Professional Documents

Culture Documents

SOP 06 - Portable Tools and Equipment

SOP 06 - Portable Tools and Equipment

Uploaded by

Edwins Gabrelle Hendrawan DalfadoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SOP 06 - Portable Tools and Equipment

SOP 06 - Portable Tools and Equipment

Uploaded by

Edwins Gabrelle Hendrawan DalfadoCopyright:

Available Formats

SOP 06 – Portable tools & Equipment

S06.1 Purpose

The purpose of this Standard is to describe the steps while using, maintaining and storing portable

tools and portable equipment. Proper usage of portable tools is crucial to EESL operations as usage

of improper tools can lead to severe injuries

S06.2 Scope

This Standard is mandatory and applies to EESL and its contractors for the on-site implementation

of programs.

S06.3 References

The following references and standards are to be followed:

IS/ISO 6789 (2003): Assembly tools for screws and nuts – Hand torque tools –

Requirements and test methods for design conformance testing, quality conformance

testing and recalibration procedure

IS 841:1983 – Specification for steel hammers

IS 844:1979 (Part 1, 2 & 3) – Technical supply conditions, dimensions, dimensions for screw

drivers for recessed head screws

IS 2027:1992 – Spanners and sockets – width across flats

IS 6131:1980 – Technical requirements for hand operated wrenches (spanners) and sockets

IS 6586:1989 – Claw hammers – specification

IS 9065: 1979 – Specification for Aluminium hammers

IS 12453:1988 – Specification for nut drivers

The hand tools comprise of the following but are not limited to – hand held power tools, knives,

ladders, mechanical hand tools, woodworking hand tools and metal working hand tools.

S06.4 General safety precautions for using portable tools

The following safety precautions must be following while using portable tools and equipment

All tools and equipment will be maintained in good working condition and have current

certificates as required by law

Equipment and tools used on site (by EESL employees or contractors) will be inspected on a

daily basis by the site supervisor

Equipment and tools approved by the supervisor on a daily basis can only be used

Any tool or equipment that is found to be unsafe or not in safe working condition must

immediately be set aside for service, repair or replacement

Only the right tools should be used for the job

Users of tools must have received training on the tools they are meant to use. The training

has to be provided by the supervisor or safety incharge of that programme

Tools and equipment must be disconnected prior to service or maintenance

Contractors and sub-contractors (irrespective of levels of sub-contracting) must take

ownership of the hand tools provided by them and be responsible for the safe upkeep of the

tools

Personal protective equipment approved for the selected hand tools must be used while

operating with the hand tools

All portable electrically powered tools need to be grounded and insulated to prevent

electrical shock

Power tools should not be lifted or carried using its cord

Pocket knives, utility knives, swiss knives or any other self-assembled tools shall not be

used for stripping wires

All fuel powered tools shall be stopped and disconnected at the time of refueling, servicing

and maintaining

Safety goggles with side shields should be used to prevent eye injuries from particles/pieces

Sharp edges of the tools should be covered with appropriate material prior to storage

Tools should not be carried in pockets or unassigned bags

Tools should not be modified informally, extended, sharpened or twisted in an

unauthorized manner

While drilling, cutting, striking or breaking, it should be ensured that any electrical wiring in

the vicinity, especially wiring that can come in contact with the hand tool is not live

Special safety requirements while using striking tools or hammers:

o Always hit with a striking face of the hammer

o Do not modify the hammer on your own

o Ensure that if the hammer head is loose, please set it aside and use an alternate

hammer

o Choose the appropriate hammers for drilling nails or strike steel or concrete chisels

o The striking face must not be cracked or mushroomed, as there is a likelihood of the

hammer chipping, leading to small particles moving around the place

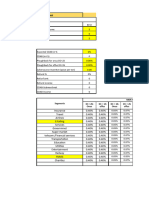

History of amendments

The latest versions of the Documentation Format must be used at all times. This page needs to be

updated whenever there is a change in the version number of the documents.

