Professional Documents

Culture Documents

Equipment Layout Option 1: GE Healthcare

Equipment Layout Option 1: GE Healthcare

Uploaded by

Adit IrmaCopyright:

Available Formats

You might also like

- The "Rail Sign": An Ultrasound Finding in Placenta Accreta Spectrum Indicating Deep Villous Invasion and Adverse OutcomesDocument17 pagesThe "Rail Sign": An Ultrasound Finding in Placenta Accreta Spectrum Indicating Deep Villous Invasion and Adverse OutcomesJoseLuisNo ratings yet

- Boysen-Osborn (2018) PDFDocument11 pagesBoysen-Osborn (2018) PDFBryan TorresNo ratings yet

- NationDocument88 pagesNationJustin Luu0% (1)

- Adding and Subtracting Polynomials LessonDocument4 pagesAdding and Subtracting Polynomials Lessonapi-249037964100% (4)

- Benefits of Assessing The Solids Production Risk in A North Sea ReservoirDocument9 pagesBenefits of Assessing The Solids Production Risk in A North Sea Reservoirredup25No ratings yet

- Tdm850 '99 Wiring Diagram: Color CodeDocument1 pageTdm850 '99 Wiring Diagram: Color CodeХаджи Христо БуюклиевNo ratings yet

- Bahan Evidance Based Dalam Keperawatan PDFDocument10 pagesBahan Evidance Based Dalam Keperawatan PDFTati Margareta MargaretaNo ratings yet

- An Action Error of Nursing Procedures: Types and Cause Factor Ners Profession StudentDocument10 pagesAn Action Error of Nursing Procedures: Types and Cause Factor Ners Profession StudentJurnal Ners UNAIRNo ratings yet

- Teknik Pencarian Literatur Dan Analisis Jurnal KeperawatanDocument30 pagesTeknik Pencarian Literatur Dan Analisis Jurnal Keperawatanmademerlin92100% (1)

- Undangan Walimatul Indah NDocument1 pageUndangan Walimatul Indah NM Kholid MawardiNo ratings yet

- Sistematic ReviewDocument7 pagesSistematic ReviewArief RafsanjaniNo ratings yet

- JurnalKGD2 PDFDocument11 pagesJurnalKGD2 PDFNurrul HudaaNo ratings yet

- Perbedaan Penanganan Antara Laparoskopi Vs Open Repair Pada Perforasi GasterDocument7 pagesPerbedaan Penanganan Antara Laparoskopi Vs Open Repair Pada Perforasi GasterAfiani JannahNo ratings yet

- Complicated AppendicitisDocument4 pagesComplicated AppendicitisMedardo ApoloNo ratings yet

- Vascular Acces in Hemodyalisi - DR DjoniDocument50 pagesVascular Acces in Hemodyalisi - DR DjoniMohamad ZulfikarNo ratings yet

- Stock ProdeviceDocument4 pagesStock ProdeviceresaNo ratings yet

- Airway EquipmentDocument47 pagesAirway Equipmentyoustiana dwi rusitaNo ratings yet

- Loopography Examination For Colon Cancer 7c394e77Document11 pagesLoopography Examination For Colon Cancer 7c394e77N. Camelya FirdausNo ratings yet

- Kebijakan Perawat Dalam Penerapan Keselamatan Pasien Di Rumah SakitDocument6 pagesKebijakan Perawat Dalam Penerapan Keselamatan Pasien Di Rumah SakitbintangNo ratings yet

- Daftar Singkatan SMF JAntungDocument5 pagesDaftar Singkatan SMF JAntungBobby RahmantoNo ratings yet

- AI PKL 1 - Calcaneus - Put AyDocument17 pagesAI PKL 1 - Calcaneus - Put AyYusuf Erlangga AWNo ratings yet

- Inventaris 2022 AGUSTUSDocument44 pagesInventaris 2022 AGUSTUSYuni Syalawiyah IINo ratings yet

- Model Manajemen StrategikDocument17 pagesModel Manajemen Strategikwaode alfianiNo ratings yet

- Analisis Efisiensi Celah Shutter Kolimator Tabung Sinar X Di Tiga Instalasi Radiologi Lahan PKL Prodi D3 Radiologi Unisa YogyakartaDocument7 pagesAnalisis Efisiensi Celah Shutter Kolimator Tabung Sinar X Di Tiga Instalasi Radiologi Lahan PKL Prodi D3 Radiologi Unisa YogyakartaNoveliaNo ratings yet

- Alur Pelayanan Kamar OperasiDocument1 pageAlur Pelayanan Kamar Operasifemi suryanti100% (1)

