Professional Documents

Culture Documents

EJB, Style D Series Classified Enclosures IF 1444: Installation & Maintenance Information

EJB, Style D Series Classified Enclosures IF 1444: Installation & Maintenance Information

Uploaded by

gustav agudeloOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EJB, Style D Series Classified Enclosures IF 1444: Installation & Maintenance Information

EJB, Style D Series Classified Enclosures IF 1444: Installation & Maintenance Information

Uploaded by

gustav agudeloCopyright:

Available Formats

EJB, Style D Series

Classified Enclosures

Installation & Maintenance Information IF 1444

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE

APPLICATION

EJB Style D series explosion proof classified enclosures are used as EJB series classified enclosures ordered with suffix -ATEX meet the

classified enclosures, pull boxes or custom control panels in rigid conduit ATEX directive and are certified by PTB. EJB classified enclosures with

systems and with metal clad cable rated for hazardous locations. Third -ATEX suffix have the following classification: ( ) II 2 G D Ex d IIB +

party approvals (UL and CSA) allow for field addition of drilled and H2. ATEX certified boxes have an IP 66 rating. ATEX suffix junction

tapped NPT conduit entries on sides, top and bottom of enclosure. Field box complies with EN50014:1997 and EN50018:2000 Certificate PTB-

addition of device holes on cover for EMP or similar devices is also 05-ATEX 1062U. ATEX certified boxes cannot be field drilled and

permitted. Attached instructions must be followed to maintain approvals. tapped for conduit entries. All conduit entries must be drilled and tapped

by Cooper Crouse-Hinds at the factory. Breather and drain options are

EJB series classified enclosures are suitable for use indoors or outdoors not available on ATEX certified enclosures.

and are UL listed and cUL certified to CSA Standards for Class I,

Groups B, C and D; Class II, Groups E, F and G; and Class III EJB series classified enclosures should be installed, inspected and

hazardous (classified) locations as defined by the National Electrical maintained by qualified and competent personnel.

Code® and the Canadian Electrical Code®. EJB classified enclosures

include a gasket on the cover to meet Type 4 watertight requirements.

INSTALLATION 2. Select a mounting location that will provide suitable strength and

rigidity for supporting all contained wiring and control devices. Figure

! WARNING 1 shows the mounting dimensions for the four detachable mounting

To avoid risk of electrical shock, electrical power must be off feet.

before and during installation and maintenance.

3 Remove cover bolts securing cover. Carefully set cover aside to

1. EJB series classified enclosures are furnished with or without drilled prevent damage to the machined joint and cover gasket. Remove

and tapped openings. Drilling and tapping of conduit openings and mounting feet kit, balance of cover screws and hinge kit (if ordered

device openings on cover are subject to the limitations of maximum with suffix -S598) from inside enclosure.

size and number of openings as well as spacings. Refer to 4. Install mounting feet.

DRILLING AND TAPPING section following. All machining must be • Use (4) 5/16-18 screws supplied to attach mounting foot to pre-

done prior to installation. drilled hole on back wall of enclosure

IMPORTANT

ATEX certified boxes MAY NOT

zz ww be field drilled and tapped.

aa

Conduit entries must be

machined by factory.

xx Ø7/16” (11mm)

bb yy

Mtg. Hole

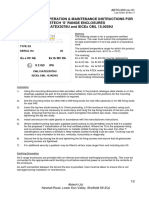

DIMENSIONS - INCHES (Millimeters) Net Weight

Inside Pounds

Catalog No. Depth aa bb ww xx yy zz (Kilograms)

EJB060404 4-5/8 (118) 8-11/32 (212) 10-11/32 (288) 8-3/4 (222) 6-1/8 (156) 5 (127) 7-1/8 (181) 43 (16)

EJB060404 SA 4-5/8 (118) 8-11/32 (212) 10-11/32 (288) 8-3/4 (222) 6-1/8 (156) 5 (127) 7-1/8 (181) 16 (6)

EJB080604 4-5/8 (118) 10-15/32 (266) 12-15/32 (317) 10-25/32 (274) 6-3/16 (157) 7 (178) 9-1/8 (232) 64 (24)

EJB080604 SA 4-5/8 (118) 10-15/32 (266) 12-15/32 (317) 10-25/32 (274) 6-3/16 (157) 7 (178) 9-1/8 (232) 24 (9)

EJB080606 6-5/8 (168) 10-15/32 (266) 12-15/32 (317) 10-25/32 (274) 8-3/16 (208) 7 (178) 9-1/8 (232) 84 (31)

EJB080606 SA 6-5/8 (168) 10-15/32 (266) 12-15/32 (317) 10-25/32 (274) 8-3/16 (208) 7 (178) 9-1/8 (232) 32 (12)

EJB080806 6-5/8 (168) 12-15/32 (317) 12-15/32 (317) 12-25/32 (325) 8-7/32 (209) 7 (178) 11-1/8 (283) 98 (37)

