Professional Documents

Culture Documents

100%(1)100% found this document useful (1 vote)

340 viewsWelding Procedure Specification: Page 1 of 1

Welding Procedure Specification: Page 1 of 1

Uploaded by

Anderson Perez MartinezThis welding procedure specification outlines the parameters for welding duplex stainless steel to carbon steel fillet welds using the shielded metal arc welding process. The base metals are duplex stainless steel grades P1 to P10H and the filler metal is an E2594 classification 2.5mm diameter electrode. Welding will be done in all positions using multiple string bead passes with direct current electrode positive polarity. Preheating is required to a minimum of 25°C and interpass temperature must not exceed 150°C. Impact testing of welds produced using this procedure achieved average values of 26J at the weld centerline and 17J in the heat affected zone on the carbon steel side.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 pagesWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- 37507022-WPS-PQR-SS-316 LDocument5 pages37507022-WPS-PQR-SS-316 LVarun Malhotra100% (6)

- Blank Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)Document1 pageBlank Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)GMNo ratings yet

- 2018 Ibc Seaoc Structural Seismic Design Manual Volume 2 Examplespdf CompressDocument385 pages2018 Ibc Seaoc Structural Seismic Design Manual Volume 2 Examplespdf Compressvkch saipavan100% (3)

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- TABLE 100.12.1 Bolt-Torque Values For Electrical Connections US Standard Fasteners Heat-Treated Steel - Cadmium or Zinc PlatedDocument3 pagesTABLE 100.12.1 Bolt-Torque Values For Electrical Connections US Standard Fasteners Heat-Treated Steel - Cadmium or Zinc PlatedKennedy VasconezNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- WPS and PQRDocument4 pagesWPS and PQRdandiar1No ratings yet

- Atf Wpqr-Blank v1Document1 pageAtf Wpqr-Blank v1lth770310No ratings yet

- Welding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Document2 pagesWelding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Harshit AdwaniNo ratings yet

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- MACRO AIR SABST Roofing InsulationDocument28 pagesMACRO AIR SABST Roofing InsulationBer Salazar Jr100% (1)

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad Pathan100% (1)

- Welding Proposed Pwps For Our Jubail WorkDocument2 pagesWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (3)

- ASME IX Sample WPS GTAW SMAWDocument1 pageASME IX Sample WPS GTAW SMAWDeepak ShrivastavNo ratings yet

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- Carbon Steel: Wps No. Rev. P.No Material PQR Thickness Process PWHT Preheat SR # Filler MaterialDocument6 pagesCarbon Steel: Wps No. Rev. P.No Material PQR Thickness Process PWHT Preheat SR # Filler Materialvipin100% (1)

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document2 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Emmanuel Loayza100% (1)

- GMAW Welding Gas SelectionDocument4 pagesGMAW Welding Gas SelectionkapsarcNo ratings yet

- Welding Procedure Specification (WPS) : N.A N.ADocument1 pageWelding Procedure Specification (WPS) : N.A N.AMajdi Jerbi100% (1)

- WPS Pipe 08'' SHD 40 SMAW REV02Document2 pagesWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejNo ratings yet

- SS WPSDocument1 pageSS WPSMOHAMEDABBASNo ratings yet

- WQT - WPS 01Document71 pagesWQT - WPS 01Gururaj P Kundapur100% (1)

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- WPQR2Document3 pagesWPQR2Thanasis KyrgiazoglouNo ratings yet

- ASME P NumbersDocument1 pageASME P NumbersFahri Risfa ZulfiNo ratings yet

- WPS ListDocument2 pagesWPS ListAdeel OmerNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- WPS - Api 5L X52 - Codigo Api1104Document1 pageWPS - Api 5L X52 - Codigo Api1104Cristhian Camilo Quiroga WalterosNo ratings yet

- 1 5 1Document5 pages1 5 1daemsalNo ratings yet

- Wps 1010 IfrDocument28 pagesWps 1010 IfrSyed Mahmud Habibur RahmanNo ratings yet

