Professional Documents

Culture Documents

Method of Statement For Waterproofing

Method of Statement For Waterproofing

Uploaded by

Joe PsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method of Statement For Waterproofing

Method of Statement For Waterproofing

Uploaded by

Joe PsCopyright:

Available Formats

END USER: CONSULTANT: MAIN CONTRACTOR: CIVIL SUB CONTRACTOR:

SIEMENS

SIMPLEX INFRASTRUCTURES

LIMITED

Main Contractor:

SIEMENS

Civil Contractor:

SIMPLEX INFRASTRUCTURES LIMITED

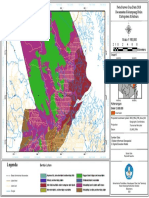

Project/Contract Ref: Construction of 132/11kv Substation (G+1) Saada Street, Plot no.-

3372212

Document Title: METHOD STATEMENT - SUBSTRUCTURE WATERPROOFING WORKS

Document No:

2 0 1 6 M S 03 0 0 0 0 Rev. 0

0 18/04/2016 Issue for Subir Lalit Mr Rajesh

approval Adhikari Talpada

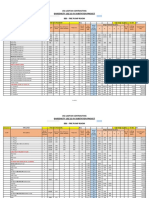

Rev Date Purpose Prep. Check Approved Client Date

SUBSTRUCTURE WATERPROOFING WORKS SS/P2/MS/003/0 Page 1

END USER: CONSULTANT: MAIN CONTRACTOR: CIVIL SUB CONTRACTOR:

SIEMENS

SIMPLEX INFRASTRUCTURES

LIMITED

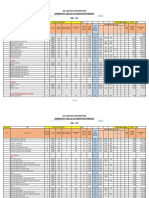

Document No: Project Rev : DATE:

Substation 0 18-04-2016

Title: METHOD STATEMENT - SUBSTRUCTURE WATERPROOFING WORKS

METHOD STATEMENT FOR SUBSTRUCTURE WATERPROOFING WORKS FOR SAADA STREET

132/11 KV SUBSTATION

CONTENTS

1.0 OBJECTIVE

2.0 SCOPE

3.0 APPLICABLE DOCUMENT OR REFERENCES

4.0 PREPARATION

5.0 CONTROL MEASURES

6.0 RESPONSIBILITY

7.0 WORK SEQUENCE

8.0 QUALITY/TESTING

9.0 PPE

10.0 MISCELLANEOUS

11.0 RESOURCES

12.0 SAFETY

13.0 SITE TIMING

SUBSTRUCTURE WATERPROOFING WORKS SS/P2/MS/003/0 Page 2

END USER: CONSULTANT: MAIN CONTRACTOR: CIVIL SUB CONTRACTOR:

SIEMENS

SIMPLEX INFRASTRUCTURES

LIMITED

Document No: Project Rev : DATE:

Substation 0 18-04-2016

Title: METHOD STATEMENT - SUBSTRUCTURE WATERPROOFING WORKS

1.0 OBJECTIVE

This method statement describes a work explanation of the method for carrying out

substructure waterproofing works on concrete surface at sites for DEWA substation projects

to ensure that during the entire execution stage, the work is done in line with good

engineering practices and in compliance with engineering standard practices, nation & local

codes.

2.0 SCOPE OF WORKS

The procedure shall be applicable to for all types of substructure waterproofing works on

concrete surface undertaken by the company for substructure works.

3.0 APPLICABLE DOCUMENT OR REFERENCES

Contract / Project Specification.

Drawing (3761500066/SAADAST/C/15/281A)

Risk Assessment

4.0 PREPARATION

Simplex will produce a programme of works such that Client are aware of proposed area of

works and can advise on logistical constraints imposed by other contractors.

5.0 CONTROL MEASURES

Ensure all permissions and consents have been obtained.

Ensure approval status of this Method Statement has received “1” or “2” status.

Ensure drawing for substructure waterproofing works to be submitted for approval.