EJB080806 SA 6-5/8 (168) 12-15/32 (317) 12-15/32 (317) 12-25/32 (325) 8-7/32 (209) 7 (178) 11-1/8 (283) 37 (14)

EJB100806 SA 6-3/4 (172) 12-21/32 (321) 14-21/32 (372) 12-1/2 (318) 8-9/16 (217) 9 (229) 11-1/8 (283) 45 (20)

EJB101006 SA 6-3/4 (172) 14-21/32 (372) 14-21/32 (372) 14-1/2 (368) 8-9/16 (217) 9 (229) 13-1/8 (333) 52 (24)

EJB101008 SA 8-5/8 (219) 14-21/32 (372) 14-21/32 (372) 14-7/8 (378) 10-3/8 (264) 9 (229) 13-1/8 (333) 59 (22)

EJB120604 SA 4-5/8 (118) 10-1/2 (267) 16-1/2 (419) 10-13/16 (275) 6-3/16 (157) 11 (279) 9-1/8 (232) 32 (12)

EJB120804 4-5/8 (118) 12-1/2 (318) 16-1/2 (419) 12-13/16 (325) 6-3/8 (162) 11 (279) 11-1/8 (283) 103 (38)

EJB120804 SA 4-5/8 (118) 12-1/2 (318) 16-1/2 (419) 12-13/16 (325) 6-3/8 (162) 11 (279) 11-1/8 (283) 39 (15)

EJB120806 SA 6-3/4 (172) 12-21/32 (321) 16-1/2 (419) 12-1/2 (318) 8-9/16 (217) 11 (279) 11-1/8 (283) 53 (24)

EJB120808 SA 8-5/8 (219) 12-1/2 (318) 16-1/2 (419) 12-13/16 (325) 10-3/8 (264) 11 (279) 11-1/8 (283) 56 (21)

EJB141006 SA 6-5/8 (168) 14-21/32 (372) 18-21/32 (474) 14-7/8 (378) 8-15/32 (215) 13 (330) 13-1/8 (333) 66 (25)

EJB160404 4-5/8 (118) 8-1/2 (216) 20-1/2 (521) 8-13/16 (224) 6-5/32 (156) 15 (381) 7-1/8 (181) 86 (32)

EJB160404 SA 4-5/8 (118) 8-1/2 (216) 20-1/2 (521) 8-13/16 (224) 6-5/32 (156) 15 (381) 7-1/8 (181) 33 (12)

* Body and Cover Figure 1. EJB Style D Dimensions

® National Electrical Code is a Register Trademark of the National Fire Protection Association.

® Canadian Electrical Code is a voluntary code for Adoption and Enforcement by Regulatory Authorities.

IF 1444 • 09/11 Copyright © 2011, Cooper Industries, Inc. Page 1

5. Securely fasten enclosure to the mounting location, then attach into

1. Attach female hinge leaf to cover

conduit system. Install approved conduit or cable sealing fittings in using two lock washers and screws

all conduit entries within 18 inches of enclosure. as shown. When required, place

spacer between cover and female

! CAUTION leaf.

To avoid risk of ignition: 2. After female hinge leaf is secured

• Hazardous location information specifying class and group listing of to cover, slide pin of male hinge

each device is marked on the nameplate of each enclosure. Class leaf into female leaf. Align

and group listing for any device penetrating the enclosure must be mounting holes with holes in body

suitable for the classification of the location in which the enclosure flange and secure with two lock

is installed. washers and screws.

Note: Spacer required on EJB120804

• All unused conduit openings must be plugged with a listed plug that

and EJB120808.

engages a minimum of five full threads and is a minimum of 1/8

inch thick. Use Cooper Crouse-Hinds PLG Series plugs.

Figure 2

• In Class I, Division 1 locations, conduit sealing fittings MUST be

installed in each attached conduit run (within eighteen inches of the

SCREW

enclosure) to comply with the latest edition of the National

Electrical Code plus any other applicable code.

LOCK WASHER

! CAUTION

To avoid risk of ignition: FEMALE HINGE LEAF

Hammers or prying tools must not be allowed to damage the flat

machined-joint surfaces or cover gasket. Do not handle covers SPACER (WHEN REQ’D)

roughly, or place them on surfaces that might damage or scratch

the flat machined joint surfaces. COVER

MALE

HINGE LEAF

6. Pull wires into enclosure, making sure they are long enough to make

the required connections. Make all electrical connections.

Enclosures with suffix “ATEX” are provided with an external

grounding lug. The internal grounding terminal shall be used as

equipment grounding means. The external terminal is only a

supplemental bonding connection.

7. Test wiring for correctness with continuity checks and also for

unwanted grounds with insulation resistance tester.

! CAUTION SCREW

To avoid risk of ignition:

Clean both machined-joint surfaces of body and cover before LOCK BODY

closing. Dirt or foreign material must not accumulate on flat WASHER

machined-joint surfaces. Surfaces must seat fully against each Figure 3

other to provide a proper explosionproof joint.

