Professional Documents

Culture Documents

S30 Non-Metallic Containment Duty Pump: Technical Data Sheet

S30 Non-Metallic Containment Duty Pump: Technical Data Sheet

Uploaded by

Muhamad nurul aminOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

S30 Non-Metallic Containment Duty Pump: Technical Data Sheet

S30 Non-Metallic Containment Duty Pump: Technical Data Sheet

Uploaded by

Muhamad nurul aminCopyright:

Available Formats

S30 NON-METALLIC CONTAINMENT DUTY PUMP

TECHNICAL DATA SHEET

SERIES

CONTAINMENT DUTY BALL VALVE PUMPS

The only complete line of AODD pumps featuring superior fluid containment;

protecting your people, environment, and pump.

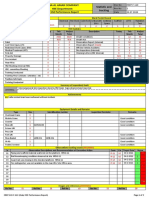

PERFORMANCE

SUCTION / DISCHARGE PORT SIZE

• 3” ANSI Flange or 80mm DIN Flange

CAPACITY

• 0 to 280 GPM (0 to 1060 LPM)

AIR DISTRIBUTION VALVE

• No-lube, no-stall design

BAR

20 (34)

PSI

SOLIDS-HANDLING 40 (68) Performance based on water at ambient temperature.

60 (102)

• Up to .75 (19 mm) 7 100

100 P 80 (136) AIR CONSUMPTION IN SCFM

SI (6.8

HEADS UP TO Bar) AIR PRESSURE IN PSI

• 100 psi or 231 ft. of water 6

100 (170)

(7 bar or 70 meters) 80

80 P 120 (204)

SI (5

MAXIMUM OPERATING PRESSURE 5

.44 B

ar)

• 100 psi (7 bar)

140 (238)

DISPLACEMENT/STROKE 60

HEAD

4 60 PSI

• 1.0 Gallon / 3.78 liter (4.08 B

ar)

WEIGHTS

3

• Polypropylene 271 lbs (123 kg) 40

• PVDF 208 lbs (94 kg) 40 PSI (2

.72 Bar)

2

20

20 PSI (1.3

1 6 Bar) Air

Inlet Pressu

re

0

0 20 40 60 80 100 120 140 160 180 200 220 240 GPM

0 50 150 250 350 450 550 650 750 850 LPM

CAPACITY

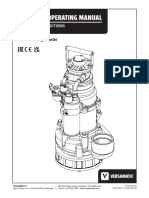

DIMENSIONS

18.80 478

STANDARD ENCAPSULATED DISCHARGE PORT

3" STANDARD 125# FLANGE CONFIGURATION 16.19 411

MUFFLER

1" NPT EXHAUST PORT FOR OPTIONAL .75 [4] HOLES EQUALLY SPACED

5.00 127

MUFFLER STYLES OR PIPING EXHAUST ON A 6.00 [152] BOLT CIRCLE

AIR IN SUBMERGED APPLICATIONS 37.01 940

AIR INLET

3/4 NPT

2X 22.42 569

4X .75 19 2X 6.51 165

40.66 1033

2X 11.00 279

20.25 514

4X 1.00 25 2X 15.00 381 4.94 125

SUCTION PORT 4.85 123 5.00 127

3" STANDARD 125# FLANGE CONFIGURATION

.75 [4] HOLES EQUALLY SPACED

ON A 6.00 [152] BOLT CIRCLE

Warren Rupp, Inc. • A Unit of IDEX Corporation

800 N. Main St., Mansfield, Ohio 44902 USA ISO 9001 Certified

S A N D P I P E R P U M P. C O M Telephone 419.524.8388 • Fax 419.522.7867 ISO 14001 Certified

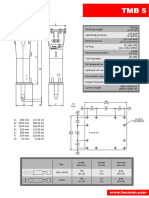

EXPLANATION OF PUMP NOMENCLATURE

S

Your Model

#: __ ____ __ __ __ __ __ __ __ __ __ ____

(fill in from

pump nameplate)

