Professional Documents

Culture Documents

Model 11A17-001 Regulator: Rebuild Instructions

Model 11A17-001 Regulator: Rebuild Instructions

Uploaded by

luis tocoraCopyright:

Available Formats

You might also like

- AT520JK Users ManualDocument15 pagesAT520JK Users ManualgerezairNo ratings yet

- Manitou MTA8044 ServiceManualDocument474 pagesManitou MTA8044 ServiceManualmayadin yadin100% (1)

- Atlas Copco Service & Maintenance InstructionsDocument20 pagesAtlas Copco Service & Maintenance Instructionsaaron alicanoNo ratings yet

- PT - Toyota Astra Motor: Installation ManualDocument16 pagesPT - Toyota Astra Motor: Installation ManualArdi AgusmanNo ratings yet

- CAT 01 Hydraulic Fundamental Student GuideDocument106 pagesCAT 01 Hydraulic Fundamental Student Guidewarshipvn100% (6)

- Model L: Two-Stage Regulator Repair Kit InstructionsDocument14 pagesModel L: Two-Stage Regulator Repair Kit Instructionsbernardo angeles rojasNo ratings yet

- KN Regulator Repair Instructions: DisassemblyDocument2 pagesKN Regulator Repair Instructions: Disassemblybernardo angeles rojasNo ratings yet

- Ca55 MixerDocument7 pagesCa55 MixerramoNo ratings yet

- Series 1204: Orange Research IncDocument3 pagesSeries 1204: Orange Research IncWilson VelásquezNo ratings yet

- SB3 1 102Document6 pagesSB3 1 102jussmeeeNo ratings yet

- In07 05Document2 pagesIn07 05medjebeurmoustafaNo ratings yet

- Chute Assist Installation Instructions Rev1016 FinalDocument13 pagesChute Assist Installation Instructions Rev1016 FinalGabriel Castillo MuñozNo ratings yet

- Installation Manual: GPT-25, GPT-3, GPT-4 & GPT-5Document43 pagesInstallation Manual: GPT-25, GPT-3, GPT-4 & GPT-5ddufour.8419No ratings yet

- DC9735 Special Opt Instructions (Tmi)Document2 pagesDC9735 Special Opt Instructions (Tmi)plopezNo ratings yet

- Bombas CentrifugasDocument4 pagesBombas CentrifugasmasanmartinfNo ratings yet

- AFRA - Air Filter Regulator AssemblyDocument3 pagesAFRA - Air Filter Regulator AssemblyDavid GarciaNo ratings yet

- Model J Series Converter: Repair Kit InstructionsDocument12 pagesModel J Series Converter: Repair Kit InstructionsAcaJoksimovicNo ratings yet

- Nuflo Turbine Flow Meter Repair KitsDocument6 pagesNuflo Turbine Flow Meter Repair KitsJeremy JerezNo ratings yet

- p077 02 PDFDocument8 pagesp077 02 PDFJuan ZamoraNo ratings yet

- 6991 1252 01 - 1 - Gas SpringDocument18 pages6991 1252 01 - 1 - Gas SpringRaiza GabrielaNo ratings yet

- Operating Manual: Gilson Economy 8in Sieve Shakers SS-15 & SS-15DDocument13 pagesOperating Manual: Gilson Economy 8in Sieve Shakers SS-15 & SS-15DcamiloNo ratings yet

- 416-LFMCE SPMDocument12 pages416-LFMCE SPMLuis Manuel Perez AlzuruNo ratings yet

- Disassembly and Reassembly: 3.1. Precautions When Replacing PartsDocument15 pagesDisassembly and Reassembly: 3.1. Precautions When Replacing PartsLaboratorio BvtechNo ratings yet

- Agco Serie 800 PDFDocument24 pagesAgco Serie 800 PDFJohnny VargasNo ratings yet

- Descarga Riva VXR 18Document7 pagesDescarga Riva VXR 18lucasNo ratings yet

- 3.7 Meter ASC 208VAC Tedlar DP-7SSDocument36 pages3.7 Meter ASC 208VAC Tedlar DP-7SSpower kartoffelNo ratings yet

- SV Pilot Crosby Type-93Document22 pagesSV Pilot Crosby Type-93MarcelocrossNo ratings yet

- Motor M14 ControlDocument6 pagesMotor M14 ControlROBERSON ROMERÒNo ratings yet

- Tosaca-Manual Engelsk 01Document9 pagesTosaca-Manual Engelsk 01jajakaNo ratings yet

- MANUAL016Document8 pagesMANUAL016kim johnNo ratings yet

- Disconnecting Snap To Connect FittingsDocument4 pagesDisconnecting Snap To Connect Fittingsbenjir shuvoNo ratings yet

- Operations Manual 1S03 Sand Probe RelayDocument2 pagesOperations Manual 1S03 Sand Probe RelayantonioNo ratings yet

- Section 8005: Removal and Installation of The Attachement CylindersDocument14 pagesSection 8005: Removal and Installation of The Attachement CylindersJefferson PaixãoNo ratings yet

- GN128 Explosion Proof Piston - 0Document2 pagesGN128 Explosion Proof Piston - 0Luz Stella Calixto GomezNo ratings yet

- Krystal Clear Saltwater System Model CS8110: Important Safety RulesDocument27 pagesKrystal Clear Saltwater System Model CS8110: Important Safety RulesJordyn Ashley PhillipsNo ratings yet

- Removal PDFDocument5 pagesRemoval PDFkarlosNo ratings yet

- Didde175altra Install 240306 143150Document41 pagesDidde175altra Install 240306 143150Luis TeixeiraNo ratings yet

- CCP420 Clean and ClearDocument20 pagesCCP420 Clean and ClearHéctor RomeroNo ratings yet

- Valves S&S B Series 8-Inch Globe: Instruction ManualDocument12 pagesValves S&S B Series 8-Inch Globe: Instruction ManualpedroNo ratings yet

