Professional Documents

Culture Documents

Check and Inspect The Surrounding Area of The Workplace and Check, If Any Honeybee or Any Other Hazards Stop Work and Inform The Area Operator

Check and Inspect The Surrounding Area of The Workplace and Check, If Any Honeybee or Any Other Hazards Stop Work and Inform The Area Operator

Uploaded by

Vitthal PatnechaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Check and Inspect The Surrounding Area of The Workplace and Check, If Any Honeybee or Any Other Hazards Stop Work and Inform The Area Operator

Check and Inspect The Surrounding Area of The Workplace and Check, If Any Honeybee or Any Other Hazards Stop Work and Inform The Area Operator

Uploaded by

Vitthal PatnechaCopyright:

Available Formats

STANDARD MAINTENANCE PROCEDURE Ref No: CGP-SMP-ELEC-019

Issue No.01

FOR Rev No:00

LIGHTING CIRCUIT MAINTENACE Eff. Date: 25.06.2019

PAGE : 1 of 6

1.0 Objective: To standardize proper Maintenance of Lighting circuit.

2.0 Scope: All Lighting circuit at Coal Gasification Plant

3.0 Responsibility: Unit in charge/Shift in-charge

4.0 Amendment Status:

Issue/ Revision Number

Sl. No. Page No. Summary of Change

Old Date New Date

5.0 Procedure:

Pre-Condition checks:

1. Check the historical records, any repairs performed since the last Maintenance and note any

outstanding repair work.

2. Check and ensure that the tag / equipment identification is in place, secure, correct and legible

for the equipment under review.

3. Obtain applicable permit to work and carry out a tool box talk prior to commencement of work.

4. Take the work permit from operation shift in charge.

5. Isolate the Power Supply from source from LDB/ELDB.

6. Before starting the job ensure that power is isolated by checking the voltage using multi

meter.

7. Provide barricading or marking at the location where the lighting circuit maintenance job

performing.

8. Check and inspect the surrounding area of the workplace and check, if any Honeybee or

any other hazards stop work and inform the area operator.

Prepared by: Electrical CGP Approved by: HOD CGP

Reviewed by: Factory Manager Issued by: Management Representative

STANDARD MAINTENANCE PROCEDURE Ref No: CGP-SMP-ELEC-019

Issue No.01

FOR Rev No:00

LIGHTING CIRCUIT MAINTENACE Eff. Date: 25.06.2019

PAGE : 2 of 6

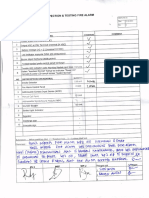

Check List

Sl no. Task Status Remarks

Equipment Tag no: Date:

Equipment Description:

Equipment Rating: Permit no:

Tools Required: Insulated Hand tools, Megger, Multi-meter.

SAP Order no: SAP Notification no:

Lighting Feeder Checks:

Sl no Activity Description OK Not OK Remarks/Values

1 Clean the all outgoing Lighting feeders with

blower, vacuum cleaner or cotton waste.

2 Check the tightness of the power terminations.

3 Check the tightness of the control terminations.

4 Ensure that proper sizes of lugs are used for

power and control terminations.

5 Open the front covers of the Lighting feeder if

removable clean the fixed and removing.

6 Ensure that feeder RCCB, MCB’s are as per the

connected equipment rating.

7 Ensure that all lighting case covers are properly

installed.

8 Check for the temporary loops if observed to be

made permanent.

9 Ensure the working of all selector switches and

other control elements.

10 Ensure the working of all indication lamps.

11 Ensure the mechanical door lock is working

properly.

12 Ensure that feeder’s lamps are working if

provided.

13 Ensure that feeder door is properly closing.

14 Check the cable dressing inside the feeder, if

required need to be done.

