Professional Documents

Culture Documents

Section 54-10-00 Repair 029 Air Intake Cowl Acoustic Liner Facing Sheet Hole Repair

Section 54-10-00 Repair 029 Air Intake Cowl Acoustic Liner Facing Sheet Hole Repair

Uploaded by

Danilo SuarezOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section 54-10-00 Repair 029 Air Intake Cowl Acoustic Liner Facing Sheet Hole Repair

Section 54-10-00 Repair 029 Air Intake Cowl Acoustic Liner Facing Sheet Hole Repair

Uploaded by

Danilo SuarezCopyright:

Available Formats

GOODRICH AEROSTRUCTURES

STRUCTURAL REPAIR MANUAL

REPAIR NO. 029

AIR INTAKE COWL ACOUSTIC LINER FACING SHEET HOLE REPAIR

VRS2780

1. General.

A. This procedure may be used to repair holes in the acoustic liner

facing sheet. The holes must be less than 2.00 in. (50,80 mm) in

diameter. Refer to paragraph 5. for damage limitations.

B. This type of damage can be repaired by carefully removing the

wiremesh and carbon ply (without damage to the septum layer). The

void is then filled with epoxy paste adhesive.

C. This repair causes blockage in the acoustically treated areas. For

approved limits, refer to SRM 54-01-00, Acoustic Treatment

Blockage Area Limits.

D. Damage which is not in the limits of this repair must be referred

to UTAS.

2. Referenced Information.

54-01-00 Structural Repair Manual (SRM)

TASK 70-09-00-400-501 Standard Practices Manual (SPM)

3. Equipment and Material.

Equivalent materials and equipment can be used.

A. Standard equipment

Heat lamp, 0o - 212oF (0 o - 100oC)

Syringe

Rotary file

Suction Cleaner

Standard workshop tools and equipment

B. Consumable materials (Ref. Overhaul Processes and Consumables

Index)

CoMat 01-438 Turco 6646 solvent

CoMat 02-099 Lint-free cloth

CoMat 02-367 Non-porous parting film

CoMat 05-019 Waterproof abrasive paper

CoMat 06-131 Marking Pen

CoMat 08-021 EA934NA Epoxy paste adhesive

V2500 54-10-00 REPAIR No. 029

Page 201

May 1/19

Printed in the U.S.A.

Rohr, inc., a subsidiary of Goodrich Corporation, operating as Goodrich Aerostructures; Goodrich Proprietary

Information subject to the limitation contained in the title page section of the manual.

GOODRICH AEROSTRUCTURES

STRUCTURAL REPAIR MANUAL

C. Special Tools

IAE 1N20444 Tapping Tool

D. Component Material

--------------------------------------------

--------------------------------------------

PART IDENT MATERIAL

PART IDENT MATERIAL

--------------------------------------------

--------------------------------------------

Air intake cowl Composite structure

4. Clean the damaged area.

WARNING: BEFORE YOU USE CHEMICALS, READ, UNDERSTAND, AND OBEY ALL

SAFETY INSTRUCTIONS FOR THE CHEMICALS. THESE INSTRUCTIONS

INCLUDE INSTRUCTIONS FROM THE MANUFACTURER, THE MATERIAL

SAFETY DATA SHEET (MSDS), AND GOVERNMENT REGULATIONS.

CHEMICALS MAY CAUSE INJURY TO YOU OR MAKE YOU SICK WHEN

SAFETY INSTRUCTIONS ARE NOT OBEYED. AN MSDS GIVES

INSTRUCTIONS ON HOW YOU MUST SAFELY USE, KEEP, AND DISCARD

CHEMICALS. GET INSTRUCTIONS FROM YOUR EMPLOYER ON HOW YOU

MUST SAFELY USE, KEEP AND DISCARD CHEMICALS.

A. Clean the damaged area with turco 6646 solvent (CoMat 01-438) and

lint-free cloth (CoMat 02-099). Use a clean lint-free cloth (CoMat

02-099) to dry the area.