Pump Pump Check Design Wetted Diaphragm/ Check Valve

Non-Wetted Porting Pump Pump Kit

Config. Size Valve Level Material Check Valve Seat Material Options Style Options Options

Model #: S XX X X X X X X X X X XX

PUMP BRAND DIAPHRAGM/CHECK VALVE MATERIALS 7 Dual Porting (ANSI)

S SANDPIPER® 3 PTFE Pumping, PTFE - Santoprene, 8 Top Dual Porting (ANSI)

Backup Driver / PTFE 9 Bottom Dual Porting (ANSI)

PUMP SIZE 4 Santoprene Pumping, Santoprene

30 3” Driver / Santoprene PUMP STYLE

6 PTFE Pumping, PTFE-Neoprene Backup Driver/PTFE D with Electronic Leak Detection (110V)

CHECK VALVE TYPE

E with Electronic Leak Detection (220V)

B Ball CHECK VALVE SEAT

M with Mechanical Leak Detection

K PVDF

DESIGN LEVEL V with Visual Leak Detection

P Polypropylene

3 Design Level

PUMP OPTIONS

NON-WETTED MATERIAL OPTIONS

WETTED MATERIAL 0 None

P 40% Glass Filled Polypropylene

K PVDF

1 40% Glass Filled Polypropylene w / PTFE Coated Hardware KIT OPTIONS

P Polypropylene

Porting Options CONSULT FACTORY

A ANSI Flange

MATERIALS

D DIN Flange

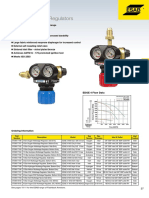

Material Profile: Operating

Temperatures:

POLYPROPYLENE: A thermoplastic polymer. Moderate tensile

and flex strength. Resists stong acids and alkali. Attacked by

180°F

82°C

32°F

0°C

CAUTION! Operating temperature limitations are as follows: chlorine, fuming nitric acid and other strong oxidizing agents.

Max. Min.

PVDF: (Polyvinylidene Fluoride) A durable fluoroplastic with 250°F 0°F

CONDUCTIVE ACETAL: Tough, impact resistant, ductile. Good 190°F -20°F

excellent chemical resistance. Excellent for UV applications. 121°C -18°C

abrasion resistance and low friction surface. Generally inert, 88°C -29°C

High tensile strength and impact resistance.

with good chemical resistance except for strong acids and

oxidizing agents. SANTOPRENE®: Injection molded thermoplastic elastomer with 275°F -40°F

no fabric layer. Long mechanical flex life. Excellent abrasion 135°C -40°C

EPDM: Shows very good water and chemical resistance. Has 280°F -40°F

resistance.

poor resistance to oils and solvents, but is fair in ketones and 138°C -40°C

alcohols. UHMW PE: A thermoplastic that is highly resistant to a broad 180°F -35°F

range of chemicals. Exhibits outstanding abrasion and impact 82°C -37°C

FKM (FLUOROCARBON): Shows good resistance to a wide 350°F -40°F

resistance, along with environmental stress-cracking resistance.

range of oils and solvents; especially all aliphatic, aromatic and 177°C -40°C

halogenated hydrocarbons, acids, animal and vegetable oils. URETHANE: Shows good resistance to abrasives. Has poor 150°F 32°F

Hot water or hot aqueous solutions (over 70°F(21°C)) will attack resistance to most solvents and oils. 66°C 0°C

FKM.

