Professional Documents

Culture Documents

175 Lb. WWP Iron Body Gate Valve: 175 PSI Non-Shock Cold Water

175 Lb. WWP Iron Body Gate Valve: 175 PSI Non-Shock Cold Water

Uploaded by

Gerardo Mendoza CisnerosCopyright:

Available Formats

You might also like

- flgx213 (2) Pkjun2015Document6 pagesflgx213 (2) Pkjun2015Jason Van Den HeeverNo ratings yet

- Vic 2019 CatalogDocument893 pagesVic 2019 CatalogAnna Mae Marantan100% (1)

- Catalogue Van Shin Yi 2021Document64 pagesCatalogue Van Shin Yi 2021duc22198No ratings yet

- A105 A216 ComparisonDocument10 pagesA105 A216 Comparisonprihartono_diasNo ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Class 125 Iron Body Gate Valves: Bolted Bonnet - Outside Screw and Yoke - Solid Wedge - Bronze MountedDocument1 pageClass 125 Iron Body Gate Valves: Bolted Bonnet - Outside Screw and Yoke - Solid Wedge - Bronze MountedJOSE GABRIELNo ratings yet

- Data SheetDocument1 pageData SheetMathi Vinoth PillaiNo ratings yet

- Valvula Globo en AnguloDocument1 pageValvula Globo en AnguloRobertoNo ratings yet

- CS Ball Valve TM-590Document1 pageCS Ball Valve TM-590Hector Dario Tobon BenjumeaNo ratings yet

- Gala Valve Fire Fighting Catalogue 2018 V#5 - A4 - BDocument7 pagesGala Valve Fire Fighting Catalogue 2018 V#5 - A4 - BChhomNo ratings yet

- Valtech Catalogue-1Document44 pagesValtech Catalogue-1Bashir AliNo ratings yet

- 175 PSI WWP Iron Body Gate ValvesDocument1 page175 PSI WWP Iron Body Gate ValvestremendousNo ratings yet

- Valvula de Globo de MediaDocument1 pageValvula de Globo de MediaRobertoNo ratings yet

- Ficha Tecnica Valvula Cortina Ranurada OSYDocument1 pageFicha Tecnica Valvula Cortina Ranurada OSYrobinson18e2No ratings yet

- Kirloskar Process Pump - GK (P) : ISO 2858 / DIN EN 22858 / ISO 5199Document12 pagesKirloskar Process Pump - GK (P) : ISO 2858 / DIN EN 22858 / ISO 5199Amit pumpXpertzNo ratings yet

- CI Wafer / DI Lug Butterfly Valves: Series 0160Document2 pagesCI Wafer / DI Lug Butterfly Valves: Series 0160Vignesh NadimuthuNo ratings yet

- FT918BBI (1) Cheque NipcoDocument1 pageFT918BBI (1) Cheque NipcoRobertoNo ratings yet

- B8 ValvulasDocument1 pageB8 ValvulasPROCESOS PROCESOSNo ratings yet

- Gate Valve (Promet) TYCODocument3 pagesGate Valve (Promet) TYCOSupawat RangsiwongNo ratings yet

- F58 CraneDocument1 pageF58 CraneMarco DiazNo ratings yet

- Union Bonnet Globe Valve: Submittal SheetDocument1 pageUnion Bonnet Globe Valve: Submittal SheetRajesh ChoudharyNo ratings yet

- Class 150 Bronze Gate ValvesDocument1 pageClass 150 Bronze Gate Valvescristian villegasNo ratings yet

- Walworth 5202F 150lb GatesDocument5 pagesWalworth 5202F 150lb GatesAnthonyNo ratings yet

- F 908 WDocument1 pageF 908 WHaythem AhmedNo ratings yet

- Econ Gate Valve Cast Iron Bronze Trim ANSI Class 125 Fig. 1800Document1 pageEcon Gate Valve Cast Iron Bronze Trim ANSI Class 125 Fig. 1800ChristianGuerreroNo ratings yet