Ensure all the materials for waterproofing works are approved prior to using at site.

SUBSTRUCTURE WATERPROOFING WORKS SS/P2/MS/003/0 Page 3

END USER: CONSULTANT: MAIN CONTRACTOR: CIVIL SUB CONTRACTOR:

SIEMENS

SIMPLEX INFRASTRUCTURES

LIMITED

Document No: Project Rev : DATE:

Substation 0 18-04-2016

Title: METHOD STATEMENT - SUBSTRUCTURE WATERPROOFING WORKS

Ensure maintain a system of records that permit verification of any issued report before

and after work.

Prepare necessary Toolbox talks.

Ensure work area is cordoned off.

Site briefings will be undertaken to induct all operatives in the detail of this method

statement. All personnel attending will sign the briefing sheet acknowledging they

understand the briefing given.

6.0 RESPONSIBILITY

6.1 The Project Manager along with his site team is responsible for entire substructure

waterproofing works of main building raft foundation to be done as per this Method

Statement.

6.2 The Site Engineer, Foremen are responsible for all the works and all associated

activities under this method statement at his assigned work location.

6.3 The QC Engineer is responsible for compliance of complete work as per the approved

method statement will offer for Consultants approval.

6.4 The Surveyor will mark along the areas where the substructure waterproofing work

needs to be done.

6.5 The Safety Officer is responsible to ensure all safety precautions are in place. Tool box

talks will be conducted for awareness of the operatives involved in the work and PPE are

worn at all time.

7.0 WORK SEQUENCE

The method statement included safety aspect during the work, preparation of the work, main

tools and equipment utilized, survey and all related necessary to complete the entire work.

SUBSTRUCTURE WATERPROOFING WORKS SS/P2/MS/003/0 Page 4

END USER: CONSULTANT: MAIN CONTRACTOR: CIVIL SUB CONTRACTOR:

SIEMENS

SIMPLEX INFRASTRUCTURES

LIMITED

Document No: Project Rev : DATE:

Substation 0 18-04-2016

Title: METHOD STATEMENT - SUBSTRUCTURE WATERPROOFING WORKS

WORK SEQUENCE FOR WATERPROOFING WORKS

7.1 Sequence of works :- Horizontal surface (bottom of Raft Foundation)

Make sure concrete surface clean and free from contamination such as dust, oil, grease,

release agent and curing compounds.

Existing concrete surface should be smooth and without any sharp edges, fill with

approved cementicious material if pot holes found at surface of concrete.

Mix/Stir the Polyprime SB until a homogenous consistency is achieved.

Apply Polyprime SB using a brush or roller to the prepared surface to give an even,

continuous, unbroken coating.

Ensure top of primed surface should be clean before application of Bituplus E4270-SBS

Modified Bitumen Waterproofing Membrane-4mm thick. Single Layer

Fix the membrane to the desired length and shape with a help of torch application,

allowing for a 100mm side lap and 100mm end lap on the rolls.

Place the membrane on the area to be covered and check the pieces match as required

on the substrate.

Subsequent rolls should be laid in a similar fashion, overlapping by 100mm long the side

selvedge & 100mm at the ends of the rolls to provide continuous waterproofing

membrane.

Roll all overlaps to ensure full contact between rolls & with the primer.

Continue to waterproof the entire area, extending by a minimum of 250mm beyond the

building line in order to create an overlap with the vertical membrane.

After completion of waterproofing protect the membrane by laying of screed concrete.

SUBSTRUCTURE WATERPROOFING WORKS SS/P2/MS/003/0 Page 5

END USER: CONSULTANT: MAIN CONTRACTOR: CIVIL SUB CONTRACTOR:

SIEMENS

SIMPLEX INFRASTRUCTURES

LIMITED

Document No: Project Rev : DATE:

Substation 0 18-04-2016

Title: METHOD STATEMENT - SUBSTRUCTURE WATERPROOFING WORKS

7.2 Sequence of works :- Vertical surface (Walls)

Make sure concrete surface clean and free from contamination such as dust, oil, grease

&release agent and curing compounds.

