Professional Documents

Culture Documents

Lining Railway Tunnels - 2012 - : Section/Article Description

Lining Railway Tunnels - 2012 - : Section/Article Description

Uploaded by

Mike2322Copyright:

Available Formats

You might also like

- AREMA MRE 2010 Volume 2 PDFDocument1,542 pagesAREMA MRE 2010 Volume 2 PDFDianaslashNo ratings yet

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- AREMA CHAPTER 1 - Section 4.9 Corrugated Polypropylene Pipe - Approval Januray 2016Document15 pagesAREMA CHAPTER 1 - Section 4.9 Corrugated Polypropylene Pipe - Approval Januray 2016pquiroga2No ratings yet

- Concrete Slab Track - 2011 - : Section/Article DescriptionDocument30 pagesConcrete Slab Track - 2011 - : Section/Article DescriptionMike2322No ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- 2 09P01 PDFDocument54 pages2 09P01 PDFMike2322No ratings yet

- Materials, Tests and Construction Requirements - 2004 - : Section/Article DescriptionDocument72 pagesMaterials, Tests and Construction Requirements - 2004 - : Section/Article DescriptionMarwan MokhadderNo ratings yet

- Retaining Walls, Abutments and Piers - 2002 - : Section/Article DescriptionDocument26 pagesRetaining Walls, Abutments and Piers - 2002 - : Section/Article DescriptionMike2322No ratings yet

- Cantilever Poles - 2003 - : Section/Article DescriptionDocument12 pagesCantilever Poles - 2003 - : Section/Article DescriptionMike2322No ratings yet

- 2 08P02 PDFDocument78 pages2 08P02 PDFMike2322No ratings yet

- C00 ContentsDocument21 pagesC00 ContentsRsjBugtongNo ratings yet

- Cantilever Poles - 1992 - : Section/Article DescriptionDocument12 pagesCantilever Poles - 1992 - : Section/Article DescriptionRavi Chandra IvpNo ratings yet

- Navfac Design Manual DM2.04Document27 pagesNavfac Design Manual DM2.04Dianna Lambert100% (1)

- Slurry Wall Construction - 2012 - : Section/Article DescriptionDocument14 pagesSlurry Wall Construction - 2012 - : Section/Article DescriptionMike2322No ratings yet

- 2 07P01 PDFDocument28 pages2 07P01 PDFMike2322No ratings yet

- 01-Arema Mre 2012 Volume 2Document1,596 pages01-Arema Mre 2012 Volume 2roberto floresNo ratings yet

- 1 01CH1Document4 pages1 01CH1HARINo ratings yet

- Arema Mre 2013 Toc-Vol1 Ch5Document3 pagesArema Mre 2013 Toc-Vol1 Ch5Ndoro Bei0% (3)

- 2 15P08 PDFDocument60 pages2 15P08 PDFMike2322No ratings yet

- Earth DamsDocument78 pagesEarth Damsbaray2007No ratings yet

- Arema Mre Chapter 9 2018Document94 pagesArema Mre Chapter 9 2018diablopapanatasNo ratings yet

- ABS Helicopter Decks Guide E-June12Document33 pagesABS Helicopter Decks Guide E-June12triminhdang_phar6701No ratings yet

- Sanders Unr-Aashto Shear Eq ComparisonDocument48 pagesSanders Unr-Aashto Shear Eq ComparisonhemalcmistryNo ratings yet

- Tunnels - 2019 - : ForewordDocument48 pagesTunnels - 2019 - : ForewordHARINo ratings yet

- Appurtenant Structures For Dams PDFDocument55 pagesAppurtenant Structures For Dams PDFpggopal_85No ratings yet

- AREMA MRE 2013 TOC-Vol2 Ch7 PDFDocument2 pagesAREMA MRE 2013 TOC-Vol2 Ch7 PDFalaajabbar0% (1)

- Concrete Structures and Foundations: ForewordDocument8 pagesConcrete Structures and Foundations: ForewordMarwan MokhadderNo ratings yet

- FDOT, 2021, Structural Design Guidelines.Document402 pagesFDOT, 2021, Structural Design Guidelines.Álvaro MendozaNo ratings yet

- Em 1110 3 142Document83 pagesEm 1110 3 142FrancoRojasNo ratings yet

- Engineer Manual - Engineer and Design Liquid Process Piping - ReviewDocument245 pagesEngineer Manual - Engineer and Design Liquid Process Piping - ReviewSyedFAkharAbbas100% (5)

- Liquid Process PipingDocument245 pagesLiquid Process PipingFreddy KannanNo ratings yet

- Structures Design Guidelines: Florida Department of TransportationDocument258 pagesStructures Design Guidelines: Florida Department of TransportationdiablopapanatasNo ratings yet

- Preliminary Design: Ndot Structures ManualDocument74 pagesPreliminary Design: Ndot Structures ManualFasil GeberemeskelNo ratings yet

- Tire ModelingDocument60 pagesTire ModelingJoe BartlettNo ratings yet

- Embankment Dams (CH 9) - Reclamation PDFDocument126 pagesEmbankment Dams (CH 9) - Reclamation PDFMAXO44No ratings yet

- Excavation Support AnalysisDocument95 pagesExcavation Support AnalysisMike TurnerNo ratings yet

- Surface Science of Tin Oxide PDFDocument108 pagesSurface Science of Tin Oxide PDFJorge Alexis RamosNo ratings yet