8. To install cover, make sure cover and body machined joint surfaces BREATHER AND DRAIN

are clean and not scratched. Lift cover to approximate position, and (Not permitted on ATEX Certified enclosures)

line up bolt holes of cover with body. Avoid sliding cover machined

Classified Enclosures installed with breather and/or drains must be

joint surface over machined joint surface of body. Cover and body

protected during hosedown operations. The junction box is watertight

bolt holes must match up. Hand start the corner bolts. Fully tighten

but the breather and drain are not.

all cover bolts in the cover. See Table 1.

CATALOG COVER REQUIRED TORQUE ! CAUTION

NUMBER SCREW FOOT- POUNDS NEWTON-METERS To avoid risk of ignition check breather and/or drain or their

carton label to be certain that they are suitable for the hazardous

EJB060404 1/4 - 20 10 - 15 14 - 20

location (class and group) in which they are being installed.

EJB080604 5/16 -18 20 - 25 27 - 34

EJB080606 5/16 -18 20 - 25 27 - 34

EJB080806 5/16 -18 20 - 25 27 - 34

DRILLING AND TAPPING FOR CONDUIT ENTRIES

EJB100806 3/8/-16 35 - 40 48 - 54 (ATEX Certified boxes must have all drilled and tapped

EJB101006 3/8/-16 35 - 40 48 - 54 conduit entries machined at Cooper Crouse-Hinds factory)

EJB101008 3/8 -16 35 - 40 48 - 54 • To comply with the NEC, all conduit entries must be provided with a

EJB120604 3/8 -16 35 - 40 48 - 54 smooth rounded entry into the enclosure. This may be accomplished

EJB120804 3/8/-16 35 - 40 48 - 54 in various ways including the use of Crouse-Hinds RE reducers or by

EJB120806 3/8/-16 35 - 40 48 - 54 using LNR series conduit liners.

EJB120808 3/8/-16 35 - 40 48 - 54

EJB141006 3/8/-16 35 - 40 48 - 54 The location and maximum sizes of conduit openings must be in

EJB160404 3/8/-16 35 - 40 48 - 54 accordance with Table 2 on the next page.

Table 1 • Female conduit openings or entries must be taper tapped with the

9. If hinges were ordered (suffix -S598) install hinges to body and cover thread form and taper (3/4 in. per ft.) conforming to NPT. A standard

as shown in figure 2 and 3. NPT male gage must enter the tapped opening 1-1/2 turns past the

gage notch. Openings are tapped deeper than standard NPT gage to

10. Install sealing fittings (when required) in accordance with the ensure a minimum of five full threads engagement with standard

instructions supplied with each of the approved fittings and sealing NPT threaded conduit.

compound.

IF 1444 • 09/11 Copyright © 2011, Cooper Industries, Inc. Page 2

Maximum Size of Drilled and Tapped Conduit Openings

(Long Side) (Short Side)