Prepared by: Electrical CGP Approved by: HOD CGP

Reviewed by: Factory Manager Issued by: Management Representative

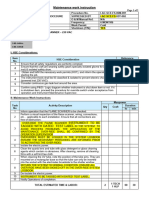

STANDARD MAINTENANCE PROCEDURE Ref No: CGP-SMP-ELEC-019

Issue No.01

FOR Rev No:00

LIGHTING CIRCUIT MAINTENACE Eff. Date: 25.06.2019

PAGE : 3 of 6

15 Check the IR value of cable with respect to Earth.

Field Lighting Circuit Checks:

Sl no Activity Description OK Not OK Remarks/Values

1 Inspect the surrounding area and condition of

work.

2 Inspect all the Power circuit.

3 If working on Height Ensure the proper fixed

platform is provided or use certified leader and

safety belt.

4 Inspect and Clean gear box and all other

miscellaneous equipments with blower, vacuum

cleaner or cotton waste.

5 Check the lights are properly hanging in that

area or not.

6 Check the illumination and the cable condition

7 Ensure that all cables firmly secured no any joint

and insulation damage allow.

8 Ensure that all lighting cable used are of proper

size and free from heating.

9 Ensure that all cable should be in cable try

properly.

10 In Flame proof area use only IP protection

lighting fixture.

Post-Condition:

1. After completion of the Lighting maintenance remove unwanted material.

2. Conduct the visual inspection for lighting for any foreign or heating materials.

3. Conduct the visual inspection for lighting Power cable for any joint and insulation

damage if found replaces it or provides proper insulation.

4. Close all the doors of the Lighting Feeder.

5. Surrender the isolation work permit.

6. Surrender the operation work permit.

7. Check the voltage using multi meter.

Prepared by: Electrical CGP Approved by: HOD CGP

Reviewed by: Factory Manager Issued by: Management Representative

STANDARD MAINTENANCE PROCEDURE Ref No: CGP-SMP-ELEC-019

Issue No.01

FOR Rev No:00

LIGHTING CIRCUIT MAINTENACE Eff. Date: 25.06.2019

PAGE : 4 of 6

5.1 Competence & Training:

Level Education Experience Industry Training Requirement

Maintenance Min Min 5 year/3 HC/Power Isolations should be carried out by

Engineer Diploma /B years industries personnel possessing Electrical

Tech level license.

6.0 Operational control procedure for HSE risk:

1. Take the work permit from control room before doing maintenance of transformer and return

the work permit after the job.

2. Provide toolbox talk for the crew before starting the job.

3. Carry walkie-talkie to the work spot.

4. Wear personal protective equipment such as Safety shoes, Safety Helmet, Dust mask, Ear plug,

Goggles.

5. Ensure sufficient lighting at work place.

6. Ensure the workplace is free from any Honeybee and others (Safe for work).

7. Always carry portable Gas detector at work place and continuously monitor the Gas level at

work place.

8. Clean the area of work and dump the waste generated, in the designated place as per waste

handling work instruction.

7.0 Records:

Retention

Sl. No. Document No. Document Title Responsibility

Period

Manager

REC-CGP-ELEC- Bus bar and Bus bar 6 Months

1 Electrical

019-01 chambers

Manager

REC-CGP-ELEC- 6 Months

2 Outgoing Feeders Electrical

019-02

Manager

REC-CGP-ELEC- 6 Months

3 General Checks Electrical

019-03

Prepared by: Electrical CGP Approved by: HOD CGP

Reviewed by: Factory Manager Issued by: Management Representative

You might also like

- Air Handling Unit PDFDocument16 pagesAir Handling Unit PDFizani_idrisNo ratings yet

- User Guide 1531 Clas - 3ag - 21608 - Ahaa - Rkzza - Ed01Document338 pagesUser Guide 1531 Clas - 3ag - 21608 - Ahaa - Rkzza - Ed01iaomsuet100% (2)

- PM Text As Per Bcel-002Document4 pagesPM Text As Per Bcel-002Jay Rameshbhai ParikhNo ratings yet