VIRGIN PTFE: (PFA/TFE) Chemically inert, virtually impervious. 220°F -35°F

HYTREL®: Good on acids, bases, amines and glycols at room 220°F -20°F Very few chemicals are known to chemically react with PTFE; 104°C -37°C

temperatures only. 104°C -29°C molten alkali metals, turbulent liquid or gaseous fluorine and a few

fluoro-chemicals such as chlorine trifluoride or oxygen difluoride

NEOPRENE: All purpose. Resistance to vegetable oils. Gener- 200°F -10°F

which readily liberate free fluorine at elevated temperatures.

ally not affected by moderate chemicals, fats, greases and 93°C -23°C

many oils and solvents. Generally attacked by strong oxidizing Maximum and Minimum Temperatures are the limits for which these materials can be

acids, ketones, esters and nitro hydrocarbons and chlorinated operated. Temperatures coupled with pressure affect the longevity of diaphragm pump

aromatic hydrocarbons. components. Maximum life should not be expected at the extreme limits of the

temperature ranges.

NITRILE: General purpose, oil-resistant. Shows good solvent, 190°F -10°F

oil, water and hydraulic fluid resistance. Should not be used with

highly polar solvents like acetone and MEK, ozone, chlorinated

88°C -23°C

Metals:

hydrocarbons and nitro hydrocarbons. ALLOY C: Equal to ASTM494 CW-12M-1 specification for nickel and nickel alloy.

NYLON: 6/6 High strength and toughness over a wide tem- 180°F 32°F STAINLESS STEEL: Equal to or exceeding ASTM specification A743 CF-8M for corro-

perature range. Moderate to good resistance to fuels, oils and 82°C 0°C sion resistant iron chromium, iron chromium nickel and nickel based alloy castings for

chemicals. general applications. Commonly referred to as 316 Stainless Steel in the pump industry.

For specific applications, always consult the Chemical Resistance Chart.

5 YEAR LIMITED PRODUCT WARRANTY USE ONLY GENUINE SANDPIPER PARTS

EX

CLUSIVE

5 Year Guarantee for defects in material or workmanship. See All certification, standards, guarantees & warranties

FE

sandpiperpump.com/content/warranty-certifications originally supplied with this pump will be invalidated by the use of

AT U R E

for complete warranty, including terms and conditions, limitations service parts not identified as “Genuine

and exclusions. SANDPIPER Parts.”

Warren Rupp, Inc. • A Unit of IDEX Corporation

800 N. Main St., Mansfield, Ohio 44902 USA

S A N D P I P E R P U M P. C O M Telephone 419.524.8388 • Fax 419.522.7867 SP_DS_TemplateDataSheet_0817

You might also like

- Daily ReportDocument3 pagesDaily ReportHussein AbumaisNo ratings yet

- CG4352 GM1927 03a Gas Mig Braze Weld Quality Verification ProcedureDocument10 pagesCG4352 GM1927 03a Gas Mig Braze Weld Quality Verification ProcedureBruna VitalNo ratings yet

- 06 237046 001 - BDDocument1 page06 237046 001 - BDcarlos yepezNo ratings yet

- Lone WolfDocument286 pagesLone WolfAmoo Mayowa IsraelNo ratings yet

- Sump PumpDocument2 pagesSump PumpRAM SANNo ratings yet

- S20 Metallic Pump: Technical Data SheetDocument3 pagesS20 Metallic Pump: Technical Data SheetDang LucNo ratings yet

- s20 Metalik Data Sheet Rev0817Document2 pagess20 Metalik Data Sheet Rev0817STEPF cryptoNo ratings yet

- s05 M StandardDocument3 pagess05 M Standardlaura.diazNo ratings yet

- Sandpiper Standard Duty Metallic Pumps s30 Data SheetDocument3 pagesSandpiper Standard Duty Metallic Pumps s30 Data Sheetjose manuel alvarez rodriguezNo ratings yet

- Sandpiper S15 Bomba NeumaticaDocument3 pagesSandpiper S15 Bomba NeumaticaAlejandro AdriasolaNo ratings yet

- S1F Non-Metallic Pump: Technical Data SheetDocument3 pagesS1F Non-Metallic Pump: Technical Data SheetspattacutNo ratings yet