Number of Openings Number of Openings Outlined Dimensiones Defined Area

Catalog No 1 2 3 4 1 2 3 4 A B C X Y Z

EJB060404 2 1 - 1/2 1 2 3/4 1 1- 1/16 1- 3/16 2 -1/2 4 -3/4 2 -3/4

EJB060404 SA 2 1 - 1/2 1 2 3/4 1 1- 1/16 1- 3/16 2 -1/2 4 -3/4 2 -3/4

EJB080604 2 2 1 - 1/4 3/4 2 1- 1/2 3/4 1 1- 1/4 1- 3/16 2 -1/2 6 -3/4 4 -3/4

EJB080604 SA 2 2 1 - 1/4 3/4 2 1- 1/2 3/4 1 1- 1/4 1- 3/16 2 -1/2 6 -3/4 4 -3/4

EJB080606 3 -1/2 2 -1/2 1 - 1/4 3/4 3 -1/2 1- 1/2 3/4 1 1- 1/4 1- 7/16 4 -3/8 6 -3/4 4 -3/4

EJB080606 SA 3 -1/2 2 -1/2 1 - 1/4 3/4 3 -1/2 1- 1/2 3/4 1 1- 1/4 1- 7/16 4 -3/8 6 -3/4 4 -3/4

EJB080806 3 -1/2 2 -1/2 1 - 1/4 3/4 3 -1/2 2 -1/2 1- 1/4 3/4 1 1- 3/8 1- 7/16 4 -3/8 6 -3/4 6 -3/4

EJB080806 SA 3 -1/2 2 -1/2 1 - 1/4 3/4 3 -1/2 2 -1/2 1- 1/4 3/4 1 1- 3/8 1- 7/16 4 -3/8 6 -3/4 6 -3/4

EJB100806 SA 3 -1/2 3 1 - 1/2 1 3 -1/2 2 -1/2 1- 1/4 3/4 1 1- 3/8 1- 7/16 4 -5/8 8 -3/4 6 -3/4

EJB101006 SA 3 -1/2 3 1 - 1/2 1 3 -1/2 3 1- 1/2 1 1 1- 3/8 1- 7/16 4 -5/8 8 -3/4 8 -3/4

EJB101008 SA 4 3 1 - 1/2 1 4 3 1- 1/2 1 1- 1/8 1- 1/2 1- 7/16 6 -1/8 8 -3/4 8 -3/4

EJB120604 SA 2 2 2 1 - 1/4 2 1- 1/2 3/4 1 1- 3/8 1- 3/16 2 -1/4 10 -3/4 4 -3/4

EJB120804 2 2 2 1 - 1/4 2 2 1- 1/4 3/4 1 1- 1/8 1- 3/16 2 -5/8 10 -3/4 6 -3/4

EJB120804 SA 2 2 2 1 - 1/4 2 2 1- 1/4 3/4 1 1- 1/8 1- 3/16 2 -5/8 10 -3/4 6 -3/4

EJB120806 SA 3 -1/2 3 -1/2 2 -1/2 1 - 1/2 3 -1/2 2 -1/2 1- 1/4 3/4 1 1- 3/8 1- 7/16 4 -5/8 10 -3/4 6 -3/4

EJB120808 SA 4 4 2 -1/2 1 - 1/2 4 2 -1/2 1- 1/4 3/4 1 1- 1/2 1- 7/16 6 -1/4 10 -3/4 6 -3/4

EJB141006 SA 3 -1/2 3 -1/2 3 2 3 -1/2 3 2 1 1- 1/8 1- 5/8 1- 7/16 4 -1/8 12 -3/4 8 -3/4

EJB160404 2 2 2 2 2 3/4 1 1- 1/8 1- 3/16 2 -7/16 14 -3/4 2 -3/4

EJB160404 SA 2 2 2 2 2 3/4 1 1- 1/8 1- 3/16 2 -7/16 14 -3/4 2 -3/4

TABLE 2

Consult Crouse-Hinds for proper space for installing and servicing fittings such as seals, unions, etc.

If more than four (4) conduit entries, or a mix of conduit entry

trade sizes are needed in any wall of the enclosure, use the

following instructions:

1. From Table 2, determine how many 4” conduit entries are

permitted on a side. For example, a quantity of (2) 4” entries are

permitted on the long side of an EJB120808.

2. For each 4” conduit entry permitted, one may substitute a quantity of

smaller conduit entry trade sizes.

3. Some smaller enclosures cannot accept a 4” opening, in which case,

the maximum number of 3-1/2” or 2” conduit openings must be

TABLE 4 - Minimum clearance for unions only.

determined (again, using Table 2).

4. Use Table 3 to determine how many of the smaller conduit entries • For conduit entries with non-interfering vertical seals: center-to-center

may be substituted for either the 4”, the 3-1/2” or the 2” trade size. distance is the total of 1/2 the outside diameter of the larger conduit

plus the turning radius of the sealing fitting used in the smaller conduit

Use Table 4 for minimum spacing of conduit entries.

plus 1/4 inch clearance.

Basis of • For conduit entries with non-interfering horizontal seals: center-to-

Substitution 1

/2” 3

/4” 1” 11/4” 11/2” 2 21/2” 3” 31/2” 4” center distance is the total of 1/2 the outside diameter of the larger

4” 7 5 4 3 2 1 1 1 1 1

conduit plus the turning radius of the sealing fitting used in the smaller

conduit plus 2 inches clearance for pouring.

3-1/2” 5 4 3 2 1 1 1 1 1 0

2” 2 2 1 1 1 1 0 0 0 0 IMPORTANT

While the number of openings derived from the above will result in a

TABLE 3

Number and size of smaller conduit entries which may be substituted for safe configuration, the number of openings could be reduced if center-

4”, 3-1/2”, or 2” entries. to-center spacings were required to be increased for the following

reason:

• If sealing fittings are required to be installed in the conduit, sufficient

room must be provided to install, pack and pour the fitting after the

conduit and fittings are installed and the conductors are in place.

This is particularly important in horizontal conduit runs, when fittings

are directly over one another.

IF 1444 • 09/11 Copyright © 2011, Cooper Industries, Inc. Page 3

Note: Cable entries as well as sealing plugs of simple construction

IMPORTANT must not be used.

The space between drilled & tapped conduit entries is a factor of the Cable entries (conduit threads) and sealing plugs of simple designs

following considerations: must not be used. Should the EJB be connected by means of a

conduit entry which has been approved for this purpose, the

• Ability to install conduit with a variety of fittings (for various reasons, required sealing device shall be provided immediately at the

the conduit which is to be threaded into each conduit entry may, in terminal box.

turn, be threaded into a variety of fittings including (but not limited to)

the following: unions, sealing fittings of various types. Dimensions of Any openings not used shall be sealed as specified in EN 50018,

these fittings are provided in the Crouse-Hinds catalog, and should section 11.9.

be referred to in planning a conduit layout.)

The connecting wire of the EJB shall be installed to provide for

permanent wiring and adequate protection against mechanical

• All drilled and tapped conduit entries must fall completely within the

damage.

defined areas as specified in Table 1.