- Evapco CT Maintenance ChecklistDocument2 pagesEvapco CT Maintenance Checklistfazzlie0% (1)

- KHATIB ABDUL RAHIM CV... HDocument4 pagesKHATIB ABDUL RAHIM CV... HAbdulrahimNo ratings yet

- Check List Inspection Fire AlarmDocument2 pagesCheck List Inspection Fire AlarmMUHAMMAD FAISALNo ratings yet

- 5.section-Lt Switchgear, Rev 05Document28 pages5.section-Lt Switchgear, Rev 05Uday Sankar YadavNo ratings yet

- Boiler Feed Water Treatment Demineralization Reverse Osmosis Plant DeaeratorDocument8 pagesBoiler Feed Water Treatment Demineralization Reverse Osmosis Plant Deaeratorrambabu100% (1)

- RCA Copy Generator RotorDocument1 pageRCA Copy Generator RotorPraneeth ReddyNo ratings yet

- Power Cable Magger-TEST PROCEDUREDocument1 pagePower Cable Magger-TEST PROCEDUREKarthikeyan GanesanNo ratings yet

- Pump House Test ReportDocument4 pagesPump House Test ReportAizat Faliq100% (1)

- Electric ShopDocument17 pagesElectric ShopBest SellerNo ratings yet

- Terminaiton Kit SpecificaitonDocument5 pagesTerminaiton Kit SpecificaitonVaibhav ShahNo ratings yet

- Fan ScheduleDocument2 pagesFan Schedulekkn1234No ratings yet

- Technical Trading Co. LLC Fire Projects Division Fm-200 SystemDocument7 pagesTechnical Trading Co. LLC Fire Projects Division Fm-200 SystemmuthuvelaaNo ratings yet

- From Preventive Maintenance FCUDocument2 pagesFrom Preventive Maintenance FCUbaguspercostNo ratings yet

- Installation InstructionsDocument38 pagesInstallation InstructionsNestor Rhamses Garcia SantiagoNo ratings yet

- MV Switchgear Insulating MediumsDocument25 pagesMV Switchgear Insulating MediumsMoon3pellNo ratings yet

- HUD Homes Baltimore - 20571 SUMMERSONG LANE, GERMANTOWN MD 20874Document29 pagesHUD Homes Baltimore - 20571 SUMMERSONG LANE, GERMANTOWN MD 20874Nishika JGNo ratings yet

- TemplifierDocument8 pagesTemplifiermdalt9180100% (1)

- Maintenance Schedule For SubstationDocument21 pagesMaintenance Schedule For SubstationSajid Shaikh100% (1)

- 26.Lv SystemDocument10 pages26.Lv Systempepenapao1217No ratings yet

- Technical Specification of LT Panel (Switchboard) : To Be Found in The One-Line DiagramDocument13 pagesTechnical Specification of LT Panel (Switchboard) : To Be Found in The One-Line DiagramSharath CherryNo ratings yet

- Checklist For Preventive Maintenance Machine: Power Press Machine Code: Frequency: Monthly / Quarterly / Annually Checks M Q ADocument1 pageChecklist For Preventive Maintenance Machine: Power Press Machine Code: Frequency: Monthly / Quarterly / Annually Checks M Q ASanjay MalhotraNo ratings yet

- Sample ReportDocument12 pagesSample Reportyahya100% (1)

- Energy Efficiency in Power PlantsDocument27 pagesEnergy Efficiency in Power PlantsRachit KhannaNo ratings yet

- Guidelines For Life Safety Plan (LSP) SubmissionsDocument6 pagesGuidelines For Life Safety Plan (LSP) SubmissionsJawwad HussainNo ratings yet

- Melamchi Water Treatment PlantDocument29 pagesMelamchi Water Treatment PlantSandesh KhadkaNo ratings yet