- Non Return Valves Cast Steel APIDocument4 pagesNon Return Valves Cast Steel APILinson GeorgeNo ratings yet

- 600scjs#cy 2-12 - 15Document2 pages600scjs#cy 2-12 - 15MohamadIbnuHassanNo ratings yet

- Fox ™ Triple Effect Air Vent + Anti Water Hammer: FeaturesDocument5 pagesFox ™ Triple Effect Air Vent + Anti Water Hammer: FeaturesNicolás Polito MuñozNo ratings yet

- Cast Iron Gate Valve Non Rising Stem PN16: Features & BenefitsDocument1 pageCast Iron Gate Valve Non Rising Stem PN16: Features & BenefitsMohamed RaafatNo ratings yet

- FlowBiz Cast Steel Angle Type Globe ValvesDocument2 pagesFlowBiz Cast Steel Angle Type Globe ValvesShakir AnsariNo ratings yet

- Filtro DuplexDocument8 pagesFiltro DuplexGuillermo ArandaNo ratings yet

- Malwaukee - F2885MRWDocument1 pageMalwaukee - F2885MRWSoojaelimNo ratings yet

- Fig FM63 Gate CraneFS DS 1702 P133Document1 pageFig FM63 Gate CraneFS DS 1702 P133afzal_aabNo ratings yet

- T301WFPDocument1 pageT301WFPcristian villegasNo ratings yet

- Bellow Seal Valves: AN ISO 9001:2000 COMPANYDocument20 pagesBellow Seal Valves: AN ISO 9001:2000 COMPANYDeepak HishikarNo ratings yet

- Cast Steel Bolted Bonnet Gates: Styles: CB2, CB3, & CB4/2 Class: 1500 - Sizes: 2" Thru 12"Document1 pageCast Steel Bolted Bonnet Gates: Styles: CB2, CB3, & CB4/2 Class: 1500 - Sizes: 2" Thru 12"OceanexNo ratings yet

- Fig. No. 208: RED WHITE Bronze Gate Valve - 125 LBDocument1 pageFig. No. 208: RED WHITE Bronze Gate Valve - 125 LBSergio DjbucaneroNo ratings yet

- Valv. Bola Bronce T580-85-70Document1 pageValv. Bola Bronce T580-85-70byron_a24No ratings yet

- Technical Data Sheet: Series 4200 Type W Pressure GateDocument2 pagesTechnical Data Sheet: Series 4200 Type W Pressure GateJayNo ratings yet

- Civ CatalogDocument7 pagesCiv CatalogMichel Simas de OliveiraNo ratings yet

- Gate Valve 150Document2 pagesGate Valve 150Masih BelajarNo ratings yet

- Art 826Document1 pageArt 826MASOUDNo ratings yet

- Spring Loaded Safety Valve: SRV1 (Open Bonnet) / SRV2 (Closed Bonnet)Document4 pagesSpring Loaded Safety Valve: SRV1 (Open Bonnet) / SRV2 (Closed Bonnet)cmpuckNo ratings yet

- 2309+QT04 - Gala-Motorized Butterfly ValveDocument4 pages2309+QT04 - Gala-Motorized Butterfly ValveNam Đỗ100% (1)

- Fivalco PDFDocument16 pagesFivalco PDFjhoger2012No ratings yet

- Check Ranurado RH84X MechDocument1 pageCheck Ranurado RH84X MechFLOW INDUSTRIAL SACNo ratings yet

- F607RWSFPDocument1 pageF607RWSFPleonardo ramirezNo ratings yet

- Filtro Tipo yDocument5 pagesFiltro Tipo yKaren BasoaltoNo ratings yet

- FMC GGCDocument8 pagesFMC GGCsheshidharrajubNo ratings yet

- RED WHITE Cast Iron Gate Valve - 125 LB.: FeaturesDocument1 pageRED WHITE Cast Iron Gate Valve - 125 LB.: FeaturesSergio DjbucaneroNo ratings yet