- Ufgs 13 34 19Document45 pagesUfgs 13 34 19sharandeep1112No ratings yet

- ΠΛΟΙΑ ΚΑΤΩ ΤΩΝ 90 ΜΕΤΡΩΝDocument239 pagesΠΛΟΙΑ ΚΑΤΩ ΤΩΝ 90 ΜΕΤΡΩΝWilliam RussellNo ratings yet

- Time-dependent Behaviour and Design of Composite Steel-concrete StructuresFrom EverandTime-dependent Behaviour and Design of Composite Steel-concrete StructuresNo ratings yet

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityFrom EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNo ratings yet

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsFrom EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsNo ratings yet

- Ultimate Limit State Analysis and Design of Plated StructuresFrom EverandUltimate Limit State Analysis and Design of Plated StructuresNo ratings yet

- Design of Foundations for Offshore Wind TurbinesFrom EverandDesign of Foundations for Offshore Wind TurbinesRating: 5 out of 5 stars5/5 (3)

- Engineering Vibroacoustic Analysis: Methods and ApplicationsFrom EverandEngineering Vibroacoustic Analysis: Methods and ApplicationsStephen A. HambricNo ratings yet

- Shallow Foundations: Discussions and Problem SolvingFrom EverandShallow Foundations: Discussions and Problem SolvingRating: 5 out of 5 stars5/5 (1)

- Foundation Design: Theory and PracticeFrom EverandFoundation Design: Theory and PracticeRating: 4.5 out of 5 stars4.5/5 (2)

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsFrom EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsNo ratings yet

- Pillared Metal-Organic Frameworks: Properties and ApplicationsFrom EverandPillared Metal-Organic Frameworks: Properties and ApplicationsNo ratings yet

- Design of Piles Under Cyclic Loading: SOLCYP RecommendationsFrom EverandDesign of Piles Under Cyclic Loading: SOLCYP RecommendationsAlain PuechNo ratings yet

- LARSA WJE Solving-For-StabilityDocument39 pagesLARSA WJE Solving-For-StabilityMike2322No ratings yet

- NCHRP RPT 725AppendixHDocument10 pagesNCHRP RPT 725AppendixHMike2322No ratings yet

- AASHTO NSBA POST TENSIONED CAP Steel - Bridge - News - v6 - n3Document8 pagesAASHTO NSBA POST TENSIONED CAP Steel - Bridge - News - v6 - n3Mike2322No ratings yet

- FOR Informational: LA DotdDocument8 pagesFOR Informational: LA DotdMike2322No ratings yet

- Simulating Section StiffnessDocument3 pagesSimulating Section StiffnessMike2322No ratings yet

- 2021-11-16 - ABCD NEOH - Cross-Frames - ChavelDocument36 pages2021-11-16 - ABCD NEOH - Cross-Frames - ChavelMike2322No ratings yet

- Camber Haunch Girder WSDOT A-Dimension RevisionsDocument8 pagesCamber Haunch Girder WSDOT A-Dimension RevisionsMike2322No ratings yet

- Guard Rail Special Details MASHDocument11 pagesGuard Rail Special Details MASHMike2322No ratings yet

- Guard Rail On-System Bridge (MASH) Set (4-13-23)Document11 pagesGuard Rail On-System Bridge (MASH) Set (4-13-23)Mike2322No ratings yet

- Seismic Design Bridges For Rural Areas South East AsiaDocument85 pagesSeismic Design Bridges For Rural Areas South East AsiaMike2322No ratings yet

- Seismic Bridge Design Mitigation Outline Part 5Document398 pagesSeismic Bridge Design Mitigation Outline Part 5Mike2322No ratings yet

- Seismic Design of Bridges South East Asia Part 1Document173 pagesSeismic Design of Bridges South East Asia Part 1Mike2322No ratings yet

- Mitigation of Seismic Disasters in Bridges Part 1Document291 pagesMitigation of Seismic Disasters in Bridges Part 1Mike2322No ratings yet

- Public Roads Vol 23 Issue 7Document32 pagesPublic Roads Vol 23 Issue 7Mike2322No ratings yet

- Seismic Design of Bridges South East Asia Part 3Document192 pagesSeismic Design of Bridges South East Asia Part 3Mike2322No ratings yet

- Seismic Bridge Design Mitigation Outline Part 4Document170 pagesSeismic Bridge Design Mitigation Outline Part 4Mike2322No ratings yet

- Design Spectra Philippines Seismic Part 4Document144 pagesDesign Spectra Philippines Seismic Part 4Mike2322No ratings yet

- ETL 1110-2-322 (1990) Retaining and Flood Walls (2 of 3) WMDocument18 pagesETL 1110-2-322 (1990) Retaining and Flood Walls (2 of 3) WMMike2322No ratings yet

- Mitigation of Seismic Disasters in Bridges Part 1Document466 pagesMitigation of Seismic Disasters in Bridges Part 1Mike2322No ratings yet

- Seismic Bridge Design Mitigation Outline Part 3Document156 pagesSeismic Bridge Design Mitigation Outline Part 3Mike2322No ratings yet

- MATHCAD DESIGN OF PSC GIRDER NCHRP - RPT - 907Document195 pagesMATHCAD DESIGN OF PSC GIRDER NCHRP - RPT - 907Mike2322No ratings yet

- Seismic Design of Bridges in PhilippinesDocument80 pagesSeismic Design of Bridges in PhilippinesMike2322No ratings yet

- Xu - Jian Gong - DissertationDocument341 pagesXu - Jian Gong - DissertationMike2322No ratings yet