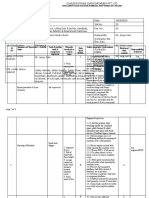

S. No Date of amendment Version Details of amendment

1. DD.MM.YYYY 01 Initial approval of the documentation format

Prepared by Approved by

You might also like

- Ethics For Engineers by Martin Peterson Full ChapterDocument41 pagesEthics For Engineers by Martin Peterson Full Chapterashley.torres627100% (26)

- Collins Pre-Intermediate Business Grammar Practice SB WWW - TienganheduDocument208 pagesCollins Pre-Intermediate Business Grammar Practice SB WWW - TienganheduJota Borges100% (1)

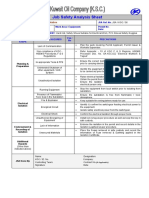

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document3 pagesJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair VanmazhyNo ratings yet

- CKE6150 Spare Parts ManualDocument74 pagesCKE6150 Spare Parts ManualVanessa RiveraNo ratings yet

- Jsa For Alignment of Vessel and DrumDocument3 pagesJsa For Alignment of Vessel and DrumMohammed MinhajNo ratings yet

- JSA-012 Low-Flow Groundwater SamplingDocument3 pagesJSA-012 Low-Flow Groundwater SamplingfrancisseeNo ratings yet

- Sop Hydraulic Punch and ShearDocument1 pageSop Hydraulic Punch and ShearBorislav VulićNo ratings yet

- TLE 7/8 Computer Systems Servicing 2 Quarter: Ict (Exploratory)Document5 pagesTLE 7/8 Computer Systems Servicing 2 Quarter: Ict (Exploratory)Joan Cala-or Valones100% (2)

- HSE 14 Lockout and TagoutDocument1 pageHSE 14 Lockout and TagoutBa N Nhim100% (1)

- Jsa Energizing Final Tapping Back FeedingDocument7 pagesJsa Energizing Final Tapping Back FeedingekapadwiNo ratings yet

- Jsa Psa & GisDocument3 pagesJsa Psa & GisMohammed NouzalNo ratings yet

- Material Handeling OCPDocument1 pageMaterial Handeling OCPAshwani KumarNo ratings yet

- Standard Operating Procedures of Hand and Power Tool SafetyDocument3 pagesStandard Operating Procedures of Hand and Power Tool Safetysingenaadam100% (1)

- LOTO HandbookDocument24 pagesLOTO Handbookhse docsNo ratings yet

- Welding JSADocument2 pagesWelding JSAMD AbdullahNo ratings yet

- 2 JHA On Shot Grit Blasting1Document3 pages2 JHA On Shot Grit Blasting1Akhilesh KumarNo ratings yet

- Jsa CompressorDocument9 pagesJsa CompressorRavi thokalNo ratings yet

- Sop Welder TigDocument2 pagesSop Welder TigShahid Raza100% (1)

- Bench GrinderDocument1 pageBench GrinderSreejith S NairNo ratings yet

- Rock Breaker Self ChecklistDocument1 pageRock Breaker Self ChecklistNair R RakeshNo ratings yet

- Jsa Lifitng Gantry FabricationDocument3 pagesJsa Lifitng Gantry FabricationOsiobe EwomazinoNo ratings yet

- Hand Trolley PDFDocument1 pageHand Trolley PDFcityofdarwingisNo ratings yet

- JSA Format Erection of Column 901-C-01Document9 pagesJSA Format Erection of Column 901-C-01sakthi venkatNo ratings yet

- Job Safety Analysis Forklift OperationsDocument2 pagesJob Safety Analysis Forklift Operationssufiyanshaikh50% (2)

- JSA ProjectDocument4 pagesJSA ProjectbrantasNo ratings yet

- Jsa-001 Manual Handling & Heavy LiftingDocument2 pagesJsa-001 Manual Handling & Heavy LiftingDamien Monize100% (1)

- JSA - Electrical IsolationDocument1 pageJSA - Electrical IsolationRaju KhalifaNo ratings yet

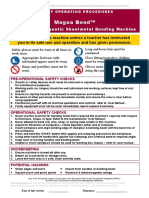

- SWP Manual Bending Rolls AS524Document2 pagesSWP Manual Bending Rolls AS524jason cepadaNo ratings yet

- Magna Bend SopDocument1 pageMagna Bend SopClarkKent Fabro Batucan0% (1)