- Roto Neck Cleaner: Tool DataDocument17 pagesRoto Neck Cleaner: Tool Datahmayda riadNo ratings yet

- Disassembly SCX 4600 23Document31 pagesDisassembly SCX 4600 23Gavrilescu Razvan50% (2)

- Caterpillar Cat 320D L Excavator (Prefix A9F) Service Repair Manual (A9F00001 and Up)Document23 pagesCaterpillar Cat 320D L Excavator (Prefix A9F) Service Repair Manual (A9F00001 and Up)kfmuseddk0% (1)

- Valtek Pressure-Balanced Trim: General Instructions Disassembly and ReassemblyDocument4 pagesValtek Pressure-Balanced Trim: General Instructions Disassembly and ReassemblyEduardo Landa GonzalezNo ratings yet

- Installation Instruction & Owner'S Manual: 3-Stage Water Filtration SystemDocument20 pagesInstallation Instruction & Owner'S Manual: 3-Stage Water Filtration SystemMehmet GülenerNo ratings yet

- Kitz F14a IomDocument13 pagesKitz F14a IomNasr PooyaNo ratings yet

- Ppi 109Document5 pagesPpi 109Ricardo RicardoNo ratings yet

- Crestline Dampening Systems: Installation InstructionsDocument73 pagesCrestline Dampening Systems: Installation InstructionsSergey PhilippovNo ratings yet

- Mi 115880Document3 pagesMi 115880Varun S KumarNo ratings yet

- AIR-X Circuit Replacement InstructionsDocument9 pagesAIR-X Circuit Replacement InstructionsscabdNo ratings yet

- Automation PVT LTD.: Fugitive Emission: Installation, Operation, Maintenance & Safety ManualDocument11 pagesAutomation PVT LTD.: Fugitive Emission: Installation, Operation, Maintenance & Safety ManualDanielle JohnsonNo ratings yet

- Ispring Water Filter ManualDocument28 pagesIspring Water Filter ManualdthibodeNo ratings yet

- Stainless-Steel-Ball-Valves F262 Pentair Seat Seal ReplacementDocument4 pagesStainless-Steel-Ball-Valves F262 Pentair Seat Seal Replacementred patriotNo ratings yet

- PGA Valve: Installation and Operating Instructions Troubleshooting GuideDocument8 pagesPGA Valve: Installation and Operating Instructions Troubleshooting GuidehakimNo ratings yet

- 7" Casing Circulator Inflation Modules 700-CE-11B 700-CE-11C 11-CE-11ADocument14 pages7" Casing Circulator Inflation Modules 700-CE-11B 700-CE-11C 11-CE-11AubermonzonNo ratings yet

- Pwi IomDocument26 pagesPwi IomCyrus CerezoNo ratings yet

- SKEE BALL Classic: Installation and Operation Single Ball ReleaseDocument30 pagesSKEE BALL Classic: Installation and Operation Single Ball ReleaseTylerMidkiffNo ratings yet

- Imo-030en 05-11Document4 pagesImo-030en 05-11HASBUL AZIZI BIN MAHMUNNo ratings yet

- 3500 Retractable Corrosion Probe ManualDocument7 pages3500 Retractable Corrosion Probe ManualEdgar I RamirezNo ratings yet

- EFC ActuatorDocument4 pagesEFC ActuatorRonald BoocNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Yale Fault Codes DTC (1)Document4 pagesYale Fault Codes DTC (1)luis tocoraNo ratings yet

- Steering SystemDocument12 pagesSteering Systemluis tocoraNo ratings yet

- MASTILDocument16 pagesMASTILluis tocoraNo ratings yet

- Mantto DCDocument15 pagesMantto DCluis tocoraNo ratings yet

- Sm-575 C5Ooylso-200-225S-225L 25Os-25Ol-3Oos-3Ool-350Document705 pagesSm-575 C5Ooylso-200-225S-225L 25Os-25Ol-3Oos-3Ool-350luis tocoraNo ratings yet

- Service Manual: C15/18/20s D/L/G C20/25/30/35 D/L/G C15/18/20sC L/G C20/25/30/32C L/GDocument1,389 pagesService Manual: C15/18/20s D/L/G C20/25/30/35 D/L/G C15/18/20sC L/G C20/25/30/32C L/Gluis tocoraNo ratings yet

- WMT 210Document38 pagesWMT 210luis tocoraNo ratings yet

- Brake SystemDocument12 pagesBrake Systemluis tocoraNo ratings yet

- Tilt CylinderDocument7 pagesTilt Cylinderluis tocoraNo ratings yet

- E50fr FrameDocument11 pagesE50fr Frameluis tocoraNo ratings yet

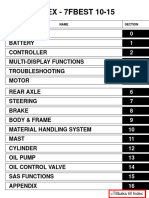

- 7fbest 10Document16 pages7fbest 10luis tocoraNo ratings yet

- Hydraulic SystemDocument16 pagesHydraulic Systemluis tocoraNo ratings yet

- Steering AxleDocument42 pagesSteering Axleluis tocoraNo ratings yet

- bbx50 SeriesDocument35 pagesbbx50 Seriesluis tocoraNo ratings yet

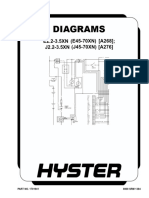

- DIAGRAMSDocument24 pagesDIAGRAMSluis tocoraNo ratings yet

- Hydraulic PumpDocument11 pagesHydraulic Pumpluis tocoraNo ratings yet

- DIAGRAMSDocument21 pagesDIAGRAMSluis tocora100% (1)

- Ejc 214Document250 pagesEjc 214luis tocoraNo ratings yet

- Description: Mast and ForkDocument17 pagesDescription: Mast and Forkluis tocoraNo ratings yet