- CompositeFloorSystems - ChienRitchie1984 Canada CISCDocument171 pagesCompositeFloorSystems - ChienRitchie1984 Canada CISCMike2322No ratings yet

- ETL 1110-2-322 (1990) Retaining and Flood Walls (1 of 3) WMDocument18 pagesETL 1110-2-322 (1990) Retaining and Flood Walls (1 of 3) WMMike2322No ratings yet

- AZDOT EXAMPLE SUBSTRUCTURE Appendix - A - Example - 2 - 2 PDFDocument76 pagesAZDOT EXAMPLE SUBSTRUCTURE Appendix - A - Example - 2 - 2 PDFMike2322No ratings yet

- Microstructure and Residual Stress of Laser Rapid Formed Inconel 718 Nickel-Base SuperalloyDocument6 pagesMicrostructure and Residual Stress of Laser Rapid Formed Inconel 718 Nickel-Base SuperalloyAnush RajNo ratings yet

- LIIL RefractoryDocument33 pagesLIIL RefractoryMOHD AZAMNo ratings yet

- Experimental Investigation On Partial Replacement of Cement by Prosopis Juliflora Ash & Coarse Aggregate by SeashellsDocument9 pagesExperimental Investigation On Partial Replacement of Cement by Prosopis Juliflora Ash & Coarse Aggregate by SeashellsIJRASETPublicationsNo ratings yet

- C1063 15a Standard Specification PDFDocument10 pagesC1063 15a Standard Specification PDFRemi KernNo ratings yet

- Deck - Calistoga Spa SurroundDocument4 pagesDeck - Calistoga Spa SurroundHelicon1No ratings yet

- Document G703 - 1992: Continuation SheetDocument6 pagesDocument G703 - 1992: Continuation Sheetpooja patelNo ratings yet

- Design and Control of Concrete Mixtures1-25 PDFDocument25 pagesDesign and Control of Concrete Mixtures1-25 PDFNarcisa RudnicNo ratings yet

- HDG Steel Combined With Al-AlloyDocument9 pagesHDG Steel Combined With Al-AlloySreedhar Patnaik.MNo ratings yet

- Avenida Tower: Supermix Redi ConcreteDocument1 pageAvenida Tower: Supermix Redi ConcreteADEN LIUNo ratings yet

- M-15 PCCDocument38 pagesM-15 PCCRaj PandeyNo ratings yet

- Railway Toilet Detail 1Document1 pageRailway Toilet Detail 1Shreenidhi JoshiNo ratings yet

- TDS 8201 PT NewDocument2 pagesTDS 8201 PT NewWahyudi Rendiana NyotoNo ratings yet

- Astn A194 - 2018Document12 pagesAstn A194 - 2018Danny TriwibowoNo ratings yet

- Coram Brochure 2015Document25 pagesCoram Brochure 2015higgs1No ratings yet

- Perno Hex Unc AstmDocument1 pagePerno Hex Unc AstmEsther CVNo ratings yet

- 1-Resin Casting ClassDocument17 pages1-Resin Casting ClassDRKIMBONo ratings yet

- Chapter-2 Thermal InsulationDocument29 pagesChapter-2 Thermal InsulationDawit TesfayNo ratings yet

- Development of FlatFlameDocument3 pagesDevelopment of FlatFlameSafetyjoe2No ratings yet

- Steps of Concrete Mix DesignDocument11 pagesSteps of Concrete Mix DesignKok Kean YoongNo ratings yet

- DELTA-FC 1020 Tds - EngDocument2 pagesDELTA-FC 1020 Tds - EngAhmed HassanNo ratings yet

- FRDLDocument3 pagesFRDLrameshNo ratings yet

- Sample Maintenance Checklist: (See Note 2) (See Note 1 at Theend of The Checklist)Document3 pagesSample Maintenance Checklist: (See Note 2) (See Note 1 at Theend of The Checklist)NurnazihaNo ratings yet

- p355n NH Nl1 Nl2 TubesDocument4 pagesp355n NH Nl1 Nl2 Tubesado31No ratings yet

- Suru BuriDocument369 pagesSuru BuriAttila SiklodiNo ratings yet

- Schedule Pelaksanaan: No Uraian PekerjaanDocument5 pagesSchedule Pelaksanaan: No Uraian PekerjaanAdi DeckNo ratings yet

- Ground Floor Plan Electrical and Sanitary LayoutDocument1 pageGround Floor Plan Electrical and Sanitary LayoutWhitepearlNo ratings yet

- WIKUS Band Saw BladesDocument64 pagesWIKUS Band Saw BladesRashedul HasanNo ratings yet

- En Eur 8pipeDocument73 pagesEn Eur 8pipeTransgulf2013No ratings yet

- Fusible PVC SpecificationsDocument17 pagesFusible PVC Specificationsamir_hayfaNo ratings yet

- Bhai Brochure Cement Flyash Storage Silo - PDF (Semple)Document2 pagesBhai Brochure Cement Flyash Storage Silo - PDF (Semple)Anand PuntambekarNo ratings yet

Lining Railway Tunnels - 2012 - : Section/Article Description

Lining Railway Tunnels - 2012 - : Section/Article Description

Uploaded by

Mike2322Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lining Railway Tunnels - 2012 - : Section/Article Description

Lining Railway Tunnels - 2012 - : Section/Article Description

Uploaded by

Mike2322Copyright:

Available Formats

8

Part 11

Lining Railway Tunnels1

— 2012 –

TABLE OF CONTENTS

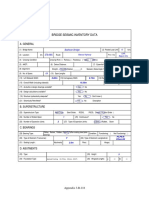

Section/Article Description Page

11.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11-2

11.1.1 Scope (2004) R(2012) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11-2

11.2 Design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11-2

11.2.1 Interior Dimensions (2004) R(2012) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11-2 1

11.2.2 Preliminary Data (2004) R(2012) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11-2

11.2.3 Floors (2004) R(2012) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11-2

11.2.4 Sidewalls and Arch (2004) R(2012) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11-3

11.2.5 Construction and Expansion Joints (2004) R(2012) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11-3

11.2.6 Drains (2004) R(2012) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11-7

11.2.7 Refuge Niches (Bays) (2004) R(2012) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11-7 3

11.2.8 Conduit and Inserts (2004) R(2012) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11-7

11.3 Forms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11-7

11.3.1 General (2004) R(2012) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11-7

11.3.2 Filling of Forms (2004) R(2012) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11-7

11.3.3 Removal of Forms (2004) R(2012) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11-7

11.3.4 Inspection Doors (2004) R(2012) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11-8

11.4 Concrete. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11-8

11.4.1 General (2012) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11-8

11.4.2 Order of Placing (2004) R(2012) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11-8

11.4.3 Consolidation (2004) R(2012) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11-8

11.4.4 Laitance and Bonding (2004) R(2012) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11-8

11.4.5 Drainage During Placing (2004) R(2012) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11-8

11.4.6 Shotcrete (2004) R(2012). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11-8

1

References Vol. 37, 1936, pp. 645, 1042; Vol. 42, 1941, pp. 309, 878; Vol. 54, 1953, pp. 814, 1343; Vol. 62, 1961, pp. 445, 861; Vol. 63, 1962, pp. 277, 687;

Vol. 74, 1973, p. 140; Vol. 89, 1988, p. 108. Rewritten 1988.

© 2017, American Railway Engineering and Maintenance-of-Way Association

8-11-1

Concrete Structures and Foundations

LIST OF FIGURES

Figure Description Page

8-11-1 Plain Concrete Tunnel Lining – Rock Section Single Track . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11-4

8-11-2 Plain Concrete Tunnel Lining – Single Track Temporary Supports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11-5

8-11-3 Plain Concrete Tunnel Lining – Double Track . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11-6

SECTION 11.1 GENERAL

11.1.1 SCOPE (2004) R(2012)

This recommended practice covers the lining of new tunnels in rock and those portions of old tunnels in rock which involve no

extraordinary side pressure or special features. The recommended practice covers linings of cast-in-place concrete and

shotcrete with steel sets.

SECTION 11.2 DESIGN

11.2.1 INTERIOR DIMENSIONS (2004) R(2012)

a. The interior dimensions of the clear space provided for single and double-track tunnels should not at any point be less

than tunnel clearances recommended by the AREMA Manual. Where legal requirements provide clearances greater

than AREMA, such legal requirements shall govern.

b. On curved track, the lateral clearance should be increased in conformance with Chapter 28, Clearances, Part 1,

Clearance Diagrams – Fixed Obstructions. The superelevation of the outer rail should be in accordance with the

recommended practice of Chapter 5, Track.

c. To provide for drainage, minimum side clearance of 10 feet (3 m) from centerline of track should be used in tunnels

likely to be wet. Where ventilation is required, the height of single-track tunnel should be increased 1 foot (300 mm)

minimum.

11.2.2 PRELIMINARY DATA (2004) R(2012)

Information shall be obtained for design of new tunnels, consisting of field surveys showing geological formations,

groundwater conditions, environmental conditions, adjacent structures, locations of faults, core borings, hardness and

condition of rock to be encountered, together with any special features and data on existing tunnels through similar formations.

Where a new tunnel is driven adjacent to an existing tunnel, records shall be searched for data as to groundwater conditions,

fault zones, and other special features. Consideration should be given to taking core borings from existing adjacent tunnels.

11.2.3 FLOORS (2004) R(2012)

Floors should, if practical, be paved and may have a ballasted track section, direct fixation to the concrete floor, or other

suitable track design. Paved floors shall be designed for the track section to be used.

© 2017, American Railway Engineering and Maintenance-of-Way Association

8-11-2 AREMA Manual for Railway Engineering

Lining Railway Tunnels

11.2.4 SIDEWALLS AND ARCH (2004) R(2012)

a. The depth of sidewalls in sound rock shall be at least 6 inches (150 mm) below the bottom of the gutter and at least 6

inches (150 mm) below the intersection of the floor surface with the sidewalls. In unsound rock, the sidewalls shall be

carried down to provide a stable foundation. At portals and vicinity, sidewalls shall extend at least 6 inches (150 mm)

below the frost line.

b. The minimum thickness of the cast-in-place sidewalls and arch shall be:

(1) Where temporary supports for excavation are not required:

• Single track – See Figure 8-11-1.

• Double track – See Figure 8-11-3.

(2) Where temporary supports are required for face of excavation see Figure 8-11-2 or Figure 8-11-3.

c. Encased timber sets are subject to decay and are not recommended. Exposed timber sets create a fire hazard and also

are not recommended.

d. Steel sets are spaced at least 8 inches (200 mm) apart, and in general not greater than 4 feet (1.2 m) apart. Solid liners

may also be considered.

e. Lagging may be wood, steel lags, steel liner plates, or steel water-diverting lagging. Where the nature of the rock and

water conditions permit, lagging shall be spaced to allow a clearance of 4 inches (100 mm) or more between lags to 1

permit free access of concrete to the face of the tunnel excavation. Prior to concreting, remove as many lags as is

possible. Where it is necessary to solid-lag for protection during excavation and where it is impractical to open up the

lagging just prior to concreting, the space between the lagging and face of excavation shall be packed with lean

concrete, crushed stone, coarse gravel, or pea gravel placed pneumatically. Consolidation grouting shall be used to fill

any voids behind lining. Where timber lagging is used, or where existing packing consists of timber, special care must

be exercised in torch cutting or welding of steel ribs or other components to eliminate the risk of fire.