5. Examine the damaged area.

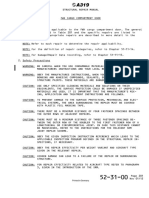

A. Examine the damaged area to make an estimate of the damage. The

damage must not have a diameter more than 2.0 in. (50,80 mm).

B. The center of damage must be a minimum of 5 times the largest

damage diameter apart from the adjacent damage center. Damage

separation must be measured from damage center to damage center.

(Figure 201 Sheet 1).

C. The edge distance of the damage must be a minimum of 0.75 times the

damage diameter from the no damage area. (Fig 201 Sheet 2 and 3)

D. On the 3-piece acoustic liner, the minimum edge distance is in

addition to the 1.5 in. (38,10 mm) no damage area (Figure 201

(Sheet 2)). On the 2-piece acoustic liner, the minimum edge

distance is in addition to the 2.0 in. (50,80 mm) no damage area

(Figure 201 (Sheet 3)).

V2500 54-10-00 REPAIR No. 029

Page 202

Feb 1/17

Printed in the U.S.A.

Rohr, inc., a subsidiary of Goodrich Corporation, operating as Goodrich Aerostructures; Goodrich Proprietary

Information subject to the limitation contained in the title page section of the manual.

GOODRICH AEROSTRUCTURES

STRUCTURAL REPAIR MANUAL

6. Prepare the damaged area for repair (Ref. Fig. 201 Sheet 4).

A. Use a marking pen (CoMat 06-131) to make a mark around the damaged

area. Make sure that all cracks and areas of delamination are

included.

NOTE: The damaged area must be within the limitations contained in

paragragph 5. above.

7. Remove the damaged area.

WARNING: WEAR APPLICABLE PERSONAL PROTECTIVE EQUIPMENT (PPE) WHEN YOU

DO THIS TASK. BEFORE YOU USE PPE, READ UNDERSTAND AND OBEY

ALL INSTRUCTIONS FOR ITS USE. THESE INSTRUCTIONS INCLUDE

INSTRUCTIONS FROM THE MANUFACTURER, YOUR EMPLOYER AND

GOVERNMENT REGULATIONS. YOU CAN GET INJURED IF YOU DO NOT USE

PPE. GET INSTRUCTIONS FROM YOUR EMPLOYER ON WHICH PPE IS

NECESSARY.

A. Remove the damaged area.

(1) Use hand tools and an applicable rotary cutter to remove all

the wiremesh and carbon ply from the damaged area.

NOTE: Make sure that you do not fray the edges of the mesh.

(2) Use a high speed rotary sander to remove the honeycomb from

the repair area.

NOTE: Make sure that you do not damage the septum layer.

(3) Use suitable tooling to undercut the honeycomb core to

0.25in. (6,35 mm) ref figure 201 sheet 4.

(4) Use the rotary file and remove any sharp edges from the

damaged area.

8. Clean the damaged area.

WARNING: BEFORE YOU USE CHEMICALS, READ, UNDERSTAND, AND OBEY ALL

SAFETY INSTRUCTIONS FOR THE CHEMICALS. THESE INSTRUCTIONS

INCLUDE INSTRUCTIONS FROM THE MANUFACTURER, THE MATERIAL

SAFETY DATA SHEET (MSDS), AND GOVERNMENT REGULATIONS.

CHEMICALS MAY CAUSE INJURY TO YOU OR MAKE YOU SICK WHEN

SAFETY INSTRUCTIONS ARE NOT OBEYED. AN MSDS GIVES

INSTRUCTIONS ON HOW YOU MUST SAFELY USE, KEEP, AND DISCARD

CHEMICALS. GET INSTRUCTIONS FROM YOUR EMPLOYER ON HOW YOU

MUST SAFELY USE, KEEP AND DISCARD CHEMICALS.

