Professional Documents

Culture Documents

Single Angle Flexure

Single Angle Flexure

Uploaded by

Jose Ernesto Martinez MendozaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Single Angle Flexure

Single Angle Flexure

Uploaded by

Jose Ernesto Martinez MendozaCopyright:

Available Formats

Return to Table of Contents

F-46

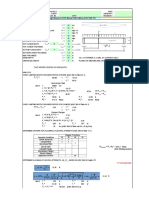

Check flange slenderness.

E

λ rf = 1.0 from AISC Specification Table B4.1b Case 10

Fy

29,000 ksi

= 1.0

50 ksi

= 24.1

bf

λ=

2t f

= 9.43 < λ rf ; therefore, the flange is not slender

For a WT with a noncompact flange, the nominal flexural strength due to flange local buckling is:

⎡ ⎛ λ − λ pf ⎞ ⎤

Mn = ⎢ M p − ( M p − 0.7 Fy S xc ) ⎜ ⎟ ⎥ < 1.6My (Spec. Eq. F9-6)

⎣⎢ ⎝ λ rf − λ pf ⎠ ⎥⎦

⎧ ⎛ 9.43 − 9.15 ⎞ ⎫

= ⎨110 kip-in. − ⎡⎣110 kip-in. − 0.7 ( 50 ksi ) ( 3.20 in.3 ) ⎤⎦ ⎜ ⎟ ⎬ < 97.6 kip-in.

⎩ ⎝ 24.1 − 9.15 ⎠ ⎭

= 110 kip-in. > 97.6 kip-in.

Therefore use:

Mn = 97.6 kip-in. or 8.13 kip-ft

Mn = Mp

= 8.13 kip-ft yielding limit state controls (Spec. Eq. F9-1)

From AISC Specification Section F1, the available flexural strength is:

LRFD ASD

φb = 0.90 Ωb = 1.67

M n 8.13 kip-ft

φb M n = 0.90 ( 8.13 kip-ft ) =

Ωb 1.67

= 7.32 kip-ft > 2.16 kip-ft o.k. = 4.87 kip-ft > 1.44 kip-ft o.k.

Design Examples V14.0

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

Return to Table of Contents

F-47

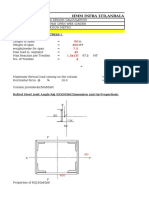

EXAMPLE F.11A SINGLE ANGLE FLEXURAL MEMBER

Given:

Select an ASTM A36 single angle with a simple span of 6 ft. The vertical leg of the single angle is up and the toe

is in compression. The vertical loads are a uniform dead load of 0.05 kip/ft and a uniform live load of 0.15 kip/ft.

There are no horizontal loads. There is no deflection limit for this angle. The angle is braced at the end points

only. Assume bending about the geometric x-x axis and that there is no lateral-torsional restraint.

Solution:

From AISC Manual Table 2-4, the material properties are as follows:

ASTM A36

Fy = 36 ksi

Fu = 58 ksi

From Chapter 2 of ASCE/SEI 7, the required flexural strength is:

LRFD ASD

wux = 1.2(0.05 kip/ft) + 1.6(0.15 kip/ft) wax = 0.05 kip/ft + 0.15 kip/ft

= 0.300 kip/ft = 0.200 kip/ft

0.300 kip/ft ( 6 ft ) 0.200 kip/ft ( 6 ft )

2 2

Mux = Max =

8 8

= 1.35 kip-ft = 0.900 kip-ft

Try a L4×4×4.

From AISC Manual Table 1-7, the geometric properties are as follows:

L4×4×4

Sx = 1.03 in.3

Nominal Flexural Strength, Mn

Flexural Yielding

From AISC Specification Section F10.1, the nominal flexural strength due to the limit state of flexural yielding is:

M n = 1.5M y (Spec. Eq. F10-1)

= 1.5 Fy S x

= 1.5 ( 36 ksi ) (1.03in.3 )

= 55.6 kip-in.

Design Examples V14.0

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

Return to Table of Contents

F-48

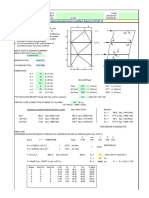

Lateral-Torsional Buckling

From AISC Specification Section F10.2, for single angles bending about a geometric axis with no lateral-torsional

restraint, My is taken as 0.80 times the yield moment calculated using the geometric section modulus.