- Twm-z1 & Z-2 - PH & FF SpecsDocument175 pagesTwm-z1 & Z-2 - PH & FF SpecsmimrusfanNo ratings yet

- Membrane CleanerDocument2 pagesMembrane CleanerJoselito Cortes100% (1)

- Pacu Checklist MonthlyDocument1 pagePacu Checklist MonthlySelvester M. AvilesNo ratings yet

- HVAC Preventive Maintenance Checklists-12Document61 pagesHVAC Preventive Maintenance Checklists-12JawadNo ratings yet

- Lighting SystemDocument49 pagesLighting SystemsunilNo ratings yet

- Electrical Findings 6Document13 pagesElectrical Findings 6Lester Musca100% (1)

- Installation Operation & Maintenance of 33kV & 11kV SwitchgearDocument23 pagesInstallation Operation & Maintenance of 33kV & 11kV SwitchgearSaff MdNo ratings yet

- Maintenance Schedule Checklist For Alpha GeneratorsDocument23 pagesMaintenance Schedule Checklist For Alpha GeneratorsAsnake TegenawNo ratings yet

- Electrical Tech SpecificationDocument62 pagesElectrical Tech SpecificationNipun KohliNo ratings yet

- 9tech Spec 100 To 2500 KVA Dry Type Dist - Tranformer 1Document30 pages9tech Spec 100 To 2500 KVA Dry Type Dist - Tranformer 1Yazhisai SelviNo ratings yet

- Preventative Maintenance Task Sheet: Plant/Equipment: Job IDDocument29 pagesPreventative Maintenance Task Sheet: Plant/Equipment: Job IDJaveria KhanNo ratings yet

- RCA Lighting DB Short CircuitDocument2 pagesRCA Lighting DB Short CircuitAmir ShehzadNo ratings yet

- Chiller Check ListDocument3 pagesChiller Check ListMohammed ErshadNo ratings yet

- Testing Commisioning Report Telephone: ProjectDocument1 pageTesting Commisioning Report Telephone: Projectagun gunawanNo ratings yet

- Powermaster Standard Spec SheetDocument7 pagesPowermaster Standard Spec SheetGel4947No ratings yet

- Testing Commisioning Report Calorifier: ProjectDocument1 pageTesting Commisioning Report Calorifier: Projectagun gunawanNo ratings yet

- Atlas Copco - Auditorium BOQ 170919Document4 pagesAtlas Copco - Auditorium BOQ 170919calvin.bloodaxe4478No ratings yet

- Diesel GeneratorDocument36 pagesDiesel Generatorwintermae100% (1)

- MFM Consolidated Preventive Maintenance Ver 2 - 3132017Document201 pagesMFM Consolidated Preventive Maintenance Ver 2 - 3132017Paul CansinoNo ratings yet

- Basic Laboratory Energy Audit ChecklistDocument7 pagesBasic Laboratory Energy Audit ChecklistkeyojeliNo ratings yet

- Mr. Slim System Pre-Commissioning and Installation Check ListDocument4 pagesMr. Slim System Pre-Commissioning and Installation Check Listamerico zambrano contrerasNo ratings yet

- SMP For Thermography SurveyDocument4 pagesSMP For Thermography SurveySiemens OLM BorlNo ratings yet

- Elv BoqDocument11 pagesElv BoqbalabhaviniNo ratings yet

- Power Engineering PM Check ListDocument11 pagesPower Engineering PM Check ListSelvn SubramanianNo ratings yet

- Specifications Sakya GeneratorDocument10 pagesSpecifications Sakya Generator123agattarNo ratings yet

- Testing Commisioning Report Water Softener: ProjectDocument1 pageTesting Commisioning Report Water Softener: Projectagun gunawanNo ratings yet

- Domestic - MTD SilentDocument6 pagesDomestic - MTD SilentVan Vinh NguyenNo ratings yet