Existing concrete surface should be smooth and without any sharp edges, fill with

approved cementicious material if pot holes found at surface of concrete.

Fill the tie-rod holes with approved materials.

Mix/Stir the Polyprime SB until a homogenous consistency is achieved.

Apply Polyprime SB using a brush or roller to the prepared surface to give an even,

continuous, unbroken coating.

Apply a 45-degree sand/cement fillet at floor/wall junctions and allow to cure.

A 200mm wide reinforcing strip should be provided at all corners and changes in

direction such as floor/wall junctions, prior to the main membrane applications.

Apply the Bituplus E4270-SBS Modified Bitumen Waterproofing Membrane-4mm tk.

Single Layer membrane vertically with a torch application in the same fashion as for

horizontal, however always waterproof from the lowest to the highest point, allowing for

an overlap of 100mm on end joints giving a weathered lap.

Press the membrane onto the substrate from the centre to the sides, to ensure a good

bond to the primer and removal of any entrapped air, Roll all overlaps to ensure full

contact with the primer.

Subsequent rolls should again be overlapped by 100mm along the sides using the

selvedge.

Continue applying until the entire area is covered.

Membranes to be terminate as per required level with the help of Bitumastic Bitumen

Rubber Mastic Sealant.

SUBSTRUCTURE WATERPROOFING WORKS SS/P2/MS/003/0 Page 6

END USER: CONSULTANT: MAIN CONTRACTOR: CIVIL SUB CONTRACTOR:

SIEMENS

SIMPLEX INFRASTRUCTURES

LIMITED

Document No: Project Rev : DATE:

Substation 0 18-04-2016

Title: METHOD STATEMENT - SUBSTRUCTURE WATERPROOFING WORKS

Apply the 3.2mm tk. Bituboard protection board to protect the membrane on Vertical

Surface with the spot bonding system.

Backfill the area with approved method statement to complete the waterproofing

system.

7.3 Main tools & equipment

Crane – 1 No. (For shifting of materials)

Mini Roller / Plate compactor – 01 No.

Diesel Generators for Power supply.

Wheel barrow

Shovels/spades

Scrapers

Knife for cutting membranes

Brush/Roller

Electrical Air Blower

Mixing Paddle

Propane Gas Torch Machine

8.0 QUALITY/TESTING

Visual inspection by Consultant / Client Representative.

Site Engineer on site for conformance.

The waterproofing work activities will be controlled using an Inspection Test Plan (ITP). The

ITP will be approved by the Consultants / Client and will include:

SUBSTRUCTURE WATERPROOFING WORKS SS/P2/MS/003/0 Page 7

END USER: CONSULTANT: MAIN CONTRACTOR: CIVIL SUB CONTRACTOR:

SIEMENS

SIMPLEX INFRASTRUCTURES

LIMITED

Document No: Project Rev : DATE:

Substation 0 18-04-2016

Title: METHOD STATEMENT - SUBSTRUCTURE WATERPROOFING WORKS

Hold points for Consultant / Client Inspections.

Frequency and Standard of Testing.

Test Points for Independent Testing Agencies.

Details of retained and non-retained documents.

Applicator for the substructure waterproofing works will be certified from Manufacturer.

9.0 PPE

Hand tools

Barriers

Hand Gloves (Rubber) & Safety Goggles

Safety Boots (Gum Boots with Steel Toe

Hard Hats

Coverall/Uniform.

10.0 MISCELLANEOUS

Small Tools

Fire Extinguishers

11.0 RESOURCES

SITE ENGINEER - Ensure operatives confirm to Method Statement.

Direct surveyor on site.

Ensure that correct drawings are used on site.

SURVEYOR - Work with Engineer to establish levels for information.

Carry out as-built survey works as directed by the Engineer.

Set up and check rotating laser level and other level control.