V2500 54-10-00 REPAIR No. 029

Page 203

Feb 1/17

Printed in the U.S.A.

Rohr, inc., a subsidiary of Goodrich Corporation, operating as Goodrich Aerostructures; Goodrich Proprietary

Information subject to the limitation contained in the title page section of the manual.

GOODRICH AEROSTRUCTURES

STRUCTURAL REPAIR MANUAL

A. Remove debris from the area using a suction cleaner.

B. Clean the damaged area with turco 6646 solvent (CoMat 01-438) and

lint-free cloth (CoMat 02-099). Use a clean lint-free cloth (CoMat

02-099) to dry the area.

9. Examine the repair area

A. Visually examine the area to make sure all defects have been

prepared for repair.

10. Dry the repair area.

A. Use heat lamps to dry the repair area. Keep the temperature

between 149.0oF - 170.6 oF (65oC - 77oC) for 8 hours. The repair

materials must be applied immediately at the end of the 8 hours.

11. Prepare the repair materials

WARNING: BEFORE YOU USE CHEMICALS, READ, UNDERSTAND, AND OBEY ALL

SAFETY INSTRUCTIONS FOR THE CHEMICALS. THESE INSTRUCTIONS

INCLUDE INSTRUCTIONS FROM THE MANUFACTURER, THE MATERIAL

SAFETY DATA SHEET (MSDS), AND GOVERNMENT REGULATIONS.

CHEMICALS MAY CAUSE INJURY TO YOU OR MAKE YOU SICK WHEN

SAFETY INSTRUCTIONS ARE NOT OBEYED. AN MSDS GIVES

INSTRUCTIONS ON HOW YOU MUST SAFELY USE, KEEP, AND DISCARD

CHEMICALS. GET INSTRUCTIONS FROM YOUR EMPLOYER ON HOW YOU

MUST SAFELY USE, KEEP AND DISCARD CHEMICALS.

A. Mix the epoxy paste adhesive (CoMat 08-021) in accordance with the

manufacturer’s instructions.

NOTE: Make sure that you do not mix more than 250 grams of the

epoxy paste adhesive in one container.

B. Use the syringe and apply the epoxy paste adhesive into the hole in

the facing sheet.

NOTE: Make sure that there is an overflow of epoxy paste adhesive

from the hole.

12. Seal the epoxy paste adhesive, if necessary (Ref. Fig. 201 Sheet 4).

A. Cut a piece of non-porous parting film (CoMat 02-367) for each hole

in the facing sheet.

NOTE: Make sure that each piece of non-porous parting film is

larger all around than its applicable hole.

V2500 54-10-00 REPAIR No. 029

Page 204

Feb 1/17

Printed in the U.S.A.

Rohr, inc., a subsidiary of Goodrich Corporation, operating as Goodrich Aerostructures; Goodrich Proprietary

Information subject to the limitation contained in the title page section of the manual.

GOODRICH AEROSTRUCTURES

STRUCTURAL REPAIR MANUAL

B. Put the pieces of non-porous parting film (CoMat 02-367) over each

applicable hole and safety into position with speed tape.

C. Clean all unwanted epoxy paste adhesive away from the repair holes.

13. Cure the epoxy paste adhesive.

A. Use the heat lamps to cure the epoxy paste adhesive for 1 hour at a

temperature of 200.0 oF (93 oC).

NOTE: Make sure that the cure temperature does not get higher than

200.0oF (93oC).

14. Remove the repair equipment (if necessary).

A. Remove the speed tape and the non-porous parting film

(CoMat 02-367) from each repair hole.

NOTE: Make sure that you do not fray the edges of the mesh.

