Professional Documents

Culture Documents

Val Caraig WPQT

Val Caraig WPQT

Uploaded by

Mark Jason M. BrualOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Val Caraig WPQT

Val Caraig WPQT

Uploaded by

Mark Jason M. BrualCopyright:

Available Formats

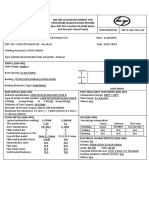

NIKKERU PLANT MAINTENANCE SOLUTION INC.

#446-A Central Libjo, Batangas City

Batangas City, Philippines 4200

Telephone No.: (043) 741-5891 / (043) 980 7084

Mobile No.: (+63) 917 701 5804/ (+63) 998 792 8544

WELDER PERFORMANCE QUALIFICATION TESTING (WPQT)

Welder’s Name VAL V. CARAIG ID No. NW-003

Ref. WPS No. NPMSI-018 Test Coupon Production Weld

Base Metal A106/A53 Thickness 6.02mm

Testing Conditions and Qualification Limits

Welding Variables Actual Values Range Qualified

Process GTAW SMAW

Process Type Manual Manual

Backing Without With or Without

Pipe (Enter Pipe Dia.) Pipe 4 ” Ø Pipe ≥114.30 mm OD

Base Metal P- or S-Number to P- or S-Number P1 P1

Filler Metal or Electrode Specification(s) SFA 5.18 SFA 5.1

Filler Metal or Electrode Classification(s) ER 70S-2 E-7018

Filler Metal F-Number(s) 6 4

Consumable Insert (GTAW or PAW) - -

Filler Type (solid/metal or flux cored/powder) (GTAW or PAW) - -

Deposited Weld Metal Thickness - -

Process 1 1.5mm 12.04mm

Process 2 - -

Position Qualified 6G All ( Pipe)

Welding Progression (uphill or Downhill) Uphill Uphill

Type of Fuel Gas (OFW) - -

Inert Gas Backing - -

Transfer Mode (spray/globular or pulse to short circuit-GMAW) - -

Current type/polarity DCSP DCRP

RESULTS

Visual Examination of Completed Weld Accepted

Bend Test Transverse Root and Face Bend Test Longitudinal Root and Face Bend Test Side Bend Test

Pipe Bend Specimen, corrosion resistant overlay Plate Bend Specimen, corrosion resistant overlay

Macro Test for fusion Macro Test for fusion

Type Result Type Result

FACE BEND 1 26-180 FACE BEND 2 26-180

ROOT FACE BEND 1 26-180 ROOT FACE BEND 2 26-180

Alternative Radiographic Examination results Accepted (WTL-OP-TM-2019-NPMSI)9PWHT-2K19-004B

Fillet Weld – fracture test Length and percent of defects

Macro Examination Fillet Size (in.) Concavity/convexity (in.)

Other Tests PWHT (9PWHT-2K19-004B)

Film or specimens evaluated by Accepted (WTL-OP-TM-2019 NPMSI)9PWHT-2K19-004B) COMPANY WTL

Mechanical Tests conducted by MIRDC Laboratory Test No. MIRDC-092019-MML-1259

Welding Supervised by

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and tested in accordance

with the requirements of Section IX of the ASME Boiler and Pressure Vessel Code.

Test Witnessed by: Noted by: Approved by:

Company NPMSI NPMSI

Name MJ.M.BRUAL R.V.CONTRERAS

Sign

Date 27-OCT-2019 27-OCT-2019

You might also like

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocument1 pageAws D1.1 - WPS - Smaw-Fcaw PDFThe Welding Inspections CommunityNo ratings yet

- WPS PQR A36.20Document5 pagesWPS PQR A36.20gchaves504100% (3)

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Document5 pagesWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- Welding Procedure Qualification Certificate EN ISO 15614-1: 2017Document3 pagesWelding Procedure Qualification Certificate EN ISO 15614-1: 2017dcsamaraweera100% (1)

- Wps Is 2062 GR B Butt-OkDocument2 pagesWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- P-WPS 135 - MAG (GR 316)Document9 pagesP-WPS 135 - MAG (GR 316)Tarun PatelNo ratings yet

- WPSDocument2 pagesWPSJuli Agus50% (2)

- WPSDocument6 pagesWPSNur Wijianto100% (1)

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- Muet 2006 To 2019 Past PapersDocument148 pagesMuet 2006 To 2019 Past PapersUmaid Ali Keerio100% (2)

- Audio Information and MediaDocument2 pagesAudio Information and Mediajosefalarka75% (4)

- Slamet WPQRDocument1 pageSlamet WPQRChandra Bintang W.PNo ratings yet

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (3)