Ensure that site instrumentation in maintained.

SUBSTRUCTURE WATERPROOFING WORKS SS/P2/MS/003/0 Page 8

END USER: CONSULTANT: MAIN CONTRACTOR: CIVIL SUB CONTRACTOR:

SIEMENS

SIMPLEX INFRASTRUCTURES

LIMITED

Document No: Project Rev : DATE:

Substation 0 18-04-2016

Title: METHOD STATEMENT - SUBSTRUCTURE WATERPROOFING WORKS

SUPERVISOR - Direct labour as requested by the Engineer.

Ensure operatives are working accordance with method statement.

OPERATIVES - Carry out work as directed by the Charge Hand & Engineer.

12.0 SAFETY

Site safety induction will be carried out.

All operative will receive a method statement briefing and this will be maintained as a site

record.

All operative will maintain all the safety requirements for the project throughout the work

duration. This will include the wearing of Safety hats, High Visibility vests & Safety boots

and others as required for the job.

Trained and Skilled Operators shall be employed for operating heavy machineries like

cranes, etc.

13.0 SITE TIMING

7:00 AM to 7:00 PM

SS—SUB STATION

P2—CONTROL OF RECORDS

MS—METHOD STATEMENT

SUBSTRUCTURE WATERPROOFING WORKS SS/P2/MS/003/0 Page 9

END USER: CONSULTANT: MAIN CONTRACTOR: CIVIL SUB CONTRACTOR:

SIEMENS

SIMPLEX INFRASTRUCTURES

LIMITED

Document No: Project Rev : DATE:

Substation 0 18-04-2016

Title: METHOD STATEMENT - SUBSTRUCTURE WATERPROOFING WORKS

SUBSTRUCTURE WATERPROOFING WORKS SS/P2/MS/003/0 Page 10

You might also like

- 007 - Internal Waterproofing ChecklistDocument2 pages007 - Internal Waterproofing ChecklistCarl Xhing85% (27)

- Method of Statement - Repair HoneycombDocument2 pagesMethod of Statement - Repair Honeycombaubar81% (32)

- Method Statement For Wall Insulation, CladdingDocument16 pagesMethod Statement For Wall Insulation, Claddingstrikersam100% (15)

- METHOD STATEMENT Gypsum Board Ceiling, Gypsum Partitions, Ceiling TilesDocument9 pagesMETHOD STATEMENT Gypsum Board Ceiling, Gypsum Partitions, Ceiling TilesMoataz Medhat60% (5)

- Method Statement For Waterproofing of ToiletsDocument1 pageMethod Statement For Waterproofing of ToiletsUpali Karunarathne100% (3)

- Roof Waterproofing-Method StatementDocument5 pagesRoof Waterproofing-Method StatementTATATAHER100% (1)

- 5 Method Statement For BRICK WORKSDocument4 pages5 Method Statement For BRICK WORKSSana Nazir50% (2)

- Method Statement For Interlock WorksDocument3 pagesMethod Statement For Interlock Worksqoci5ko80% (5)

- Method Statement For Plastering WorkDocument15 pagesMethod Statement For Plastering Workstrikersam100% (9)

- Method Statement-Waterproofing System SubstructureDocument6 pagesMethod Statement-Waterproofing System Substructureramtsan33% (3)

- Method Statement For Screeding WorksDocument5 pagesMethod Statement For Screeding WorksArunKumar Chandrasekar100% (2)

- Method Statement For Railing WorksDocument6 pagesMethod Statement For Railing WorksMin LuoNo ratings yet

- Ms For Block WorkDocument8 pagesMs For Block Workprasath_subramanian100% (2)

- Method Statement Pressure GroutingDocument2 pagesMethod Statement Pressure GroutingStephen David Gozun100% (7)

- WaterproofingDocument2 pagesWaterproofingyusz780% (2)