15. Prepare the repaired surface (Ref. Fig. 201 Sheet 4).

WARNING: WEAR APPLICABLE PERSONAL PROTECTIVE EQUIPMENT (PPE) WHEN YOU

DO THIS TASK. BEFORE YOU USE PPE, READ UNDERSTAND AND OBEY

ALL INSTRUCTIONS FOR ITS USE. THESE INSTRUCTIONS INCLUDE

INSTRUCTIONS FROM THE MANUFACTURER, YOUR EMPLOYER AND

GOVERNMENT REGULATIONS. YOU CAN GET INJURED IF YOU DO NOT USE

PPE. GET INSTRUCTIONS FROM YOUR EMPLOYER ON WHICH PPE IS

NECESSARY.

CAUTION: DO NOT CAUSE DAMAGE TO THE CARBON PLIES OF THE REPAIR AREA OR

THE OUTER SURFACE OF THE ACOUSTIC STRUCTURE. BE CAREFUL AND

ONLY REMOVE MATERIAL FROM THE EDGE OF THE OUTER PLY. DO NOT

USE A LIQUID WITH THE ABRASIVE PAPER.

A. Use the waterproof abrasive paper (CoMat 05-019) and make the

repair adhesive smooth. The contours of the repair adhesive must be

smooth with the surrounding skin.

16. Clean the repair area.

A. Remove all unwanted material from the repair area with a suction

cleaner.

NOTE: Make sure that no unwanted particles stay in the acoustic

panel.

V2500 54-10-00 REPAIR No. 029

Page 205

Feb 1/17

Printed in the U.S.A.

Rohr, inc., a subsidiary of Goodrich Corporation, operating as Goodrich Aerostructures; Goodrich Proprietary

Information subject to the limitation contained in the title page section of the manual.

GOODRICH AEROSTRUCTURES

STRUCTURAL REPAIR MANUAL

WARNING: BEFORE YOU USE CHEMICALS, READ, UNDERSTAND, AND OBEY ALL

SAFETY INSTRUCTIONS FOR THE CHEMICALS. THESE INSTRUCTIONS

INCLUDE INSTRUCTIONS FROM THE MANUFACTURER, THE MATERIAL

SAFETY DATA SHEET (MSDS), AND GOVERNMENT REGULATIONS.

CHEMICALS MAY CAUSE INJURY TO YOU OR MAKE YOU SICK WHEN

SAFETY INSTRUCTIONS ARE NOT OBEYED. AN MSDS GIVES

INSTRUCTIONS ON HOW YOU MUST SAFELY USE, KEEP, AND DISCARD

CHEMICALS. GET INSTRUCTIONS FROM YOUR EMPLOYER ON HOW YOU

MUST SAFELY USE, KEEP AND DISCARD CHEMICALS.

B. Clean the surface with turco 6646 solvent (CoMat 01-438) and a

lint-free cloth (CoMat 02-099). Use a clean lint-free cloth (CoMat

02-099) to dry the area.

17. Make an inspection of the repair.

A. Do a visual inspection to make sure that the repair has been done

in accordance with these procedures.

B. Inspect the repaired area using IAE 1N20444 tapping tool and the

tap test method, (Ref. SRM 54-01-00) Composite Structure Tap Test,

to confirm that the repair is correctly bonded.

18. Identify the repair.

A. Record the REPAIR no. VRS 2780 in the component/log book.

(Ref. SPM TASK 70-09-00-400-501).

V2500 54-10-00 REPAIR No. 029

Page 206

May 1/19

Printed in the U.S.A.

Rohr, inc., operating as Goodrich Aerostructures

Goodrich Proprietary - This document is subject to the controls and restrictions on the title page.

GOODRICH AEROSTRUCTURES

STRUCTURAL REPAIR MANUAL

Acoustic Liner Wire Mesh/Facing Sheet Delamination Repair

Figure 201 (Sheet 1)

V2500 54-10-00 REPAIR No. 029

Page 207

Feb 1/17

Printed in the U.S.A.

Rohr, inc., a subsidiary of Goodrich Corporation, operating as Goodrich Aerostructures; Goodrich Proprietary

Information subject to the limitation contained in the title page section of the manual.

