Professional Documents

Culture Documents

Cosmos Alminium-Technical - Specifications PDF

Cosmos Alminium-Technical - Specifications PDF

Uploaded by

mindsopenOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cosmos Alminium-Technical - Specifications PDF

Cosmos Alminium-Technical - Specifications PDF

Uploaded by

mindsopenCopyright:

Available Formats

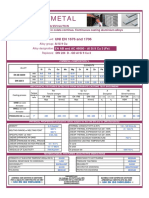

Extruded alloys and tempers

Cosmos aluminium can extrude the majority of the 6XXX alloy series in various tempers. The most common alloys &

tempers used, are: EN-AW 6060 (Al MgSi0,5) acc. to DIN 3.3206, EN-AW 6063 (Al Mg0,7Si) acc. to DIN 3.2315 and

EN-AW 6082 (Al Si1MgMn) acc. to DIN 3.2315.

According to EN 573-3 (EN- AW chemical composition %)

Alloy Si Fe Cu Mn Mg Cr Zn Ti Other Al

Each Total

6060 0,30-0,60 0,10-0,30 0,10 0,10 0,35-0,60 0,05 0,15 0,10 0,05 0,15 Rest

6063 0,20-0,60 0,35 0,10 0,10 0,45-0,90 0,10 0,10 0,10 0,05 0,15 Rest

6082 0,70-1,30 0,50 0,10 0,40-1,00 0,60-1,20 0,25 0,20 0,10 0,05 0,15 Rest

Temper designation (according to EN 515)

O Annealed wrought alloys.

T4 Solution heat treated & naturally aged.

T5 Cooled from an elevated temperature forming operation & artificially aged (precipitation hardened)

Solution heat treated & artificially aged (precipitation hardened).

T6

Press quenching required.

Cooled from an elevated temperature forming operation & artificially aged (precipitation hardened) to a

T66 higher level of mechanical properties through special control of manufacturing processes.

Press quenching required.

Physical properties

Alloys EN-AW 6060 6063 6082

Melting range 0C 585-650 585-650

Density g/cm3 2,70 2,70 2,70

Electrical Conductivity MS/m 34-38 24-32

Thermal Conductivity W/(m K) 200-220 170-220

Specific Heat J /(Kg K) 898 896

Thermal Expansion Values

0 -6

-50 to 20 C (10 /K) 21,8

0 -6

20 to 100 C (10 /K) 23,4 23,4 23,4

0 -6

20 to 200 C (10 /K) 24,5

0 -6

20 to 300 C (10 /K) 25,6

Young’s Modulus MPa 69500 69500 70000

Shear Modulus MPa 26100 26100 26400

Mechanical properties (according to EN 755-2 Extruded Profiles)

Wall Proof Tensile Brinell

Alloy Elongation Temper

Thickness stress strength Hardness

RP0,2 Rm A50mm A

MPa MPa % %

e mm* HB**

min min min min

e≤ 25 60 120 14 16 45 T4

e≤ 5 120 160 6 8 55 T5

e≤ 3 150 190 6 8 65

EN-AW 6060 T6

3<e≤25 140 170 6 8 60

e≤ 3 160 215 6 8 70

T66

3<e≤25 150 195 6 8 65

e≤ 25 65 130 12 14 45 T4

e≤ 3 130 175 6 8 55

T5

3<e≤25 110 160 5 7 50

EN-AW 6063 e≤ 10 170 215 6 8 65

T6

10<e≤25 160 195 6 8 60

e≤ 10 200 245 6 8 75

T66

10<e≤25 180 225 6 8 70

e≤ 25 110 205 12 14 70 T4

e≤ 5 230 270 6 8 80 T5

EN-AW 6082

e≤ 5 250 290 6 8 95

T6

10<e≤25 260 310 8 10 95

* For different wall thicknesses of a given profile, the lowest specified values of properties shall be considered as valid for the whole

profile cross-section.