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- Wps Aws d1.1 Ss400 To Ss400 Gmaw-RevDocument2 pagesWps Aws d1.1 Ss400 To Ss400 Gmaw-RevAnonymous zfC1zo9C100% (2)

- WPQ Sample PrintoutDocument1 pageWPQ Sample PrintoutKannan VelNo ratings yet

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocument2 pagesASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (2)

- PQR Sample PrintoutDocument2 pagesPQR Sample PrintoutDhewo Rachmad Yansyah100% (3)

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- QA-R-04 - Visual Inspection ReportDocument1 pageQA-R-04 - Visual Inspection ReportvinothNo ratings yet

- Sa 516 WPQDocument1 pageSa 516 WPQElgen IgloriaNo ratings yet

- WPS PQR FormatDocument1 pageWPS PQR FormatJatin Kamdar100% (2)

- Welding Electrode Selection Table - Piping StudyDocument1 pageWelding Electrode Selection Table - Piping StudySujay AsukarNo ratings yet

- TableQW-461.9 Performance Qualification-Position and Diameter LimitationsDocument1 pageTableQW-461.9 Performance Qualification-Position and Diameter LimitationsMadidj_2014No ratings yet

- Welding Procedure Specification (PWPS) - 5fpipe To Plate: Joint Design Used PositionDocument2 pagesWelding Procedure Specification (PWPS) - 5fpipe To Plate: Joint Design Used PositionTrudie0% (1)

- WPS - Smaw - 2Document6 pagesWPS - Smaw - 2Harkesh RajputNo ratings yet

- Wps Magi Tig Exemple PDFDocument6 pagesWps Magi Tig Exemple PDFJaime PatrónNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- WPS PQR PDFDocument23 pagesWPS PQR PDFtomj9104No ratings yet

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaNo ratings yet

- RT Acceptance Criteria For Welder Test According To ASME Sec IX (QW 191 1.2)Document20 pagesRT Acceptance Criteria For Welder Test According To ASME Sec IX (QW 191 1.2)Oscar Iván Duque Diaz100% (1)

- 202 1sp 0 Saw Cs CsDocument8 pages202 1sp 0 Saw Cs CskrishimaNo ratings yet

- WPS 304L &316LDocument2 pagesWPS 304L &316LShakeel Memon100% (1)

- QIR-104-Welding Parameters Record SheetDocument1 pageQIR-104-Welding Parameters Record SheetSamer Bayati100% (2)

- (Section IX, ASME Boiler and Pressure Vessel Code) : Welding Procedure Specification (WPS)Document2 pages(Section IX, ASME Boiler and Pressure Vessel Code) : Welding Procedure Specification (WPS)Quality LaveenaNo ratings yet

- Birla Copper WPS For Tube To Tubesheet Welding MOC - CSDocument2 pagesBirla Copper WPS For Tube To Tubesheet Welding MOC - CSJitu Padhiyar PadhiyarNo ratings yet

- Qap Hot Induction BendsDocument6 pagesQap Hot Induction BendsVidyut UjalaNo ratings yet

- WPS E6013+e7018Document2 pagesWPS E6013+e7018Anvesh Vaddi100% (1)

- Welding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Document2 pagesWelding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Saravanan Palanisamy Lakshmi100% (1)

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- Introduction To Design, Construction Practice and Application of HT Abc (Aerial Bunched Cable)Document46 pagesIntroduction To Design, Construction Practice and Application of HT Abc (Aerial Bunched Cable)Achu Deepu100% (3)

- Design of Lintel BeamDocument10 pagesDesign of Lintel BeamAnonymous LiddTaTaZTNo ratings yet

- Manual Pinch Valves BrochureDocument9 pagesManual Pinch Valves BrochureVenkatesh GangadharNo ratings yet

- Plasson Catalogue 2016 - EF Fittings PDFDocument44 pagesPlasson Catalogue 2016 - EF Fittings PDFMora ArthaNo ratings yet

- Lorient Finger GuardsDocument1 pageLorient Finger GuardsNick VincentNo ratings yet

