T50 Tier 4 PDFDocument138 pages9852 3313 01a Maintenance Instructions PowerROC T50 Tier 4 PDFtodd100% (2)

- Saic M 1002Document2 pagesSaic M 1002Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1030Document3 pagesSaic M 1030Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1073Document6 pagesSaic M 1073Hussain Nasser Al- NowiesserNo ratings yet

- Saic e 2005Document13 pagesSaic e 2005jerinNo ratings yet

- Saic M 1025Document4 pagesSaic M 1025Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1067Document2 pagesSaic M 1067Hussain Nasser Al- Nowiesser100% (2)

- Saudi Aramco Inspection Checklist: Nitrogen and Pearlite Application On BAHE Frame SAIC-E-2011 15-Nov-17 MechDocument1 pageSaudi Aramco Inspection Checklist: Nitrogen and Pearlite Application On BAHE Frame SAIC-E-2011 15-Nov-17 MechmominNo ratings yet

- Saic M 1031Document1 pageSaic M 1031Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1034Document3 pagesSaic M 1034Hussain Nasser Al- NowiesserNo ratings yet

- Saic o 1004Document1 pageSaic o 1004Hussain Nasser Al- NowiesserNo ratings yet

- Saic o 1001Document1 pageSaic o 1001Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 2004Document6 pagesSaic M 2004Hussain Nasser Al- NowiesserNo ratings yet

- SATIP-S-060-08 Rev 8 Copper Piping FinalDocument2 pagesSATIP-S-060-08 Rev 8 Copper Piping FinalmominNo ratings yet

- Saic M 1064Document3 pagesSaic M 1064Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1033Document4 pagesSaic M 1033Hussain Nasser Al- NowiesserNo ratings yet

- Saic B 1001Document1 pageSaic B 1001Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1005Document2 pagesSaic M 1005Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1004Document2 pagesSaic M 1004Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1060Document1 pageSaic M 1060Hussain Nasser Al- NowiesserNo ratings yet

- SATIP-S-060-02 Rev 8 Electric Drinking Water Coolers FinalDocument2 pagesSATIP-S-060-02 Rev 8 Electric Drinking Water Coolers FinalmominNo ratings yet

- Saic M 1043Document1 pageSaic M 1043Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1053Document1 pageSaic M 1053Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1070Document1 pageSaic M 1070Hussain Nasser Al- NowiesserNo ratings yet

- Saudi Aramco Inspection Checklist: Storage Handling & Presevation of Heat Exchangers. SAIC-E-2003 15-Nov-17 MechDocument7 pagesSaudi Aramco Inspection Checklist: Storage Handling & Presevation of Heat Exchangers. SAIC-E-2003 15-Nov-17 MechmominNo ratings yet

- Saic M 1032Document3 pagesSaic M 1032Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1047Document1 pageSaic M 1047Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1065Document2 pagesSaic M 1065Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1062Document1 pageSaic M 1062Hussain Nasser Al- NowiesserNo ratings yet

- Saic A 1001Document2 pagesSaic A 1001Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1041Document1 pageSaic M 1041Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1052Document1 pageSaic M 1052Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1001Document4 pagesSaic M 1001Hussain Nasser Al- NowiesserNo ratings yet

- Saic A 1002Document2 pagesSaic A 1002karthi51289No ratings yet

- Saic M 1008Document1 pageSaic M 1008Hussain Nasser Al- NowiesserNo ratings yet

- Saudi Aramco Inspection ChecklistDocument19 pagesSaudi Aramco Inspection ChecklistIrshad IqbalNo ratings yet

- Saudi Aramco Inspection Checklist: Review of SIS For Air Cooled Heat Exchanger SAIC-E-2004 15-Nov-17 MechDocument8 pagesSaudi Aramco Inspection Checklist: Review of SIS For Air Cooled Heat Exchanger SAIC-E-2004 15-Nov-17 MechmominNo ratings yet

- Saudi Aramco Inspection Checklist: Internal Cleanliness Inspection of Heat Exchangers SAIC-E-2009 15-Nov-17 MechDocument3 pagesSaudi Aramco Inspection Checklist: Internal Cleanliness Inspection of Heat Exchangers SAIC-E-2009 15-Nov-17 MechmominNo ratings yet

- SATIP-B-069-01 Rev 8 Emergency EyewashShower System FinalDocument2 pagesSATIP-B-069-01 Rev 8 Emergency EyewashShower System FinalmominNo ratings yet

- Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 Weldm4metzNo ratings yet

- 01-SAMSS-048 PDF Download - CRA Clad or Lined Steel PipeDocument4 pages01-SAMSS-048 PDF Download - CRA Clad or Lined Steel PipeZahidRafiqueNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Saic e 2002Document10 pagesSaic e 2002jerinNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistWaleed MedhatNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanmominNo ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklistkartik_harwani4387No ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinNo ratings yet

- Saic A 1006Document1 pageSaic A 1006Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 2021Document6 pagesSaic M 2021Hussain Nasser Al- NowiesserNo ratings yet

- Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Dec-09 WeldDocument27 pagesSaudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Dec-09 WeldIrshad IqbalNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument1 pageInspection & Testing Requirements Scope:: Test and Inspection PerEagle SpiritNo ratings yet

- Saic B 1002Document2 pagesSaic B 1002Hussain Nasser Al- NowiesserNo ratings yet

- Saudi Aramco Inspection Checklist: Concrete Fireproofing Final Inspection SAIC-B-1004 3-Jul-18 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Concrete Fireproofing Final Inspection SAIC-B-1004 3-Jul-18 Civilkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 30-Apr-13 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 30-Apr-13 CivilJeffrey Lipata Jr.No ratings yet

- Saic Q 1017Document1 pageSaic Q 1017Hussain Nasser Al- Nowiesser100% (2)

- Saic M 2010Document17 pagesSaic M 2010jerinNo ratings yet

- SAIC-D-2004 Rev 8Document3 pagesSAIC-D-2004 Rev 8Syed ImranNo ratings yet

- SAIC-D-2020 Tank Trim Installation MAS-rlcDocument3 pagesSAIC-D-2020 Tank Trim Installation MAS-rlcAnonymous S9qBDVkyNo ratings yet

- Saudi Aramco Inspection Checklist: Installation of Wellhead Guard Rails. SAIC-L-2088 25-May-05 MechDocument2 pagesSaudi Aramco Inspection Checklist: Installation of Wellhead Guard Rails. SAIC-L-2088 25-May-05 MechAnonymous S9qBDVkyNo ratings yet

- Saudi Aramco Inspection Checklist: Installation of Wellhead Guard Rails. SAIC-L-2088 30-Apr-17 MechDocument4 pagesSaudi Aramco Inspection Checklist: Installation of Wellhead Guard Rails. SAIC-L-2088 30-Apr-17 Mechkarthi51289No ratings yet

- IMS ManualDocument6 pagesIMS ManualmominNo ratings yet

- Management Review 2020Document2 pagesManagement Review 2020mominNo ratings yet

- Ba090205 001Document1 pageBa090205 001mominNo ratings yet

- Project Quality Plan (JFJS-788)Document18 pagesProject Quality Plan (JFJS-788)mominNo ratings yet

- Alf Piping 117 009Document6 pagesAlf Piping 117 009mominNo ratings yet

- Magnetic Particle Testing ProcedureDocument11 pagesMagnetic Particle Testing ProceduremominNo ratings yet

- Part.1 Issued For Construction (Fire Protection)Document322 pagesPart.1 Issued For Construction (Fire Protection)mominNo ratings yet

- Ba090211 005Document1 pageBa090211 005mominNo ratings yet

- Sep Mgse CM SCM 0031 Procedure For Valve Testing and InstallationDocument6 pagesSep Mgse CM SCM 0031 Procedure For Valve Testing and InstallationmominNo ratings yet

- Mgse T Sep Sa 0029Document1 pageMgse T Sep Sa 0029mominNo ratings yet

- 0001Document1 page0001mominNo ratings yet

- SATIP-S-030-01, Rev 8 Storm Water Drainage System G FinalDocument3 pagesSATIP-S-030-01, Rev 8 Storm Water Drainage System G Finalmomin0% (1)

- Saic-H-2027Document3 pagesSaic-H-2027momin0% (1)

- Saic-H-2030Document9 pagesSaic-H-2030mominNo ratings yet

- Saudi Aramco Inspection Checklist: Re-Instatement of Air Cooled Heat Exchanger SAIC-E-2008 15-Nov-17 MechDocument5 pagesSaudi Aramco Inspection Checklist: Re-Instatement of Air Cooled Heat Exchanger SAIC-E-2008 15-Nov-17 MechmominNo ratings yet

- Saic-H-2028Document11 pagesSaic-H-2028mominNo ratings yet

- Saudi Aramco Inspection Checklist: Storage Handling & Presevation of Heat Exchangers. SAIC-E-2003 15-Nov-17 MechDocument7 pagesSaudi Aramco Inspection Checklist: Storage Handling & Presevation of Heat Exchangers. SAIC-E-2003 15-Nov-17 MechmominNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 15-Nov-17 MechDocument13 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 15-Nov-17 MechmominNo ratings yet

- Satr-H-2006 3.3Document3 pagesSatr-H-2006 3.3mominNo ratings yet

- Saic-H-2029Document12 pagesSaic-H-2029mominNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanmominNo ratings yet

- Saudi Aramco Inspection Checklist: Review of SIS For Air Cooled Heat Exchanger SAIC-E-2004 15-Nov-17 MechDocument8 pagesSaudi Aramco Inspection Checklist: Review of SIS For Air Cooled Heat Exchanger SAIC-E-2004 15-Nov-17 MechmominNo ratings yet

- Saudi Aramco Inspection Checklist: Nitrogen and Pearlite Application On BAHE Frame SAIC-E-2011 15-Nov-17 MechDocument1 pageSaudi Aramco Inspection Checklist: Nitrogen and Pearlite Application On BAHE Frame SAIC-E-2011 15-Nov-17 MechmominNo ratings yet