M y = 0.80 Fy S x

= 0.80 ( 36 ksi ) (1.03in.3 )

= 29.7 kip-in.

Determine Me.

For bending moment about one of the geometric axes of an equal-leg angle with no axial compression, with no

lateral-torsional restraint, and with maximum compression at the toe, use AISC Specification Section

F10.2(b)(iii)(a)(i), Equation F10-6a.

Cb = 1.14 from AISC Manual Table 3-1

0.66 Eb 4 tCb ⎛⎜ ⎞

2

⎛ Lb t ⎞ ⎟

Me = 1 + 0.78 ⎜ 2 ⎟ − 1 (Spec. Eq. F10-6a)

Lb 2 ⎜ ⎝ b ⎠ ⎟

⎝ ⎠

⎛ 2 ⎞

0.66 ( 29, 000 ksi )( 4.00 in.) (4 in.)(1.14 ) ⎜ ⎛ ( 72.0 in.)(4 in.) ⎞

4

= ⎜ 1 + 0.78 ⎜⎜ ⎟ − 1⎟⎟

( 72.0 in.) ⎟

⎝ ( 4.00 in.)

2 2

⎜ ⎠ ⎟

⎝ ⎠

= 110 kip-in. > 29.7 kip-in.; therefore, AISC Specification Equation F10-3 is applicable

⎛ My ⎞

M n = ⎜ 1.92 − 1.17 ⎟ M y ≤ 1.5M y (Spec. Eq. F10-3)

⎜ M e ⎟⎠

⎝

⎛ 29.7 kip-in. ⎞

= ⎜⎜ 1.92 − 1.17 ⎟ 29.7 kip-in. ≤ 1.5 ( 29.7 kip-in.)

⎝ 110 kip-in. ⎟⎠

= 39.0 kip-in. ≤ 44.6 kip-in.; therefore, Mn = 39.0 kip-in.

Leg Local Buckling

AISC Specification Section F10.3 applies when the toe of the leg is in compression.

Check slenderness of the leg in compression.

b

λ=

t

4.00 in.

=

4 in.

= 16.0

Determine the limiting compact slenderness ratios from AISC Specification Table B4.1b Case 12.

E

λ p = 0.54

Fy

Design Examples V14.0

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

Return to Table of Contents

F-49

29,000 ksi

= 0.54

36 ksi

= 15.3

Determine the limiting noncompact slenderness ratios from AISC Specification Table B4.1b Case 12.

E

λ r = 0.91

Fy

29,000 ksi

= 0.91

36 ksi

= 25.8

λ p < λ < λ r , therefore, the leg is noncompact in flexure

⎛ ⎛ b ⎞ Fy ⎞

M n = Fy Sc ⎜ 2.43 − 1.72 ⎜ ⎟ ⎟ (Spec. Eq. F10-7)

⎜ ⎝ t ⎠ E ⎟⎠

⎝

Sc = 0.80S x

= 0.80 (1.03in.3 )

= 0.824 in.3

⎛ 36 ksi ⎞

M n = 36 ksi ( 0.824 in.3 ) ⎜⎜ 2.43 − 1.72(16.0) ⎟

⎝ 29, 000 ksi ⎟⎠

= 43.3 kip-in.

The lateral-torsional buckling limit state controls.

Mn = 39.0 kip-in. or 3.25 kip-ft

From AISC Specification Section F1, the available flexural strength is:

LRFD ASD

φb = 0.90 Ωb = 1.67

M n 3.25 kip-ft

φb M n = 0.90 ( 3.25 kip-ft ) =

Ωb 1.67

= 2.93 kip-ft > 1.35 kip-ft o.k.

= 1.95 kip-ft > 0.900 kip-ft o.k.

Design Examples V14.0

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

Return to Table of Contents

F-50

EXAMPLE F.11B SINGLE ANGLE FLEXURAL MEMBER

Given:

Select an ASTM A36 single angle with a simple span of 6 ft. The vertical leg of the single angle is up and the toe

is in compression. The vertical loads are a uniform dead load of 0.05 kip/ft and a uniform live load of 0.15 kip/ft.

There are no horizontal loads. There is no deflection limit for this angle. The angle is braced at the end points and

at the midspan. Assume bending about the geometric x-x axis and that there is lateral-torsional restraint at the

midspan and ends only.