- Repair Ac MotorsDocument42 pagesRepair Ac Motorsluis tocora100% (1)

- Ajustes ElectricsDocument9 pagesAjustes Electricsluis tocoraNo ratings yet

- Upright: Bussman Alphabetical Table of ContentsDocument26 pagesUpright: Bussman Alphabetical Table of Contentsluis tocoraNo ratings yet

- A1n1 MM en PDFDocument12 pagesA1n1 MM en PDFluis tocoraNo ratings yet

- Front Tire and Rear TireDocument6 pagesFront Tire and Rear Tireluis tocoraNo ratings yet

- A1n1 HD en PDFDocument62 pagesA1n1 HD en PDFluis tocoraNo ratings yet

- A1n1 Du en PDFDocument16 pagesA1n1 Du en PDFluis tocoraNo ratings yet

- Periodic MaintenanceDocument40 pagesPeriodic Maintenanceluis tocora100% (1)

- Telescopic Handler Parts Manual: Catalog 50960027 Rev. BDocument166 pagesTelescopic Handler Parts Manual: Catalog 50960027 Rev. Bluis tocoraNo ratings yet

- A1n1 BF en PDFDocument10 pagesA1n1 BF en PDFluis tocoraNo ratings yet

- 2020-10-20 Quotation ListDocument4 pages2020-10-20 Quotation Listluis tocoraNo ratings yet

- MM 212 Materials Evaluation Techniques Fall Semester 2020, FMCE, GIKIDocument39 pagesMM 212 Materials Evaluation Techniques Fall Semester 2020, FMCE, GIKIElbert VonVerimNo ratings yet

- PDE-EQP-G000-DZ-00030-0003 P000 - R03 - Edition - 0 - 3011T001Document1 pagePDE-EQP-G000-DZ-00030-0003 P000 - R03 - Edition - 0 - 3011T001Ionut FloricaNo ratings yet

- Engineering Practices Laboratory: by R.Nathan Assistant Professor Department of Mechanical EngineeringDocument13 pagesEngineering Practices Laboratory: by R.Nathan Assistant Professor Department of Mechanical Engineeringஎன் கருத்து100% (1)

- AP Physics Study GuideDocument96 pagesAP Physics Study GuideBenjamin GroffNo ratings yet

- Appendix A Ductwork 61294 - 29Document36 pagesAppendix A Ductwork 61294 - 29rastogishivendra100% (9)

- Simucube 2 Quick Release GuideDocument7 pagesSimucube 2 Quick Release Guideemyrs12No ratings yet

- Basic HydraulicsDocument121 pagesBasic HydraulicsGunaNo ratings yet

- Brochures - i-FX2-W-G04 ( - H) 0402 - 1242Document12 pagesBrochures - i-FX2-W-G04 ( - H) 0402 - 1242Qui documNo ratings yet

- Directional Control Valves SB 12 LSDocument71 pagesDirectional Control Valves SB 12 LSnoid1nl8264No ratings yet

- ME2113-1 Lab Report DEFLECTION AND BENDING STRESSES IN BEAMSDocument8 pagesME2113-1 Lab Report DEFLECTION AND BENDING STRESSES IN BEAMSsteven mcqueen69% (16)

- Approved For Construction: Only Areas Encircled in Red To Be Actioned (Points 5, 6, 7 &8)Document21 pagesApproved For Construction: Only Areas Encircled in Red To Be Actioned (Points 5, 6, 7 &8)BeantickNo ratings yet

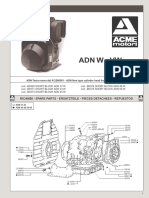

- Acme AdnDocument21 pagesAcme AdnbaiardimircoNo ratings yet

- Som 1Document8 pagesSom 1Sachin SainiNo ratings yet

- Bender Calculation PDFDocument24 pagesBender Calculation PDFgio_flores_4No ratings yet

- Automation Chapter 6 PDFDocument240 pagesAutomation Chapter 6 PDFRaed Al Ma'aniNo ratings yet

- ACI-373r 97Document26 pagesACI-373r 97Pablo Augusto Krahl100% (1)

- USSC - SGI-2015-ring Loc Technical Manual PDFDocument73 pagesUSSC - SGI-2015-ring Loc Technical Manual PDFAzad pravesh khanNo ratings yet

- Hsslive Xi Physics FY 224Document16 pagesHsslive Xi Physics FY 224Renjith Raveendran PillaiNo ratings yet

- Shell Forces/Stresses Form: Load Case/ Load Combination / Modal CaseDocument5 pagesShell Forces/Stresses Form: Load Case/ Load Combination / Modal CasesovannchhoemNo ratings yet

- Simple Stresses ProblemsDocument2 pagesSimple Stresses ProblemsAbreo Dan Vincent AlmineNo ratings yet

- Development of Beam EquationsDocument61 pagesDevelopment of Beam Equations4091 Varun SharmaNo ratings yet

- Automotive TestingDocument4 pagesAutomotive Testingtahera aqeelNo ratings yet

- b6xg1ms Type Ball Valve ManifoldDocument2 pagesb6xg1ms Type Ball Valve ManifoldRoo FaNo ratings yet

- Flanges and Pipe Fitting ManufacturerDocument12 pagesFlanges and Pipe Fitting Manufacturer9823458877No ratings yet

- Energy Use Characteristics of Variable Primary FloDocument9 pagesEnergy Use Characteristics of Variable Primary FloThanhNo ratings yet

- Varela (2011) - Control of Vibration Induce by People Walking On Large Span Composite Floor Decks PDFDocument10 pagesVarela (2011) - Control of Vibration Induce by People Walking On Large Span Composite Floor Decks PDFJosé Francisco AnunciaçãoNo ratings yet

- Design of Tank and Tubes - TransformersDocument6 pagesDesign of Tank and Tubes - TransformersAJAY KOSHY PS 18-20No ratings yet

- FLC Marine Catalog enDocument31 pagesFLC Marine Catalog enOfelia DiazNo ratings yet

Model 11A17-001 Regulator: Rebuild Instructions

Model 11A17-001 Regulator: Rebuild Instructions

Uploaded by

luis tocoraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Model 11A17-001 Regulator: Rebuild Instructions

Model 11A17-001 Regulator: Rebuild Instructions

Uploaded by

luis tocoraCopyright:

Available Formats

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

MODEL 11A17-001 REGULATOR

REBUILD INSTRUCTIONS

Important: Any maintenance, service or repair

should be performed by trained and experienced

service technicians. Proper tools and equipment

should be used to prevent injury to the servicing

technician, property or system components. Service

repairs should always be performed in a safe

environment and the technician should always wear

protective clothing to prevent injury.