- SATIP-S-060-04 REV 8 Plumbing Fixtures and Fittings FinalDocument2 pagesSATIP-S-060-04 REV 8 Plumbing Fixtures and Fittings FinalmominNo ratings yet

- Saudi Aramco Inspection Checklist: Internal Cleanliness Inspection of Heat Exchangers SAIC-E-2009 15-Nov-17 MechDocument3 pagesSaudi Aramco Inspection Checklist: Internal Cleanliness Inspection of Heat Exchangers SAIC-E-2009 15-Nov-17 MechmominNo ratings yet

- SATIP-S-060-02 Rev 8 Electric Drinking Water Coolers FinalDocument2 pagesSATIP-S-060-02 Rev 8 Electric Drinking Water Coolers FinalmominNo ratings yet

- SATIP-S-060-08 Rev 8 Copper Piping FinalDocument2 pagesSATIP-S-060-08 Rev 8 Copper Piping FinalmominNo ratings yet

- Oral Iron ProductsDocument2 pagesOral Iron ProductsOlga BabiiNo ratings yet

- Lemon Grass FeasibilityDocument7 pagesLemon Grass FeasibilityGanyfer DoradoNo ratings yet

- Respiratory FailureDocument29 pagesRespiratory Failureageng rusbaya0% (1)

- Essentials of Genetics 9th Edition Klug Test BankDocument7 pagesEssentials of Genetics 9th Edition Klug Test Banklloydngann6w9100% (33)

- HNBB & Febsan Drug StudyDocument4 pagesHNBB & Febsan Drug StudyKeziah PilotosNo ratings yet

- Growth of Beauty E-Commerce in IndiaDocument9 pagesGrowth of Beauty E-Commerce in IndiaHemant AnantNo ratings yet

- Health As Wealth, Amin and Jamilya PDFDocument13 pagesHealth As Wealth, Amin and Jamilya PDFMohammadamin SadeghiyanNo ratings yet

- Human Genome ProjectDocument57 pagesHuman Genome ProjectIsma Velasco100% (1)

- Guidelines For Human Settlement Planning and Design Redbook V2Document379 pagesGuidelines For Human Settlement Planning and Design Redbook V2Mark JacobsNo ratings yet

- 319 6904116 Om 10 05 PDFDocument136 pages319 6904116 Om 10 05 PDFvatasaNo ratings yet

- Homework Should Be Banned Debate AgainstDocument6 pagesHomework Should Be Banned Debate Againstcjavymac100% (1)

- A Presentation On: Presented byDocument67 pagesA Presentation On: Presented byOlufemi KolawoleNo ratings yet

- Applying The Chronic Care Model in Low-Resource Settings Ada Dec2013Document44 pagesApplying The Chronic Care Model in Low-Resource Settings Ada Dec2013Wawan JokoNo ratings yet

- bài tập câu điều kiện tổng hợpDocument2 pagesbài tập câu điều kiện tổng hợpNguyễn Kim LongNo ratings yet

- Outside 2014-01Document116 pagesOutside 2014-01virgilionescuNo ratings yet

- QCP 040 QCP CrmsDocument7 pagesQCP 040 QCP Crmsarockiyathass100% (1)

- CastleDocument299 pagesCastlejeffaustonNo ratings yet

- Non-Catalytic Pyrolysis of Ethane To Ethylene in The Presence of CO2 With or Without Limited O2Document7 pagesNon-Catalytic Pyrolysis of Ethane To Ethylene in The Presence of CO2 With or Without Limited O2Sharry ApudNo ratings yet

- Pricelist Toza Juices NewDocument1 pagePricelist Toza Juices NewREZHASP OFFICIALNo ratings yet

- Agro Climatic Zones of India - Zone 10Document23 pagesAgro Climatic Zones of India - Zone 10Parvathi MurukeshNo ratings yet

- Home Economics Book 1Document183 pagesHome Economics Book 1Josephine MaestreNo ratings yet

- Army TM 9-2320-289-20P Air Force To 36a12-1a-2084-1 Marine Corps TM 2320-20P/3Document724 pagesArmy TM 9-2320-289-20P Air Force To 36a12-1a-2084-1 Marine Corps TM 2320-20P/3Albaro AguirreNo ratings yet

- Seguritan v. PeopleDocument9 pagesSeguritan v. PeopleAAMCNo ratings yet

- Brain Computer Interface FinalDocument18 pagesBrain Computer Interface FinalMOHAMMED PARVEZ ALAM60% (10)

- C Ase Format: Govt of Kerala Department of HomoeopathyDocument4 pagesC Ase Format: Govt of Kerala Department of HomoeopathyDr.Augustin.A.JNo ratings yet

- DDCP SF 04 04aDocument6 pagesDDCP SF 04 04aMohammad FarajNo ratings yet

- HT 100 101 130 131 ManualDocument106 pagesHT 100 101 130 131 ManualKer Salas GonzálezNo ratings yet

- Ufc 3 600 01Document132 pagesUfc 3 600 01Juan RomeroNo ratings yet