If the temperature at entry fittings should exceed 70ºC, the

connecting cables used have to be of the temperature-resistant

DRILLING AND TAPPING FOR COVER DEVICE type.

HOLES

(ATEX Certified boxes must have all drilled and tapped

conduit entries machined at Cooper Crouse-Hinds factory) MAINTENANCE

! WARNING

• Maximum quantity, location and minimum spacing of cover device

holes for field drilling are subject to limits shown in Table 5 on next To avoid electrical shock or risk of ignition:

page. Restrictions are based on size of enclosure cover. Always disconnect primary power source before opening

enclosure for inspection or service.

1. Mark appropriate hole locations in accordance with Table 5.

2. Drill a 0.938” diameter through hole perpendicular to cover surface.

In addition to the following required maintenance procedures, we

3. Tap hole using a ¾-14 NPSM tap. recommend an Electrical Preventative Maintenance program as

described in the National Fire Protection Association NFPA No. 70B.

4. Visually inspect hole for well formed thread. Gage hole with

standard ¾-14 NPSM GO / NO-GO gage. 1. Frequent inspection should be made. A schedule for maintenance

check should be determined by the environment and frequency of

5. Install appropriate Crouse-Hinds EMP device or 0207959 ¾-14 use. It is recommended that it should be at least once a year.

NPSM plug ensuring at least 8 full threads engagement.

2. Perform visual, electrical and mechanical checks on all components

on a regular basis.

FOR ATEX ENCLOSURES:

- Before opening the enclosure in a flammable atmosphere circuits • Visually check for undue heating evidenced by

must be interrupted. discoloration of wires or other components, damaged or

worn parts, or leakage evidenced by water or corrosion in

- The approval applies to equipment without cable glands. When

the interior.

mounting the flameproof enclosure in a hazardous area, only rigid

metal conduit systems or flameproof cable glands certified to

• Electrically check to make sure that all connections are

EN50018 must be used.

clean and tight and that contacts in the components make

- All unused conduit entries must be closed with a flameproof plug and break as required.

certified to EN50018.

• Mechanically check that all parts are properly assembled

- Any components attached or installed (e.g. terminal compartments, and operating mechanisms move freely.

bushings, explosionproof cable entries, connectors) shall be of a

technical standard that complies with the specifications on the 3. EJB gasketed Classified Enclosures: do not attempt field

cover sheet as minimum and for which a separate type replacement or repair of cover gasket. Instead, remove damaged

examination certificate has been issued. The operating conditions gasket and continue to use cover without gasket. This will assure

set forth in the relevant component certificates must by all means safety for use in Class I and Class II hazardous (classified) locations.

be complied with.

However, the enclosure will not be watertight.

Securely fasten enclosure to the mounting location, then attach into

conduit system.

! CAUTION

The EJB shall be connected by means of suitable cable entries or

conduit systems, which meet the requirements of EN 50018, To avoid electrical shock or risk of ignition:

sections 13.1 and 13.2, and for which a separate type examination Clean both machined joint surfaces of body and cover before

certificate has been issued. closing. Dirt or foreign material must not accumulate on flat

machined joint surfaces. Surfaces must seat fully against each other

The enclosure is intended for wiring connections only, or for to provide a proper explosionproof joint.

controller devices or other equipment which fall within the electrical

parameters indicated above.

IF 1444 • 09/11 Copyright © 2011, Cooper Industries, Inc. Page 4

Table 5

All statements, technical information and recommendations contained herein are based on information and tests we believe to be

reliable. The accuracy or completeness thereof are not guaranteed. In accordance with Cooper Crouse-Hinds "Terms and Conditions of

Sale", and since conditions of use are outside our control, the purchaser should determine the suitability of the product for his intended

use and assumes all risk and liability whatsoever in connection therewith.

Cooper Crouse-Hinds, LLC IF 1444

PO Box 4999, Syracuse, New York 13221 • U.S.A. Revision 5

Copyright© 2011, Cooper Industries, Inc. Revised 09/11

Supercedes 08/05

You might also like

- Edexcel International GCSE (9-1) Physics Student Book PDFDocument163 pagesEdexcel International GCSE (9-1) Physics Student Book PDFRaFaT HaQ75% (32)

- TB 11-5820-890-30-5 Technical Bulletin: Approved For Public Release Distribution Is UnlimitedDocument40 pagesTB 11-5820-890-30-5 Technical Bulletin: Approved For Public Release Distribution Is UnlimitedgjudkejhNo ratings yet

- Diesel Engine Generator Set Site Acceptance Test Procedure 48 JamDocument7 pagesDiesel Engine Generator Set Site Acceptance Test Procedure 48 Jambambang ismail100% (4)

- Pioneer Lexus Dex-Mg9487zt Dex-Mg9587zt Crt4255Document148 pagesPioneer Lexus Dex-Mg9487zt Dex-Mg9587zt Crt4255boroda2410No ratings yet

- DassdafDocument15 pagesDassdafEdmar Bataque100% (1)