The IMPCO PPI-126 repair kit instructions will

provide the technician information to successfully

repair the model 11A17-001. The kit may be used

to repair the discontinued 11A17 and 11A27 model

regulators. Always inspect the major casting pieces

for damage, corrosion or cracks before attempting a

service repair. Be sure the repair kit part number

you are using is correct for the regulator being

serviced.

11A17-001 Regulator

REPAIR KIT

PART # DESCRIPTION

R11-27 Repair Kit, 11A17/11A27 Major

Do not use Teflon tape to seal any fuel fittings

used to carry fuel in the fuel system. Failure to

follow this warning may cause the regulator to

leak internally, that may cause serious injury

and/or property damage.

March, 2015 IMPCO Technologies Inc. PPI-126 REV. C

3030 South Susan St. Page 1 of 12

Santa Ana, CA 92704

www.impcotechnologies.com

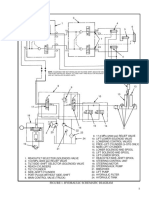

ITEM # DESCRIPTION QTY

1* Screw, Cover 2

2 Cover 1

3* Diaphragm Assy 1

4* Retainer 1

5 Plate 1

6 Body 1

7* Valve Stem 1

8* Valve Guide 1

9* Spring, Valve 1

10* O-ring, Plug Seal 1

11 Plug 1

Not

O-ring, 2.36" ID (11A27 Only) 1

Shown*

*Included in Repair Kit P/N R11-27

PPI-126 REV. C IMPCO Technologies Inc March, 2015

3030 South Susan St. Page 2 of 12

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

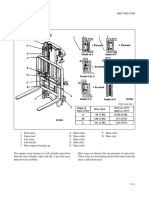

1. Remove Screws (1) securing the Cover (2).

2. Remove Cover (2) and Diaphragm Assembly

(3).

3. Carefully remove Retainer (4) while not

damaging the Body (6), Retainer (4) or Plate (5).

Once the Retainer is removed, also remove the

Plate (5).

March, 2015 IMPCO Technologies Inc. PPI-126 REV. C

3030 South Susan St. Page 3 of 12

Santa Ana, CA 92704

www.impcotechnologies.com

4. Remove the outlet plug opposite the inlet port.

5. Insert any spare 1/4” NPT fittings into ports in

the regulator body.on opposite sides (180

degrees from each other)

6. Place Regulator upside down in the jaws of a

vise and turn counter clockwise until the fittings

are up against the jaws. Note that the fittings

are necessary to prevent the cylindrical regulator

from turning inside the jaws.

NOTE: The use of the outlet plugs or no spare

fittings may result in heavy scoring of the

regulator body from the vise jaws.

WARNING: Do not over tighten vise. Excessive

tightening will damage the regulator body.

PPI-126 REV. C IMPCO Technologies Inc March, 2015

3030 South Susan St. Page 4 of 12

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

7. Using a 1 3/8” socket, remove the Plug (11).

NOTE: The use of an open end or adjustable

wrench will likely round off and damage the hex

end of the brass Plug (11). Always use a socket

or box end wrench to remove the bolt.

8. Remove the Valve Stem (7), Spring (9) and

Valve Guide (8) assembly from the Regulator

Body (6).

9. Inspect the regulator Body (6) for scoring or

damage. Inspect all of the parts removed and

those in the repair kit for dirt, debris or damage.

Clean as necessary.

March, 2015 IMPCO Technologies Inc. PPI-126 REV. C

3030 South Susan St. Page 5 of 12

Santa Ana, CA 92704

www.impcotechnologies.com

10. Place Spring (9) on Valve Guide (8).

11. Place Valve Stem (7) on Valve Guide (8).

12. Insert Valve Stem (7), Spring (9) and Valve

Guide (8) into Regulator Body (6).

PPI-126 REV. C IMPCO Technologies Inc March, 2015

3030 South Susan St. Page 6 of 12

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

13. Ensure the Spring (9), Valve Guide (8) and Stem

(7) assembly is properly seated in the body of

the Regulator.

14. Apply lubricant to O-ring (10).

15. Place O-ring (1) on Plug (11).

March, 2015 IMPCO Technologies Inc. PPI-126 REV. C

3030 South Susan St. Page 7 of 12

Santa Ana, CA 92704

www.impcotechnologies.com

16. Loosen vise and turn the Regulator counter

clockwise until the fittings are up against the

jaws. Insert Plug (11) into Regulator Body (6)

and torque to 40 ft lbs.

WARNING: Do not over tighten vise. Excessive

tightening will damage the regulator body.

17. Rotate Plate (5) so that the opening is centered

over the outlet port directly opposite (180

degrees) from the inlet port.

18. Place the Retainer (4) ring over the Plate (5) and

press into place using the 1 3/8” socket

PPI-126 REV. C IMPCO Technologies Inc March, 2015

3030 South Susan St. Page 8 of 12

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

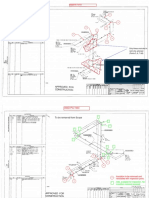

19. Turn over and place the diaphragm assembly on

top of the Regulator and align holes.