- Scanline Sampling Techniques For Rock Engineering Surveys: Insights From Intrinsic Geologic Variability and UncertaintyDocument5 pagesScanline Sampling Techniques For Rock Engineering Surveys: Insights From Intrinsic Geologic Variability and UncertaintyRivaiNo ratings yet

- Method Statement For Foundation WaterProofingDocument9 pagesMethod Statement For Foundation WaterProofingMuhammad Sami ParvezNo ratings yet

- Work Method Statement - TEXTURE PAINTDocument3 pagesWork Method Statement - TEXTURE PAINTSathish Gowda0% (2)

- Inspection and Test Plan For Internal Gypsum Plaster: Oberoi Maxima ProjectDocument5 pagesInspection and Test Plan For Internal Gypsum Plaster: Oberoi Maxima Projectlokesh.kukadiya100% (1)

- MOS WaterproofingDocument18 pagesMOS WaterproofingHenry Ambau100% (2)

- MOS For CMU Block WorkDocument10 pagesMOS For CMU Block WorkAlvene TagocNo ratings yet

- Method Statement For Water Stopper-BSMMUDocument5 pagesMethod Statement For Water Stopper-BSMMUEngr. Masud RahmanNo ratings yet

- Doors Method StatementDocument5 pagesDoors Method StatementTAHER AMMAR100% (2)

- Method Statement For False Ceiling WorksDocument2 pagesMethod Statement For False Ceiling WorksTAHER AMMAR33% (3)

- 7-Method Statement For Gypsum PartitionDocument9 pages7-Method Statement For Gypsum Partitionozyoclown100% (5)

- Waterproofing Check List PDFDocument20 pagesWaterproofing Check List PDFErdem Sarıeyyüpoğlu100% (2)

- Method Statement For Ceramic Tiles-Wall & Floor) (K)Document11 pagesMethod Statement For Ceramic Tiles-Wall & Floor) (K)Akash YadavNo ratings yet

- Method Statement For RCC WorksDocument10 pagesMethod Statement For RCC WorksSagar AliasjackeyNo ratings yet

- Civil Engineering - Septic Tank DrawingsDocument65 pagesCivil Engineering - Septic Tank DrawingsAnonymous sId0uhkEIV100% (1)

- Fundamentals of Surveying by S.K. RoyDocument613 pagesFundamentals of Surveying by S.K. RoyChalamaiah Vadlamudi100% (1)

- Method Statement FOR Roof Waterproofing Works: Revision RecordDocument18 pagesMethod Statement FOR Roof Waterproofing Works: Revision RecordYash Sharma100% (6)

- Method Statement For PLASTERINGDocument6 pagesMethod Statement For PLASTERINGVinodh Palanichamy100% (1)

- Method Statement For Finishing WorksDocument13 pagesMethod Statement For Finishing WorksEmadHassan100% (4)

- Method Statement For Waterproofing System of Prefabricated BathroomDocument14 pagesMethod Statement For Waterproofing System of Prefabricated BathroomGary LoNo ratings yet

- Method Statement For Concrete Repairing WorksDocument42 pagesMethod Statement For Concrete Repairing WorksKAKA100% (1)

- Waterproofing Method StatementDocument27 pagesWaterproofing Method StatementSuprodip Das0% (1)

- Method Statement Fo Reinforcement Works BlogDocument8 pagesMethod Statement Fo Reinforcement Works BlogMohasin Khan100% (1)

- METHOD STATEMENT FOR Cast in Situ Concrete - Rev 0Document7 pagesMETHOD STATEMENT FOR Cast in Situ Concrete - Rev 0Osama MZ100% (1)

- 9.Ms-METHOD STATEMENT FOR TILING, SKIRTING, TOILET DADO & KITCHEN PLATFORM WORKDocument15 pages9.Ms-METHOD STATEMENT FOR TILING, SKIRTING, TOILET DADO & KITCHEN PLATFORM WORKShenbagaraja Pandian100% (2)

- 02 MS Waterproofing WORKSDocument10 pages02 MS Waterproofing WORKSNhel G. Pascual67% (3)