- Spesifikasi PHILIPS Ultrasound System EPIQ 5 WHC BasicDocument2 pagesSpesifikasi PHILIPS Ultrasound System EPIQ 5 WHC BasichsNo ratings yet

- REVISI 1st Announcement Book 27th ASMIHA 2018 - 12des2017Document21 pagesREVISI 1st Announcement Book 27th ASMIHA 2018 - 12des2017Jimmy Oi SantosoNo ratings yet

- Alat Dan Instrumen Di Ruang CathlabDocument27 pagesAlat Dan Instrumen Di Ruang CathlabAkram BatjoNo ratings yet

- Anesthesia Cosmetic SurgeryDocument7 pagesAnesthesia Cosmetic SurgerySergio ArbelaezNo ratings yet

- Manajemen Stratejik (Umar Said)Document70 pagesManajemen Stratejik (Umar Said)Donny Rahman KhalikNo ratings yet

- Biodata Parestesi Juli 2011 Edit IpoDocument56 pagesBiodata Parestesi Juli 2011 Edit Iporahmat feryadiNo ratings yet

- MATERI EWS PerbaikanDocument24 pagesMATERI EWS PerbaikanagusNo ratings yet

- Clinical Pathways RSWSDocument93 pagesClinical Pathways RSWSHeri JauhariNo ratings yet

- Newer Airway Devices PDFDocument74 pagesNewer Airway Devices PDFDharmesh GandhiNo ratings yet

- Ai Pengujian Lead ApronDocument8 pagesAi Pengujian Lead Apronwildan sanjayaNo ratings yet

- Kebutuhan Alat Alat AnestesiDocument5 pagesKebutuhan Alat Alat AnestesiidrisNo ratings yet

- Proposal Kegiatan Rumah Sakit Umum Jend.A.Yani MetroDocument3 pagesProposal Kegiatan Rumah Sakit Umum Jend.A.Yani MetroIvana Belinda PanggabeanNo ratings yet

- Informed ConsentDocument19 pagesInformed ConsentMuhammad Ibnu Widyanto BasriNo ratings yet

- Announcement IndoanesthesiaDocument24 pagesAnnouncement IndoanesthesiaAndrian100% (1)

- Jurnal AnastesiDocument10 pagesJurnal AnastesiAnonymous m07Ogz0rNo ratings yet

- Prone Positioning Under AnesthesiaDocument32 pagesProne Positioning Under Anesthesiabuddy9568100% (1)

- Angiografi Femoralis-1Document24 pagesAngiografi Femoralis-1Sepahit Kopi Hitam100% (1)

- Contoh Denah Ruangan PanoramicDocument2 pagesContoh Denah Ruangan PanoramicBagas SanjayaNo ratings yet

- Supervisi Berjenjang Di Era Pandemi Covid-19 Dalam Manajemen KeperawatanDocument10 pagesSupervisi Berjenjang Di Era Pandemi Covid-19 Dalam Manajemen Keperawatanfebrian rahmatNo ratings yet

- Template StaseDocument12 pagesTemplate StasefikhryNo ratings yet

- Daftar Harga Airway PT. Surgika 2017Document16 pagesDaftar Harga Airway PT. Surgika 2017Syaofi SofiNo ratings yet

- Final 2nd Announcement Konas Perdatin Perdici 2019 - WebsiteDocument67 pagesFinal 2nd Announcement Konas Perdatin Perdici 2019 - WebsiteWirjapratama PutraNo ratings yet

- CV Pembicara SeminarDocument77 pagesCV Pembicara SeminarMunawwar AweNo ratings yet

- E PosterDocument1 pageE PosterIlham AjiNo ratings yet

- Ozid Iv (Omeprazole) : Cedocard Iv (Isosorbid Dinitrat)Document15 pagesOzid Iv (Omeprazole) : Cedocard Iv (Isosorbid Dinitrat)Galih Aryo UtomoNo ratings yet

- Teori & Model Keperawatan Dan Penerapan Dalam Asuhan KeperawatanDocument81 pagesTeori & Model Keperawatan Dan Penerapan Dalam Asuhan Keperawatanannis fathiaNo ratings yet

- Surveilans Health Care Associated Infections: PersiDocument49 pagesSurveilans Health Care Associated Infections: Persifebri12No ratings yet

- Konas Perdatin 2019Document66 pagesKonas Perdatin 2019Akreditasi RSPC19No ratings yet

- Dmergency in Cardiology Part II-dr - Erika Maharani, Sp. JP (K) (2019)Document44 pagesDmergency in Cardiology Part II-dr - Erika Maharani, Sp. JP (K) (2019)lia ancillaNo ratings yet