20. Insert one Screw (1) and turn a few times, but

do not tighten. Insert another Screw on the

opposite side and turn, but do not tighten.

21. Insert the remaining screws and lightly finger

tighten each, then in a criss-cross pattern,

torque each to 16-24 in.lbs.

March, 2015 IMPCO Technologies Inc. PPI-126 REV. C

3030 South Susan St. Page 9 of 12

Santa Ana, CA 92704

www.impcotechnologies.com

22. Place pipe thread compound on the port plug

and insert into the port outlet. Torque until finger

tight, plus 1-2 turns.

CAUTION: Use only pipe thread compound

compatible with LPG. Do not use Telfon tape.

23. Insert a male quick release air hose fitting into

the 1/4” NPT fuel inlet port then fit a hose barb

into the fuel outlet. Connect a hose to the barb

and 15 psi pressure gauge. Secure hose fittings

using hose clamps.

24. Connect to shop air pressure (approximately 90

psi). The outlet pressure reading should be 9-12

psi. Any pressure readings below or above 9-12

psi indicates the Regulator or rebuild has failed

and must be replaced.

PPI-126 REV. C IMPCO Technologies Inc March, 2015

3030 South Susan St. Page 10 of 12

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

25. Apply a commercial liquid leak test solution to all

seals, fittings and the atmospheric vent (the

small hole on top of cover) to ensure there are

no leaks. If leaks are found, repair or replace

the Regulator.

26. If no leaks are detected, the Regulator may be

returned to service.

March, 2015 IMPCO Technologies Inc. PPI-126 REV. C

3030 South Susan St. Page 11 of 12

Santa Ana, CA 92704

www.impcotechnologies.com

WARNING:

IMPROPER INSTALLATION OR USE OF THIS PRODUCT MAY CAUSE

SERIOUS INJURY AND/OR PROPERTY DAMAGE.

SERVICE TECHNICIANS AND USERS SHOULD CAREFULLY READ AND ABIDE BY THE PROVISIONS SET

FORTH IN NATIONAL FIRE PROTECTION ASSOCIATION PAMPHLET #37 FOR STATIONARY ENGINES, #52

FOR CNG VEHICULAR FUEL SYSTEMS OR #58 FOR LPG SYSTEMS.

INSTALLERS LPG INSTALLATIONS IN THE UNITED STATES MUST BE DONE IN ACCORDANCE WITH

FEDERAL STATE AND LOCAL LAWS AND NATIONAL FIRE PROTECTION ASSOCIATION PAMPHLET #58,

STANDARD FOR STORAGE AND HANDLING OF LIQUEFIED PETROLEUM GASES, TO THE EXTENT THESE

STANDARDS ARE NOT IN VIOLATION OF FEDERAL, STATE OR LOCAL LAW.

COUNTRIES OUTSIDE OF USA REFER TO THE GOVERNING AGENCIES OVERSEEING CNG AND

PROPANE APPLICATIONS.

CNG INSTALLATIONS IN THE UNITED STATES MUST BE DONE IN ACCORDANCE WITH FEDERAL, STATE

AND LOCAL LAW AND NATIONAL FIRE PROTECTION ASSOCIATION PAMPHLET #52, COMPRESSED

NATURAL GAS (CNG) VEHICULAR FUEL SYSTEMS, TO THE EXTENT THESE STANDARDS ARE NOT IN

VIOLATION OF FEDERAL, STATE OR LOCAL LAW.

LPG AND/OR NATURAL GAS INSTALLATIONS ON STATIONARY ENGINES MUST BE DONE IN

ACCORDANCE WITH FEDERAL, STATE AND LOCAL LAW AND NATIONAL FIRE PROTECTION

ASSOCIATION PAMPHLET #37, STATIONARY COMBUSTION ENGINES AND GAS TURBINE ENGINES, TO

THE EXTENT THESE STANDARDS ARE NOT IN VIOLATION WITH FEDERAL, STATE OR LOCAL LAW.

FAILURE TO ABIDE BY THE ABOVE WILL VOID ANY IMPCO WARRANTY ON THE PRODUCTS AND MAY

CAUSE SERIES INJURY OR PROPERTY DAMAGE.

SERVICE TECHNICIANS DUE TO THE INHERENT DANGER OF GASEOUS FUELS, IMPCO PRODUCTS

SHOULD NOT BE INSTALLED OR USED BY PERSONS NOT KNOWLEDGEABLE OF THE HAZARDS

ASSOCIATED WITH THE USE OF GASEOUS FUELS. ANY MAINTENANCE, SERVICE OR REPAIR SHOULD

BE PERFORMED BY TRAINED AND EXPERIENCED SERVICE TECHNICIANS.

PROPER TOOLS AND EQUIPMENT PROPER TOOLS AND EQUIPMENT SHOULD BE USED TO PREVENT

INJURY TO THE SERVICING TECHNICIAN, PROPERTY OR SYSTEM COMPONENTS. SERVICE REPAIRS

SHOULD ALWAYS BE PERFORMED IN A SAFE ENVIRONMENT AND THE TECHNICIAN SHOULD ALWAYS

WEAR PROTECTIVE CLOTHING TO PREVENT INJURY.

INSPECT BEFORE USE ALWAYS INSPECT THE MAJOR CASTING PIECES FOR DAMAGE, CORROSION OR

CRACKS BEFORE ATTEMPTING A SERVICE REPAIR. BE SURE THE REPAIR KIT PART NUMBER YOU ARE

USING IS CORRECT FOR THE REGULATOR BEING SERVICED.