- Welder'S Qualification Test Certificate: (As Per Asme Sec Ix)Document2 pagesWelder'S Qualification Test Certificate: (As Per Asme Sec Ix)vijay100% (1)

- WQTDocument1 pageWQTRamkunwar YadavNo ratings yet

- WPQ Formats NEWDocument4 pagesWPQ Formats NEWMANABENDRA MAITRANo ratings yet

- Format WPQDocument2 pagesFormat WPQAkash Singh TomarNo ratings yet

- Abdul Muhid WPQRDocument1 pageAbdul Muhid WPQRChandra Bintang W.PNo ratings yet

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocument1 pageWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavNo ratings yet

- Pt. Vista Bangun Utama: in Accordance With Section IX, ASME Boiler and Pressure Vessel Code 2013 EditionDocument1 pagePt. Vista Bangun Utama: in Accordance With Section IX, ASME Boiler and Pressure Vessel Code 2013 EditionHaryanto RNo ratings yet

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaNo ratings yet

- HOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)Document3 pagesHOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)TuTuy AnNo ratings yet

- WPQDocument10 pagesWPQayoki100% (3)

- VLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmDocument3 pagesVLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmTuTuy AnNo ratings yet

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pages163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- QW-484A (WPQ) GTAW 4MM FilletDocument2 pagesQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- PQR With-PwhtDocument2 pagesPQR With-PwhtKarthikNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (2)

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pages(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- WPS 19Document15 pagesWPS 19Avishek Gupta100% (1)

- Aws d1.1 WPS, PQR & WQTDocument4 pagesAws d1.1 WPS, PQR & WQTWeld Bro SandeepNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document2 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmackNo ratings yet

- WPS - 024Document4 pagesWPS - 024MAT-LIONNo ratings yet

- WPS Dissimilar UpdatedDocument3 pagesWPS Dissimilar UpdatedVimin Prakash100% (1)

- Welding Procedure Specification: Neo StructoDocument2 pagesWelding Procedure Specification: Neo Structohareesh13hNo ratings yet

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNo ratings yet

- PQR - PipeDocument3 pagesPQR - PipeAdvanced Quality Centre AQC100% (1)

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoNo ratings yet

- Final - WPS PQR 86Document4 pagesFinal - WPS PQR 86Parag WadekarNo ratings yet

- QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQW-301, Section IX, ASME Boiler and Pressure Vessel Code)rajuNo ratings yet

- Wps Gmaw SawDocument2 pagesWps Gmaw Sawupedro26No ratings yet

- Wps Aws d1.1 NEWDocument2 pagesWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- Welding Procedure Qualification Certificate (EN ISO 15614-1)Document3 pagesWelding Procedure Qualification Certificate (EN ISO 15614-1)mohdfirdausNo ratings yet

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- 385 2 Internal Gtaw+SmawDocument2 pages385 2 Internal Gtaw+Smawsubash1688No ratings yet

- Aws 001Document1 pageAws 001akshay sarfareNo ratings yet

- Dokumen - Tips Wqt-FormatDocument2 pagesDokumen - Tips Wqt-FormatMr Pie100% (1)

- PQR Gmaw3gDocument4 pagesPQR Gmaw3gdevendrasingh2021100% (3)

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- PQR TipsDocument4 pagesPQR TipsWaqas WaqasNo ratings yet

- WPQT FormatDocument176 pagesWPQT FormatRafiqKu50% (2)

- Welder Certificate Akilesh YadavDocument1 pageWelder Certificate Akilesh Yadavtripatipankaj023No ratings yet

- MD - Akibur Sheikh WQTDocument2 pagesMD - Akibur Sheikh WQTMD Shadikul Huq ShezanNo ratings yet

- Sujan Das WQTDocument2 pagesSujan Das WQTMD Shadikul Huq ShezanNo ratings yet

- I-963 Welder Certificate Smaw-Gtaw-1Document1 pageI-963 Welder Certificate Smaw-Gtaw-1nivedithdigitals onlineservices100% (1)

- WPQ Sunil Yadav W-13 PQR 003 Smaw - PipeDocument1 pageWPQ Sunil Yadav W-13 PQR 003 Smaw - Pipeharshileng3992100% (1)

- Welder Performance Qualification (WPQ) According To ASME IX Hassan HussienDocument1 pageWelder Performance Qualification (WPQ) According To ASME IX Hassan HussienMahmoud shawkyNo ratings yet

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDocument3 pagesWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniNo ratings yet

- WPQ WeldCanada PDFDocument1 pageWPQ WeldCanada PDFAhmad DanielNo ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationMark Jason M. BrualNo ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationMark Jason M. BrualNo ratings yet