- Metallic Design Level 1 Ball Valve: Air-Powered Double-Diaphragm PumpDocument6 pagesMetallic Design Level 1 Ball Valve: Air-Powered Double-Diaphragm PumpCarlos Alberto OspinaNo ratings yet

- Sandpiper s1f PumpDocument3 pagesSandpiper s1f PumpAdi PurnomoNo ratings yet

- Sandpiper s30nmdl2dsDocument4 pagesSandpiper s30nmdl2dsYongfeng QianNo ratings yet

- HDF1 M HdflapDocument2 pagesHDF1 M HdflapAlvaro Iparraguirre NavarroNo ratings yet

- s30 SMetallic Data SheetDocument5 pagess30 SMetallic Data Sheetluis miguel velarde manrique100% (1)

- pb025 NM STANDARDDocument3 pagespb025 NM STANDARDAlvaro Iparraguirre NavarroNo ratings yet

- Bomba Neumatica Sandpiper Metalica Modelo S20Document8 pagesBomba Neumatica Sandpiper Metalica Modelo S20Edgar EncinaNo ratings yet

- VM Sludgemaster Rev1222Document15 pagesVM Sludgemaster Rev1222Pkk Siam Rayong co-saleNo ratings yet

- Bulldog 43:1 Air-Powered Pump: Ideal For Blowout Preventor SystemsDocument2 pagesBulldog 43:1 Air-Powered Pump: Ideal For Blowout Preventor Systemsangel benito PortilloNo ratings yet

- Colorflow - Control Valves F PDFDocument3 pagesColorflow - Control Valves F PDFAlejandraNo ratings yet

- Operating Instructions: 1" Elima-Matic Bolted PumpDocument13 pagesOperating Instructions: 1" Elima-Matic Bolted PumpJOSE INESNo ratings yet

- T100 Medium-Pressure DatasheetDocument6 pagesT100 Medium-Pressure DatasheetjuninNo ratings yet

- Valvula Serie F ParkerDocument3 pagesValvula Serie F ParkerRogelio ArandaNo ratings yet

- Belgas p39Document4 pagesBelgas p39Syach FirmNo ratings yet

- Eaton 421 Pump Sheet Vers-BDocument2 pagesEaton 421 Pump Sheet Vers-Bdzakky syahputraNo ratings yet

- Sru5 168 HDDocument1 pageSru5 168 HDvicenteNo ratings yet

- Third Angle Projection Do Not Scale: Dimensions in MillimetresDocument1 pageThird Angle Projection Do Not Scale: Dimensions in Millimetres陆军No ratings yet

- Curvas de DesempeñoDocument116 pagesCurvas de DesempeñoRene RodriguezNo ratings yet

- 152 Series RegulatorsDocument1 page152 Series RegulatorsScientific EquipmentNo ratings yet

- Catalog 3900 - Flow Control Valves: F SeriesDocument3 pagesCatalog 3900 - Flow Control Valves: F SeriesRaul CalizayaNo ratings yet

- S07nmdl1ds ENDocument5 pagesS07nmdl1ds ENYongfeng QianNo ratings yet

- ADC 3010 AC 212 Series RegulatorDocument2 pagesADC 3010 AC 212 Series RegulatorkicsnerNo ratings yet

- Operating ParametersDocument1 pageOperating Parameters陆军No ratings yet

- Tecman TMB5 Web Spec V160921Document1 pageTecman TMB5 Web Spec V160921thomas.templierNo ratings yet

- Husky 1050 Plastic Pumps: Technical SpecificationsDocument2 pagesHusky 1050 Plastic Pumps: Technical SpecificationsRene Gabriel CatorcenoNo ratings yet

- Catalogue - Husky Pump 1050 Stainless SteelDocument1 pageCatalogue - Husky Pump 1050 Stainless Steelahmadhafiz.engNo ratings yet

- Tuthil Gear Pump Performance CurveDocument6 pagesTuthil Gear Pump Performance CurveLuis R MartínezNo ratings yet