Solution:

From AISC Manual Table 2-4, the material properties are as follows:

ASTM A36

Fy = 36 ksi

Fu = 58 ksi

From Chapter 2 of ASCE/SEI 7, the required flexural strength is:

LRFD ASD

wux = 1.2(0.05 kip/ft) + 1.6(0.15 kip/ft) wax = 0.05 kip/ft + 0.15 kip/ft

= 0.300 kip/ft = 0.200 kip/ft

0.300 kip/ft ( 6 ft ) 0.200 kip/ft ( 6 ft )

2 2

Mux = Max =

8 8

= 1.35 kip-ft = 0.900 kip-ft

Try a L4×4×4.

From AISC Manual Table 1-7, the geometric properties are as follows:

L4×4×4

Sx = 1.03 in.3

Nominal Flexural Strength, Mn

Flexural Yielding

From AISC Specification Section F10.1, the nominal flexural strength due to the limit state of flexural yielding is:

M n = 1.5M y (Spec. Eq. F10-1)

= 1.5 Fy S x

Design Examples V14.0

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

Return to Table of Contents

F-51

= 1.5 ( 36 ksi ) (1.03in.3 )

= 55.6 kip-in.

Lateral-Torsional Buckling

From AISC Specification Section F10.2(b)(iii)(b), for single angles with lateral-torsional restraint at the point of

maximum moment, My is taken as the yield moment calculated using the geometric section modulus.

M y = Fy S x

= 36 ksi (1.03in.3 )

= 37.1 kip-in.

Determine Me.

For bending moment about one of the geometric axes of an equal-leg angle with no axial compression, with

lateral-torsional restraint at the point of maximum moment only (at midspan in this case), and with maximum

compression at the toe, Me shall be taken as 1.25 times Me computed using AISC Specification Equation F10-6a.

Cb = 1.30 from AISC Manual Table 3-1

⎞⎛ ⎞

2

⎛ 0.66 Eb 4 tCb ⎛ Lb t ⎞

M e = 1.25 ⎜ ⎟ ⎜ 1 + 0.78 ⎜ 2 ⎟

− 1⎟ (Spec. Eq. F10-6a)

⎝ Lb 2 ⎠ ⎜⎝ ⎝b ⎠ ⎟

⎠

⎡ 0.66 ( 29, 000 ksi )( 4.00 in.)4 (4 in.)(1.30 ) ⎤ ⎜⎛ ⎞

2

⎛ ( 36.0 in.)(4 in.) ⎞ ⎟

= 1.25 ⎢ ⎥ ⎜ 1 + 0.78 ⎜ ⎟ − 1 ⎟

( 36.0 in.) ⎜ ⎟

⎝ ( 4.00 in.)

2 2

⎣⎢ ⎦⎥ ⎝⎜ ⎠ ⎟

⎠

= 179 kip-in. > 37.1 kip-in., therefore, AISC Specification Equation F10-3 is applicable

⎛ My ⎞

M n = ⎜ 1.92 − 1.17 ⎟ M y ≤ 1.5M y (Spec. Eq. F10-3)

⎜ M e ⎟⎠

⎝

⎛ 37.1 kip-in. ⎞

= ⎜⎜ 1.92 − 1.17 ⎟ 37.1 kip-in. ≤ 1.5 ( 37.1kip-in.)

⎝ 179 kip-in. ⎟⎠

= 51.5 kip-in. ≤ 55.7 kip-in., therefore, Mn = 51.5 kip-in.

Leg Local Buckling

Mn = 43.3 kip-in. from Example F.11A.

The leg local buckling limit state controls.

Mn = 43.3 kip-in. or 3.61 kip-ft

From AISC Specification Section F1, the available flexural strength is:

Design Examples V14.0

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

Return to Table of Contents

F-52

LRFD ASD

φb = 0.90 Ωb = 1.67

M n 3.61kip-ft

φb M n = 0.90 ( 3.61 kip-ft ) =

Ωb 1.67

= 3.25 kip-ft > 1.35 kip-ft o.k.

= 2.16 kip-ft > 0.900 kip-ft o.k.