- Method Statement Concrete Works PDFDocument18 pagesMethod Statement Concrete Works PDFdndudc95% (22)

- Method Statement For Drywall Gypsum PartitionDocument12 pagesMethod Statement For Drywall Gypsum PartitionPunk Gowthaman80% (5)

- Methos Statement For SubstructureDocument14 pagesMethos Statement For SubstructureĐărsĥąna RanasingheNo ratings yet

- Method Statement For Interlock PaversDocument3 pagesMethod Statement For Interlock PaversSumit Gupta100% (2)

- MS - Substructure Waterproofing Works For PileDocument11 pagesMS - Substructure Waterproofing Works For Pilesalman khanNo ratings yet

- Method Statement TileDocument10 pagesMethod Statement Tilebeshnu garanaikNo ratings yet

- 06 THOE - MS For Concrete Screed For Floor FinishingDocument9 pages06 THOE - MS For Concrete Screed For Floor FinishingStraus WaseemNo ratings yet

- Method Statement For Cement Board Dry Wall PartitionsDocument10 pagesMethod Statement For Cement Board Dry Wall PartitionsComet GroupNo ratings yet

- Vetonit Spatter Dash-MC SDM212Document2 pagesVetonit Spatter Dash-MC SDM212toni mujiyono100% (1)

- Method Statement For Marble Granite Flooring BlogDocument8 pagesMethod Statement For Marble Granite Flooring BlogMohasin Khan100% (1)

- Method Statement For Substructural Waterproofing Works REV 00Document40 pagesMethod Statement For Substructural Waterproofing Works REV 00Bleep News100% (1)

- Inspection & Test Plan For Concrete Protective CoatingDocument6 pagesInspection & Test Plan For Concrete Protective CoatingQaisar KhaiyamNo ratings yet

- Method Statement For Wall PuttyDocument5 pagesMethod Statement For Wall PuttySagar ParabNo ratings yet

- Method Statement FALSE CEILING-1Document7 pagesMethod Statement FALSE CEILING-1beshnu garanaik100% (1)

- Method StatementDocument102 pagesMethod StatementSagar AliasjackeyNo ratings yet

- Method Statement FlooringDocument11 pagesMethod Statement Flooringmanish100% (1)

- Method Statement For Anti Termite TreatmentDocument5 pagesMethod Statement For Anti Termite TreatmentrayNo ratings yet

- Method Statement For Ceramic Tile WorksDocument12 pagesMethod Statement For Ceramic Tile Worksprasath_subramanian100% (13)

- Water Proofing WorksDocument8 pagesWater Proofing Worksukali_csNo ratings yet

- Method Statement For Rebar, Formworks and Concrete WorksDocument13 pagesMethod Statement For Rebar, Formworks and Concrete Workswajid Zia100% (7)

- IASLC-MS-001& 002 - Excavation, Back Filling and Compaction WorksDocument8 pagesIASLC-MS-001& 002 - Excavation, Back Filling and Compaction WorksJoe PsNo ratings yet

- IASLC-MS-006 - Raft Concrete WorksDocument6 pagesIASLC-MS-006 - Raft Concrete WorksJoe PsNo ratings yet

- Method Statement & Risk Assessment (Rams) : ClientDocument36 pagesMethod Statement & Risk Assessment (Rams) : ClientAbdul RaheemNo ratings yet

- Icc2 - Candidates - Obervation Report - JOE PAULRAJ STELLABAI - 00550058Document7 pagesIcc2 - Candidates - Obervation Report - JOE PAULRAJ STELLABAI - 00550058Joe PsNo ratings yet

- Knauf Fire & Moisture Resistant Gypsum Boards (FM)Document2 pagesKnauf Fire & Moisture Resistant Gypsum Boards (FM)Joe PsNo ratings yet

- Icc2 - Candidates - Report - JOE PAULRAJ STELLABAI - 00550058Document6 pagesIcc2 - Candidates - Report - JOE PAULRAJ STELLABAI - 00550058Joe PsNo ratings yet