** The values for the HB hardness are indicative only.

Alloys Forms Characteristic properties Applications

V.good corrosion resistance, Architectural sections, frames,

EN-AW 6060 Extruded round rod/bar Medium strength, Complex lightings, railing, ladders, furniture,

sections, Anodising quality fences, flooring

Extruded square, rectangular, V.good corrosion resistance Architectural sections, frames,

EN-AW 6063 hexagonal rod/bar Medium strength, Complex lightings, railing, ladders, furniture,

Extruded tube sections, Anodising quality fences, heat sink

V.good corrosion resistance, Heavy duty structures, truck frames,

EN-AW 6082 Extruded profiles Medium-High strength, bicycles, flanges, pylons, towers,

Not complex sections scaffolding tubes

The quality control department at Cosmos Aluminium abides with the following standards for the production quality

control and delivery of aluminium profiles.

EN Standard Description

Aluminium & aluminium alloys- Extruded rod/bar, tubes and profiles

EN 755-1 Technical conditions for inspection & delivery

EN 755-3 Round bars, tolerances on dimension & form

EN 755-4 Square bars, tolerances on dimension & form

EN 755-5 Rectangular bars, tolerances on dimension & form

EN 755-6 Hexagonal bars, tolerances on dimension & form

EN 755-7 Seamless tubes, tolerances on dimension & form

EN 755-9 Profiles, tolerances on dimension & form

Aluminium & aluminium alloys- Extruded precision profiles in alloys EN- AW 6060 & EN- AW 6063

EN- 12020-1 Technical conditions for inspection & delivery (precision profiles)

EN- 12020-2 Tolerances on dimension & form (precision profiles)

Metallic products- Types of inspection documents

Inspection 2.3, 3.1, 3.2

In process of EN ISO 9001:2000 certification.

Profile size production range

PROFILE SIZE PRODUCTION CAPACITY

110

100

90

80

70

60

50

40

30

20

10

150 130 110 90 70 50 30 30 50 70 90 110 130 150

140 120 100 80 60 40 20 20 40 60 80 100 120 140

10

20

30

40

50

60

70

80

90

100

110

NORMAL RANGE

LIMIT RANGE

UPPER LIMIT RANGE

If your profile fits within the above limits, Cosmos Aluminium can extrude it.

Profile weight production range

Minimum profile weight: 100 gr/m Maximum profile weight: 8000 gr/m

You might also like

- Merritt H.E. Hydraulic Control SystemsDocument366 pagesMerritt H.E. Hydraulic Control Systemsrwcooldude100% (2)

- Assignment 4 Model Answer PDFDocument8 pagesAssignment 4 Model Answer PDFRyan HuangNo ratings yet

- 39 Checklist For Wood and Furniture IndustriesDocument6 pages39 Checklist For Wood and Furniture Industriesmindsopen0% (1)

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706satheeskumar VikramasingarajNo ratings yet

- Metz 58 Af2 Flash Manual PDFDocument44 pagesMetz 58 Af2 Flash Manual PDFelgrandebgNo ratings yet

- Product Catalog AluminiuDocument32 pagesProduct Catalog AluminiusnoofsnoofNo ratings yet

- AW60Document1 pageAW60Fitra VertikalNo ratings yet

- Tehnicke Karakteristike Asistal Alu OkapnicaDocument2 pagesTehnicke Karakteristike Asistal Alu OkapnicaDARKO RADICEVICNo ratings yet

- Data - 6060 Mechanical PropertiesDocument1 pageData - 6060 Mechanical Propertiesganeshnsg1980No ratings yet

- 90 MN CR V8Document1 page90 MN CR V8arunajay724No ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Raj RajeshNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Martin DuarteNo ratings yet

- En Aw 6082 Rev 2 Final PDFDocument3 pagesEn Aw 6082 Rev 2 Final PDFtechspawNo ratings yet