- Remote FCU ManualDocument12 pagesRemote FCU ManualHạ NhậtNo ratings yet

- LPDDocument2 pagesLPDDesigner ForeverNo ratings yet

- 2013 Esser CatalogDocument364 pages2013 Esser CatalogArman Ul Nasar100% (2)

- Work Instruction VCBDocument3 pagesWork Instruction VCBTAHIR HUSAINNo ratings yet

- SLPG - HT Motor-4yDocument4 pagesSLPG - HT Motor-4yAshraf MohammedNo ratings yet

- Maintenance Work Instruction: Instrument To Be Tagged With Dated Test LabelDocument2 pagesMaintenance Work Instruction: Instrument To Be Tagged With Dated Test Labelhobam3297No ratings yet

- LinkedIn Group Technical DiscussionsDocument5 pagesLinkedIn Group Technical DiscussionsVitthal PatnechaNo ratings yet

- Service Portfolio - System ProtectionDocument2 pagesService Portfolio - System ProtectionVitthal PatnechaNo ratings yet

- RDG Gas Development ProjectDocument4 pagesRDG Gas Development ProjectVitthal PatnechaNo ratings yet

- Islanding ReportDocument15 pagesIslanding ReportVitthal PatnechaNo ratings yet

- TA Reimbursement Form PDFDocument1 pageTA Reimbursement Form PDFVitthal PatnechaNo ratings yet

- Testing Record Sheet of ELCBDocument2 pagesTesting Record Sheet of ELCBVitthal PatnechaNo ratings yet

- MOM of E&T Meeting Held On 23rd July'19Document1 pageMOM of E&T Meeting Held On 23rd July'19Vitthal PatnechaNo ratings yet

- Contingency Analysis in Smart Grid Power SystemDocument45 pagesContingency Analysis in Smart Grid Power SystemVitthal PatnechaNo ratings yet

- Backup Protection of TransformerDocument1 pageBackup Protection of TransformerVitthal PatnechaNo ratings yet

- External Faults in Power TransformerDocument1 pageExternal Faults in Power TransformerVitthal PatnechaNo ratings yet

- Matlab Programe For DesertationDocument19 pagesMatlab Programe For DesertationVitthal PatnechaNo ratings yet

- Chapter 3: Power System Contingency Analysis: 3.1 OverviewDocument2 pagesChapter 3: Power System Contingency Analysis: 3.1 OverviewVitthal PatnechaNo ratings yet

- Implementation of Line Stability Index For Contingency Analysis and Screening in Power SystemsDocument6 pagesImplementation of Line Stability Index For Contingency Analysis and Screening in Power SystemsVitthal PatnechaNo ratings yet

- Contingency Ranking For Voltage Stability Analysis of Large-Scale Power SystemsDocument8 pagesContingency Ranking For Voltage Stability Analysis of Large-Scale Power SystemsVitthal PatnechaNo ratings yet

- Load Flow, Contingency Analysis, State Estimation and Optimal Operation For Ieee 14-Bus SystemDocument7 pagesLoad Flow, Contingency Analysis, State Estimation and Optimal Operation For Ieee 14-Bus SystemVitthal PatnechaNo ratings yet

- New Desert 1Document86 pagesNew Desert 1Vitthal PatnechaNo ratings yet

- Improved Sensitivities in MW Dispatch For Control of VoltageDocument7 pagesImproved Sensitivities in MW Dispatch For Control of VoltageVitthal PatnechaNo ratings yet

- Singh1997 PDFDocument9 pagesSingh1997 PDFVitthal PatnechaNo ratings yet

- Introduction To Information Technology TCT 0113Document29 pagesIntroduction To Information Technology TCT 0113Muhaizat NazmiNo ratings yet

- American With Disabilities Act AdaDocument16 pagesAmerican With Disabilities Act Adaapi-376186426100% (1)