- Flowcom - Ranurada y BridadaDocument1 pageFlowcom - Ranurada y BridadaErickNo ratings yet

- Shinyi Catalogue 2017Document64 pagesShinyi Catalogue 2017Huy NguyễnNo ratings yet

- Angle Valve Figure B-222T Class 150 - Union Bonnet - PTFE Disc - Threaded EndsDocument1 pageAngle Valve Figure B-222T Class 150 - Union Bonnet - PTFE Disc - Threaded Endsmax_powerNo ratings yet

- B3000 & Eb3000Document1 pageB3000 & Eb3000husamNo ratings yet

- Hidrante Seco Mod F0733Document1 pageHidrante Seco Mod F0733Julio FloresNo ratings yet

- Bronze Valves PDFDocument10 pagesBronze Valves PDFashish_pradhan75No ratings yet

- Steel Colour Code PDFDocument1 pageSteel Colour Code PDFJuan ZamoraNo ratings yet

- 175 PSI WWP Bronze Gate Valves: 175 PSI/12 .1 Bar Non-Shock Cold Water (400 PSI Non-Shock CWP General Service)Document1 page175 PSI WWP Bronze Gate Valves: 175 PSI/12 .1 Bar Non-Shock Cold Water (400 PSI Non-Shock CWP General Service)Ncmii AppnNo ratings yet

- Query4 PDFDocument1 pageQuery4 PDFAlessandro1975No ratings yet

- Lead-Free Bronze Gate Valves: T-113-LF S-113-LFDocument1 pageLead-Free Bronze Gate Valves: T-113-LF S-113-LFAlessandro1975No ratings yet

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- GVC To IVC To SVC (Ganges Valley Civilization To Indus Valley Civilization To Sarasvati Valley Civilization) PDFDocument28 pagesGVC To IVC To SVC (Ganges Valley Civilization To Indus Valley Civilization To Sarasvati Valley Civilization) PDFanjanaNo ratings yet

- EthicsDocument9 pagesEthicsMJ UyNo ratings yet

- TunePatSpotifyConverterforWindows ManualDocument13 pagesTunePatSpotifyConverterforWindows ManualEmre TekinerNo ratings yet

- The Belbin Team RolesDocument10 pagesThe Belbin Team RolesMarlon BoucaudNo ratings yet

- Time Cost Trade OffDocument22 pagesTime Cost Trade Offtulsi pokhrelNo ratings yet

- 7eme Synthese June2023Document3 pages7eme Synthese June2023nourhene SaidiNo ratings yet

- ExamplesDocument1 pageExamplesSwordhamza KyatNo ratings yet

- Georges A. Barrois, Jesus Christ and The Temple: Cărți Pentru TraducereDocument2 pagesGeorges A. Barrois, Jesus Christ and The Temple: Cărți Pentru TraducereAlin GogaNo ratings yet

- Canup Moon Nature 01 PDFDocument5 pagesCanup Moon Nature 01 PDFArcibaldMilicNo ratings yet

- Data AlatDocument29 pagesData AlatRefi Opti faniNo ratings yet

- Bongabon Senior High School Brgy. Sinipit, Bongabon, Nueva Ecija, 3128Document2 pagesBongabon Senior High School Brgy. Sinipit, Bongabon, Nueva Ecija, 3128Cire HerreraNo ratings yet

- 2010 Drama For Life Festival - ProgrammeDocument13 pages2010 Drama For Life Festival - ProgrammeSA BooksNo ratings yet

- Semester 5 SyllabusDocument16 pagesSemester 5 SyllabusParas kapoorNo ratings yet

- Ohes4411 - 4Document42 pagesOhes4411 - 4Emre ParlakNo ratings yet

- ACP1withsolution 16303 16301873391Document23 pagesACP1withsolution 16303 16301873391Arman DehuriNo ratings yet