Design Examples V14.0

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

You might also like

- Constellations A PlayDocument88 pagesConstellations A PlayMora Gabaroni89% (18)

- Example 3.4 - One Way Continuous SlabDocument12 pagesExample 3.4 - One Way Continuous SlabFareez Sedaka50% (4)

- Quiz 5: Machine Design Part 1: Fig. 1: Isometric View of Rod OABDocument6 pagesQuiz 5: Machine Design Part 1: Fig. 1: Isometric View of Rod OABGururaj0% (1)

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Trestles Design 1Document10 pagesTrestles Design 1Anonymous sfkedkymNo ratings yet

- CH 23Document28 pagesCH 23Nelson MeiNo ratings yet

- Fully Restrained - Moment Connection PDFDocument19 pagesFully Restrained - Moment Connection PDFMauricio RiquelmeNo ratings yet

- Chapter IIB Fully-Restrained (FR) Moment ConnectionsDocument29 pagesChapter IIB Fully-Restrained (FR) Moment ConnectionsHarshaVeeragandhamNo ratings yet

- AISC Design Guide 29 - Vertical Bracing Connections - Analysis and Design 2 de 2 PDFDocument196 pagesAISC Design Guide 29 - Vertical Bracing Connections - Analysis and Design 2 de 2 PDFMartin Cristobal CupitayNo ratings yet

- Unbraced Column ExampleDocument9 pagesUnbraced Column ExampleAJA14No ratings yet

- Composite Floor Beam With CantileverDocument6 pagesComposite Floor Beam With CantileverprasNo ratings yet

- Structural Analylsis and Design ComputationsDocument8 pagesStructural Analylsis and Design ComputationsDorothy Leonardo ObriqueNo ratings yet

- AISC SCM2013 - Designexample Chapter H Design of Members For Combined Forces and TorsionDocument30 pagesAISC SCM2013 - Designexample Chapter H Design of Members For Combined Forces and TorsionriodejaneiryeoNo ratings yet

- Tomo 1 - FlexionDocument10 pagesTomo 1 - FlexionangelicalbotacioaNo ratings yet

- Uniform Force Method Design ExamplesDocument30 pagesUniform Force Method Design ExamplesKen SuNo ratings yet

- A. Design Case: Analysis For Design-1 B. Member InformationDocument4 pagesA. Design Case: Analysis For Design-1 B. Member InformationSopanat BoonkhanNo ratings yet

- Steel ColumnDocument41 pagesSteel Columnchristian abogadoNo ratings yet

- Ce 03024Document211 pagesCe 03024kimchhoungNo ratings yet

- W18X46 W3-7 1/2" NW 30 10 106: The Beam Design Is AdequateDocument7 pagesW18X46 W3-7 1/2" NW 30 10 106: The Beam Design Is Adequateஅம்ரு சாந்திவேலுNo ratings yet

- Ejercicio 24.1Document3 pagesEjercicio 24.1Mario Antonio Gomez CruzNo ratings yet

- Shear Analysis - Beams: V F' B A F V V V V + V +Document4 pagesShear Analysis - Beams: V F' B A F V V V V + V +S. M. Habibul AhsanNo ratings yet

- MasonryShearWall IBCDocument8 pagesMasonryShearWall IBCjklo12No ratings yet

- Time Saving Design AidsDocument86 pagesTime Saving Design AidsPurvish Joshi50% (2)

- Bracing ConnectionDocument15 pagesBracing ConnectionrajedmaglinteNo ratings yet

- Chevron Brace ConnectionDocument5 pagesChevron Brace ConnectionNBV2381No ratings yet

- FRP Flexural - Strengthening - Design - ExampleDocument5 pagesFRP Flexural - Strengthening - Design - ExampledleechuyNo ratings yet

- W21X57 Subject To Combined Axial Compression and FlexureDocument3 pagesW21X57 Subject To Combined Axial Compression and Flexureaddrien danielNo ratings yet

- Trestles Design 1Document10 pagesTrestles Design 1Anonymous sfkedkymNo ratings yet

- Steel Beam Problems (WSD) W Sol PDFDocument7 pagesSteel Beam Problems (WSD) W Sol PDFApao, Trixie Ann P.No ratings yet

- Mstrip-Base Plate QueryDocument2 pagesMstrip-Base Plate QueryPANKAJ TAMBAKHENo ratings yet