NO TEFLON TAPE DO NOT USE TEFLON TAPE TO SEAL ANY FUEL FITTINGS. FAILURE TO FOLLOW THIS

WARNING MAY CAUSE THE REGULATOR TO LEAK INTERNALLY, POSSIBLY RESULTING IN SERIOUS

INJURY, DEATH AND/OR PROPERTY DAMAGE AND MAY VOID ANY WARRANTY COVERAGE.

.

PPI-126 REV. C IMPCO Technologies Inc March, 2015

3030 South Susan St. Page 12 of 12

Santa Ana, CA 92704

www.impcotechnologies.com

You might also like

- AT520JK Users ManualDocument15 pagesAT520JK Users ManualgerezairNo ratings yet

- Manitou MTA8044 ServiceManualDocument474 pagesManitou MTA8044 ServiceManualmayadin yadin100% (1)

- Atlas Copco Service & Maintenance InstructionsDocument20 pagesAtlas Copco Service & Maintenance Instructionsaaron alicanoNo ratings yet

- PT - Toyota Astra Motor: Installation ManualDocument16 pagesPT - Toyota Astra Motor: Installation ManualArdi AgusmanNo ratings yet

- CAT 01 Hydraulic Fundamental Student GuideDocument106 pagesCAT 01 Hydraulic Fundamental Student Guidewarshipvn100% (6)

- Model L: Two-Stage Regulator Repair Kit InstructionsDocument14 pagesModel L: Two-Stage Regulator Repair Kit Instructionsbernardo angeles rojasNo ratings yet

- KN Regulator Repair Instructions: DisassemblyDocument2 pagesKN Regulator Repair Instructions: Disassemblybernardo angeles rojasNo ratings yet

- Ca55 MixerDocument7 pagesCa55 MixerramoNo ratings yet

- Series 1204: Orange Research IncDocument3 pagesSeries 1204: Orange Research IncWilson VelásquezNo ratings yet

- SB3 1 102Document6 pagesSB3 1 102jussmeeeNo ratings yet

- In07 05Document2 pagesIn07 05medjebeurmoustafaNo ratings yet

- Chute Assist Installation Instructions Rev1016 FinalDocument13 pagesChute Assist Installation Instructions Rev1016 FinalGabriel Castillo MuñozNo ratings yet

- Installation Manual: GPT-25, GPT-3, GPT-4 & GPT-5Document43 pagesInstallation Manual: GPT-25, GPT-3, GPT-4 & GPT-5ddufour.8419No ratings yet

- DC9735 Special Opt Instructions (Tmi)Document2 pagesDC9735 Special Opt Instructions (Tmi)plopezNo ratings yet

- Bombas CentrifugasDocument4 pagesBombas CentrifugasmasanmartinfNo ratings yet

- AFRA - Air Filter Regulator AssemblyDocument3 pagesAFRA - Air Filter Regulator AssemblyDavid GarciaNo ratings yet

- Model J Series Converter: Repair Kit InstructionsDocument12 pagesModel J Series Converter: Repair Kit InstructionsAcaJoksimovicNo ratings yet

- Nuflo Turbine Flow Meter Repair KitsDocument6 pagesNuflo Turbine Flow Meter Repair KitsJeremy JerezNo ratings yet

- p077 02 PDFDocument8 pagesp077 02 PDFJuan ZamoraNo ratings yet

- 6991 1252 01 - 1 - Gas SpringDocument18 pages6991 1252 01 - 1 - Gas SpringRaiza GabrielaNo ratings yet

- Operating Manual: Gilson Economy 8in Sieve Shakers SS-15 & SS-15DDocument13 pagesOperating Manual: Gilson Economy 8in Sieve Shakers SS-15 & SS-15DcamiloNo ratings yet

- 416-LFMCE SPMDocument12 pages416-LFMCE SPMLuis Manuel Perez AlzuruNo ratings yet

- Disassembly and Reassembly: 3.1. Precautions When Replacing PartsDocument15 pagesDisassembly and Reassembly: 3.1. Precautions When Replacing PartsLaboratorio BvtechNo ratings yet

- Agco Serie 800 PDFDocument24 pagesAgco Serie 800 PDFJohnny VargasNo ratings yet

- Descarga Riva VXR 18Document7 pagesDescarga Riva VXR 18lucasNo ratings yet

- 3.7 Meter ASC 208VAC Tedlar DP-7SSDocument36 pages3.7 Meter ASC 208VAC Tedlar DP-7SSpower kartoffelNo ratings yet

- SV Pilot Crosby Type-93Document22 pagesSV Pilot Crosby Type-93MarcelocrossNo ratings yet

- Motor M14 ControlDocument6 pagesMotor M14 ControlROBERSON ROMERÒNo ratings yet

- Tosaca-Manual Engelsk 01Document9 pagesTosaca-Manual Engelsk 01jajakaNo ratings yet

- MANUAL016Document8 pagesMANUAL016kim johnNo ratings yet

- Disconnecting Snap To Connect FittingsDocument4 pagesDisconnecting Snap To Connect Fittingsbenjir shuvoNo ratings yet

- Operations Manual 1S03 Sand Probe RelayDocument2 pagesOperations Manual 1S03 Sand Probe RelayantonioNo ratings yet

- Section 8005: Removal and Installation of The Attachement CylindersDocument14 pagesSection 8005: Removal and Installation of The Attachement CylindersJefferson PaixãoNo ratings yet

- GN128 Explosion Proof Piston - 0Document2 pagesGN128 Explosion Proof Piston - 0Luz Stella Calixto GomezNo ratings yet

- Krystal Clear Saltwater System Model CS8110: Important Safety RulesDocument27 pagesKrystal Clear Saltwater System Model CS8110: Important Safety RulesJordyn Ashley PhillipsNo ratings yet

- Removal PDFDocument5 pagesRemoval PDFkarlosNo ratings yet

- Didde175altra Install 240306 143150Document41 pagesDidde175altra Install 240306 143150Luis TeixeiraNo ratings yet