- Comparing SPIR and SPAIR Fat Suppression Techniques in Magnetic Resonance Imaging (MRI) of Wrist JointDocument6 pagesComparing SPIR and SPAIR Fat Suppression Techniques in Magnetic Resonance Imaging (MRI) of Wrist JointRini IndratiNo ratings yet

- Persiapan Pasien Petugas N Instrumen Cath LabDocument20 pagesPersiapan Pasien Petugas N Instrumen Cath LabAgus SupriyadiNo ratings yet

- NeurointervensiDocument58 pagesNeurointervensiarief nugrohoNo ratings yet

- MRI Protokol Review Adi WS QCDocument150 pagesMRI Protokol Review Adi WS QChadiNo ratings yet

- Post-Operative Care, DSTC Online, Jun.2021Document38 pagesPost-Operative Care, DSTC Online, Jun.2021tepat rshsNo ratings yet

- 2juni PPT JOURNAL READING AnestesiDocument25 pages2juni PPT JOURNAL READING AnestesiYudha KhusniaNo ratings yet

- Dual Source CT Imaging PDFDocument275 pagesDual Source CT Imaging PDFAnisa SetiawatiNo ratings yet

- 1 Introduction To Mechvent Final PERDATINDocument29 pages1 Introduction To Mechvent Final PERDATINFriss TellaNo ratings yet

- XRAY RoomDocument1 pageXRAY RoomSehad KadiriNo ratings yet

- 204 Parts Manual 1999Document162 pages204 Parts Manual 1999Ильдар АхмеровNo ratings yet

- Brosur Kowa KT980Document2 pagesBrosur Kowa KT980Adit IrmaNo ratings yet

- Jadwal MumetDocument15 pagesJadwal MumetAdit IrmaNo ratings yet

- MANAJEMEN Vs MARKETINGDocument19 pagesMANAJEMEN Vs MARKETINGAdit IrmaNo ratings yet

- CPPT PDFDocument1 pageCPPT PDFAdit IrmaNo ratings yet

- Top-Up Degrees - Entry To Year 3Document14 pagesTop-Up Degrees - Entry To Year 3poudelnNo ratings yet

- Clinical ChemistryDocument10 pagesClinical ChemistryChristina AtefNo ratings yet

- Effective Learning StrategiesDocument5 pagesEffective Learning StrategiesRossy Milena JarabaNo ratings yet

- Methods of Teaching (Handouts)Document3 pagesMethods of Teaching (Handouts)Даша ГалкаNo ratings yet

- Acquistion of Jaguar Land Rover by Tata MotorsDocument9 pagesAcquistion of Jaguar Land Rover by Tata Motorsajinkya8400No ratings yet

- Ingenieria Basica y Detalle ISADocument50 pagesIngenieria Basica y Detalle ISAdalver17100% (1)

- Depth-First Search: COMP171 Fall 2005Document27 pagesDepth-First Search: COMP171 Fall 2005Praveen KumarNo ratings yet

- Topical Revision 2 AnswersDocument8 pagesTopical Revision 2 AnswersmichelleNo ratings yet

- Oracle Commerce and WebCenter Sites Integration GuidelinesDocument11 pagesOracle Commerce and WebCenter Sites Integration GuidelinesMatteo MartelloNo ratings yet

- Math 3FM3 Fall 2012 Course OutlineDocument2 pagesMath 3FM3 Fall 2012 Course OutlineAngela DaqustNo ratings yet

- Date - 1 - 9 - 2024 Time - 8 - 42 - 56 - 850Document1 pageDate - 1 - 9 - 2024 Time - 8 - 42 - 56 - 850ANKUSH 87205312No ratings yet

- Stay Where You Are' For 21 Days: Modi Puts India Under LockdownDocument8 pagesStay Where You Are' For 21 Days: Modi Puts India Under LockdownshivendrakumarNo ratings yet

- Pressure Safety Valve-Preliminary Sizing: Input DataDocument6 pagesPressure Safety Valve-Preliminary Sizing: Input DataPIDNo ratings yet

- CS Dec 2018-Jan 2019 PDFDocument78 pagesCS Dec 2018-Jan 2019 PDFPavanNo ratings yet

- LSS BB Body of KnowledgeDocument5 pagesLSS BB Body of KnowledgeVigneshNo ratings yet

- Somatoform Disorders in DSM SoalDocument6 pagesSomatoform Disorders in DSM SoalNurlita trianiNo ratings yet

- Telecom Resource Planning Tool - Brochure - Apr 09Document12 pagesTelecom Resource Planning Tool - Brochure - Apr 09brajesh_er1709No ratings yet

- Mansi Mba Sip Report PDFDocument85 pagesMansi Mba Sip Report PDFAmul PatelNo ratings yet