- Allfasteners Anchor Selection GuideDocument68 pagesAllfasteners Anchor Selection GuideMattNo ratings yet

- 776 Dayton's Engineered Clearance-WebDocument6 pages776 Dayton's Engineered Clearance-WebNaukowyDrpNo ratings yet

- Stainless Steel Utensils - Specification: Indian StandardDocument18 pagesStainless Steel Utensils - Specification: Indian Standardgobinath VPNo ratings yet

- 5 Point I Water ProofingDocument46 pages5 Point I Water Proofingcollins014No ratings yet

- Commodity ThermoplasticsDocument55 pagesCommodity ThermoplasticsBernard GanzwaNo ratings yet

- Project Relative Advantages and Disadvantages of UPVC, Aluminum and Wooden Doors/WindowsDocument16 pagesProject Relative Advantages and Disadvantages of UPVC, Aluminum and Wooden Doors/Windowskhan03355No ratings yet

- Plumbing Fixture Flow Rate Tables (Non Residential)Document1 pagePlumbing Fixture Flow Rate Tables (Non Residential)DNo ratings yet

- Refnet & Piping SelectionDocument4 pagesRefnet & Piping SelectionZeeshan HasanNo ratings yet

- Chapter 01 - Introduction To Prestressed ConcreteDocument21 pagesChapter 01 - Introduction To Prestressed Concreterafee ahmad18-17100% (1)

- Content of ReportDocument52 pagesContent of ReportZaim AdliNo ratings yet

- Concrete Products Plant ProposalDocument8 pagesConcrete Products Plant ProposalFady AntonNo ratings yet

- Performance of Epoxy Resin As Self-Healing AgentDocument15 pagesPerformance of Epoxy Resin As Self-Healing AgentsusmithaNo ratings yet

- TIG Gas RodsDocument6 pagesTIG Gas RodsSankar KrishnanNo ratings yet

- Saudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Mar-16 MechDocument2 pagesSaudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Mar-16 MechSajid ShaikhNo ratings yet

- 1.8 Non Destructive Testing DisciplineDocument1 page1.8 Non Destructive Testing DisciplineTechie ndtNo ratings yet

- Reservedelsliste Spare Parts List Ersatzteilliste Onderdelenlijst Liste de Pièce de Rechange Lista Dei Pezzi Di RicambioDocument36 pagesReservedelsliste Spare Parts List Ersatzteilliste Onderdelenlijst Liste de Pièce de Rechange Lista Dei Pezzi Di RicambioOTO TAKNo ratings yet

- Corrosion and Cracking of Bottom Scrapers in Continuous DigestersDocument27 pagesCorrosion and Cracking of Bottom Scrapers in Continuous DigestersIndra NainggolanNo ratings yet

- Chapter 1Document61 pagesChapter 1ቀዳሚሃ ለጥበብ ፈሪሃ እግዚያብሔርNo ratings yet

- Tarkett Norma Centra BrochureDocument6 pagesTarkett Norma Centra Brochuresay itNo ratings yet

- Markal-Laco-Tempil 2019Document46 pagesMarkal-Laco-Tempil 2019Adelina EstrellaNo ratings yet

- Elimination of Crack Formation in Stainless Steel After Tig Welding - 2-427-151816990575-79Document5 pagesElimination of Crack Formation in Stainless Steel After Tig Welding - 2-427-151816990575-79arjun prajapatiNo ratings yet

- Preview 30371362Document9 pagesPreview 30371362Amira HossamNo ratings yet

Welding Procedure Specification: Page 1 of 1

Welding Procedure Specification: Page 1 of 1

Uploaded by

Anderson Perez Martinez100%(1)100% found this document useful (1 vote)

340 views2 pagesThis welding procedure specification outlines the parameters for welding duplex stainless steel to carbon steel fillet welds using the shielded metal arc welding process. The base metals are duplex stainless steel grades P1 to P10H and the filler metal is an E2594 classification 2.5mm diameter electrode. Welding will be done in all positions using multiple string bead passes with direct current electrode positive polarity. Preheating is required to a minimum of 25°C and interpass temperature must not exceed 150°C. Impact testing of welds produced using this procedure achieved average values of 26J at the weld centerline and 17J in the heat affected zone on the carbon steel side.