- CCP420 Clean and ClearDocument20 pagesCCP420 Clean and ClearHéctor RomeroNo ratings yet

- Valves S&S B Series 8-Inch Globe: Instruction ManualDocument12 pagesValves S&S B Series 8-Inch Globe: Instruction ManualpedroNo ratings yet

- Roto Neck Cleaner: Tool DataDocument17 pagesRoto Neck Cleaner: Tool Datahmayda riadNo ratings yet

- Disassembly SCX 4600 23Document31 pagesDisassembly SCX 4600 23Gavrilescu Razvan50% (2)

- Caterpillar Cat 320D L Excavator (Prefix A9F) Service Repair Manual (A9F00001 and Up)Document23 pagesCaterpillar Cat 320D L Excavator (Prefix A9F) Service Repair Manual (A9F00001 and Up)kfmuseddk0% (1)

- Valtek Pressure-Balanced Trim: General Instructions Disassembly and ReassemblyDocument4 pagesValtek Pressure-Balanced Trim: General Instructions Disassembly and ReassemblyEduardo Landa GonzalezNo ratings yet

- Installation Instruction & Owner'S Manual: 3-Stage Water Filtration SystemDocument20 pagesInstallation Instruction & Owner'S Manual: 3-Stage Water Filtration SystemMehmet GülenerNo ratings yet

- Kitz F14a IomDocument13 pagesKitz F14a IomNasr PooyaNo ratings yet

- Ppi 109Document5 pagesPpi 109Ricardo RicardoNo ratings yet

- Crestline Dampening Systems: Installation InstructionsDocument73 pagesCrestline Dampening Systems: Installation InstructionsSergey PhilippovNo ratings yet

- Mi 115880Document3 pagesMi 115880Varun S KumarNo ratings yet

- AIR-X Circuit Replacement InstructionsDocument9 pagesAIR-X Circuit Replacement InstructionsscabdNo ratings yet

- Automation PVT LTD.: Fugitive Emission: Installation, Operation, Maintenance & Safety ManualDocument11 pagesAutomation PVT LTD.: Fugitive Emission: Installation, Operation, Maintenance & Safety ManualDanielle JohnsonNo ratings yet

- Ispring Water Filter ManualDocument28 pagesIspring Water Filter ManualdthibodeNo ratings yet

- Stainless-Steel-Ball-Valves F262 Pentair Seat Seal ReplacementDocument4 pagesStainless-Steel-Ball-Valves F262 Pentair Seat Seal Replacementred patriotNo ratings yet

- PGA Valve: Installation and Operating Instructions Troubleshooting GuideDocument8 pagesPGA Valve: Installation and Operating Instructions Troubleshooting GuidehakimNo ratings yet

- 7" Casing Circulator Inflation Modules 700-CE-11B 700-CE-11C 11-CE-11ADocument14 pages7" Casing Circulator Inflation Modules 700-CE-11B 700-CE-11C 11-CE-11AubermonzonNo ratings yet

- Pwi IomDocument26 pagesPwi IomCyrus CerezoNo ratings yet

- SKEE BALL Classic: Installation and Operation Single Ball ReleaseDocument30 pagesSKEE BALL Classic: Installation and Operation Single Ball ReleaseTylerMidkiffNo ratings yet

- Imo-030en 05-11Document4 pagesImo-030en 05-11HASBUL AZIZI BIN MAHMUNNo ratings yet

- 3500 Retractable Corrosion Probe ManualDocument7 pages3500 Retractable Corrosion Probe ManualEdgar I RamirezNo ratings yet

- EFC ActuatorDocument4 pagesEFC ActuatorRonald BoocNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Yale Fault Codes DTC (1)Document4 pagesYale Fault Codes DTC (1)luis tocoraNo ratings yet

- Steering SystemDocument12 pagesSteering Systemluis tocoraNo ratings yet

- MASTILDocument16 pagesMASTILluis tocoraNo ratings yet

- Mantto DCDocument15 pagesMantto DCluis tocoraNo ratings yet

- Sm-575 C5Ooylso-200-225S-225L 25Os-25Ol-3Oos-3Ool-350Document705 pagesSm-575 C5Ooylso-200-225S-225L 25Os-25Ol-3Oos-3Ool-350luis tocoraNo ratings yet

- Service Manual: C15/18/20s D/L/G C20/25/30/35 D/L/G C15/18/20sC L/G C20/25/30/32C L/GDocument1,389 pagesService Manual: C15/18/20s D/L/G C20/25/30/35 D/L/G C15/18/20sC L/G C20/25/30/32C L/Gluis tocoraNo ratings yet

- WMT 210Document38 pagesWMT 210luis tocoraNo ratings yet

- Brake SystemDocument12 pagesBrake Systemluis tocoraNo ratings yet

- Tilt CylinderDocument7 pagesTilt Cylinderluis tocoraNo ratings yet

- E50fr FrameDocument11 pagesE50fr Frameluis tocoraNo ratings yet

- 7fbest 10Document16 pages7fbest 10luis tocoraNo ratings yet

- Hydraulic SystemDocument16 pagesHydraulic Systemluis tocoraNo ratings yet

- Steering AxleDocument42 pagesSteering Axleluis tocoraNo ratings yet

- bbx50 SeriesDocument35 pagesbbx50 Seriesluis tocoraNo ratings yet

- DIAGRAMSDocument24 pagesDIAGRAMSluis tocoraNo ratings yet

- Hydraulic PumpDocument11 pagesHydraulic Pumpluis tocoraNo ratings yet

- DIAGRAMSDocument21 pagesDIAGRAMSluis tocora100% (1)

- Ejc 214Document250 pagesEjc 214luis tocoraNo ratings yet

- Description: Mast and ForkDocument17 pagesDescription: Mast and Forkluis tocoraNo ratings yet