- The 7 Levels of Wealth ManualDocument215 pagesThe 7 Levels of Wealth Manualawakejoy89% (18)

- Iso 30400-2016Document12 pagesIso 30400-2016Shekhar100% (3)

- Riksbanken Nat UpplagaDocument528 pagesRiksbanken Nat UpplagaOscar Ubeda SegmarNo ratings yet

- Nature Is The World Around UsDocument3 pagesNature Is The World Around UsKarthikgeyan Munesveran100% (1)

- TLE ICT 10 - Quizalize Pre TestDocument8 pagesTLE ICT 10 - Quizalize Pre TestGioSanBuenaventuraNo ratings yet

- CRM # 4044662347 (Zpec # 5)Document1 pageCRM # 4044662347 (Zpec # 5)Mohammad MushtaqNo ratings yet

- MBA Programme: Wayamba University of Sri Lanka Faculty of Business Studies and FinanceDocument44 pagesMBA Programme: Wayamba University of Sri Lanka Faculty of Business Studies and FinanceTommba TommyNo ratings yet

- SchedulingDocument44 pagesSchedulingKonark PatelNo ratings yet

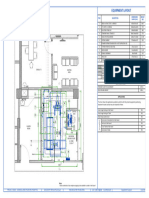

Equipment Layout Option 1: GE Healthcare

Equipment Layout Option 1: GE Healthcare

Uploaded by

Adit IrmaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Equipment Layout Option 1: GE Healthcare

Equipment Layout Option 1: GE Healthcare

Uploaded by

Adit IrmaCopyright:

Available Formats

DIMENSIONS WEIGHT

EQUIPMENT LAYOUT Option 1 ITEM DESCRIPTION LxWxH (mm) (kg)

1 LC GANTRY 1552x1070x2234 750

2 OMEGA V PATIENT TABLE 2997x727x780 590

3 MONITOR SUSPENSION RAILS (x2) L=4724 63

4 MONITOR SUSPENSION LONG BRIDGE 2986x648x50 102

5 SUSPENSION WITH 4 MONITORS 135

6 XRAY BUZZER 1

7 MAVIG RAD SHIELD AND LAMP WITH CEILING PLATE 92

8 INJECTOR ON PEDESTAL - -

9 OPERATOR CONSOLE - 19.6

10 MACLAB MONITORING SYSTEM 94

11 C1 CABINET 900x654x1854 457

12 C2 CABINET 900x654x1854 258.5

13 COOLIX 4100 WATER CHILLER 555x610x1200 120

14 COOLIX 4100 AUTOTRANSFORMER 370x304x340 30

15 15 DETECTOR CHILLER 283x351x378 13.6

16 POWER DISTRIBUTION BOX (PDB) 800x300x1200 110

17 EMI FILTER BOX 300x210x950 <40

18 FLUORO UPS CE 680x800x1450 480

7 EXAM ROOM

19 FLUORO UPS INTERFACE BOX 280x314x124.5 4

20 AW WORK STATION 1000x690 22

10

STRUCTURE - ACCORDING TO RECEIVED DRAWING

20

WALL - ACCORDING TO RECEIVED DRAWING

CONTROL ROOM

6 WALLS - RECOMMENDED MODIFICATIONS BY GE

3

9 4

EXAM ROOM HEIGHT

1

FINISHED FLOOR TO FALSE CEILING HEIGHT 3.00m

2 504

Door openings: Exam room min 1160, Technical room min 800, rec 1000

8 5

RSMK Gading Serpong

Tangerang

Indonesia

Jumarsono Saidi Sunarno

GE Healthcare +628111941195

jumarsono.sunarno@ge.com

TECHNICAL ROOM 17

PRE-INSTALLATION REQUIREMENTS FOR

IGS 520

18

13 PRELIMINARY STUDY

14

19 < 25 °C 16

11 12

A 24/SEP/2018 FIRST ISSUE DRAWING

REV DATE MODIFICATIONS

All dimensions are in millimeters unless otherwise specified. Do not scale from printed pdf files. GE accepts no responsibility or liability for defective work due

to scaling from these drawings.