GOODRICH AEROSTRUCTURES

STRUCTURAL REPAIR MANUAL

Acoustic Liner Wire Mesh/Facing Sheet Delamination Repair

Figure 201 (Sheet 2)

V2500 54-10-00 REPAIR No. 029

Page 208

Feb 1/17

Printed in the U.S.A.

Rohr, inc., a subsidiary of Goodrich Corporation, operating as Goodrich Aerostructures; Goodrich Proprietary

Information subject to the limitation contained in the title page section of the manual.

GOODRICH AEROSTRUCTURES

STRUCTURAL REPAIR MANUAL

Acoustic Liner Wire Mesh/Facing Sheet Delamination Repair

Figure 201 (Sheet 3)

V2500 54-10-00 REPAIR No. 029

Page 209

Aug 1/17

Printed in the U.S.A.

Rohr, inc., a subsidiary of Goodrich Corporation, operating as Goodrich Aerostructures; Goodrich Proprietary

Information subject to the limitation contained in the title page section of the manual.

GOODRICH AEROSTRUCTURES

STRUCTURAL REPAIR MANUAL

2.00 in. (50,8 mm)

MAXIMUM

SECTION

B-B

(With damaged area removed)

UNDERCUT BY 0.25 in. (6,35 mm)

STRUCTUAL SPEED

NON-POROUS

ADHESIVE TAPE

PARTING FILM

SECTION

B-B

(With repair materials installed)

STRUCTUAL

ADHESIVE

SECTION

B-B

(Completed repair)

Acoustic Liner Wire Mesh/Facing Sheet Delamination Repair

Figure 201 (Sheet 4)

V2500 54-10-00 REPAIR No. 029

Page 210

Feb 1/17

Printed in the U.S.A.

Rohr, inc., a subsidiary of Goodrich Corporation, operating as Goodrich Aerostructures; Goodrich Proprietary

Information subject to the limitation contained in the title page section of the manual.

You might also like

- Tfe731 5br IpcDocument1,018 pagesTfe731 5br IpcbrennaNo ratings yet

- ATA20 Permaswage Install ProcessDocument42 pagesATA20 Permaswage Install ProcessWalter Jair Rodriguez Munoz (LATAM)No ratings yet

- SRS Hockey Stick RepairDocument8 pagesSRS Hockey Stick Repairjpsullivan24No ratings yet

- CFM56-7B Fan Blade Lubrication CESM-005Document2 pagesCFM56-7B Fan Blade Lubrication CESM-005Keith Humphrey0% (2)

- Routine Task CardDocument10 pagesRoutine Task CardDiego HaradaNo ratings yet

- Human Factor Essay Sample (Task Handover)Document2 pagesHuman Factor Essay Sample (Task Handover)Patrick Tong100% (2)

- 90 EPIKOTE Resin 845 - EPIKURE Curing Agent 05378-EnglishDocument10 pages90 EPIKOTE Resin 845 - EPIKURE Curing Agent 05378-EnglishCesar Candelaria ChavezNo ratings yet

- NDT20-00-01 Rev0Document22 pagesNDT20-00-01 Rev0kien Duy PhanNo ratings yet

- Inspection Program ManualCRJ-200-Rev 24 - RedactedDocument182 pagesInspection Program ManualCRJ-200-Rev 24 - RedactedAayus PatelNo ratings yet

- C172 Inspection Time IntervalsDocument6 pagesC172 Inspection Time IntervalsAndy WiyonoNo ratings yet

- Electro Cultur IDocument47 pagesElectro Cultur Isicedaca212100% (2)

- Ameron GRE Fabrication GuidelineDocument355 pagesAmeron GRE Fabrication GuidelineAbdul Hakam Mohamed Yusof100% (2)

- A318 - A319 - A320 - A321 - AMM - 01-Feb-2020 - 72-21-20-210-802-A - Visual Inspection of The Fan BladeDocument30 pagesA318 - A319 - A320 - A321 - AMM - 01-Feb-2020 - 72-21-20-210-802-A - Visual Inspection of The Fan Bladesaid PalaoNo ratings yet