- Petronas Technical Standards: Site Preparation and EarthworksDocument29 pagesPetronas Technical Standards: Site Preparation and EarthworksFirdausi FauziNo ratings yet

- Things To Do When BoredDocument4 pagesThings To Do When BoredKarla MravunacNo ratings yet

- Textbook A World of Three Cultures Honor Achievement and Joy 1St Edition Miguel E Basanez Ebook All Chapter PDFDocument53 pagesTextbook A World of Three Cultures Honor Achievement and Joy 1St Edition Miguel E Basanez Ebook All Chapter PDFkatie.martinez610100% (23)

- Here Is The MoonDocument2 pagesHere Is The MoonDeepakNo ratings yet

- Raine 2002 PDFDocument32 pagesRaine 2002 PDFdiyei_patoNo ratings yet

- X ZXZXDocument2 pagesX ZXZXDaniel BrownNo ratings yet

- Merged Smallpdf - Com 2Document185 pagesMerged Smallpdf - Com 2molihoneyNo ratings yet

- 4-SSS SAS ASA and AAS Congruence PDFDocument4 pages4-SSS SAS ASA and AAS Congruence PDFAivie Jannelle Columna BejoNo ratings yet

- Final Reflection Essay Outline 1Document8 pagesFinal Reflection Essay Outline 1api-643387955No ratings yet

- TLE Handicraft Production Module 1Document5 pagesTLE Handicraft Production Module 1Celemin CuajotorNo ratings yet

- ISA 706 (Revised)Document19 pagesISA 706 (Revised)karnanNo ratings yet

- Group 70 - COMPONENT LOCATIONS - Mitsubishi Outlander III - Wiring DiagramsDocument19 pagesGroup 70 - COMPONENT LOCATIONS - Mitsubishi Outlander III - Wiring DiagramsandreslionNo ratings yet

- Slide Plate ApplicationsDocument2 pagesSlide Plate ApplicationsvietrossNo ratings yet

175 Lb. WWP Iron Body Gate Valve: 175 PSI Non-Shock Cold Water

175 Lb. WWP Iron Body Gate Valve: 175 PSI Non-Shock Cold Water

Uploaded by

Gerardo Mendoza CisnerosOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

175 Lb. WWP Iron Body Gate Valve: 175 PSI Non-Shock Cold Water

175 Lb. WWP Iron Body Gate Valve: 175 PSI Non-Shock Cold Water

Uploaded by

Gerardo Mendoza CisnerosCopyright:

Available Formats

NIBCO INC. World Headquarters n 1516 Middlebury St. n Elkhart, IN 46516-4714 U.S.A. n www.nibco.

com

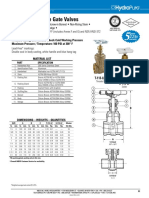

175 lb. wwp iron body gate valve

Fire Protection Valve • UL/ULC Listed • FMRC Approved • Approved by the New York City B.S.A.

143-69-SA • Conforms to MSS SP-70

Bolted Bonnet • Outside Screw and Yoke • Solid Wedge • Pre-Grooved Stem for Supervisory