- Crouse Hinds Exd JBDocument8 pagesCrouse Hinds Exd JBomh129No ratings yet

- Anclajes Red HeadDocument8 pagesAnclajes Red HeadLeonardo AvilaNo ratings yet

- Q7800 - Base de RM7800Document6 pagesQ7800 - Base de RM7800Andrey VegaNo ratings yet

- Technical Information ASSET DOC LOC 1543385Document21 pagesTechnical Information ASSET DOC LOC 1543385Alfonso ChNo ratings yet

- Cable Gland Types Px2K-Rex, Px2Kw-Rex & Px2Kx-Rex & VariantsDocument2 pagesCable Gland Types Px2K-Rex, Px2Kw-Rex & Px2Kx-Rex & VariantsPT INDORAD MEGA BINTANGNo ratings yet

- Barrier Cable Glands CMP PX2KX InstructionsDocument2 pagesBarrier Cable Glands CMP PX2KX InstructionsMohammed MustafaNo ratings yet

- CMP PX Type ResinDocument2 pagesCMP PX Type Resinmuhammad khuram usmanNo ratings yet

- Cable Gland Tech501 453univDocument1 pageCable Gland Tech501 453univHardik AcharyaNo ratings yet

- Cable Gland Types Px2Krex, Px2Kwrex, Px2Kxrex & PB VariantsDocument2 pagesCable Gland Types Px2Krex, Px2Kwrex, Px2Kxrex & PB VariantsNikhil E ANo ratings yet

- WBB Weatherproof Back Box Accessory: 3825 Ohio Avenue, St. Charles, Illinois 60174 1-800-SENSOR2, FAX: 630-377-6495Document1 pageWBB Weatherproof Back Box Accessory: 3825 Ohio Avenue, St. Charles, Illinois 60174 1-800-SENSOR2, FAX: 630-377-6495Carlos YepezNo ratings yet

- Wet Chemical Deep Fat FryerDocument64 pagesWet Chemical Deep Fat FryerSergei KurpishNo ratings yet

- MODELS 300GC, 300GCX (-CN), 302GC, AND 302GCX (-CN) : 2562226A REV. A1 1218 Printed in U.S.ADocument28 pagesMODELS 300GC, 300GCX (-CN), 302GC, AND 302GCX (-CN) : 2562226A REV. A1 1218 Printed in U.S.AJuan Carlos GòmezNo ratings yet

- Optional Parts: 4-3. External Electronic Expansion Valve Kit For Indoor Unit CZ-P56SVK2, CZ-P160SVK2 (For R410A)Document3 pagesOptional Parts: 4-3. External Electronic Expansion Valve Kit For Indoor Unit CZ-P56SVK2, CZ-P160SVK2 (For R410A)Priesilia PresleyNo ratings yet

- Section E: EnclosuresindexDocument32 pagesSection E: EnclosuresindexNMETETRNo ratings yet

- Pressure Vessel PDFDocument8 pagesPressure Vessel PDFdanielreyeshernandezNo ratings yet

- Installation Instructions For CMP Cable Gland Type Tmc2XDocument2 pagesInstallation Instructions For CMP Cable Gland Type Tmc2XAnonymous fbeCwgBFYNo ratings yet

- Simpson EtDocument3 pagesSimpson EtJohn McClaneNo ratings yet

- Applications:: Hinge Kits For Field Installation (No Field Machining Required)Document8 pagesApplications:: Hinge Kits For Field Installation (No Field Machining Required)Anonymous zTUWsMNo ratings yet

- Cable Gland Types E1FW, E2FW, E1FX, E2Fx, E1Fu & E2FuDocument2 pagesCable Gland Types E1FW, E2FW, E1FX, E2Fx, E1Fu & E2FusubramanyaNo ratings yet

- RoxtecBG Tech SpecDocument8 pagesRoxtecBG Tech SpecBob JohnsonNo ratings yet

- Adalet 50201415218490Document15 pagesAdalet 50201415218490Jose Angel GonzalezNo ratings yet

- Siemens Eg Type Circuit BreakerDocument15 pagesSiemens Eg Type Circuit BreakerAna Hernández MonterrubioNo ratings yet

- Bobinas Atex Serie SG AscoDocument2 pagesBobinas Atex Serie SG AscoBase SistemasNo ratings yet

- TB 00700001 eDocument9 pagesTB 00700001 eRicardo LopezNo ratings yet

- Model BFV-300/BFV-300C Butterfly Valve Grooved End General DescriptionDocument8 pagesModel BFV-300/BFV-300C Butterfly Valve Grooved End General DescriptionMERCURE GARINDOLPGNo ratings yet

- Integral Pilot (External Exhaust) Threaded or Quick Mount Connection 3/4 To 1 1/2Document12 pagesIntegral Pilot (External Exhaust) Threaded or Quick Mount Connection 3/4 To 1 1/2Lê Duy MinhNo ratings yet

- Panasonic Th-32c200dx Chassis Km14Document40 pagesPanasonic Th-32c200dx Chassis Km14VinylJogjaNo ratings yet