- Welder Qualification Record TemplateDocument1 pageWelder Qualification Record TemplateMark Jason M. BrualNo ratings yet

- Handover List (JG Summit) Item Description RemarksDocument5 pagesHandover List (JG Summit) Item Description RemarksMark Jason M. BrualNo ratings yet

- Materials Fittings For TAB Shell Item Description QTY 1 1/2" Welded Neck Flange Cs 4 2 1/2" Ball Valve SW 2Document1 pageMaterials Fittings For TAB Shell Item Description QTY 1 1/2" Welded Neck Flange Cs 4 2 1/2" Ball Valve SW 2Mark Jason M. BrualNo ratings yet

- Mapeh GR9 First Quarter ReviewerDocument8 pagesMapeh GR9 First Quarter ReviewerRalph Emerson SantillanNo ratings yet

- A Picture Is Worth A Thousand Words: The Benefit of Medical Illustration in Medical PublishingDocument6 pagesA Picture Is Worth A Thousand Words: The Benefit of Medical Illustration in Medical PublishingSinisa RisticNo ratings yet

- 5054 s16 Ms 41 PDFDocument3 pages5054 s16 Ms 41 PDFKritish RamnauthNo ratings yet

- The Design of An Annular Combustion Chamber: October 2017Document11 pagesThe Design of An Annular Combustion Chamber: October 2017ko koNo ratings yet

- MTCNA Lab Guide INTRA 1st Edition - Id.en PDFDocument87 pagesMTCNA Lab Guide INTRA 1st Edition - Id.en PDFreyandyNo ratings yet

- Springer Nature Latex TemplateDocument13 pagesSpringer Nature Latex TemplateAndres FloresNo ratings yet

- CS FinalDocument52 pagesCS FinalLucky KhuhaNo ratings yet

- Jamboree GRE StudyPlan PDFDocument3 pagesJamboree GRE StudyPlan PDFMd Minhaj Ahmed AhmedNo ratings yet

- Machine Tool TestingDocument4 pagesMachine Tool Testingnm2007k100% (1)

- English For ITDocument276 pagesEnglish For ITBao Tram100% (1)

- Whittaker Dynamics 17Document442 pagesWhittaker Dynamics 17Mahmoud Ahmed 202201238No ratings yet

- Grade 7 Lesson: ReproductionDocument4 pagesGrade 7 Lesson: ReproductionJoedelyn Wagas100% (2)

- William Gann Method PDFDocument1 pageWilliam Gann Method PDFchandra widjajaNo ratings yet

- Lancaster University Dissertation HandbookDocument5 pagesLancaster University Dissertation HandbookPaperWritingServiceCheapAnnArbor100% (1)

- FACTORY IO-Sorting of Boxes (1) / PLC - 1 (CPU 1212C AC/DC/Rly) / Pro Gram BlocksDocument3 pagesFACTORY IO-Sorting of Boxes (1) / PLC - 1 (CPU 1212C AC/DC/Rly) / Pro Gram BlocksHasaan HussainNo ratings yet

- Beginner's Guide To SoloDocument12 pagesBeginner's Guide To SoloTiurNo ratings yet

- Respuestas Evaluacion 1Document9 pagesRespuestas Evaluacion 1Juan Carlos Ospina ReyesNo ratings yet

- Manual C28 Plus enDocument28 pagesManual C28 Plus enSveto SlNo ratings yet

- Ai PresentationDocument13 pagesAi Presentationapi-534191655No ratings yet

- Revisit of Harriott's Method For Process ControlDocument3 pagesRevisit of Harriott's Method For Process ControlkiddhoNo ratings yet

- LPPDocument35 pagesLPPommprakashpanda15scribdNo ratings yet

- UNHCR Hygiene Promotion GuidelinesDocument112 pagesUNHCR Hygiene Promotion GuidelinesBrandie ShackelfordNo ratings yet

- Tut Sheet7Document2 pagesTut Sheet7Ekta SharmaNo ratings yet

- BNVD Eaufrance Metadonnees Vente 20230130Document16 pagesBNVD Eaufrance Metadonnees Vente 20230130moussaouiNo ratings yet

- Genuine Eaton Vicker HidrauDocument28 pagesGenuine Eaton Vicker HidrauJenner Volnney Quispe ChataNo ratings yet

- MTT Assay To Evaluate The Cytotoxic Potential of A DrugDocument5 pagesMTT Assay To Evaluate The Cytotoxic Potential of A DrugThanh KieuNo ratings yet

- BitBox CarList 2022 10 28Document97 pagesBitBox CarList 2022 10 28marcos hernandezNo ratings yet

- Hayden Esterak Resume 1Document1 pageHayden Esterak Resume 1api-666885986No ratings yet