Switch Mounting

175 PSI Non-Shock Cold Water

MATERIAL LIST

PART SPECIFICATION

1. Stem Brass ASTM B-16 Alloy C3600

2. Handwheel Nut Cast Bronze B-584 Alloy C84400

3. Identification Plate Aluminum

4. Yoke Bushing Cast Bronze B-584 Alloy C84400

5. Handwheel Cast Iron ASTM A-126 Class B

6. Bonnet Cap Nut Steel ASTM A-307

7. Bonnet Cap Ductile Iron ASTM A-536

1

8. Bonnet Cast Iron ASTM A-126 Class B

9. Bonnet Cap Bolt Steel ASTM A-307

10. Gland Follower Nut Brass ASTM B-36

11. Gland Follower Ductile Iron ASTM A-536

12. Packing Gland Zinc Plated Powdered Iron ASTM B-310

or Cast Brass ASTM Alloy C36000

13. Packing Non Asbestos

14. Gland Follower Bolt Steel ASTM A-307

15. Backseat Bushing Cast Bronze B-584 Alloy C84400

16. Body Nut Steel ASTM A-307

17. Body Bolt Steel ASTM A-307

18. Wedge Pin Silicon Bronze ASTM B-371

Alloy C69400 or B-140 Alloy C31400

19. Body Cast Iron ASTM A-126 Class B

20. Seat Ring Cast Bronze B-584 Alloy C84400

21. Wedge Face Pin Cast Bronze B-584 Alloy C84400

2

22. Wedge Cast Iron ASTM A-126 Class B

23. Body Gasket Non Asbestos

24. Stem Collar Brass ASTM B-16 Alloy C36000

1

Sizes up to 8" inclusive made with yoke integral with bonnet.

10" and 12" sizes made with separate yoke bolted to bonnet.

F-607-OTS

2

Sizes 2 / " thru 6" are all bronze wedges.

1

2 flanged

Sizes 8" thru 12" made with cast iron wedge with bronze wedge face rings

TS: pre-grooved stem for supervisory switch mounting.

F-607-OTS Flanged

DIMENSIONS - WEIGHTS

Dimensions

Nominal Approx.

Size A B C D. E Net Wt.

21/2 71/2 167/8 8 7 11

/16 50

3 8 193/4 8 71/2 3

/4 62

4 9 24 10 9 15

/16 104

5 10 271/2 10 10 15

/16 137

6 10 /2

1

31 /2

1

12 11 1 173

8 111/2 403/4 14 131/2 11/8 306

10 13 481/2 16 16 13/16 494

12 14 57 18 19 11/4 699

FREEZING WEATHER PRECAUTION: Subsequent to testing a piping system gate

valve should be in an open position to allow complete drainage.

NOTE: Available to ISO Flange dimensions. Specify F-607-OI.

See page 49.

19

You might also like

- flgx213 (2) Pkjun2015Document6 pagesflgx213 (2) Pkjun2015Jason Van Den HeeverNo ratings yet

- Vic 2019 CatalogDocument893 pagesVic 2019 CatalogAnna Mae Marantan100% (1)

- Catalogue Van Shin Yi 2021Document64 pagesCatalogue Van Shin Yi 2021duc22198No ratings yet

- A105 A216 ComparisonDocument10 pagesA105 A216 Comparisonprihartono_diasNo ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Class 125 Iron Body Gate Valves: Bolted Bonnet - Outside Screw and Yoke - Solid Wedge - Bronze MountedDocument1 pageClass 125 Iron Body Gate Valves: Bolted Bonnet - Outside Screw and Yoke - Solid Wedge - Bronze MountedJOSE GABRIELNo ratings yet

- Data SheetDocument1 pageData SheetMathi Vinoth PillaiNo ratings yet

- Valvula Globo en AnguloDocument1 pageValvula Globo en AnguloRobertoNo ratings yet

- CS Ball Valve TM-590Document1 pageCS Ball Valve TM-590Hector Dario Tobon BenjumeaNo ratings yet

- Gala Valve Fire Fighting Catalogue 2018 V#5 - A4 - BDocument7 pagesGala Valve Fire Fighting Catalogue 2018 V#5 - A4 - BChhomNo ratings yet

- Valtech Catalogue-1Document44 pagesValtech Catalogue-1Bashir AliNo ratings yet

- 175 PSI WWP Iron Body Gate ValvesDocument1 page175 PSI WWP Iron Body Gate ValvestremendousNo ratings yet

- Valvula de Globo de MediaDocument1 pageValvula de Globo de MediaRobertoNo ratings yet