3

f. Rock bolts may be considered as part of a support system.

11.2.5 CONSTRUCTION AND EXPANSION JOINTS (2004) R(2012)

a. Properly placed and consolidated construction joints do not require keyways. Waterstops shall be provided as

necessary. Monoliths shall be as long as practical to minimize the number of construction joints. 4

b. Construction joints shall not be formed at such locations where they might reduce the effectiveness of the lining to

resist pressure from surrounding earth or rock.

c. Where construction joints are provided, expansion joints are not required.

© 2017, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 8-11-3

Concrete Structures and Foundations

Figure 8-11-1. Plain Concrete Tunnel Lining – Rock Section Single Track

© 2017, American Railway Engineering and Maintenance-of-Way Association

8-11-4 AREMA Manual for Railway Engineering

Lining Railway Tunnels

4

Figure 8-11-2. Plain Concrete Tunnel Lining – Single Track Temporary Supports

© 2017, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 8-11-5

Concrete Structures and Foundations

Figure 8-11-3. Plain Concrete Tunnel Lining – Double Track

© 2017, American Railway Engineering and Maintenance-of-Way Association

8-11-6 AREMA Manual for Railway Engineering

Lining Railway Tunnels

11.2.6 DRAINS (2004) R(2012)

a. Wherever groundwater is encountered or anticipated, vertical and diagonal openings, trench drains, PVC or iron pipe

drains shall be installed between the concrete lining and rock. Adequate outlets shall be provided through sidewalls

with the outer end of the outlets not less than 12 inches (300 mm) above the bottom of the gutter. Subdrains shall be

provided under the concrete floor wherever groundwater is found. Drains shall be provided through curb to drain

ballast section.

b. Where hydrostatic pressure below the floor may be present, consideration should be given to designing the floor to

withstand the pressure.

c. Wherever groundwater drains are installed, they shall be attached to the rock so as to prevent being clogged when

concrete is poured.

d. Drain type selection should take into consideration an analysis of groundwater constituents and effects of water

aeration to discourage formation of precipitates or adverse chemical reaction which may plug or damage the drainage

system.

11.2.7 REFUGE NICHES (BAYS) (2004) R(2012)

Refuge niches shall be provided as shown on the example figures at approximate intervals of 200 feet (60 m) and staggered

with opposite sides so that spacing of niches shall be approximately 100 feet (30 m). Width of niches should accommodate the

number of people and the equipment to be protected. Bottom of niches shall be at elevation of bottom of track ties for

ballasted track sections and at elevation of intersection of invert and walls for solid track sections. For long tunnels, larger

refuge niches should be considered at appropriate intervals to accommodate equipment. 1

11.2.8 CONDUIT AND INSERTS (2004) R(2012)

Where required, provisions shall be made in the lining for conduit or hangers for cables, wires, and lights.

3

SECTION 11.3 FORMS

11.3.1 GENERAL (2004) R(2012)

a. Forms shall conform to requirements as outlined in Part 1, Materials, Tests and Construction Requirements, together

with additional provisions given herewith.

4

b. The length of forms between construction joints shall be as long as possible to limit number of joints. Waterproofing at

joints should be considered where appropriate.

11.3.2 FILLING OF FORMS (2004) R(2012)

The space between the face of the form and face of excavation or tight lagging shall be entirely filled with concrete, except for

drainage openings, and except that large cavities back of the normal face of excavation may be packed as outlined in

Paragraph 11.2.4(e).

11.3.3 REMOVAL OF FORMS (2004) R(2012)

Forms shall not be removed until concrete has reached strength sufficient to prevent distortion and sustain the applied load.

© 2017, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 8-11-7

Concrete Structures and Foundations

11.3.4 INSPECTION DOORS (2004) R(2012)

Forms shall be provided with inspection doors in the arch and walls so that the concrete can be thoroughly vibrated and

inspected during the placing.

SECTION 11.4 CONCRETE

11.4.1 GENERAL (2012)

Concrete for lining shall be proportioned and placed in accordance with Part 1, Materials, Tests and Construction

Requirements, together with the additional provisions given herewith. Placement of reinforcement shall be in accordance with

Part 2, Reinforced Concrete Design.

11.4.2 ORDER OF PLACING (2004) R(2012)

A section of the wall and footing may be placed separately from the rest of the wall, but a construction joint shall not be more

than 2 feet (600 mm) above the top of ballast curb elevation. The remainder of the wall and arch shall be placed

monolithically. The floor ballast retainers shall preferably be placed in one operation.

11.4.3 CONSOLIDATION (2004) R(2012)

All concrete shall be consolidated during and immediately after placing by means of internal vibration applied in the mass of

concrete and external vibration applied to the forms.

11.4.4 LAITANCE AND BONDING (2004) R(2012)

a. Concrete surfaces receiving new concrete shall be roughened and cleaned of all laitance, dirt, and water before fresh

concrete is placed. The consistency of the concrete and method of placement shall be such that laitance seams are not

formed. If such seams are formed, they shall be completely removed before additional concrete is placed.

b. All loose or unsound rock shall be removed behind walls and below floors before concrete is placed. Where the type of

rock makes this impractical, the floor and foundations for the walls shall be reinforced.