Drawn by Verified by S.O. PIM Ref & Rev Date Rev

- 5499972-1-1 EN Rev 2 24/SEP/2018 A

Scale 1:50 Format A3 RSMK GADING SERPONG - PROPOSAL LAYOUT OPT 1.DWG 01/02

TEMPERATURE AND HUMIDITY SPECIFICATIONS POWER REQUIREMENTS

IN-USE CONDITIONS POWER SUPPLY

EXAM ROOM CONTROL ROOM TECHNICAL ROOM FREQUENCIES

Min Recommended Max Min Recommended Max Min Recommended Max

Temperature MAXIMUM INPUT POWER (0.1 sec max) 150 kVA

15 °C 22 °C 32 °C 15 °C 22 °C 35 °C 20 °C 18 °C 25 °C

CONTINUOUS (AVERAGE) POWER 60 kVA

Temperature gradient

RH (1) non condensing 30% to 70% 30% to 75% 30% to 75% MAXIMUM LINE RESISTANCE

PER 2 PHASES WIRES

Humidity gradient 10%/h 10%/h 10%/h

Max Max Max

Heat dissipation

2.12 kW 0.25 kW 13.48 kW · An EMI filter, provided by GE, is required in front of the PDB.

· Neutral is mandatory for UPS control.

· TNC neutral point connection must not be used.

STORAGE CONDITIONS 20 kVA FLUORO UPS IN INDEPENDENT ROOM · In case of IT or delta configuration without neutral, an isolation transformer is needed (supplied by customer)

Temperature +10 °C to +40 °C Temperature +20 °C to +25 °C · Three-phase, 5 conductors (3 phase conductors, 1 neutral and 1 protective earth conductor)

RH (1) non condensing 10% to 70% Temperature gradient · Power supply should come into a power distribution box (PDB) containing the protective units and controls.

Material should not be stored for more than 90 days. RH (1) non condensing 30% to 75% · The section of the supply cable should be calculated in accordance with its length and the maximum line

(1) Relative humidity Humidity gradient 10%/h

resistance per 2 phases.

Air renewal 625 m³/h

AIR RENEWAL

According to local standards.

NOTE

In case of using air conditioning systems that have a risk of water leakage it is recommended not to install it above electric equipment or to

take measures to protect the equipment from dropping water.

DELIVERY DISCLAIMER

THE CUSTOMER/CONTRACTOR SHOULD: This drawing is a preliminary drawing. Site conditions and/or equipment configuration may have a significant

impact on room layout and site preparation. Final study must be done before installation of the GE equipment. GE

· Provide an area adjacent to the installation site for delivery and unloading of the GE equipment. cannot accept any responsibility for errors due to lack of information.

· Ensure that the dimensions of all doors, corridors, ceiling heights are sufficient to accommodate the

movement of GE equipment from the delivery area into the definitive installation room. The room dimensions used to create the equipment layout may originate from a previous layout and may not be

· Ensure that access routes for equipment will accommodate the weights of the equipment and any accurate as they may not have been verified on site. GE cannot take any responsibility for errors due to lack of

transportation, lifting and rigging equipment. information.

· Ensure that all necessary arrangements for stopping and unloading on public or private property not

belonging to the customer have been made. It is the responsibility of the customer to prepare the site in accordance with the specifications stated in the final

drawings. These drawings are not to be used for actual construction purposes. The company cannot take

responsibility for any damage resulting therefrom.

The customer must ensure the floor strength is sufficient to support the fixings as required. A qualified structural

engineer must be consulted and all work carried out according to his specifications.

Suitable radiological protection must be determined by a qualified radiological physicist in conformation with local

regulations. GE does not take responsibility for the specification or provision of radio-protection.

DIMENSIONS OF DELIVERY WITH DOLLY TRANSPORT EQUIPMENT

THE UNDERSIGNED, HEREBY CERTIFIES THAT I HAVE READ AND APPROVED THE PLANS IN THIS DOCUMENT.

EQUIPMENT DIMENSIONS WEIGHT

LENGTH 2790 mm DATE NAME SIGNATURE

GANTRY WIDTH 1160 mm 1060 kg

HEIGHT 1950 mm

RSMK GADING SERPONG - PROPOSAL LAYOUT OPT 1.DWG Rev: A Rev Date: 24/SEP/2018 Delivery - Disclaimer 02/02

You might also like

- The "Rail Sign": An Ultrasound Finding in Placenta Accreta Spectrum Indicating Deep Villous Invasion and Adverse OutcomesDocument17 pagesThe "Rail Sign": An Ultrasound Finding in Placenta Accreta Spectrum Indicating Deep Villous Invasion and Adverse OutcomesJoseLuisNo ratings yet

- Boysen-Osborn (2018) PDFDocument11 pagesBoysen-Osborn (2018) PDFBryan TorresNo ratings yet

- NationDocument88 pagesNationJustin Luu0% (1)

- Adding and Subtracting Polynomials LessonDocument4 pagesAdding and Subtracting Polynomials Lessonapi-249037964100% (4)

- Benefits of Assessing The Solids Production Risk in A North Sea ReservoirDocument9 pagesBenefits of Assessing The Solids Production Risk in A North Sea Reservoirredup25No ratings yet