- FEWA-GE-GEN-TS-0111Document47 pagesFEWA-GE-GEN-TS-0111Joe PsNo ratings yet

- Ias Lootah Contracting Gardencity 132/11 KV Substation Project Bbs - Fire Pipe TrenchDocument6 pagesIas Lootah Contracting Gardencity 132/11 KV Substation Project Bbs - Fire Pipe TrenchJoe PsNo ratings yet

- Daily Manpower ReportDocument1 pageDaily Manpower ReportJoe PsNo ratings yet

- Ias Lootah Contracting Gardencity 132/11 KV Substation Project Bbs - Fire Pump RoomDocument11 pagesIas Lootah Contracting Gardencity 132/11 KV Substation Project Bbs - Fire Pump RoomJoe PsNo ratings yet

- Ias Lootah Contracting Gardencity 132/11 KV Substation Project Bbs Consumption - Cable PitsDocument8 pagesIas Lootah Contracting Gardencity 132/11 KV Substation Project Bbs Consumption - Cable PitsJoe PsNo ratings yet

- Ias Lootah Contracting Gardencity 132/11 KV Substation Project Bbs - IdtDocument10 pagesIas Lootah Contracting Gardencity 132/11 KV Substation Project Bbs - IdtJoe PsNo ratings yet

- Ias Lootah Contracting Gardencity 132/11 KV Substation ProjectDocument26 pagesIas Lootah Contracting Gardencity 132/11 KV Substation ProjectJoe Ps100% (1)

- GoToGate FBDocument1 pageGoToGate FBJoe PsNo ratings yet

- Method Statement For Pile Head TreatmentDocument7 pagesMethod Statement For Pile Head TreatmentJoe Ps100% (1)

- Exp Letter ModelDocument1 pageExp Letter ModelJoe PsNo ratings yet

- 2018-04-07 Activity Status ReportDocument3 pages2018-04-07 Activity Status ReportJoe PsNo ratings yet

- Housekeeping 8 PDFDocument5 pagesHousekeeping 8 PDFJoe PsNo ratings yet

- RFI - 57 Working Pile Concreting and Removal of CasingDocument1 pageRFI - 57 Working Pile Concreting and Removal of CasingJoe PsNo ratings yet

- Method Statement For PCC Pouring, Waterproofing & ScreedDocument9 pagesMethod Statement For PCC Pouring, Waterproofing & ScreedJoe PsNo ratings yet

- 132/11Kv Garden City Substation Daily House Keeping Progress ReportDocument2 pages132/11Kv Garden City Substation Daily House Keeping Progress ReportJoe PsNo ratings yet

- IASLC-MS-001& 002 - Excavation, Back Filling and Compaction WorksDocument8 pagesIASLC-MS-001& 002 - Excavation, Back Filling and Compaction WorksJoe PsNo ratings yet

- 132/11Kv Garden City Substation Daily House Keeping Progress Report Daily Housekeeping On DailyDocument3 pages132/11Kv Garden City Substation Daily House Keeping Progress Report Daily Housekeeping On DailyJoe PsNo ratings yet

- IASLC-MS-006 - Raft Concrete WorksDocument6 pagesIASLC-MS-006 - Raft Concrete WorksJoe PsNo ratings yet

- Iaslc Ra 013 Working Under Direct Sun LightDocument4 pagesIaslc Ra 013 Working Under Direct Sun LightJoe PsNo ratings yet

- Iaslc Ms 004 Tower Crane ErectionDocument12 pagesIaslc Ms 004 Tower Crane ErectionJoe PsNo ratings yet

- Client Authority Consultant Main Contractor Civil SubcontractorDocument2 pagesClient Authority Consultant Main Contractor Civil SubcontractorJoe PsNo ratings yet

- CE ID Geomatics Engineering I QuesDocument10 pagesCE ID Geomatics Engineering I QuesashishcivilknitNo ratings yet