- HSE InductionDocument20 pagesHSE InductionShailendraNo ratings yet

- Hazardous Energy Control Procedure: Lockout/Tagout SheetDocument3 pagesHazardous Energy Control Procedure: Lockout/Tagout SheetPaul HymanNo ratings yet

- The Definition of HSE Performance RecordsDocument2 pagesThe Definition of HSE Performance RecordsFortuna HunilaNo ratings yet

- SOP Grinding & CuttingDocument3 pagesSOP Grinding & CuttingIMRANNo ratings yet

- Jsa n2 Purging PDF FreeDocument1 pageJsa n2 Purging PDF FreeSKH CultureNo ratings yet

- Job Safety Analysis Form HydrotestDocument3 pagesJob Safety Analysis Form Hydrotestyayongjcs100% (4)

- Stop Work Procedure: Document Number: USPL-COW-490-003Document8 pagesStop Work Procedure: Document Number: USPL-COW-490-003Andhika HerdiawanNo ratings yet

- Powder Actuated ToolsDocument1 pagePowder Actuated ToolsJayvee Baradas ValdezNo ratings yet

- Water Tank Cleaning TRADocument5 pagesWater Tank Cleaning TRAyehia sayedNo ratings yet

- Job Safety Analysis Erection SiloDocument3 pagesJob Safety Analysis Erection SiloDanangNo ratings yet

- Inspection Form Lockout TagoutDocument4 pagesInspection Form Lockout TagoutCarina Kouamé100% (1)

- SOP Workshop Hy FinalDocument4 pagesSOP Workshop Hy FinalanbuNo ratings yet

- Eil Permit For Energy Isolation & De-IsolationDocument1 pageEil Permit For Energy Isolation & De-IsolationAvesh ChauahanNo ratings yet

- JSA NO 2 Piling WorkDocument6 pagesJSA NO 2 Piling WorkfadliNo ratings yet

- Job Safety & Environment Analysis: Revision NoDocument3 pagesJob Safety & Environment Analysis: Revision NonishanthNo ratings yet

- PTW JHA Prayer Garment Hanging Rack InstallationDocument2 pagesPTW JHA Prayer Garment Hanging Rack InstallationPHH9834No ratings yet

- ENO JHA SHELL 001 - Cutting and Excavation Work at None - Hazardous AreaDocument4 pagesENO JHA SHELL 001 - Cutting and Excavation Work at None - Hazardous Areamyn maliQue0% (1)

- SOP-Welding Cutting and Brazing (Detailed)Document10 pagesSOP-Welding Cutting and Brazing (Detailed)Nitish SinghNo ratings yet

- Metal LatheDocument1 pageMetal LatheNibhaNo ratings yet

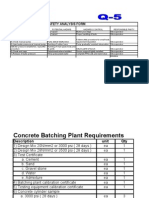

- JSA-Piling or Concreting For Foundations & BuildingDocument2 pagesJSA-Piling or Concreting For Foundations & BuildingSanjeet SinghNo ratings yet

- SandblastingDocument2 pagesSandblastingAL SALEH ELECTRONo ratings yet

- HSE Policy PDFDocument10 pagesHSE Policy PDFgiovadiNo ratings yet

- Job Safety & Environment Analysis (Jsa) : Activity or TaskDocument3 pagesJob Safety & Environment Analysis (Jsa) : Activity or TaskLusy Gusti EfendiNo ratings yet

- Sogetrap JSA Lifting Cabin by ForkliftDocument2 pagesSogetrap JSA Lifting Cabin by ForkliftTSP HSENo ratings yet

- 18 SOP CBL Trench DiggingDocument10 pages18 SOP CBL Trench DiggingMd Gulam SafiNo ratings yet

- SOP - ForkliftDocument4 pagesSOP - ForkliftGyanendra Narayan Nayak100% (1)

- Aj Infratech: Job Hazard AnalysisDocument5 pagesAj Infratech: Job Hazard AnalysisDwitikrushna RoutNo ratings yet

- Press On Permit To Work SystemDocument7 pagesPress On Permit To Work SystemashwaniNo ratings yet

- Safe Operating Procedures 08 Air CompressorDocument2 pagesSafe Operating Procedures 08 Air CompressorAkbarNo ratings yet

- Catalyst Filling & SeggregationDocument3 pagesCatalyst Filling & SeggregationMohammed MinhajNo ratings yet