Original Description:

norma 3

Original Title

WPS-for-P-10H

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis welding procedure specification outlines the parameters for welding duplex stainless steel to carbon steel fillet welds using the shielded metal arc welding process. The base metals are duplex stainless steel grades P1 to P10H and the filler metal is an E2594 classification 2.5mm diameter electrode. Welding will be done in all positions using multiple string bead passes with direct current electrode positive polarity. Preheating is required to a minimum of 25°C and interpass temperature must not exceed 150°C. Impact testing of welds produced using this procedure achieved average values of 26J at the weld centerline and 17J in the heat affected zone on the carbon steel side.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

100%(1)100% found this document useful (1 vote)

340 views2 pagesWelding Procedure Specification: Page 1 of 1

Welding Procedure Specification: Page 1 of 1

Uploaded by

Anderson Perez MartinezThis welding procedure specification outlines the parameters for welding duplex stainless steel to carbon steel fillet welds using the shielded metal arc welding process. The base metals are duplex stainless steel grades P1 to P10H and the filler metal is an E2594 classification 2.5mm diameter electrode. Welding will be done in all positions using multiple string bead passes with direct current electrode positive polarity. Preheating is required to a minimum of 25°C and interpass temperature must not exceed 150°C. Impact testing of welds produced using this procedure achieved average values of 26J at the weld centerline and 17J in the heat affected zone on the carbon steel side.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

Page 1 of 1

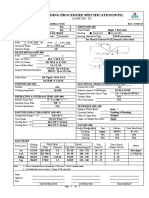

WELDING PROCEDURE SPECIFICATION

WPS No: 5130 – P1-P10H-SM – 01. PQR: PQR – A – 210 – SM

- 10

Revision No: - 1 Date: 06.04.2011.

Welding Processes: SMAW, Type: Manual

Code: ASME Sec VIII DIV.1, ASME Sec.IX, 2007ED. 2009b ADD

JOINTS (QW-402)

Backing: Without (SMAW).

Retainer: None.

Preparation: Plasma cutting/ Machining / Grinding.

BASE METALS (QW-403)

P1 Group 1/2 to P10H Group 1

Thickness Range:

Base Metal: 10 mm to 20 mm Fillet: All.

FILLER METALS (QW-404) SMAW POSITIONS (QW-405)

Position : ALL

SFA Specification No. A5.4 Progression : Uphill (GTAW).

AWS Classification E 2594

PREHEAT (QW-406)

F No. 5 Preheat Temp. Min : 25 Deg C

A No. 8 Interpass Temp. Max: 150 Deg C

Size of Electrode 2.5 mm Preheat Maintenance : None

Brand Name AVESTA 2507/P100 Measurement : Thermostick / Digital Thermometer

TECHNIQUE (QW-410)

Flux / Wire Class N/A String or Weave Bead : String

Alloy Flux N/A

Method of Cleaning : Grinding / Power Brushing

Supplemental Wire

N/A Method of Back Gouging : NIL.

Alloy Elements

N/A Multiple or Single Pass per side : Multiple Pass

Flux Designation

N/A Single or Multiple Electrodes : Single

Flux Type

N/A Peening : Not allowed.

Recrushed Slag

N/A Oscillation : None

Weld Metal Thickness Range

Groove 20 mm (Max) Tube – Work Distance : N/A

Fillet All

Electrode Spacing : N/A

Tube Expansion : NA.