- Repair Ac MotorsDocument42 pagesRepair Ac Motorsluis tocora100% (1)

- Ajustes ElectricsDocument9 pagesAjustes Electricsluis tocoraNo ratings yet

- Upright: Bussman Alphabetical Table of ContentsDocument26 pagesUpright: Bussman Alphabetical Table of Contentsluis tocoraNo ratings yet

- A1n1 MM en PDFDocument12 pagesA1n1 MM en PDFluis tocoraNo ratings yet

- Front Tire and Rear TireDocument6 pagesFront Tire and Rear Tireluis tocoraNo ratings yet

- A1n1 HD en PDFDocument62 pagesA1n1 HD en PDFluis tocoraNo ratings yet

- A1n1 Du en PDFDocument16 pagesA1n1 Du en PDFluis tocoraNo ratings yet

- Periodic MaintenanceDocument40 pagesPeriodic Maintenanceluis tocora100% (1)

- Telescopic Handler Parts Manual: Catalog 50960027 Rev. BDocument166 pagesTelescopic Handler Parts Manual: Catalog 50960027 Rev. Bluis tocoraNo ratings yet

- A1n1 BF en PDFDocument10 pagesA1n1 BF en PDFluis tocoraNo ratings yet

- 2020-10-20 Quotation ListDocument4 pages2020-10-20 Quotation Listluis tocoraNo ratings yet

- MM 212 Materials Evaluation Techniques Fall Semester 2020, FMCE, GIKIDocument39 pagesMM 212 Materials Evaluation Techniques Fall Semester 2020, FMCE, GIKIElbert VonVerimNo ratings yet

- PDE-EQP-G000-DZ-00030-0003 P000 - R03 - Edition - 0 - 3011T001Document1 pagePDE-EQP-G000-DZ-00030-0003 P000 - R03 - Edition - 0 - 3011T001Ionut FloricaNo ratings yet

- Engineering Practices Laboratory: by R.Nathan Assistant Professor Department of Mechanical EngineeringDocument13 pagesEngineering Practices Laboratory: by R.Nathan Assistant Professor Department of Mechanical Engineeringஎன் கருத்து100% (1)

- AP Physics Study GuideDocument96 pagesAP Physics Study GuideBenjamin GroffNo ratings yet

- Appendix A Ductwork 61294 - 29Document36 pagesAppendix A Ductwork 61294 - 29rastogishivendra100% (9)

- Simucube 2 Quick Release GuideDocument7 pagesSimucube 2 Quick Release Guideemyrs12No ratings yet

- Basic HydraulicsDocument121 pagesBasic HydraulicsGunaNo ratings yet

- Brochures - i-FX2-W-G04 ( - H) 0402 - 1242Document12 pagesBrochures - i-FX2-W-G04 ( - H) 0402 - 1242Qui documNo ratings yet

- Directional Control Valves SB 12 LSDocument71 pagesDirectional Control Valves SB 12 LSnoid1nl8264No ratings yet

- ME2113-1 Lab Report DEFLECTION AND BENDING STRESSES IN BEAMSDocument8 pagesME2113-1 Lab Report DEFLECTION AND BENDING STRESSES IN BEAMSsteven mcqueen69% (16)

- Approved For Construction: Only Areas Encircled in Red To Be Actioned (Points 5, 6, 7 &8)Document21 pagesApproved For Construction: Only Areas Encircled in Red To Be Actioned (Points 5, 6, 7 &8)BeantickNo ratings yet

- Acme AdnDocument21 pagesAcme AdnbaiardimircoNo ratings yet

- Som 1Document8 pagesSom 1Sachin SainiNo ratings yet

- Bender Calculation PDFDocument24 pagesBender Calculation PDFgio_flores_4No ratings yet

- Automation Chapter 6 PDFDocument240 pagesAutomation Chapter 6 PDFRaed Al Ma'aniNo ratings yet

- ACI-373r 97Document26 pagesACI-373r 97Pablo Augusto Krahl100% (1)

- USSC - SGI-2015-ring Loc Technical Manual PDFDocument73 pagesUSSC - SGI-2015-ring Loc Technical Manual PDFAzad pravesh khanNo ratings yet

- Hsslive Xi Physics FY 224Document16 pagesHsslive Xi Physics FY 224Renjith Raveendran PillaiNo ratings yet

- Shell Forces/Stresses Form: Load Case/ Load Combination / Modal CaseDocument5 pagesShell Forces/Stresses Form: Load Case/ Load Combination / Modal CasesovannchhoemNo ratings yet

- Simple Stresses ProblemsDocument2 pagesSimple Stresses ProblemsAbreo Dan Vincent AlmineNo ratings yet

- Development of Beam EquationsDocument61 pagesDevelopment of Beam Equations4091 Varun SharmaNo ratings yet

- Automotive TestingDocument4 pagesAutomotive Testingtahera aqeelNo ratings yet

- b6xg1ms Type Ball Valve ManifoldDocument2 pagesb6xg1ms Type Ball Valve ManifoldRoo FaNo ratings yet

- Flanges and Pipe Fitting ManufacturerDocument12 pagesFlanges and Pipe Fitting Manufacturer9823458877No ratings yet

- Energy Use Characteristics of Variable Primary FloDocument9 pagesEnergy Use Characteristics of Variable Primary FloThanhNo ratings yet

- Varela (2011) - Control of Vibration Induce by People Walking On Large Span Composite Floor Decks PDFDocument10 pagesVarela (2011) - Control of Vibration Induce by People Walking On Large Span Composite Floor Decks PDFJosé Francisco AnunciaçãoNo ratings yet

- Design of Tank and Tubes - TransformersDocument6 pagesDesign of Tank and Tubes - TransformersAJAY KOSHY PS 18-20No ratings yet

- FLC Marine Catalog enDocument31 pagesFLC Marine Catalog enOfelia DiazNo ratings yet