- A320 - 319 LCL Rev A3Document21 pagesA320 - 319 LCL Rev A3EssamNo ratings yet

- Honeywell 36-100 APUDocument3 pagesHoneywell 36-100 APUAlmas QasimNo ratings yet

- Receiving Inspections Power Point 10-22-16Document52 pagesReceiving Inspections Power Point 10-22-16Darby MorganNo ratings yet

- CFM56 NDT ManualDocument103 pagesCFM56 NDT Manualmanishprajapati707100% (3)

- Transit 737-400 19th September 2016Document4 pagesTransit 737-400 19th September 2016Iftikhar JawedNo ratings yet

- Atr 72-NDT20-00-01 Rev0Document22 pagesAtr 72-NDT20-00-01 Rev0lightjp1No ratings yet

- v2500lm01r02 General PDFDocument28 pagesv2500lm01r02 General PDFKamalVirk100% (1)

- A 318Document213 pagesA 318Paul Dan PribacNo ratings yet

- Chapter 18 CVR & FDRDocument41 pagesChapter 18 CVR & FDRveenadivyakishNo ratings yet

- Engine Variant: V2527-A5Document12 pagesEngine Variant: V2527-A5Kartika Ningtyas100% (1)

- Weekly Check A320 (ISSUE 01 REV 00 01-JUN-15) PDFDocument10 pagesWeekly Check A320 (ISSUE 01 REV 00 01-JUN-15) PDFSabeeka BatoulNo ratings yet

- B747-8 Fuel ManifoldDocument31 pagesB747-8 Fuel ManifoldDagmawiNo ratings yet

- B737 Ch70 STD PracticesDocument21 pagesB737 Ch70 STD PracticesAhmed Abdoul ZaherNo ratings yet

- Part 145 Sample ExpositionDocument114 pagesPart 145 Sample ExpositionABDELRHMAN ALINo ratings yet

- FE-V2500-1IA - Glossary of TermsDocument19 pagesFE-V2500-1IA - Glossary of TermsnegrotettNo ratings yet

- Fan and LPCDocument47 pagesFan and LPCkien Duy PhanNo ratings yet

- Training Manual: EASA Part-66 72 Level 3Document16 pagesTraining Manual: EASA Part-66 72 Level 3Luis Enrique La Font FrancoNo ratings yet

- Rmoval of NLGDocument6 pagesRmoval of NLGje_carD23100% (1)

- CFM 56 Compressor Surge PresentationDocument14 pagesCFM 56 Compressor Surge PresentationKamal Mh100% (1)

- Airbus Commercial Aircraft AC A330 Jan 2017 PDFDocument646 pagesAirbus Commercial Aircraft AC A330 Jan 2017 PDFMakhou LadoumNo ratings yet

- Service Bulletin Atr72: Transmittal Sheet Revision No. 12Document16 pagesService Bulletin Atr72: Transmittal Sheet Revision No. 12Pradeep K sNo ratings yet

- 61-12-82 Propeller De-Icer Boot Replacement - HartzellDocument164 pages61-12-82 Propeller De-Icer Boot Replacement - HartzellJacquie JimenezNo ratings yet

- Line Maintenance Manual Issue 06 Rev 04 PDFDocument144 pagesLine Maintenance Manual Issue 06 Rev 04 PDFBharath Nani100% (1)

- CFM56 3book2t Shoot PDFDocument10 pagesCFM56 3book2t Shoot PDFDiniswari Alrino100% (1)

- 70-Power Plant (CFM56)Document326 pages70-Power Plant (CFM56)Anonymous QRVqOsa5No ratings yet

- Airbus 49 A300 A310 Auxiliary Power Unit APU PDFDocument141 pagesAirbus 49 A300 A310 Auxiliary Power Unit APU PDFEstevam Gomes de Azevedo100% (1)