11.4.5 DRAINAGE DURING PLACING (2004) R(2012)

Concrete shall not be placed in moving water. Separate and distinct provisions shall be provided to drain any area receiving

fresh concrete. Effective weeps and drains shall be provided to prevent any hydrostatic pressure against the lining. Temporary

drains shall be grouted after concrete liner has attained design strength.

11.4.6 SHOTCRETE (2004) R(2012)

Shotcrete and reinforcement for shotcrete for lining shall be proportioned in accordance with Part 14, Repair and

Rehabilitation of Concrete Structures.

© 2017, American Railway Engineering and Maintenance-of-Way Association

8-11-8 AREMA Manual for Railway Engineering

You might also like

- AREMA MRE 2010 Volume 2 PDFDocument1,542 pagesAREMA MRE 2010 Volume 2 PDFDianaslashNo ratings yet

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- AREMA CHAPTER 1 - Section 4.9 Corrugated Polypropylene Pipe - Approval Januray 2016Document15 pagesAREMA CHAPTER 1 - Section 4.9 Corrugated Polypropylene Pipe - Approval Januray 2016pquiroga2No ratings yet

- Concrete Slab Track - 2011 - : Section/Article DescriptionDocument30 pagesConcrete Slab Track - 2011 - : Section/Article DescriptionMike2322No ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- 2 09P01 PDFDocument54 pages2 09P01 PDFMike2322No ratings yet

- Materials, Tests and Construction Requirements - 2004 - : Section/Article DescriptionDocument72 pagesMaterials, Tests and Construction Requirements - 2004 - : Section/Article DescriptionMarwan MokhadderNo ratings yet

- Retaining Walls, Abutments and Piers - 2002 - : Section/Article DescriptionDocument26 pagesRetaining Walls, Abutments and Piers - 2002 - : Section/Article DescriptionMike2322No ratings yet

- Cantilever Poles - 2003 - : Section/Article DescriptionDocument12 pagesCantilever Poles - 2003 - : Section/Article DescriptionMike2322No ratings yet

- 2 08P02 PDFDocument78 pages2 08P02 PDFMike2322No ratings yet

- C00 ContentsDocument21 pagesC00 ContentsRsjBugtongNo ratings yet

- Cantilever Poles - 1992 - : Section/Article DescriptionDocument12 pagesCantilever Poles - 1992 - : Section/Article DescriptionRavi Chandra IvpNo ratings yet

- Navfac Design Manual DM2.04Document27 pagesNavfac Design Manual DM2.04Dianna Lambert100% (1)

- Slurry Wall Construction - 2012 - : Section/Article DescriptionDocument14 pagesSlurry Wall Construction - 2012 - : Section/Article DescriptionMike2322No ratings yet

- 2 07P01 PDFDocument28 pages2 07P01 PDFMike2322No ratings yet

- 01-Arema Mre 2012 Volume 2Document1,596 pages01-Arema Mre 2012 Volume 2roberto floresNo ratings yet

- 1 01CH1Document4 pages1 01CH1HARINo ratings yet

- Arema Mre 2013 Toc-Vol1 Ch5Document3 pagesArema Mre 2013 Toc-Vol1 Ch5Ndoro Bei0% (3)

- 2 15P08 PDFDocument60 pages2 15P08 PDFMike2322No ratings yet

- Earth DamsDocument78 pagesEarth Damsbaray2007No ratings yet

- Arema Mre Chapter 9 2018Document94 pagesArema Mre Chapter 9 2018diablopapanatasNo ratings yet

- ABS Helicopter Decks Guide E-June12Document33 pagesABS Helicopter Decks Guide E-June12triminhdang_phar6701No ratings yet

- Sanders Unr-Aashto Shear Eq ComparisonDocument48 pagesSanders Unr-Aashto Shear Eq ComparisonhemalcmistryNo ratings yet

- Tunnels - 2019 - : ForewordDocument48 pagesTunnels - 2019 - : ForewordHARINo ratings yet

- Appurtenant Structures For Dams PDFDocument55 pagesAppurtenant Structures For Dams PDFpggopal_85No ratings yet

- AREMA MRE 2013 TOC-Vol2 Ch7 PDFDocument2 pagesAREMA MRE 2013 TOC-Vol2 Ch7 PDFalaajabbar0% (1)

- Concrete Structures and Foundations: ForewordDocument8 pagesConcrete Structures and Foundations: ForewordMarwan MokhadderNo ratings yet

- FDOT, 2021, Structural Design Guidelines.Document402 pagesFDOT, 2021, Structural Design Guidelines.Álvaro MendozaNo ratings yet

- Em 1110 3 142Document83 pagesEm 1110 3 142FrancoRojasNo ratings yet

- Engineer Manual - Engineer and Design Liquid Process Piping - ReviewDocument245 pagesEngineer Manual - Engineer and Design Liquid Process Piping - ReviewSyedFAkharAbbas100% (5)

- Liquid Process PipingDocument245 pagesLiquid Process PipingFreddy KannanNo ratings yet

- Structures Design Guidelines: Florida Department of TransportationDocument258 pagesStructures Design Guidelines: Florida Department of TransportationdiablopapanatasNo ratings yet

- Preliminary Design: Ndot Structures ManualDocument74 pagesPreliminary Design: Ndot Structures ManualFasil GeberemeskelNo ratings yet