- Job Safety Analysis (JSA) - Electrical Works DateDocument1 pageJob Safety Analysis (JSA) - Electrical Works DatenabeelNo ratings yet

- Part 3 ObservationsDocument7 pagesPart 3 ObservationsAmjadNo ratings yet

- Electrical Work PermitDocument2 pagesElectrical Work Permitadicondesit100% (2)

- Mek TopicDocument5 pagesMek TopicdevmarineacademyNo ratings yet

- Vintage Poster Lenormand 2013Document25 pagesVintage Poster Lenormand 2013Magdalena Sighild Petersson100% (2)

- ACC290 Week 1 Apply ExerciseDocument5 pagesACC290 Week 1 Apply ExerciseG JhaNo ratings yet

- Immobi Ad SpecsDocument32 pagesImmobi Ad SpecsManuj KhuranaNo ratings yet

- Craig-1977-The Structure of JacaltecDocument442 pagesCraig-1977-The Structure of JacaltecmaclbaisNo ratings yet

- Apache Trout ReportDocument7 pagesApache Trout Reportapi-460143281No ratings yet

- LP SampleDocument12 pagesLP SampleFayeNo ratings yet

- Jurnal 6 - Anton Indra Budiman - FACTORS AFFECTING UNDERSTANDIBILITY OFDocument16 pagesJurnal 6 - Anton Indra Budiman - FACTORS AFFECTING UNDERSTANDIBILITY OFsilvi snNo ratings yet

- Workshop 1 FIDP Blank TemplateDocument2 pagesWorkshop 1 FIDP Blank TemplateMii MonNo ratings yet

- 5-Average Inventories Turnover PeriodDocument2 pages5-Average Inventories Turnover PeriodMartin MinotNo ratings yet

- Medical Picture Mnemonics PDFDocument28 pagesMedical Picture Mnemonics PDFAntoine JusticeNo ratings yet

- Duodenal Stenosis PDFDocument9 pagesDuodenal Stenosis PDFDorcas KafulaNo ratings yet

- Pricing Calculator Excel Used in BanksDocument15 pagesPricing Calculator Excel Used in Banksrahul kr raiNo ratings yet

- 14 3 DP Optimal Binary Search Trees 4upDocument4 pages14 3 DP Optimal Binary Search Trees 4upcute_guddyNo ratings yet

- Sepco Online BilllDocument1 pageSepco Online Billlshaikh_piscesNo ratings yet

- Lesson Plan 1 FinalDocument2 pagesLesson Plan 1 Finalmastro100No ratings yet

- SkyEdge II Pro Brochure 2011-10-03Document2 pagesSkyEdge II Pro Brochure 2011-10-03FreddySaltosNo ratings yet

- Operational Excellence in Textile Industry Case Study: East AfricaDocument3 pagesOperational Excellence in Textile Industry Case Study: East AfricafarooquintuNo ratings yet

- EL - 124 Electronic Devices & Circuits: Experiment # 04Document6 pagesEL - 124 Electronic Devices & Circuits: Experiment # 04Jawwad IqbalNo ratings yet

- DSC-410 Smoke DetectorDocument4 pagesDSC-410 Smoke DetectorJovany Salazar100% (1)

- Rudaga - Regulations - 2021Document7 pagesRudaga - Regulations - 2021sidharthNo ratings yet

- Excel Exercise 3.4Document2 pagesExcel Exercise 3.4andreNo ratings yet

- The Dark Side of Solar PowerDocument11 pagesThe Dark Side of Solar Powershah19suriNo ratings yet

- Rdbms (Unit 3)Document19 pagesRdbms (Unit 3)hari karanNo ratings yet

- EL CPP MegaDocument8 pagesEL CPP MegaEklavya GoyalNo ratings yet

- Yom Ha'atzmaut Missing Letters: Fill in The Missing Letters To Complete The WordsDocument34 pagesYom Ha'atzmaut Missing Letters: Fill in The Missing Letters To Complete The WordsRachel MalagaNo ratings yet

- Jón Kristinsson: Edited by Andy Van Den DobbelsteenDocument17 pagesJón Kristinsson: Edited by Andy Van Den DobbelsteenWika NurikaNo ratings yet