- P39 Standard Gas Regulators: Applications SpecificationsDocument4 pagesP39 Standard Gas Regulators: Applications SpecificationsAlexander Charry GiraldoNo ratings yet

- Tech Bulletin 002: Inlet Pressure vs. Water TemperatureDocument2 pagesTech Bulletin 002: Inlet Pressure vs. Water Temperaturesf wNo ratings yet

- DBB8666 Fuel Filter Data SheetDocument2 pagesDBB8666 Fuel Filter Data SheetJamyansuren TseveendorjNo ratings yet

- 3" and 4.25" Grease Pumps - SpecificationsDocument7 pages3" and 4.25" Grease Pumps - SpecificationsZaidi OktariNo ratings yet

- R73G, R73R: Technical DataDocument4 pagesR73G, R73R: Technical DataEnrique Arellano HidalgoNo ratings yet

- Typical Performance Curve SRU3/038/ (Sru3Wls) With Hyclean SealDocument6 pagesTypical Performance Curve SRU3/038/ (Sru3Wls) With Hyclean SealSonia Marcela AriasNo ratings yet

- Relays & Volume Boosters: Type 20Document8 pagesRelays & Volume Boosters: Type 20Jholman SanchezNo ratings yet

- ESAB ExtractPage25-26cDocument8 pagesESAB ExtractPage25-26cDries VandezandeNo ratings yet

- ADC3010 AF 484 Series RegulatorDocument3 pagesADC3010 AF 484 Series RegulatormiguesobeNo ratings yet

- Q155 Low PressureDocument6 pagesQ155 Low PressureJanNo ratings yet

- Tecman TMB4-V5 Web Spec V160921Document1 pageTecman TMB4-V5 Web Spec V160921thomas.templierNo ratings yet

- Fixed Displacement Bent Axis Piston Pumps: For Truck ApplicationsDocument4 pagesFixed Displacement Bent Axis Piston Pumps: For Truck ApplicationsДаниил СторчеусNo ratings yet

- Fixed Displacement Bent Axis Piston Pumps: For Truck ApplicationsDocument4 pagesFixed Displacement Bent Axis Piston Pumps: For Truck ApplicationsДаниил СторчеусNo ratings yet

- Bap 01 T B PDFDocument4 pagesBap 01 T B PDFyoberNo ratings yet

- Bap 01 T A PDFDocument4 pagesBap 01 T A PDFyoberNo ratings yet

- Relief Valves RH4 SeriesDocument6 pagesRelief Valves RH4 SerieslorenzoNo ratings yet

- WildenDocument1 pageWildenjose coelhoNo ratings yet

- Typical Performance Curve Sru5Wld (Sru5/168) With Hyclean SealDocument1 pageTypical Performance Curve Sru5Wld (Sru5/168) With Hyclean Sealdanielagomezga_45545No ratings yet

- Aspro CNG Data 20190225Document1 pageAspro CNG Data 20190225KASIMNo ratings yet

- Theoretical Working Point Performance Chart: 5150870300-B-18 - TGT/4-400-6/18 BC 0,25KW (230/400V50HZ) IE1 V5Document17 pagesTheoretical Working Point Performance Chart: 5150870300-B-18 - TGT/4-400-6/18 BC 0,25KW (230/400V50HZ) IE1 V5Igor SpirovNo ratings yet

- Regulators Edge 4 Series RegulatorsDocument1 pageRegulators Edge 4 Series RegulatorsDries VandezandeNo ratings yet

- High Pressure FiltersDocument92 pagesHigh Pressure FiltersThabangNo ratings yet

- Datasheet RPH3-06 Ha4006 en Hydraulic Operated DCVDocument2 pagesDatasheet RPH3-06 Ha4006 en Hydraulic Operated DCVPritesh KoratNo ratings yet

- Technical Information Series C General Description: Check ValvesDocument3 pagesTechnical Information Series C General Description: Check ValvesPeter StanleyNo ratings yet