- B436-Y2 Mitsubishi 730 VSL BIGLIA LATHESDocument153 pagesB436-Y2 Mitsubishi 730 VSL BIGLIA LATHESGHZMANNo ratings yet

- Ip Sample Paper 7Document8 pagesIp Sample Paper 7NEEMA GANDHINo ratings yet

- Gis MCQDocument8 pagesGis MCQPuneet Kumar JadonNo ratings yet

- Wiring-diagram-Avanza Combination Meter Manual OnlyDocument2 pagesWiring-diagram-Avanza Combination Meter Manual OnlyMurham Munir100% (4)

- PIX-36 Catalogue Schneider 1Document46 pagesPIX-36 Catalogue Schneider 1ARYA JENANo ratings yet

- FADEC PresentationDocument76 pagesFADEC PresentationWeerapat Siri100% (1)

- Hotel and Resort Customer Assistant: A Web & Mobile Ordering & Booking Management SystemDocument7 pagesHotel and Resort Customer Assistant: A Web & Mobile Ordering & Booking Management SystemMulugeta AdamuNo ratings yet

- Training For LTBDocument20 pagesTraining For LTBrpshvjuNo ratings yet

- Overcurrent - Coordination ECE 525Document51 pagesOvercurrent - Coordination ECE 525Thức VõNo ratings yet

- ProRAE Studio II User's Guide Rev GDocument69 pagesProRAE Studio II User's Guide Rev Gnapoleon5976No ratings yet

- Method Statement - Earthing & Lightning ProtectionDocument9 pagesMethod Statement - Earthing & Lightning ProtectionKamal Deo Shah100% (1)

- Allestec 800 F&G PanelDocument66 pagesAllestec 800 F&G PanelyasserdekNo ratings yet

- SQL SequencesDocument3 pagesSQL SequencesShobha Kumari ChoudharyNo ratings yet

- MAN-MAQ012.2 Microscopio Leica LMD6 (LOC-MIC1)Document4 pagesMAN-MAQ012.2 Microscopio Leica LMD6 (LOC-MIC1)Alejandro Lopez CuquerellaNo ratings yet

- Cory R Garrett Resume For WeeblyDocument1 pageCory R Garrett Resume For Weeblyapi-283375341No ratings yet

- Readme WinCC Professional V11 SP2Document52 pagesReadme WinCC Professional V11 SP2breynneroNo ratings yet

- Rip.x264-MP4 (Download Torrent) - TPBDocument1 pageRip.x264-MP4 (Download Torrent) - TPBhpsn4xn5snNo ratings yet

- Section 5: Lighting Control and Integrated Home SystemsDocument30 pagesSection 5: Lighting Control and Integrated Home SystemsAaron AbasoloNo ratings yet

- Project TutorialDocument16 pagesProject TutorialKhalid AlmutairiNo ratings yet

- Typical Technical Specification For An HVDC Transmission ProjectDocument46 pagesTypical Technical Specification For An HVDC Transmission Projectumamaheshwarrao100% (3)

- SIMUL8Document23 pagesSIMUL8Fatma MohomedNo ratings yet

- APS ThinsulatorsDocument3 pagesAPS ThinsulatorsBobbie RuckNo ratings yet

- Computer Science: Chapter: 16 Relatonal DatabaseDocument10 pagesComputer Science: Chapter: 16 Relatonal DatabaseIshika RajputNo ratings yet

- Oracle Developer CVDocument2 pagesOracle Developer CVwaibhavNo ratings yet

- Kanban System Analysis and Improvement of The Supply Carset in BMW Logistics at Jakarta Plant Using Just in Time (JIT) MethodDocument9 pagesKanban System Analysis and Improvement of The Supply Carset in BMW Logistics at Jakarta Plant Using Just in Time (JIT) MethodInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- G12 2nd Quarter 2nd Summative TestDocument2 pagesG12 2nd Quarter 2nd Summative TestTwoneight A. Jumao-asNo ratings yet