- Tire ModelingDocument60 pagesTire ModelingJoe BartlettNo ratings yet

- Embankment Dams (CH 9) - Reclamation PDFDocument126 pagesEmbankment Dams (CH 9) - Reclamation PDFMAXO44No ratings yet

- Excavation Support AnalysisDocument95 pagesExcavation Support AnalysisMike TurnerNo ratings yet

- Surface Science of Tin Oxide PDFDocument108 pagesSurface Science of Tin Oxide PDFJorge Alexis RamosNo ratings yet

- Ufgs 13 34 19Document45 pagesUfgs 13 34 19sharandeep1112No ratings yet

- ΠΛΟΙΑ ΚΑΤΩ ΤΩΝ 90 ΜΕΤΡΩΝDocument239 pagesΠΛΟΙΑ ΚΑΤΩ ΤΩΝ 90 ΜΕΤΡΩΝWilliam RussellNo ratings yet

- Time-dependent Behaviour and Design of Composite Steel-concrete StructuresFrom EverandTime-dependent Behaviour and Design of Composite Steel-concrete StructuresNo ratings yet

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityFrom EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNo ratings yet

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsFrom EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsNo ratings yet

- Ultimate Limit State Analysis and Design of Plated StructuresFrom EverandUltimate Limit State Analysis and Design of Plated StructuresNo ratings yet

- Design of Foundations for Offshore Wind TurbinesFrom EverandDesign of Foundations for Offshore Wind TurbinesRating: 5 out of 5 stars5/5 (3)

- Engineering Vibroacoustic Analysis: Methods and ApplicationsFrom EverandEngineering Vibroacoustic Analysis: Methods and ApplicationsStephen A. HambricNo ratings yet

- Shallow Foundations: Discussions and Problem SolvingFrom EverandShallow Foundations: Discussions and Problem SolvingRating: 5 out of 5 stars5/5 (1)

- Foundation Design: Theory and PracticeFrom EverandFoundation Design: Theory and PracticeRating: 4.5 out of 5 stars4.5/5 (2)

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsFrom EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsNo ratings yet

- Pillared Metal-Organic Frameworks: Properties and ApplicationsFrom EverandPillared Metal-Organic Frameworks: Properties and ApplicationsNo ratings yet

- Design of Piles Under Cyclic Loading: SOLCYP RecommendationsFrom EverandDesign of Piles Under Cyclic Loading: SOLCYP RecommendationsAlain PuechNo ratings yet

- LARSA WJE Solving-For-StabilityDocument39 pagesLARSA WJE Solving-For-StabilityMike2322No ratings yet

- NCHRP RPT 725AppendixHDocument10 pagesNCHRP RPT 725AppendixHMike2322No ratings yet

- AASHTO NSBA POST TENSIONED CAP Steel - Bridge - News - v6 - n3Document8 pagesAASHTO NSBA POST TENSIONED CAP Steel - Bridge - News - v6 - n3Mike2322No ratings yet

- FOR Informational: LA DotdDocument8 pagesFOR Informational: LA DotdMike2322No ratings yet

- Simulating Section StiffnessDocument3 pagesSimulating Section StiffnessMike2322No ratings yet

- 2021-11-16 - ABCD NEOH - Cross-Frames - ChavelDocument36 pages2021-11-16 - ABCD NEOH - Cross-Frames - ChavelMike2322No ratings yet

- Camber Haunch Girder WSDOT A-Dimension RevisionsDocument8 pagesCamber Haunch Girder WSDOT A-Dimension RevisionsMike2322No ratings yet

- Guard Rail Special Details MASHDocument11 pagesGuard Rail Special Details MASHMike2322No ratings yet

- Guard Rail On-System Bridge (MASH) Set (4-13-23)Document11 pagesGuard Rail On-System Bridge (MASH) Set (4-13-23)Mike2322No ratings yet

- Seismic Design Bridges For Rural Areas South East AsiaDocument85 pagesSeismic Design Bridges For Rural Areas South East AsiaMike2322No ratings yet

- Seismic Bridge Design Mitigation Outline Part 5Document398 pagesSeismic Bridge Design Mitigation Outline Part 5Mike2322No ratings yet

- Seismic Design of Bridges South East Asia Part 1Document173 pagesSeismic Design of Bridges South East Asia Part 1Mike2322No ratings yet

- Mitigation of Seismic Disasters in Bridges Part 1Document291 pagesMitigation of Seismic Disasters in Bridges Part 1Mike2322No ratings yet

- Public Roads Vol 23 Issue 7Document32 pagesPublic Roads Vol 23 Issue 7Mike2322No ratings yet

- Seismic Design of Bridges South East Asia Part 3Document192 pagesSeismic Design of Bridges South East Asia Part 3Mike2322No ratings yet

- Seismic Bridge Design Mitigation Outline Part 4Document170 pagesSeismic Bridge Design Mitigation Outline Part 4Mike2322No ratings yet

- Design Spectra Philippines Seismic Part 4Document144 pagesDesign Spectra Philippines Seismic Part 4Mike2322No ratings yet

- ETL 1110-2-322 (1990) Retaining and Flood Walls (2 of 3) WMDocument18 pagesETL 1110-2-322 (1990) Retaining and Flood Walls (2 of 3) WMMike2322No ratings yet

- Mitigation of Seismic Disasters in Bridges Part 1Document466 pagesMitigation of Seismic Disasters in Bridges Part 1Mike2322No ratings yet

- Seismic Bridge Design Mitigation Outline Part 3Document156 pagesSeismic Bridge Design Mitigation Outline Part 3Mike2322No ratings yet