- Aircraft General PracticesDocument74 pagesAircraft General Practiceslivonius100% (1)

- Ground Support Equipment Manuals Index CFM56 - CFM 2019Document4 pagesGround Support Equipment Manuals Index CFM56 - CFM 2019Ibnu AhmadNo ratings yet

- 00 20 General PDFDocument67 pages00 20 General PDFkpilNo ratings yet

- Auditor Handbook Rev1Document52 pagesAuditor Handbook Rev1Kenton CharlesNo ratings yet

- SB Index 72 APR-2020 PDFDocument133 pagesSB Index 72 APR-2020 PDFMuhammad Ashraful KabirNo ratings yet

- A330-343 E.O Status Easa FormDocument31 pagesA330-343 E.O Status Easa FormAmr El Kady0% (1)

- CAAN NCAR 147 GuidelineDocument55 pagesCAAN NCAR 147 GuidelineAbhishek Man ShresthaNo ratings yet

- All in One GE DataDocument3 pagesAll in One GE DataCh Ahmed MahmoodNo ratings yet

- Airbus AbbreviationDocument46 pagesAirbus Abbreviationyeung875No ratings yet

- CMM 23-73-19 Cabin Assignment Module (A320)Document86 pagesCMM 23-73-19 Cabin Assignment Module (A320)Thax NgeNo ratings yet

- Introduccion Al SRM ATR72Document60 pagesIntroduccion Al SRM ATR72Daniel Hernandez100% (1)

- Zone and ATA Chapter PDFDocument25 pagesZone and ATA Chapter PDFdnes9999No ratings yet

- ADS B Out Instalaltion PDFDocument3 pagesADS B Out Instalaltion PDFAbdul Azis SaifuddinNo ratings yet

- Canadair Regional Jet 100/200 - Fuel SystemDocument32 pagesCanadair Regional Jet 100/200 - Fuel Systemmamon113100% (2)

- A. General Data: Engine Report Pw127F SN Pce-AmxxxDocument1 pageA. General Data: Engine Report Pw127F SN Pce-AmxxxGinanjar Pranatha0% (1)

- CorrosionDocument6 pagesCorrosiondonjon ellenNo ratings yet

- CMM Issued 6 Rev 5 (08-Nov-2019) PDFDocument318 pagesCMM Issued 6 Rev 5 (08-Nov-2019) PDFfaisal rabbaniNo ratings yet

- APU PresentationDocument8 pagesAPU PresentationIsmail mhailNo ratings yet

- AC 20-154 Incoming InspectionDocument24 pagesAC 20-154 Incoming Inspectionyvesandrade100% (1)

- TechnicalPublications Jan2010Document4 pagesTechnicalPublications Jan2010starsalingsoul8000No ratings yet

- TRENT 700 - N-TRENT-A330 - Chapter 54 PDFDocument1,689 pagesTRENT 700 - N-TRENT-A330 - Chapter 54 PDF'Izzad Afif100% (2)

- EASA Part CAMO Safety Human Factor Training Requirements Initial - 3 Days PDFDocument6 pagesEASA Part CAMO Safety Human Factor Training Requirements Initial - 3 Days PDFcarbonNo ratings yet

- A320PW11G-B12-0007.1, 70-72 PP Gen, R1 010217Document136 pagesA320PW11G-B12-0007.1, 70-72 PP Gen, R1 010217Marwa MandeelNo ratings yet

- Repair of TR Cowl TE Heat ShieldDocument10 pagesRepair of TR Cowl TE Heat ShieldJivendra KumarNo ratings yet

- Printed in GermanyDocument46 pagesPrinted in GermanyEdson CarvalhoNo ratings yet

- Journal of Science: Advanced Materials and Devices: Original ArticleDocument8 pagesJournal of Science: Advanced Materials and Devices: Original ArticleSamah SamahNo ratings yet