- Ficha Tecnica Valvula Cortina Ranurada OSYDocument1 pageFicha Tecnica Valvula Cortina Ranurada OSYrobinson18e2No ratings yet

- Kirloskar Process Pump - GK (P) : ISO 2858 / DIN EN 22858 / ISO 5199Document12 pagesKirloskar Process Pump - GK (P) : ISO 2858 / DIN EN 22858 / ISO 5199Amit pumpXpertzNo ratings yet

- CI Wafer / DI Lug Butterfly Valves: Series 0160Document2 pagesCI Wafer / DI Lug Butterfly Valves: Series 0160Vignesh NadimuthuNo ratings yet

- FT918BBI (1) Cheque NipcoDocument1 pageFT918BBI (1) Cheque NipcoRobertoNo ratings yet

- B8 ValvulasDocument1 pageB8 ValvulasPROCESOS PROCESOSNo ratings yet

- Gate Valve (Promet) TYCODocument3 pagesGate Valve (Promet) TYCOSupawat RangsiwongNo ratings yet

- F58 CraneDocument1 pageF58 CraneMarco DiazNo ratings yet

- Union Bonnet Globe Valve: Submittal SheetDocument1 pageUnion Bonnet Globe Valve: Submittal SheetRajesh ChoudharyNo ratings yet

- Class 150 Bronze Gate ValvesDocument1 pageClass 150 Bronze Gate Valvescristian villegasNo ratings yet

- Walworth 5202F 150lb GatesDocument5 pagesWalworth 5202F 150lb GatesAnthonyNo ratings yet

- F 908 WDocument1 pageF 908 WHaythem AhmedNo ratings yet

- Econ Gate Valve Cast Iron Bronze Trim ANSI Class 125 Fig. 1800Document1 pageEcon Gate Valve Cast Iron Bronze Trim ANSI Class 125 Fig. 1800ChristianGuerreroNo ratings yet

- Non Return Valves Cast Steel APIDocument4 pagesNon Return Valves Cast Steel APILinson GeorgeNo ratings yet

- 600scjs#cy 2-12 - 15Document2 pages600scjs#cy 2-12 - 15MohamadIbnuHassanNo ratings yet

- Fox ™ Triple Effect Air Vent + Anti Water Hammer: FeaturesDocument5 pagesFox ™ Triple Effect Air Vent + Anti Water Hammer: FeaturesNicolás Polito MuñozNo ratings yet

- Cast Iron Gate Valve Non Rising Stem PN16: Features & BenefitsDocument1 pageCast Iron Gate Valve Non Rising Stem PN16: Features & BenefitsMohamed RaafatNo ratings yet

- FlowBiz Cast Steel Angle Type Globe ValvesDocument2 pagesFlowBiz Cast Steel Angle Type Globe ValvesShakir AnsariNo ratings yet

- Filtro DuplexDocument8 pagesFiltro DuplexGuillermo ArandaNo ratings yet

- Malwaukee - F2885MRWDocument1 pageMalwaukee - F2885MRWSoojaelimNo ratings yet

- Fig FM63 Gate CraneFS DS 1702 P133Document1 pageFig FM63 Gate CraneFS DS 1702 P133afzal_aabNo ratings yet

- T301WFPDocument1 pageT301WFPcristian villegasNo ratings yet

- Bellow Seal Valves: AN ISO 9001:2000 COMPANYDocument20 pagesBellow Seal Valves: AN ISO 9001:2000 COMPANYDeepak HishikarNo ratings yet

- Cast Steel Bolted Bonnet Gates: Styles: CB2, CB3, & CB4/2 Class: 1500 - Sizes: 2" Thru 12"Document1 pageCast Steel Bolted Bonnet Gates: Styles: CB2, CB3, & CB4/2 Class: 1500 - Sizes: 2" Thru 12"OceanexNo ratings yet