- ..Document22 pages..Ghiffa Syauqiyya Harahap 1707113714No ratings yet

- AISC Iiia PDFDocument19 pagesAISC Iiia PDFgmlopesNo ratings yet

- 8Document6 pages8Mohan BhalmeNo ratings yet

- h02 SolutionDocument5 pagesh02 SolutionMari HernadezNo ratings yet

- Seismic Design For Ordinary Concentrically Braced Frames Based On CBC 07 & AISC 341-05Document5 pagesSeismic Design For Ordinary Concentrically Braced Frames Based On CBC 07 & AISC 341-05xuankhoi doanvanNo ratings yet

- Design Criteria: HSS8X8X5/8Document9 pagesDesign Criteria: HSS8X8X5/8Ridho ZiskaNo ratings yet

- Universidad Tecnológica de PanamaDocument13 pagesUniversidad Tecnológica de PanamaGabrielaNo ratings yet

- (Reviewed) Auto-Update Slab Design-BaldesansoDocument38 pages(Reviewed) Auto-Update Slab Design-BaldesansoElmer Leyson BaldesansoNo ratings yet

- Mathcad - 16x24MnPn4#9+2#8 - 4&60ksiwitneyDocument5 pagesMathcad - 16x24MnPn4#9+2#8 - 4&60ksiwitneyHeraldoAFNo ratings yet

- Ce510 Foundation Engineering: Delrosario, Marionjed Delacruz, Ivanjeremiaht. Encallado, JoycemarielDocument16 pagesCe510 Foundation Engineering: Delrosario, Marionjed Delacruz, Ivanjeremiaht. Encallado, JoycemarielAndrea MagtutoNo ratings yet

- AISC ExamI1&2&3Document11 pagesAISC ExamI1&2&3Dhurai KesavanNo ratings yet

- Design of Stair CaseDocument65 pagesDesign of Stair CaseNikhil100% (1)

- "Rectbeam" - Rectangular Concrete Beam Analysis/Design: Program DescriptionDocument46 pages"Rectbeam" - Rectangular Concrete Beam Analysis/Design: Program DescriptionOswaldo SuarezNo ratings yet

- Base Shear ComputationDocument5 pagesBase Shear ComputationAmante MorenoNo ratings yet

- Column Supporting DiscontinuousDocument40 pagesColumn Supporting DiscontinuousRohan JaiswalNo ratings yet

- Test PileDocument7 pagesTest PileDevesh SinghNo ratings yet

- Bracing ConnectionDocument10 pagesBracing ConnectionrajedmaglinteNo ratings yet

- Seismic Design For Ordinary Concentrically Braced Frames Based On IBC 06 & AISC 341-05Document5 pagesSeismic Design For Ordinary Concentrically Braced Frames Based On IBC 06 & AISC 341-05xuankhoi doanvanNo ratings yet

- Steps in Design of Rectangular Beam Reinforced ForDocument8 pagesSteps in Design of Rectangular Beam Reinforced ForKyran Joeffer EsporlasNo ratings yet

- Simple Bracing ConnectionDocument33 pagesSimple Bracing ConnectionRohit SinghNo ratings yet

- 7 Ejemplo Diseño Zona PlásticaDocument2 pages7 Ejemplo Diseño Zona Plásticabelen reascosNo ratings yet

- Col Interaction Diagram 6 PDFDocument35 pagesCol Interaction Diagram 6 PDFkhawaldeh jamalNo ratings yet

- CE 371 HW1 - SolutionDocument4 pagesCE 371 HW1 - SolutionjejomarNo ratings yet

- Built Up Section ExampleDocument5 pagesBuilt Up Section ExampleandibolNo ratings yet

- Simply Supported Member of Triple W-Shapes Design Based On AISC 14th (AISC 360-10)Document16 pagesSimply Supported Member of Triple W-Shapes Design Based On AISC 14th (AISC 360-10)Amey GudigarNo ratings yet

- Wind Load On Saudi Arabia According To U B C 1997Document14 pagesWind Load On Saudi Arabia According To U B C 1997Momen Adil100% (1)

- Errata To 3rd Ed - Seismic Design Manual - 1st Printing - July 2020Document2 pagesErrata To 3rd Ed - Seismic Design Manual - 1st Printing - July 2020CESAR ARMANDO JOSIMAR DEL CID JUAREZNo ratings yet

- Selection of Concrete-FilledDocument2 pagesSelection of Concrete-Filledivan bolañosNo ratings yet