- Installation, Operation & Maintenance Instructions For Abtech S' Range Enclosures Cml15Atex3078U and Iecex CML 15.0039UDocument2 pagesInstallation, Operation & Maintenance Instructions For Abtech S' Range Enclosures Cml15Atex3078U and Iecex CML 15.0039USantoshkumar GurmeNo ratings yet

- Conectores Multiconductores Serie TCDocument2 pagesConectores Multiconductores Serie TCING_MBMNo ratings yet

- 38 13 11 RiDocument6 pages38 13 11 RiÜmit KazanNo ratings yet

- HCD-GR8 RX90Document99 pagesHCD-GR8 RX90pepitito22No ratings yet

- Catalogo Contactores en Vacio MitsubichiDocument16 pagesCatalogo Contactores en Vacio MitsubichiWalter CataldoNo ratings yet

- Installation & Maintenance Instructions: Form No.V6584R8Document4 pagesInstallation & Maintenance Instructions: Form No.V6584R8RICHAR MORENONo ratings yet

- Trubolt Performance DataDocument6 pagesTrubolt Performance DataDiego martinez castellanosNo ratings yet

- Cast Sae J514 PDFDocument4 pagesCast Sae J514 PDFmanishkumar FETNo ratings yet

- Cable Gland Installation InstructionsDocument2 pagesCable Gland Installation InstructionsJairo WilchesNo ratings yet

- DS Spark Arrestors CE224 0712 Rev1Document8 pagesDS Spark Arrestors CE224 0712 Rev1Alexander OngNo ratings yet

- Adaptors & Reducers Brochure (TCS02-Feb2013)Document20 pagesAdaptors & Reducers Brochure (TCS02-Feb2013)Abdul SamiNo ratings yet

- Type 501 453 UniversalDocument1 pageType 501 453 Universalrambala123No ratings yet

- 12165-70 - 1 Sundry Instr.Document328 pages12165-70 - 1 Sundry Instr.kodrysNo ratings yet

- SNAP2IT® Connectors: No Tools!Document1 pageSNAP2IT® Connectors: No Tools!Abdel GlNo ratings yet

- F84L Series Liquid Relief Valve: Installation, Operation, & Maintenance ManualDocument15 pagesF84L Series Liquid Relief Valve: Installation, Operation, & Maintenance ManualMoe MozhganNo ratings yet

- SL162B Helicoil PDFDocument2 pagesSL162B Helicoil PDFjeffrey_fay67% (3)

- TBEX Enclosures CatalogDocument35 pagesTBEX Enclosures CatalogcubarturNo ratings yet

- TFP1511 09 2015Document8 pagesTFP1511 09 2015Enrique MurgiaNo ratings yet

- 05 Tyco TJRDocument6 pages05 Tyco TJRsamNo ratings yet

- Kunkle Relief ValveDocument4 pagesKunkle Relief ValveJonathanHarker DPZNo ratings yet

- PC3SF21YVZBFDocument15 pagesPC3SF21YVZBFVukica IvicNo ratings yet

- Antifog Disc InsulatorDocument35 pagesAntifog Disc InsulatorJayant Kumar DasNo ratings yet

- JVC TD-V662BKDocument42 pagesJVC TD-V662BKcupitzaNo ratings yet

- Dau Sprinklers TYCO - TY315Document4 pagesDau Sprinklers TYCO - TY315hungNo ratings yet

- AEC MC007 Weatherproof Outlet Boxes and CoversDocument22 pagesAEC MC007 Weatherproof Outlet Boxes and CoversSergio TC VtmNo ratings yet

- ABTECH JB - SX - Range PDFDocument34 pagesABTECH JB - SX - Range PDFprsiva2420034066No ratings yet

- Cable Glands For Armoured and Non-Armoured CablesDocument6 pagesCable Glands For Armoured and Non-Armoured CablesmustardbassmanNo ratings yet

- CMP A2fDocument2 pagesCMP A2fBJ LeeNo ratings yet

- PC3SH21YFZBFDocument15 pagesPC3SH21YFZBFkrimoNo ratings yet

- Ranking of Process Safety Cultures For Risk-Based Inspections Using Indicative Safety Culture AssessmentsDocument142 pagesRanking of Process Safety Cultures For Risk-Based Inspections Using Indicative Safety Culture Assessmentsgustav agudeloNo ratings yet

- Mass Process Safety Management PDFDocument66 pagesMass Process Safety Management PDFgustav agudeloNo ratings yet

- CEP$ Steam Trap Troubles Febr 2005 PDFDocument6 pagesCEP$ Steam Trap Troubles Febr 2005 PDFgustav agudeloNo ratings yet

- BEAC - CCMS Handbook - 1Document26 pagesBEAC - CCMS Handbook - 1gustav agudeloNo ratings yet

- Flow Calculator Explanation: ContractaDocument2 pagesFlow Calculator Explanation: Contractagustav agudeloNo ratings yet

- Mix Incompatible Storage Tanks CEPDocument1 pageMix Incompatible Storage Tanks CEPgustav agudeloNo ratings yet