- Tempering Conditions For 30CrNiMo8Document2 pagesTempering Conditions For 30CrNiMo8madyeNo ratings yet

- 6060 PropertiesDocument3 pages6060 Propertiesinterpon07No ratings yet

- 25crmo4: Steel GradeDocument3 pages25crmo4: Steel GradeCristian Stiven Martinez GonzalezNo ratings yet

- Info EN755 9Document19 pagesInfo EN755 9Don JonesNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Raj RajeshNo ratings yet

- Nedal Alloy Datasheet en AW 6060Document1 pageNedal Alloy Datasheet en AW 6060ankur panwarNo ratings yet

- OK 63.30 (Inox 316)Document1 pageOK 63.30 (Inox 316)Tiberiu MunteanuNo ratings yet

- Steel Grade: Material Data SheetDocument5 pagesSteel Grade: Material Data SheetBoberNo ratings yet

- ALUMERO - Alloys EN AW 6082 AlMgSi1 - WebDocument1 pageALUMERO - Alloys EN AW 6082 AlMgSi1 - WebemilasanovskiNo ratings yet

- CuZn33 CatalogueDocument9 pagesCuZn33 CataloguefedericoNo ratings yet

- 34 CR Ni Mo 6Document2 pages34 CR Ni Mo 6hp_vijaykNo ratings yet

- CM-9CB TG-S9Cb US-9CbDocument3 pagesCM-9CB TG-S9Cb US-9Cbamit singhNo ratings yet

- Alloy 6082 - Rev2012Document2 pagesAlloy 6082 - Rev2012Ysraels Santisteban DurandNo ratings yet

- 34crnimo6: Steel GradeDocument6 pages34crnimo6: Steel GradeBiju KNo ratings yet

- S355JRDocument3 pagesS355JRYasmeen HaiderNo ratings yet

- AISI416Document2 pagesAISI416shamsi862620No ratings yet

- Sandvik 3re60 Tube and Pipe, Seamless: DatasheetDocument10 pagesSandvik 3re60 Tube and Pipe, Seamless: DatasheetVinay TrivediNo ratings yet

- CuETP PDFDocument2 pagesCuETP PDFlovelyshreeNo ratings yet

- Quenched and Tempered Alloyed Engineering Steel DINDocument2 pagesQuenched and Tempered Alloyed Engineering Steel DINkazdoelahNo ratings yet

- 34 CR Ni Mo 6Document4 pages34 CR Ni Mo 6Jonas AnderssonNo ratings yet

- 2205 Technical Data Sheet: Chemistry Mechanical PropertiesDocument6 pages2205 Technical Data Sheet: Chemistry Mechanical PropertiesJandri JacobNo ratings yet

- Steel Grade: Material Data SheetDocument5 pagesSteel Grade: Material Data SheetNaveen HlNo ratings yet

- E10018d2-Eng LINCOLNDocument1 pageE10018d2-Eng LINCOLNBenfil ViernezNo ratings yet

- 42crmo4: Steel GradeDocument5 pages42crmo4: Steel GradeMahmoud KchaouNo ratings yet

- (UNS S66286) : NAS Heat-Resistant Stainless SteelDocument4 pages(UNS S66286) : NAS Heat-Resistant Stainless Steelsafat parNo ratings yet

- Datasheet Sandvik 2rk65 en v2019!06!19 14 - 54 Version 1Document13 pagesDatasheet Sandvik 2rk65 en v2019!06!19 14 - 54 Version 1mauferesNo ratings yet

- E 6013 Fincord M electrode-oerlikon-en-TN110429Document1 pageE 6013 Fincord M electrode-oerlikon-en-TN110429Khhg AgddsNo ratings yet