- Database Management Systems: Understanding and Applying Database TechnologyFrom EverandDatabase Management Systems: Understanding and Applying Database TechnologyRating: 4 out of 5 stars4/5 (8)

- Properties of TimberDocument44 pagesProperties of TimberMary Joy RuilesNo ratings yet

- Narra Nickel Mining Vs RedmontDocument2 pagesNarra Nickel Mining Vs RedmontRitch LibonNo ratings yet

- Adrians Resume 6Document2 pagesAdrians Resume 6api-244906905No ratings yet

- As A Man Thinketh: by James AllenDocument24 pagesAs A Man Thinketh: by James AllenAce OfbaseNo ratings yet

- Sikawrap®-900 C: Product Data SheetDocument4 pagesSikawrap®-900 C: Product Data SheetnovitaapriyaniNo ratings yet

- 1 PDFDocument103 pages1 PDF123qweNo ratings yet

- Global Vaccine Action Plan: Tetanus & Difteri (TD/DPT)Document6 pagesGlobal Vaccine Action Plan: Tetanus & Difteri (TD/DPT)Gusti IndrakusumaNo ratings yet

- CMAM Training PPT 2018 - 0Document57 pagesCMAM Training PPT 2018 - 0cabdinuux32100% (1)

- Stoichiometry Basics NotesDocument5 pagesStoichiometry Basics NoteswardaNo ratings yet

- Access - Catalog - DP&Casing Tools-15-18Document4 pagesAccess - Catalog - DP&Casing Tools-15-18RICHARDNo ratings yet

- Hysteretic Relative Permeability EffectsDocument8 pagesHysteretic Relative Permeability Effectshfdshy12No ratings yet

- Tender B1 Aluminium Glazing WorksDocument114 pagesTender B1 Aluminium Glazing WorksDaliPotter100% (1)

- Histology EssayDocument4 pagesHistology EssayalzayyanauroraNo ratings yet

- Hoja AnestesiaDocument9 pagesHoja AnestesiaCAMILO ANDRES MANTILLANo ratings yet

- TheologyDocument4 pagesTheologyLovely Platon CantosNo ratings yet

- Supply Chain Management - Pgfa1941Document9 pagesSupply Chain Management - Pgfa1941Ravina SinghNo ratings yet

- Excerpts: "Dog Bite Prevention For Law Enforcement and Other First Responders," by Randall LockwoodDocument2 pagesExcerpts: "Dog Bite Prevention For Law Enforcement and Other First Responders," by Randall LockwoodDogsBite.org100% (1)

- Drugs in Pediatrics: Submitted By: Prerna Sharma M.SC Nursing, 4 SemesterDocument42 pagesDrugs in Pediatrics: Submitted By: Prerna Sharma M.SC Nursing, 4 SemesterPrernaSharma100% (1)

- European Steel and Alloy Grades: Gx8Crni12 (1.4107)Document2 pagesEuropean Steel and Alloy Grades: Gx8Crni12 (1.4107)farshid KarpasandNo ratings yet

- The Nature of C-S-H in Hardened CementsDocument17 pagesThe Nature of C-S-H in Hardened CementsXI CHENNo ratings yet

- Quick Hoops™ High Tunnel Bender: Instruction Manual For 9018Document54 pagesQuick Hoops™ High Tunnel Bender: Instruction Manual For 9018glue2No ratings yet

- Thermal AnalysisDocument8 pagesThermal AnalysisSURESH100% (1)

- The Winners and Losers of GlobalizationDocument7 pagesThe Winners and Losers of GlobalizationRalucutsaNo ratings yet

- Brochure - HRM ThreadDocument6 pagesBrochure - HRM ThreadPrateek KumarNo ratings yet

- Student Handbook 8 Week Course: BeginnerDocument6 pagesStudent Handbook 8 Week Course: BeginnermahshadkmzNo ratings yet