- Tdm850 '99 Wiring Diagram: Color CodeDocument1 pageTdm850 '99 Wiring Diagram: Color CodeХаджи Христо БуюклиевNo ratings yet

- Bahan Evidance Based Dalam Keperawatan PDFDocument10 pagesBahan Evidance Based Dalam Keperawatan PDFTati Margareta MargaretaNo ratings yet

- An Action Error of Nursing Procedures: Types and Cause Factor Ners Profession StudentDocument10 pagesAn Action Error of Nursing Procedures: Types and Cause Factor Ners Profession StudentJurnal Ners UNAIRNo ratings yet

- Teknik Pencarian Literatur Dan Analisis Jurnal KeperawatanDocument30 pagesTeknik Pencarian Literatur Dan Analisis Jurnal Keperawatanmademerlin92100% (1)

- Undangan Walimatul Indah NDocument1 pageUndangan Walimatul Indah NM Kholid MawardiNo ratings yet

- Sistematic ReviewDocument7 pagesSistematic ReviewArief RafsanjaniNo ratings yet

- JurnalKGD2 PDFDocument11 pagesJurnalKGD2 PDFNurrul HudaaNo ratings yet

- Perbedaan Penanganan Antara Laparoskopi Vs Open Repair Pada Perforasi GasterDocument7 pagesPerbedaan Penanganan Antara Laparoskopi Vs Open Repair Pada Perforasi GasterAfiani JannahNo ratings yet

- Complicated AppendicitisDocument4 pagesComplicated AppendicitisMedardo ApoloNo ratings yet

- Vascular Acces in Hemodyalisi - DR DjoniDocument50 pagesVascular Acces in Hemodyalisi - DR DjoniMohamad ZulfikarNo ratings yet

- Stock ProdeviceDocument4 pagesStock ProdeviceresaNo ratings yet

- Airway EquipmentDocument47 pagesAirway Equipmentyoustiana dwi rusitaNo ratings yet

- Loopography Examination For Colon Cancer 7c394e77Document11 pagesLoopography Examination For Colon Cancer 7c394e77N. Camelya FirdausNo ratings yet

- Kebijakan Perawat Dalam Penerapan Keselamatan Pasien Di Rumah SakitDocument6 pagesKebijakan Perawat Dalam Penerapan Keselamatan Pasien Di Rumah SakitbintangNo ratings yet

- Daftar Singkatan SMF JAntungDocument5 pagesDaftar Singkatan SMF JAntungBobby RahmantoNo ratings yet

- AI PKL 1 - Calcaneus - Put AyDocument17 pagesAI PKL 1 - Calcaneus - Put AyYusuf Erlangga AWNo ratings yet

- Inventaris 2022 AGUSTUSDocument44 pagesInventaris 2022 AGUSTUSYuni Syalawiyah IINo ratings yet

- Model Manajemen StrategikDocument17 pagesModel Manajemen Strategikwaode alfianiNo ratings yet

- Analisis Efisiensi Celah Shutter Kolimator Tabung Sinar X Di Tiga Instalasi Radiologi Lahan PKL Prodi D3 Radiologi Unisa YogyakartaDocument7 pagesAnalisis Efisiensi Celah Shutter Kolimator Tabung Sinar X Di Tiga Instalasi Radiologi Lahan PKL Prodi D3 Radiologi Unisa YogyakartaNoveliaNo ratings yet

- Alur Pelayanan Kamar OperasiDocument1 pageAlur Pelayanan Kamar Operasifemi suryanti100% (1)

- Spesifikasi PHILIPS Ultrasound System EPIQ 5 WHC BasicDocument2 pagesSpesifikasi PHILIPS Ultrasound System EPIQ 5 WHC BasichsNo ratings yet

- REVISI 1st Announcement Book 27th ASMIHA 2018 - 12des2017Document21 pagesREVISI 1st Announcement Book 27th ASMIHA 2018 - 12des2017Jimmy Oi SantosoNo ratings yet

- Alat Dan Instrumen Di Ruang CathlabDocument27 pagesAlat Dan Instrumen Di Ruang CathlabAkram BatjoNo ratings yet

- Anesthesia Cosmetic SurgeryDocument7 pagesAnesthesia Cosmetic SurgerySergio ArbelaezNo ratings yet

- Manajemen Stratejik (Umar Said)Document70 pagesManajemen Stratejik (Umar Said)Donny Rahman KhalikNo ratings yet

- Biodata Parestesi Juli 2011 Edit IpoDocument56 pagesBiodata Parestesi Juli 2011 Edit Iporahmat feryadiNo ratings yet