- 56 Si 7Document2 pages56 Si 7Bhuvanesh ShanmugamNo ratings yet

- 34 CR Ni Mo 6Document4 pages34 CR Ni Mo 6Krzysztof WrzeszczNo ratings yet

- ALUMERO - Alloys EN AW 6060 AlMgSi0 - WebDocument1 pageALUMERO - Alloys EN AW 6060 AlMgSi0 - WebemilasanovskiNo ratings yet

- Leichtmetall Data Sheet EN AW 6082T6Document1 pageLeichtmetall Data Sheet EN AW 6082T6Satendra ThakurNo ratings yet

- Quality 39nicrmo3: Lucefin GroupDocument2 pagesQuality 39nicrmo3: Lucefin Groupmarko9292No ratings yet

- 03112015000000B - Boehler FOX NiCr 70 NB - CeDocument1 page03112015000000B - Boehler FOX NiCr 70 NB - CeFlori MovNo ratings yet

- Al Alloys Chemicals MechanicalsDocument1 pageAl Alloys Chemicals MechanicalsFactory FactoryNo ratings yet

- 1.7225 en PDFDocument2 pages1.7225 en PDFTheodoros AtheridisNo ratings yet

- 42 CR Mo 4Document3 pages42 CR Mo 4lucasNo ratings yet

- Wb2318e E9018-MDocument1 pageWb2318e E9018-McwiksjNo ratings yet

- Dual Phase Steels Voestalpine EN 28092018Document4 pagesDual Phase Steels Voestalpine EN 28092018Silverio AcuñaNo ratings yet

- 38MnMo6 3Document2 pages38MnMo6 3Adrian-Ciprian SandaNo ratings yet

- Aristo Rod 55Document1 pageAristo Rod 55joao guilhermeNo ratings yet

- Steel Grade: Material Data SheetDocument5 pagesSteel Grade: Material Data Sheetdan howsNo ratings yet

- Nedal Alloy Datasheet en AW 6005ADocument1 pageNedal Alloy Datasheet en AW 6005Aankur panwarNo ratings yet

- Datasheet Sandvik Saf 2205 en PDFDocument12 pagesDatasheet Sandvik Saf 2205 en PDFYuriy NesterovNo ratings yet

- Interlloy Grade 8620 Case Hardening SteelDocument3 pagesInterlloy Grade 8620 Case Hardening Steelajitchavan2150No ratings yet

- TIG Bohler S EMK 6 ER70S 6Document1 pageTIG Bohler S EMK 6 ER70S 6mohamedNo ratings yet

- Auto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenFrom EverandAuto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenRating: 4 out of 5 stars4/5 (2)

- sj-210,310 Series WebDocument20 pagessj-210,310 Series WebmindsopenNo ratings yet

- BrosuraDocument32 pagesBrosuramindsopenNo ratings yet

- ALRO Profile Extrudate PDFDocument2 pagesALRO Profile Extrudate PDFmindsopenNo ratings yet

- CatalogDocument544 pagesCatalogmindsopenNo ratings yet

- ISO9004 Linii Directoare PT Imbunatatirea PerformantelorDocument80 pagesISO9004 Linii Directoare PT Imbunatatirea PerformantelormindsopenNo ratings yet

- Cosmos Alminium-Technical SpecificationsDocument2 pagesCosmos Alminium-Technical SpecificationsmindsopenNo ratings yet

- Bonderite® Nt-1-EnDocument6 pagesBonderite® Nt-1-EnmindsopenNo ratings yet

- The Early History of Indo-European LanguagesDocument12 pagesThe Early History of Indo-European Languagesmindsopen100% (1)

- Origin and Propagation of The ELECTRIC FIELDDocument6 pagesOrigin and Propagation of The ELECTRIC FIELDAKISNo ratings yet

- Basic VibrationDocument76 pagesBasic VibrationJack Adam100% (2)

- 02.01.23 SR - Star Co-Sc (Model-A & B) Jee Main Ctm-2 QPDocument20 pages02.01.23 SR - Star Co-Sc (Model-A & B) Jee Main Ctm-2 QPTanay1 MitraNo ratings yet