- Technical Data: PR-1776M Class B Low Weight Fuel Tank SealantDocument2 pagesTechnical Data: PR-1776M Class B Low Weight Fuel Tank SealantEDUARDONo ratings yet

- Jota Epoxy FillerDocument4 pagesJota Epoxy FillersanthoshNo ratings yet

- UV 60-7185 Ultra Clear Uv Curable Adhesive, Coating, & EncapsulantDocument2 pagesUV 60-7185 Ultra Clear Uv Curable Adhesive, Coating, & EncapsulantCobus Kevin CaloyloyNo ratings yet

- Bio-Epoxy For Aerospace Applications - Summary 22 June 2021Document6 pagesBio-Epoxy For Aerospace Applications - Summary 22 June 2021Namelezz ShadowwNo ratings yet

- Xiameter OFS-6020 Silane: Diaminofunctional Silane Features ApplicationsDocument2 pagesXiameter OFS-6020 Silane: Diaminofunctional Silane Features ApplicationsDelovita GintingNo ratings yet

- Investigation of Hybrid Laminar Owcontrol (HLFC) Surfaces: T.M. Young, B. Humphreys, J.P. FieldingDocument20 pagesInvestigation of Hybrid Laminar Owcontrol (HLFC) Surfaces: T.M. Young, B. Humphreys, J.P. FieldingSyamsul Bahry HarahapNo ratings yet

- Pam Cijevi DuctilDocument20 pagesPam Cijevi DuctilLejla BuljetovicNo ratings yet

- Nitokit Surface SealantDocument2 pagesNitokit Surface SealantBalasubramanian AnanthNo ratings yet

- Interline 994+br+eng PDFDocument2 pagesInterline 994+br+eng PDFMohamed NouzerNo ratings yet

- Pemilihan Material PipaDocument37 pagesPemilihan Material PipaSeptian FirdausNo ratings yet

- Nano ResinsDocument10 pagesNano ResinshollabackcockNo ratings yet

- Gelling 1991 Epoxidised Natural RubberDocument27 pagesGelling 1991 Epoxidised Natural RubberlimNo ratings yet

- Creating Epoxy TablesDocument2 pagesCreating Epoxy TablesGrillobuchelliNo ratings yet

- Organic and Inorganic Zinc Rich CoatingsDocument3 pagesOrganic and Inorganic Zinc Rich CoatingsEddy Norman Benites Delgado100% (6)

- Xq2fod Switching Power SupplyDocument9 pagesXq2fod Switching Power Supplydp500No ratings yet

- 03 120000 4800000441 Boc Civ Mat 000026 - 01Document56 pages03 120000 4800000441 Boc Civ Mat 000026 - 01Yasir Nisar SyedNo ratings yet

- Products Summary Guide PDFDocument16 pagesProducts Summary Guide PDFSushil Dhungana100% (1)

- Nitotile XS GroutDocument2 pagesNitotile XS GroutBalasubramanian AnanthNo ratings yet

- Carboguard 890 GF PDSDocument2 pagesCarboguard 890 GF PDSfazeel mohammedNo ratings yet

- Summitommo Gear BoxDocument22 pagesSummitommo Gear BoxAhmad SujaiNo ratings yet

- Unsatpolyester PDFDocument11 pagesUnsatpolyester PDFNuning S N AeniNo ratings yet

- RTV-S 691Document3 pagesRTV-S 691Ishu ChandraNo ratings yet

- Stoichiometric (Percentage) Calculations: Objective of Research Research Methodology Course Work DetailsDocument117 pagesStoichiometric (Percentage) Calculations: Objective of Research Research Methodology Course Work DetailsRamesh GyadariNo ratings yet

- Fosroc Conbextra EP300: Constructive SolutionsDocument4 pagesFosroc Conbextra EP300: Constructive SolutionsVincent JavateNo ratings yet

- Loctite Solution Guide Issue 6Document56 pagesLoctite Solution Guide Issue 6José María GarcíaNo ratings yet