- Example #2 - Flexural Strength With Unbonded Tendons: 86 Post-Tensioned Concrete - Principles and PracticeDocument23 pagesExample #2 - Flexural Strength With Unbonded Tendons: 86 Post-Tensioned Concrete - Principles and PracticeMinh TríNo ratings yet

- Col30x30 CONCRETE COLUMN DESIGNDocument2 pagesCol30x30 CONCRETE COLUMN DESIGNOmar RubioNo ratings yet

- ElectricityDocument25 pagesElectricityWeb BooksNo ratings yet

- 9554662Document262 pages9554662Johnnie StrydomNo ratings yet

- Jaa Atpl Book 04 PowerplantDocument433 pagesJaa Atpl Book 04 Powerplantfoxtrot12No ratings yet

- Formulae HandbookDocument60 pagesFormulae Handbookmgvpalma100% (1)

- Seba KMT - PD Diagnostic W OWTSDocument10 pagesSeba KMT - PD Diagnostic W OWTSdes1982No ratings yet

- Probes For Measuring Liquid Levels Fall Into ThreeDocument1 pageProbes For Measuring Liquid Levels Fall Into Threedinosaur x-drakeNo ratings yet

- Fresnel EquationsDocument38 pagesFresnel Equationsepsillon124No ratings yet

- The West African Examinations Council: West African Senior School Certificate Examination 2021 / 2022 Academic SessionDocument5 pagesThe West African Examinations Council: West African Senior School Certificate Examination 2021 / 2022 Academic SessionFolorunso Emmanuel AbiodunNo ratings yet

- K192Y53Question PaperDocument47 pagesK192Y53Question PaperKAMAL MANNANo ratings yet

- RC Circuit and Its ApplicationTerm PaperDocument13 pagesRC Circuit and Its ApplicationTerm PapersummitzNo ratings yet

- Ch14HW AllDocument9 pagesCh14HW Alldhiru12314No ratings yet

- A Faithful Solid-State Spin-Wave Quantum Memory For Polarization QubitsDocument8 pagesA Faithful Solid-State Spin-Wave Quantum Memory For Polarization QubitsJay-R Notorio PallegaNo ratings yet

- JEE MAIN 2020 Solved Papers (Crackjee - Xyz) PDFDocument273 pagesJEE MAIN 2020 Solved Papers (Crackjee - Xyz) PDFSavitri Bhandari100% (1)

- Skema Jawapan Exam Question ZCA101 2008 2009Document8 pagesSkema Jawapan Exam Question ZCA101 2008 2009sirraxNo ratings yet

- Fusion Fission LabDocument4 pagesFusion Fission LabchristineNo ratings yet

- VA1 SKF Presentation Best MCM Material PDFDocument550 pagesVA1 SKF Presentation Best MCM Material PDFAhmad100% (1)

- Summative 1Document3 pagesSummative 1Shine ColterNo ratings yet

- AB AQ 10 Aqueduct AbutmentDocument25 pagesAB AQ 10 Aqueduct AbutmentachsangantengNo ratings yet

- Sweet Potato 12Document19 pagesSweet Potato 12nangphyoeNo ratings yet

- The Definitive Guide To The Order of Nine AnglesDocument1,460 pagesThe Definitive Guide To The Order of Nine AnglesDark Japer91% (22)

- NEWTON's Law of Motion Compilation ExperimentDocument14 pagesNEWTON's Law of Motion Compilation ExperimentDan BautistaNo ratings yet

- CH 1Document40 pagesCH 1Mintesinot KasaNo ratings yet

- Equilibrium NotesDocument3 pagesEquilibrium NotesAnilkumarsanctumNo ratings yet

- Introduction and Overview: Fundamentals of Thermal-Fluid SciencesDocument22 pagesIntroduction and Overview: Fundamentals of Thermal-Fluid SciencesKarl KaiNo ratings yet

- Bianconi-Barabási ModelDocument9 pagesBianconi-Barabási Modeldev414No ratings yet

- Properties of SteelDocument16 pagesProperties of SteelJustyna PacierzNo ratings yet

- 9th Final Chem PDFDocument81 pages9th Final Chem PDFZach BilsonNo ratings yet

- Baldor BasicsDocument6 pagesBaldor Basicsmaryam javedNo ratings yet