POSTWELD HEAT TREATMENT (QW-407)

GAS (QW – 408)

Shielding Gas : NA

Not Applicable Single, Mixture or % : NA

Gas Flow Rate : NA

Backing Gas : NA

Trailing Gas : NA

(QW-409) ELECTRICAL CHARACTERISTICS

Weld Process Filler Metal Current Volt Travel Speed Max. Heat input

Layers Class Dia Type/ Amp Range Range Range (mm/mt) KJ/mm

(mm) Polarity

Root SMAW E 2594 2.5 DCEP 40 - 50 20 – 24 55 – 65 1.140

Hot SMAW E 2594 2.5 DCEP 70 – 80 20 – 24 110 – 120 0.962

Fill + cap

SMAW E 2594 2.5 DCEP 55 – 65 20 – 24 120 – 130 0.710

For GMMOS : NOTE: THIS WPS IS ONLY FOR THE INTERNALS

DUPLEX TO CARBON STEEL FILLET WELDS.

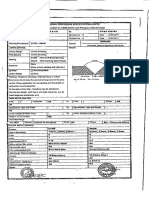

WELDING PROCEDURE SPECIFICATION

ADDENDUM TO WPS# 5130 – P1-P10H-SM – 01 REV.1

REFERENCE TO PQR-A-210-SM-10.

IMPACT TEST TEMPERATURE : - 52 DEGREE C.

IMPACT AVERAGE VALUE AT WCL: 26 J

IMPACT AVERAGE VALUE AT HAZ (CS SIDE): 17 J.

AS PER GS 146-2 PARA AA2.1 (NOTE) CONVERSION 1.5 J

PER DEGREE C.

SO., 52 X 1.5 = 78.

WCL VALUE SHALL BE 78 + 26 = 104.

HAZ (CS SIDE) VALUE SHALL BE 78 + 17 = 95.

You might also like

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 pagesWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- 37507022-WPS-PQR-SS-316 LDocument5 pages37507022-WPS-PQR-SS-316 LVarun Malhotra100% (6)

- Blank Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)Document1 pageBlank Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)GMNo ratings yet

- 2018 Ibc Seaoc Structural Seismic Design Manual Volume 2 Examplespdf CompressDocument385 pages2018 Ibc Seaoc Structural Seismic Design Manual Volume 2 Examplespdf Compressvkch saipavan100% (3)

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- TABLE 100.12.1 Bolt-Torque Values For Electrical Connections US Standard Fasteners Heat-Treated Steel - Cadmium or Zinc PlatedDocument3 pagesTABLE 100.12.1 Bolt-Torque Values For Electrical Connections US Standard Fasteners Heat-Treated Steel - Cadmium or Zinc PlatedKennedy VasconezNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- WPS and PQRDocument4 pagesWPS and PQRdandiar1No ratings yet

- Atf Wpqr-Blank v1Document1 pageAtf Wpqr-Blank v1lth770310No ratings yet

- Welding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Document2 pagesWelding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Harshit AdwaniNo ratings yet

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- MACRO AIR SABST Roofing InsulationDocument28 pagesMACRO AIR SABST Roofing InsulationBer Salazar Jr100% (1)

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad Pathan100% (1)

- Welding Proposed Pwps For Our Jubail WorkDocument2 pagesWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (3)

- ASME IX Sample WPS GTAW SMAWDocument1 pageASME IX Sample WPS GTAW SMAWDeepak ShrivastavNo ratings yet

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- Carbon Steel: Wps No. Rev. P.No Material PQR Thickness Process PWHT Preheat SR # Filler MaterialDocument6 pagesCarbon Steel: Wps No. Rev. P.No Material PQR Thickness Process PWHT Preheat SR # Filler Materialvipin100% (1)

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document2 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Emmanuel Loayza100% (1)

- GMAW Welding Gas SelectionDocument4 pagesGMAW Welding Gas SelectionkapsarcNo ratings yet

- Welding Procedure Specification (WPS) : N.A N.ADocument1 pageWelding Procedure Specification (WPS) : N.A N.AMajdi Jerbi100% (1)

- WPS Pipe 08'' SHD 40 SMAW REV02Document2 pagesWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejNo ratings yet

- SS WPSDocument1 pageSS WPSMOHAMEDABBASNo ratings yet

- WQT - WPS 01Document71 pagesWQT - WPS 01Gururaj P Kundapur100% (1)

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- WPQR2Document3 pagesWPQR2Thanasis KyrgiazoglouNo ratings yet