- MATERI EWS PerbaikanDocument24 pagesMATERI EWS PerbaikanagusNo ratings yet

- Clinical Pathways RSWSDocument93 pagesClinical Pathways RSWSHeri JauhariNo ratings yet

- Newer Airway Devices PDFDocument74 pagesNewer Airway Devices PDFDharmesh GandhiNo ratings yet

- Ai Pengujian Lead ApronDocument8 pagesAi Pengujian Lead Apronwildan sanjayaNo ratings yet

- Kebutuhan Alat Alat AnestesiDocument5 pagesKebutuhan Alat Alat AnestesiidrisNo ratings yet

- Proposal Kegiatan Rumah Sakit Umum Jend.A.Yani MetroDocument3 pagesProposal Kegiatan Rumah Sakit Umum Jend.A.Yani MetroIvana Belinda PanggabeanNo ratings yet

- Informed ConsentDocument19 pagesInformed ConsentMuhammad Ibnu Widyanto BasriNo ratings yet

- Announcement IndoanesthesiaDocument24 pagesAnnouncement IndoanesthesiaAndrian100% (1)

- Jurnal AnastesiDocument10 pagesJurnal AnastesiAnonymous m07Ogz0rNo ratings yet

- Prone Positioning Under AnesthesiaDocument32 pagesProne Positioning Under Anesthesiabuddy9568100% (1)

- Angiografi Femoralis-1Document24 pagesAngiografi Femoralis-1Sepahit Kopi Hitam100% (1)

- Contoh Denah Ruangan PanoramicDocument2 pagesContoh Denah Ruangan PanoramicBagas SanjayaNo ratings yet

- Supervisi Berjenjang Di Era Pandemi Covid-19 Dalam Manajemen KeperawatanDocument10 pagesSupervisi Berjenjang Di Era Pandemi Covid-19 Dalam Manajemen Keperawatanfebrian rahmatNo ratings yet

- Template StaseDocument12 pagesTemplate StasefikhryNo ratings yet

- Daftar Harga Airway PT. Surgika 2017Document16 pagesDaftar Harga Airway PT. Surgika 2017Syaofi SofiNo ratings yet

- Final 2nd Announcement Konas Perdatin Perdici 2019 - WebsiteDocument67 pagesFinal 2nd Announcement Konas Perdatin Perdici 2019 - WebsiteWirjapratama PutraNo ratings yet

- CV Pembicara SeminarDocument77 pagesCV Pembicara SeminarMunawwar AweNo ratings yet

- E PosterDocument1 pageE PosterIlham AjiNo ratings yet

- Ozid Iv (Omeprazole) : Cedocard Iv (Isosorbid Dinitrat)Document15 pagesOzid Iv (Omeprazole) : Cedocard Iv (Isosorbid Dinitrat)Galih Aryo UtomoNo ratings yet

- Teori & Model Keperawatan Dan Penerapan Dalam Asuhan KeperawatanDocument81 pagesTeori & Model Keperawatan Dan Penerapan Dalam Asuhan Keperawatanannis fathiaNo ratings yet

- Surveilans Health Care Associated Infections: PersiDocument49 pagesSurveilans Health Care Associated Infections: Persifebri12No ratings yet

- Konas Perdatin 2019Document66 pagesKonas Perdatin 2019Akreditasi RSPC19No ratings yet

- Dmergency in Cardiology Part II-dr - Erika Maharani, Sp. JP (K) (2019)Document44 pagesDmergency in Cardiology Part II-dr - Erika Maharani, Sp. JP (K) (2019)lia ancillaNo ratings yet

- Comparing SPIR and SPAIR Fat Suppression Techniques in Magnetic Resonance Imaging (MRI) of Wrist JointDocument6 pagesComparing SPIR and SPAIR Fat Suppression Techniques in Magnetic Resonance Imaging (MRI) of Wrist JointRini IndratiNo ratings yet

- Persiapan Pasien Petugas N Instrumen Cath LabDocument20 pagesPersiapan Pasien Petugas N Instrumen Cath LabAgus SupriyadiNo ratings yet

- NeurointervensiDocument58 pagesNeurointervensiarief nugrohoNo ratings yet

- MRI Protokol Review Adi WS QCDocument150 pagesMRI Protokol Review Adi WS QChadiNo ratings yet

- Post-Operative Care, DSTC Online, Jun.2021Document38 pagesPost-Operative Care, DSTC Online, Jun.2021tepat rshsNo ratings yet

- 2juni PPT JOURNAL READING AnestesiDocument25 pages2juni PPT JOURNAL READING AnestesiYudha KhusniaNo ratings yet

- Dual Source CT Imaging PDFDocument275 pagesDual Source CT Imaging PDFAnisa SetiawatiNo ratings yet