- Intertek Tank Calibration 2021Document4 pagesIntertek Tank Calibration 2021david montoyaNo ratings yet

- Bts3900/ Bts3900A Lte Enodeb Survey Guide: Huawei Technologies Co., LTDDocument64 pagesBts3900/ Bts3900A Lte Enodeb Survey Guide: Huawei Technologies Co., LTDlisamharleyNo ratings yet

- Model Set English-EDocument5 pagesModel Set English-ELava KarnaNo ratings yet

- Tacheometric Constants PDFDocument10 pagesTacheometric Constants PDFAditya100% (2)

- ESE 2020: Prelims Exam: Test 6Document21 pagesESE 2020: Prelims Exam: Test 6Anurag SinghNo ratings yet

- Form PER 2 - Site Quality Control EngineerDocument10 pagesForm PER 2 - Site Quality Control EngineersolebNo ratings yet

- Te-I - Question Bank Under Unit-I (Highway Planning & Alignment)Document4 pagesTe-I - Question Bank Under Unit-I (Highway Planning & Alignment)Charan Reddy100% (2)

- TS3604 PPTDocument21 pagesTS3604 PPTsathya2040No ratings yet

- Cadastre and Cadastral SurveyDocument20 pagesCadastre and Cadastral SurveyMartin Laurence Garcia Plasabas100% (1)

- M.SC Applied GeologyDocument11 pagesM.SC Applied GeologySatyam MehtaNo ratings yet

- Preparation of Detailed Area Plan (DAP) For DMDPDocument132 pagesPreparation of Detailed Area Plan (DAP) For DMDPMasud Rana60% (5)

- Peta Bentuk Lahan Data Gua 2018Document1 pagePeta Bentuk Lahan Data Gua 2018Reynaldi saputraNo ratings yet

- Board Surveyor Management PolicyDocument11 pagesBoard Surveyor Management PolicyA BNo ratings yet

- Cloisall Steel Struct Pavillion PDFDocument155 pagesCloisall Steel Struct Pavillion PDFAnonymous AXNcYVzonNo ratings yet

- GR 164356Document8 pagesGR 164356Johnray CastroNo ratings yet

- Sampangan Duta Pancasakti Textile, PT - SR (2022)Document27 pagesSampangan Duta Pancasakti Textile, PT - SR (2022)NasrullahNo ratings yet

- Trimble R8 Radio Communication Issues - GPS ForumsDocument3 pagesTrimble R8 Radio Communication Issues - GPS ForumsMamadou djibril BaNo ratings yet

- Hydrographic SurveyingDocument19 pagesHydrographic Surveyingapi-342563653No ratings yet

- 3rd Sem 24 Survey EnggDocument19 pages3rd Sem 24 Survey EnggKoushik ChatterjeeNo ratings yet

- Flexible PavementDocument59 pagesFlexible PavementAlly Hamzah100% (1)

- Seismic ContouringDocument142 pagesSeismic ContouringHuỳnh TuấnNo ratings yet

- Yeshwantrao Chavan College of Engineering: (Accredited 'A' Grade by NAAC With A Score of 3.25)Document46 pagesYeshwantrao Chavan College of Engineering: (Accredited 'A' Grade by NAAC With A Score of 3.25)Yogesh KherdeNo ratings yet

- Windshield Survey: Elements & Descriptions Community ObservationsDocument6 pagesWindshield Survey: Elements & Descriptions Community Observationslacurtis100% (1)

- Field Work No 8 SurveyingDocument18 pagesField Work No 8 SurveyingRalph GalvezNo ratings yet

- 67 - 23 68 - 23 - PDF 2023 Mar 17 13 6 40Document9 pages67 - 23 68 - 23 - PDF 2023 Mar 17 13 6 40Ashutosh SinghNo ratings yet

- BTech 3rdSemNewSyllabusDocument75 pagesBTech 3rdSemNewSyllabusNatwar LalNo ratings yet