- ASME P NumbersDocument1 pageASME P NumbersFahri Risfa ZulfiNo ratings yet

- WPS ListDocument2 pagesWPS ListAdeel OmerNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- WPS - Api 5L X52 - Codigo Api1104Document1 pageWPS - Api 5L X52 - Codigo Api1104Cristhian Camilo Quiroga WalterosNo ratings yet

- 1 5 1Document5 pages1 5 1daemsalNo ratings yet

- Wps 1010 IfrDocument28 pagesWps 1010 IfrSyed Mahmud Habibur RahmanNo ratings yet

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- Wps Aws d1.1 Ss400 To Ss400 Gmaw-RevDocument2 pagesWps Aws d1.1 Ss400 To Ss400 Gmaw-RevAnonymous zfC1zo9C100% (2)

- WPQ Sample PrintoutDocument1 pageWPQ Sample PrintoutKannan VelNo ratings yet

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocument2 pagesASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (2)

- PQR Sample PrintoutDocument2 pagesPQR Sample PrintoutDhewo Rachmad Yansyah100% (3)

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- QA-R-04 - Visual Inspection ReportDocument1 pageQA-R-04 - Visual Inspection ReportvinothNo ratings yet

- Sa 516 WPQDocument1 pageSa 516 WPQElgen IgloriaNo ratings yet

- WPS PQR FormatDocument1 pageWPS PQR FormatJatin Kamdar100% (2)

- Welding Electrode Selection Table - Piping StudyDocument1 pageWelding Electrode Selection Table - Piping StudySujay AsukarNo ratings yet

- TableQW-461.9 Performance Qualification-Position and Diameter LimitationsDocument1 pageTableQW-461.9 Performance Qualification-Position and Diameter LimitationsMadidj_2014No ratings yet

- Welding Procedure Specification (PWPS) - 5fpipe To Plate: Joint Design Used PositionDocument2 pagesWelding Procedure Specification (PWPS) - 5fpipe To Plate: Joint Design Used PositionTrudie0% (1)

- WPS - Smaw - 2Document6 pagesWPS - Smaw - 2Harkesh RajputNo ratings yet

- Wps Magi Tig Exemple PDFDocument6 pagesWps Magi Tig Exemple PDFJaime PatrónNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- WPS PQR PDFDocument23 pagesWPS PQR PDFtomj9104No ratings yet

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaNo ratings yet

- RT Acceptance Criteria For Welder Test According To ASME Sec IX (QW 191 1.2)Document20 pagesRT Acceptance Criteria For Welder Test According To ASME Sec IX (QW 191 1.2)Oscar Iván Duque Diaz100% (1)

- 202 1sp 0 Saw Cs CsDocument8 pages202 1sp 0 Saw Cs CskrishimaNo ratings yet

- WPS 304L &316LDocument2 pagesWPS 304L &316LShakeel Memon100% (1)

- QIR-104-Welding Parameters Record SheetDocument1 pageQIR-104-Welding Parameters Record SheetSamer Bayati100% (2)

- (Section IX, ASME Boiler and Pressure Vessel Code) : Welding Procedure Specification (WPS)Document2 pages(Section IX, ASME Boiler and Pressure Vessel Code) : Welding Procedure Specification (WPS)Quality LaveenaNo ratings yet

- Birla Copper WPS For Tube To Tubesheet Welding MOC - CSDocument2 pagesBirla Copper WPS For Tube To Tubesheet Welding MOC - CSJitu Padhiyar PadhiyarNo ratings yet

- Qap Hot Induction BendsDocument6 pagesQap Hot Induction BendsVidyut UjalaNo ratings yet

- WPS E6013+e7018Document2 pagesWPS E6013+e7018Anvesh Vaddi100% (1)

- Welding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Document2 pagesWelding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Saravanan Palanisamy Lakshmi100% (1)

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- Introduction To Design, Construction Practice and Application of HT Abc (Aerial Bunched Cable)Document46 pagesIntroduction To Design, Construction Practice and Application of HT Abc (Aerial Bunched Cable)Achu Deepu100% (3)