- 1 Introduction To Mechvent Final PERDATINDocument29 pages1 Introduction To Mechvent Final PERDATINFriss TellaNo ratings yet

- XRAY RoomDocument1 pageXRAY RoomSehad KadiriNo ratings yet

- 204 Parts Manual 1999Document162 pages204 Parts Manual 1999Ильдар АхмеровNo ratings yet

- Brosur Kowa KT980Document2 pagesBrosur Kowa KT980Adit IrmaNo ratings yet

- Jadwal MumetDocument15 pagesJadwal MumetAdit IrmaNo ratings yet

- MANAJEMEN Vs MARKETINGDocument19 pagesMANAJEMEN Vs MARKETINGAdit IrmaNo ratings yet

- CPPT PDFDocument1 pageCPPT PDFAdit IrmaNo ratings yet

- Top-Up Degrees - Entry To Year 3Document14 pagesTop-Up Degrees - Entry To Year 3poudelnNo ratings yet

- Clinical ChemistryDocument10 pagesClinical ChemistryChristina AtefNo ratings yet

- Effective Learning StrategiesDocument5 pagesEffective Learning StrategiesRossy Milena JarabaNo ratings yet

- Methods of Teaching (Handouts)Document3 pagesMethods of Teaching (Handouts)Даша ГалкаNo ratings yet

- Acquistion of Jaguar Land Rover by Tata MotorsDocument9 pagesAcquistion of Jaguar Land Rover by Tata Motorsajinkya8400No ratings yet

- Ingenieria Basica y Detalle ISADocument50 pagesIngenieria Basica y Detalle ISAdalver17100% (1)

- Depth-First Search: COMP171 Fall 2005Document27 pagesDepth-First Search: COMP171 Fall 2005Praveen KumarNo ratings yet

- Topical Revision 2 AnswersDocument8 pagesTopical Revision 2 AnswersmichelleNo ratings yet

- Oracle Commerce and WebCenter Sites Integration GuidelinesDocument11 pagesOracle Commerce and WebCenter Sites Integration GuidelinesMatteo MartelloNo ratings yet

- Math 3FM3 Fall 2012 Course OutlineDocument2 pagesMath 3FM3 Fall 2012 Course OutlineAngela DaqustNo ratings yet

- Date - 1 - 9 - 2024 Time - 8 - 42 - 56 - 850Document1 pageDate - 1 - 9 - 2024 Time - 8 - 42 - 56 - 850ANKUSH 87205312No ratings yet

- Stay Where You Are' For 21 Days: Modi Puts India Under LockdownDocument8 pagesStay Where You Are' For 21 Days: Modi Puts India Under LockdownshivendrakumarNo ratings yet

- Pressure Safety Valve-Preliminary Sizing: Input DataDocument6 pagesPressure Safety Valve-Preliminary Sizing: Input DataPIDNo ratings yet

- CS Dec 2018-Jan 2019 PDFDocument78 pagesCS Dec 2018-Jan 2019 PDFPavanNo ratings yet

- LSS BB Body of KnowledgeDocument5 pagesLSS BB Body of KnowledgeVigneshNo ratings yet

- Somatoform Disorders in DSM SoalDocument6 pagesSomatoform Disorders in DSM SoalNurlita trianiNo ratings yet

- Telecom Resource Planning Tool - Brochure - Apr 09Document12 pagesTelecom Resource Planning Tool - Brochure - Apr 09brajesh_er1709No ratings yet

- Mansi Mba Sip Report PDFDocument85 pagesMansi Mba Sip Report PDFAmul PatelNo ratings yet

- The 7 Levels of Wealth ManualDocument215 pagesThe 7 Levels of Wealth Manualawakejoy89% (18)

- Iso 30400-2016Document12 pagesIso 30400-2016Shekhar100% (3)

- Riksbanken Nat UpplagaDocument528 pagesRiksbanken Nat UpplagaOscar Ubeda SegmarNo ratings yet

- Nature Is The World Around UsDocument3 pagesNature Is The World Around UsKarthikgeyan Munesveran100% (1)

- TLE ICT 10 - Quizalize Pre TestDocument8 pagesTLE ICT 10 - Quizalize Pre TestGioSanBuenaventuraNo ratings yet

- CRM # 4044662347 (Zpec # 5)Document1 pageCRM # 4044662347 (Zpec # 5)Mohammad MushtaqNo ratings yet

- MBA Programme: Wayamba University of Sri Lanka Faculty of Business Studies and FinanceDocument44 pagesMBA Programme: Wayamba University of Sri Lanka Faculty of Business Studies and FinanceTommba TommyNo ratings yet

- SchedulingDocument44 pagesSchedulingKonark PatelNo ratings yet