- Fig. No. 208: RED WHITE Bronze Gate Valve - 125 LBDocument1 pageFig. No. 208: RED WHITE Bronze Gate Valve - 125 LBSergio DjbucaneroNo ratings yet

- Valv. Bola Bronce T580-85-70Document1 pageValv. Bola Bronce T580-85-70byron_a24No ratings yet

- Technical Data Sheet: Series 4200 Type W Pressure GateDocument2 pagesTechnical Data Sheet: Series 4200 Type W Pressure GateJayNo ratings yet

- Civ CatalogDocument7 pagesCiv CatalogMichel Simas de OliveiraNo ratings yet

- Gate Valve 150Document2 pagesGate Valve 150Masih BelajarNo ratings yet

- Art 826Document1 pageArt 826MASOUDNo ratings yet

- Spring Loaded Safety Valve: SRV1 (Open Bonnet) / SRV2 (Closed Bonnet)Document4 pagesSpring Loaded Safety Valve: SRV1 (Open Bonnet) / SRV2 (Closed Bonnet)cmpuckNo ratings yet

- 2309+QT04 - Gala-Motorized Butterfly ValveDocument4 pages2309+QT04 - Gala-Motorized Butterfly ValveNam Đỗ100% (1)

- Fivalco PDFDocument16 pagesFivalco PDFjhoger2012No ratings yet

- Check Ranurado RH84X MechDocument1 pageCheck Ranurado RH84X MechFLOW INDUSTRIAL SACNo ratings yet

- F607RWSFPDocument1 pageF607RWSFPleonardo ramirezNo ratings yet

- Filtro Tipo yDocument5 pagesFiltro Tipo yKaren BasoaltoNo ratings yet

- FMC GGCDocument8 pagesFMC GGCsheshidharrajubNo ratings yet

- RED WHITE Cast Iron Gate Valve - 125 LB.: FeaturesDocument1 pageRED WHITE Cast Iron Gate Valve - 125 LB.: FeaturesSergio DjbucaneroNo ratings yet

- Flowcom - Ranurada y BridadaDocument1 pageFlowcom - Ranurada y BridadaErickNo ratings yet

- Shinyi Catalogue 2017Document64 pagesShinyi Catalogue 2017Huy NguyễnNo ratings yet

- Angle Valve Figure B-222T Class 150 - Union Bonnet - PTFE Disc - Threaded EndsDocument1 pageAngle Valve Figure B-222T Class 150 - Union Bonnet - PTFE Disc - Threaded Endsmax_powerNo ratings yet

- B3000 & Eb3000Document1 pageB3000 & Eb3000husamNo ratings yet

- Hidrante Seco Mod F0733Document1 pageHidrante Seco Mod F0733Julio FloresNo ratings yet

- Bronze Valves PDFDocument10 pagesBronze Valves PDFashish_pradhan75No ratings yet

- Steel Colour Code PDFDocument1 pageSteel Colour Code PDFJuan ZamoraNo ratings yet

- 175 PSI WWP Bronze Gate Valves: 175 PSI/12 .1 Bar Non-Shock Cold Water (400 PSI Non-Shock CWP General Service)Document1 page175 PSI WWP Bronze Gate Valves: 175 PSI/12 .1 Bar Non-Shock Cold Water (400 PSI Non-Shock CWP General Service)Ncmii AppnNo ratings yet

- Query4 PDFDocument1 pageQuery4 PDFAlessandro1975No ratings yet

- Lead-Free Bronze Gate Valves: T-113-LF S-113-LFDocument1 pageLead-Free Bronze Gate Valves: T-113-LF S-113-LFAlessandro1975No ratings yet

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- GVC To IVC To SVC (Ganges Valley Civilization To Indus Valley Civilization To Sarasvati Valley Civilization) PDFDocument28 pagesGVC To IVC To SVC (Ganges Valley Civilization To Indus Valley Civilization To Sarasvati Valley Civilization) PDFanjanaNo ratings yet