- Design of Lintel BeamDocument10 pagesDesign of Lintel BeamAnonymous LiddTaTaZTNo ratings yet

- Manual Pinch Valves BrochureDocument9 pagesManual Pinch Valves BrochureVenkatesh GangadharNo ratings yet

- Plasson Catalogue 2016 - EF Fittings PDFDocument44 pagesPlasson Catalogue 2016 - EF Fittings PDFMora ArthaNo ratings yet

- Lorient Finger GuardsDocument1 pageLorient Finger GuardsNick VincentNo ratings yet

- Allfasteners Anchor Selection GuideDocument68 pagesAllfasteners Anchor Selection GuideMattNo ratings yet

- 776 Dayton's Engineered Clearance-WebDocument6 pages776 Dayton's Engineered Clearance-WebNaukowyDrpNo ratings yet

- Stainless Steel Utensils - Specification: Indian StandardDocument18 pagesStainless Steel Utensils - Specification: Indian Standardgobinath VPNo ratings yet

- 5 Point I Water ProofingDocument46 pages5 Point I Water Proofingcollins014No ratings yet

- Commodity ThermoplasticsDocument55 pagesCommodity ThermoplasticsBernard GanzwaNo ratings yet

- Project Relative Advantages and Disadvantages of UPVC, Aluminum and Wooden Doors/WindowsDocument16 pagesProject Relative Advantages and Disadvantages of UPVC, Aluminum and Wooden Doors/Windowskhan03355No ratings yet

- Plumbing Fixture Flow Rate Tables (Non Residential)Document1 pagePlumbing Fixture Flow Rate Tables (Non Residential)DNo ratings yet

- Refnet & Piping SelectionDocument4 pagesRefnet & Piping SelectionZeeshan HasanNo ratings yet

- Chapter 01 - Introduction To Prestressed ConcreteDocument21 pagesChapter 01 - Introduction To Prestressed Concreterafee ahmad18-17100% (1)

- Content of ReportDocument52 pagesContent of ReportZaim AdliNo ratings yet

- Concrete Products Plant ProposalDocument8 pagesConcrete Products Plant ProposalFady AntonNo ratings yet

- Performance of Epoxy Resin As Self-Healing AgentDocument15 pagesPerformance of Epoxy Resin As Self-Healing AgentsusmithaNo ratings yet

- TIG Gas RodsDocument6 pagesTIG Gas RodsSankar KrishnanNo ratings yet

- Saudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Mar-16 MechDocument2 pagesSaudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Mar-16 MechSajid ShaikhNo ratings yet

- 1.8 Non Destructive Testing DisciplineDocument1 page1.8 Non Destructive Testing DisciplineTechie ndtNo ratings yet

- Reservedelsliste Spare Parts List Ersatzteilliste Onderdelenlijst Liste de Pièce de Rechange Lista Dei Pezzi Di RicambioDocument36 pagesReservedelsliste Spare Parts List Ersatzteilliste Onderdelenlijst Liste de Pièce de Rechange Lista Dei Pezzi Di RicambioOTO TAKNo ratings yet

- Corrosion and Cracking of Bottom Scrapers in Continuous DigestersDocument27 pagesCorrosion and Cracking of Bottom Scrapers in Continuous DigestersIndra NainggolanNo ratings yet

- Chapter 1Document61 pagesChapter 1ቀዳሚሃ ለጥበብ ፈሪሃ እግዚያብሔርNo ratings yet

- Tarkett Norma Centra BrochureDocument6 pagesTarkett Norma Centra Brochuresay itNo ratings yet

- Markal-Laco-Tempil 2019Document46 pagesMarkal-Laco-Tempil 2019Adelina EstrellaNo ratings yet

- Elimination of Crack Formation in Stainless Steel After Tig Welding - 2-427-151816990575-79Document5 pagesElimination of Crack Formation in Stainless Steel After Tig Welding - 2-427-151816990575-79arjun prajapatiNo ratings yet

- Preview 30371362Document9 pagesPreview 30371362Amira HossamNo ratings yet