- En 1993 1 10 2005 PDFDocument19 pagesEn 1993 1 10 2005 PDFSuleyman HaliciogluNo ratings yet

- Materials 14 02273Document20 pagesMaterials 14 02273Silas Sverre ChristensenNo ratings yet

- SAMPLE PAPER Physics XI by S.K. Pandey Principal KV GangraniDocument9 pagesSAMPLE PAPER Physics XI by S.K. Pandey Principal KV GangraniAKASH KUMAR X ANo ratings yet

- Black HoleDocument14 pagesBlack HoleSagarKasarlaNo ratings yet

- Hulin Li, Zhongwei Yin, Dan Jiang, Liyong Jin, Yuqing Cui: SciencedirectDocument11 pagesHulin Li, Zhongwei Yin, Dan Jiang, Liyong Jin, Yuqing Cui: SciencedirectAnnamalai PalaniappanNo ratings yet

- Flow Through Circular PipesDocument105 pagesFlow Through Circular PipesArchangel VenantNo ratings yet

- Power System PinoybixDocument31 pagesPower System PinoybixRouel LeonenNo ratings yet

- Explain The Concepts Behind Bradford Method in Measuring Protein Concentration in A SolutionDocument4 pagesExplain The Concepts Behind Bradford Method in Measuring Protein Concentration in A SolutionRiri ShinNo ratings yet

- 17204Document30 pages17204Aftab KhanNo ratings yet

- Constructing A Plastic Bottle Wind Turbine As A Practical Aid For Learning About Using Wind Energy To Generate ElectricityDocument6 pagesConstructing A Plastic Bottle Wind Turbine As A Practical Aid For Learning About Using Wind Energy To Generate Electricityjunior_mecanicaNo ratings yet

- Alkenes Streochemistry CIS TRANSDocument43 pagesAlkenes Streochemistry CIS TRANSSherryl MontalboNo ratings yet

- Calculation of Seismic Protective Qualities of Dampefer and AbsorterDocument4 pagesCalculation of Seismic Protective Qualities of Dampefer and AbsorterdineshNo ratings yet

- MPP - SRS Class 4 Casting ProcessDocument35 pagesMPP - SRS Class 4 Casting ProcessAngelNo ratings yet

- KV of BitumenDocument10 pagesKV of Bitumendhanesh kumarNo ratings yet

- STUDENTS Lecture 4 (Chapter 3)Document19 pagesSTUDENTS Lecture 4 (Chapter 3)Sirine AjourNo ratings yet

- Microstructure and Mechanical Properties of AZ31 Magnesium Alloy Sheets Processed by Constrained Groove PressingDocument10 pagesMicrostructure and Mechanical Properties of AZ31 Magnesium Alloy Sheets Processed by Constrained Groove PressingMoin ANo ratings yet

- The History of The Atom The Periodic Table and RadioactivityDocument108 pagesThe History of The Atom The Periodic Table and RadioactivityValiNo ratings yet

- Mini Flow Channel ExperimentDocument9 pagesMini Flow Channel Experimentpotato92No ratings yet

- Surveying Observation, Surveying, ObservationDocument63 pagesSurveying Observation, Surveying, Observationthanasekar665No ratings yet

- 03 BoltzGibbsShannonDocument30 pages03 BoltzGibbsShannonroxy8marie8chanNo ratings yet

- Wee1964 N001Document9 pagesWee1964 N001Oliver RubioNo ratings yet

- Data Sheet Padus UNI M05 M11-523 ADocument1 pageData Sheet Padus UNI M05 M11-523 ADaney RockerzNo ratings yet

- Infinitely Long Fins (Document7 pagesInfinitely Long Fins (Ehl GutierrezNo ratings yet

- Chapter 2 Introduction2Document78 pagesChapter 2 Introduction2Omer IkhlasNo ratings yet