- AM-17-45 - EvansDocument14 pagesAM-17-45 - Evansgustav agudeloNo ratings yet

- Process Safety Management FundamentalsDocument15 pagesProcess Safety Management Fundamentalsgustav agudeloNo ratings yet

- HydrotreatingDocument18 pagesHydrotreatinggustav agudeloNo ratings yet

- 15.TroubleShooting BASFDocument26 pages15.TroubleShooting BASFgustav agudeloNo ratings yet

- ASTM D86 To TBPDocument2 pagesASTM D86 To TBPgustav agudeloNo ratings yet

- Auditoria PSMDocument13 pagesAuditoria PSMgustav agudeloNo ratings yet

- 13.aditivos FCCDocument26 pages13.aditivos FCCgustav agudeloNo ratings yet

- Articulo Trevor Safety ProcessDocument2 pagesArticulo Trevor Safety Processgustav agudeloNo ratings yet

- DDSD 285: Single Phase Multifunction Meter With Built in CommunicationDocument2 pagesDDSD 285: Single Phase Multifunction Meter With Built in CommunicationSameh FakhryNo ratings yet

- Cobwebb 2Document7 pagesCobwebb 2yo8rzeNo ratings yet

- Previousyearquestion Basic EEDocument15 pagesPreviousyearquestion Basic EEkkmpec2011No ratings yet

- DEWA Infrastructure GuidelineDocument819 pagesDEWA Infrastructure Guidelinenirmal mohanNo ratings yet

- Instrumentation Cables: Product CatalogueDocument44 pagesInstrumentation Cables: Product Cataloguexinying liuNo ratings yet

- Midibox 2Document8 pagesMidibox 2Ming XiaoNo ratings yet

- RGPV Syllabus Cbgs Ec 3 Sem All SubjectsDocument8 pagesRGPV Syllabus Cbgs Ec 3 Sem All SubjectsAyushNo ratings yet

- Ceramic CapDocument155 pagesCeramic Capcamiloc320No ratings yet

- Generatore MP10Document4 pagesGeneratore MP10Leonardo BruttiNo ratings yet

- Compact, Surface Mount Ultra-High Speed Response OPIC PhotocouplerDocument6 pagesCompact, Surface Mount Ultra-High Speed Response OPIC PhotocouplerZackyExlipzNo ratings yet

- Temperature Limits Iec60282-1Document2 pagesTemperature Limits Iec60282-1carlosNo ratings yet

- Swsi DwdiDocument6 pagesSwsi DwdiGuillermo MartínezNo ratings yet

- Vflex Corner Sequencing Control Panel Option Owners ManualDocument38 pagesVflex Corner Sequencing Control Panel Option Owners ManualClaudinho MontenegroNo ratings yet

- AC CIRCUITS ReviewerDocument7 pagesAC CIRCUITS ReviewerKyle Joshua BunhanNo ratings yet

- NUMBER: 7 13-09 S.M. REF.: Listed in Table Engine: Ddec Vi DATE: July 2009Document6 pagesNUMBER: 7 13-09 S.M. REF.: Listed in Table Engine: Ddec Vi DATE: July 2009Cuong DinhNo ratings yet

- Ritewing ESC Manual PDFDocument3 pagesRitewing ESC Manual PDFmastahhhNo ratings yet

- 100ma Final BroacherDocument2 pages100ma Final BroacherPrashanth VishwakarmaNo ratings yet

- Active Noise Control in Headsets by Using A Low-Cost MicrocontrollerDocument7 pagesActive Noise Control in Headsets by Using A Low-Cost MicrocontrollerEmir ŠemšićNo ratings yet

- Cisco PDS3121 Set Top Safety Sheet EnglishDocument2 pagesCisco PDS3121 Set Top Safety Sheet EnglishMišo VukadinovićNo ratings yet

- SEKN5005 Deutsch C TIPS PDFDocument7 pagesSEKN5005 Deutsch C TIPS PDFJoko SukarionoNo ratings yet

- T2FD Nvis PDFDocument2 pagesT2FD Nvis PDFPopescu NicolaeNo ratings yet

- Presentation PERU IEC Ex Brasil 2013-Set-18Document20 pagesPresentation PERU IEC Ex Brasil 2013-Set-18Oliver A. Chura QuispeNo ratings yet

- One-Cycle-Controlled Bidirectional AC-to-DC Converter With Constant Power FactorDocument12 pagesOne-Cycle-Controlled Bidirectional AC-to-DC Converter With Constant Power FactorKrishna ReddyNo ratings yet

- LM675 DS006739 1996-05Document8 pagesLM675 DS006739 1996-05Markus FaustNo ratings yet

- 1 S5J1 Route Relay InterlockingDocument63 pages1 S5J1 Route Relay InterlockingSantosh Dharphal100% (2)

- TDA2007A: 6 + 6W Stereo AmplifierDocument8 pagesTDA2007A: 6 + 6W Stereo Amplifiersaliya07No ratings yet