- EthicsDocument9 pagesEthicsMJ UyNo ratings yet

- TunePatSpotifyConverterforWindows ManualDocument13 pagesTunePatSpotifyConverterforWindows ManualEmre TekinerNo ratings yet

- The Belbin Team RolesDocument10 pagesThe Belbin Team RolesMarlon BoucaudNo ratings yet

- Time Cost Trade OffDocument22 pagesTime Cost Trade Offtulsi pokhrelNo ratings yet

- 7eme Synthese June2023Document3 pages7eme Synthese June2023nourhene SaidiNo ratings yet

- ExamplesDocument1 pageExamplesSwordhamza KyatNo ratings yet

- Georges A. Barrois, Jesus Christ and The Temple: Cărți Pentru TraducereDocument2 pagesGeorges A. Barrois, Jesus Christ and The Temple: Cărți Pentru TraducereAlin GogaNo ratings yet

- Canup Moon Nature 01 PDFDocument5 pagesCanup Moon Nature 01 PDFArcibaldMilicNo ratings yet

- Data AlatDocument29 pagesData AlatRefi Opti faniNo ratings yet

- Bongabon Senior High School Brgy. Sinipit, Bongabon, Nueva Ecija, 3128Document2 pagesBongabon Senior High School Brgy. Sinipit, Bongabon, Nueva Ecija, 3128Cire HerreraNo ratings yet

- 2010 Drama For Life Festival - ProgrammeDocument13 pages2010 Drama For Life Festival - ProgrammeSA BooksNo ratings yet

- Semester 5 SyllabusDocument16 pagesSemester 5 SyllabusParas kapoorNo ratings yet

- Ohes4411 - 4Document42 pagesOhes4411 - 4Emre ParlakNo ratings yet

- ACP1withsolution 16303 16301873391Document23 pagesACP1withsolution 16303 16301873391Arman DehuriNo ratings yet

- Petronas Technical Standards: Site Preparation and EarthworksDocument29 pagesPetronas Technical Standards: Site Preparation and EarthworksFirdausi FauziNo ratings yet

- Things To Do When BoredDocument4 pagesThings To Do When BoredKarla MravunacNo ratings yet

- Textbook A World of Three Cultures Honor Achievement and Joy 1St Edition Miguel E Basanez Ebook All Chapter PDFDocument53 pagesTextbook A World of Three Cultures Honor Achievement and Joy 1St Edition Miguel E Basanez Ebook All Chapter PDFkatie.martinez610100% (23)

- Here Is The MoonDocument2 pagesHere Is The MoonDeepakNo ratings yet

- Raine 2002 PDFDocument32 pagesRaine 2002 PDFdiyei_patoNo ratings yet

- X ZXZXDocument2 pagesX ZXZXDaniel BrownNo ratings yet

- Merged Smallpdf - Com 2Document185 pagesMerged Smallpdf - Com 2molihoneyNo ratings yet

- 4-SSS SAS ASA and AAS Congruence PDFDocument4 pages4-SSS SAS ASA and AAS Congruence PDFAivie Jannelle Columna BejoNo ratings yet

- Final Reflection Essay Outline 1Document8 pagesFinal Reflection Essay Outline 1api-643387955No ratings yet

- TLE Handicraft Production Module 1Document5 pagesTLE Handicraft Production Module 1Celemin CuajotorNo ratings yet

- ISA 706 (Revised)Document19 pagesISA 706 (Revised)karnanNo ratings yet

- Group 70 - COMPONENT LOCATIONS - Mitsubishi Outlander III - Wiring DiagramsDocument19 pagesGroup 70 - COMPONENT LOCATIONS - Mitsubishi Outlander III - Wiring DiagramsandreslionNo ratings yet

- Slide Plate ApplicationsDocument2 pagesSlide Plate ApplicationsvietrossNo ratings yet