- MATHCAD DESIGN OF PSC GIRDER NCHRP - RPT - 907Document195 pagesMATHCAD DESIGN OF PSC GIRDER NCHRP - RPT - 907Mike2322No ratings yet

- Seismic Design of Bridges in PhilippinesDocument80 pagesSeismic Design of Bridges in PhilippinesMike2322No ratings yet

- Xu - Jian Gong - DissertationDocument341 pagesXu - Jian Gong - DissertationMike2322No ratings yet

- CompositeFloorSystems - ChienRitchie1984 Canada CISCDocument171 pagesCompositeFloorSystems - ChienRitchie1984 Canada CISCMike2322No ratings yet

- ETL 1110-2-322 (1990) Retaining and Flood Walls (1 of 3) WMDocument18 pagesETL 1110-2-322 (1990) Retaining and Flood Walls (1 of 3) WMMike2322No ratings yet

- AZDOT EXAMPLE SUBSTRUCTURE Appendix - A - Example - 2 - 2 PDFDocument76 pagesAZDOT EXAMPLE SUBSTRUCTURE Appendix - A - Example - 2 - 2 PDFMike2322No ratings yet

- Microstructure and Residual Stress of Laser Rapid Formed Inconel 718 Nickel-Base SuperalloyDocument6 pagesMicrostructure and Residual Stress of Laser Rapid Formed Inconel 718 Nickel-Base SuperalloyAnush RajNo ratings yet

- LIIL RefractoryDocument33 pagesLIIL RefractoryMOHD AZAMNo ratings yet

- Experimental Investigation On Partial Replacement of Cement by Prosopis Juliflora Ash & Coarse Aggregate by SeashellsDocument9 pagesExperimental Investigation On Partial Replacement of Cement by Prosopis Juliflora Ash & Coarse Aggregate by SeashellsIJRASETPublicationsNo ratings yet

- C1063 15a Standard Specification PDFDocument10 pagesC1063 15a Standard Specification PDFRemi KernNo ratings yet

- Deck - Calistoga Spa SurroundDocument4 pagesDeck - Calistoga Spa SurroundHelicon1No ratings yet

- Document G703 - 1992: Continuation SheetDocument6 pagesDocument G703 - 1992: Continuation Sheetpooja patelNo ratings yet

- Design and Control of Concrete Mixtures1-25 PDFDocument25 pagesDesign and Control of Concrete Mixtures1-25 PDFNarcisa RudnicNo ratings yet

- HDG Steel Combined With Al-AlloyDocument9 pagesHDG Steel Combined With Al-AlloySreedhar Patnaik.MNo ratings yet

- Avenida Tower: Supermix Redi ConcreteDocument1 pageAvenida Tower: Supermix Redi ConcreteADEN LIUNo ratings yet

- M-15 PCCDocument38 pagesM-15 PCCRaj PandeyNo ratings yet

- Railway Toilet Detail 1Document1 pageRailway Toilet Detail 1Shreenidhi JoshiNo ratings yet

- TDS 8201 PT NewDocument2 pagesTDS 8201 PT NewWahyudi Rendiana NyotoNo ratings yet

- Astn A194 - 2018Document12 pagesAstn A194 - 2018Danny TriwibowoNo ratings yet

- Coram Brochure 2015Document25 pagesCoram Brochure 2015higgs1No ratings yet

- Perno Hex Unc AstmDocument1 pagePerno Hex Unc AstmEsther CVNo ratings yet

- 1-Resin Casting ClassDocument17 pages1-Resin Casting ClassDRKIMBONo ratings yet

- Chapter-2 Thermal InsulationDocument29 pagesChapter-2 Thermal InsulationDawit TesfayNo ratings yet

- Development of FlatFlameDocument3 pagesDevelopment of FlatFlameSafetyjoe2No ratings yet

- Steps of Concrete Mix DesignDocument11 pagesSteps of Concrete Mix DesignKok Kean YoongNo ratings yet

- DELTA-FC 1020 Tds - EngDocument2 pagesDELTA-FC 1020 Tds - EngAhmed HassanNo ratings yet

- FRDLDocument3 pagesFRDLrameshNo ratings yet

- Sample Maintenance Checklist: (See Note 2) (See Note 1 at Theend of The Checklist)Document3 pagesSample Maintenance Checklist: (See Note 2) (See Note 1 at Theend of The Checklist)NurnazihaNo ratings yet

- p355n NH Nl1 Nl2 TubesDocument4 pagesp355n NH Nl1 Nl2 Tubesado31No ratings yet

- Suru BuriDocument369 pagesSuru BuriAttila SiklodiNo ratings yet

- Schedule Pelaksanaan: No Uraian PekerjaanDocument5 pagesSchedule Pelaksanaan: No Uraian PekerjaanAdi DeckNo ratings yet

- Ground Floor Plan Electrical and Sanitary LayoutDocument1 pageGround Floor Plan Electrical and Sanitary LayoutWhitepearlNo ratings yet

- WIKUS Band Saw BladesDocument64 pagesWIKUS Band Saw BladesRashedul HasanNo ratings yet

- En Eur 8pipeDocument73 pagesEn Eur 8pipeTransgulf2013No ratings yet

- Fusible PVC SpecificationsDocument17 pagesFusible PVC Specificationsamir_hayfaNo ratings yet

- Bhai Brochure Cement Flyash Storage Silo - PDF (Semple)Document2 pagesBhai Brochure Cement Flyash Storage Silo - PDF (Semple)Anand PuntambekarNo ratings yet