Professional Documents

Culture Documents

Product Data Sheet: Topaz SG Enamel 524ME

Product Data Sheet: Topaz SG Enamel 524ME

Uploaded by

Tejinder KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product Data Sheet: Topaz SG Enamel 524ME

Product Data Sheet: Topaz SG Enamel 524ME

Uploaded by

Tejinder KumarCopyright:

Available Formats

Product Data Sheet

Topaz SG Enamel 524ME

Description: Topaz SG Enamel is a high quality alkyd topcoat with excellent flow properties and giv-

ing a smooth semi-gloss finish. Topaz SG Enamel gives a smooth luxurious semi-gloss

finish with outstanding opacity, flexibility and unique colour retention properties.

Recommended use: Ideally suited for interior and exterior door and window frames, furniture, and

woodwork in general, and ideal for metal surfaces. Also for internal walls, ceiling,

partitions, etc.

Substrates: Metal surfaces, wood work, fibreboards, etc. Masonry and concrete surfaces after

proper priming with alkali resistant primer.

Features: Superior non-yellowing properties

Excellent whiteness

Outstanding smoothness

Excellent flow properties

Sealing/priming:

On ferrous metals: Maestro Alkyd primer or as specified.

On wood: Topaz SB primer

Maestro Alkyd undercoat or as specified.

On concrete: Topaz WB primer

Maestro WB primer or as specified.

Filling: Exterior: Topaz exterior filler

Interior: Topaz interior filler

Maestro easy filler or as specified.

Certificates/approvals: Dry film thickness, BS EN ISO 2808:2007

Pull off, BS EN 4624:2004

Blistering, cracking, flaking, chalking, BS EN ISO4628–8:2012

Anti-corrosion, BS EN ISO 4623 and BS EN ISO 12944

Viscosity, ASTM D2196

Fineness of grind, ASTM D1210

Shelf life/storage conditions: 24 months from date of production.

The product must be stored as per local storage regulations and should be kept in dry

and well-ventilated location far from heat and direct sunlight.

Availability: Available in 1L, 3.79L, 18L

(Packing may vary from country to country depending on local requirements)

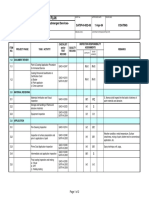

Physical constants:*

Colours/shade nos: White/10000 and refer to intertior colour card

Finish: Semi-gloss

Volume solids, %: 46±2%

Theoretical spreading rate: 15.3 m2/l – 30 microns**

o

Flash point: 38 C

Specific gravity: 1.29 kg/l

o o o

Surface dry: 12 hours (10 C) 6 hours (20 C) 3 hours (40 C)

o o o

Through-dry: 48 hours (10 C) 24 hours (20 C) 12 hours (40 C)

VOC content 402.2 g/l

Produced by Hempel Middle East, issued in September 2016 Page: 1 of 2

Product Data Sheet

Topaz SG Enamel 524ME

Application details:

Application method: Roller/Brush Conventional spray Airless spray

Thinner (max vol): 08230 (5%) 08230 (15%) 08230 (5%)

Nozzle orifice: n/a .052”–.070” .013”–.017”

Nozzle pressure: n/a 3–4 bar (40–60 psi) 150 bar (2175 psi)

o o o o

Spray angle: n/a 30 –50 40 –50

Filter: n/a n/a 100

Cleaning of tools: Thinner 08230

Indicated film thickness, dry: 30 microns

Indicated film thickness, wet: 65 microns

o o o

Recoat interval, min: 48 hours (10 C) 24 hours (20 C) 12 hours (40 C)

Recoat interval, max: None None None

Safety: Handle with care. Before and during use, observe all safety labels on packaging and

paint containers, consult Hempel material safety data sheets and follow all local or

national safety regulations. Avoid inhalation, avoid contact with skin and eyes and do

not swallow. Take precautions against possible risks of fire or explosions as well as

protection of the environment. Apply only in well-ventilated areas.

Surface preparation: Ideally suited for interior and exterior door and window frames, furniture, and wood

work in general, and ideal for metal surfaces. Also for internal walls, ceilings, partitions,

etc.

o

Application conditions: Use only where application and drying can proceed at temperatures above 5 C, and

relative humidity is below 75%.

Remarks: Drying data given is on the assumption that proper ventilation is provided.

Masking tapes used during paint application should be removed when the paint is still

in the wet condition.

Note: *The physical constants stated are nominal data according to the Hempel Group’s

approved formulas. They are subject to normal manufacturing tolerances and where

stated, being standard deviation according to ISO 3534–1.

**The theoretical spreading rate has been calculated for the stated volume solids

and dry film thickness. A practical spreading rate will depend on the actual dry film

thickness, the nature of the substrate and the relevant consumption factor.

The physical constants are subject to normal manufacturing tolerances.

Further reference is made to ‘explanatory notes’.

Issued by: HEMPEL MIDDLE EAST

This Product Data Sheet supersedes those previously issued.

For explanations, definitions and scope, see 'Explanatory Notes' available on www.hempel.com. Data, specifications, directions and recommendations given

in this data sheet represent only test results or experience obtained under controlled or specially defined circumstances. Their accuracy, completeness or

appropriateness under the actual conditions of any intended use of the products herein must be determined exclusively by the Buyer and/or User.

The Products are supplied and all technical assistance is given subject to Hempel's general conditions of sales, delivery and service, unless otherwise

expressly agreed in writing. The Manufacturer and Seller disclaim, and Buyer and/or User waive all claims involving, any liability, including but not limited

to negligence, except as expressed in said general conditions for all results, injury or direct or consequential losses or damages arising from the use of the

products as recommended above, on the overleaf or otherwise. Product data are subject to change without notice and become void five years from the

date of issue.

Produced by Hempel Middle East, issued in September 2016 Page: 2 of 2

You might also like

- 09 Samss 070Document11 pages09 Samss 070NASIR SYEDNo ratings yet

- Australian StandardDocument2 pagesAustralian Standardlauren_connors9172100% (4)

- Torsion Report PDFDocument31 pagesTorsion Report PDFKalKatu MaLam100% (22)

- 4 Final ReportDocument36 pages4 Final ReportAmeenNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanMoghal AliNo ratings yet

- Durapol UHT (Spray Grade) - 2014 PDFDocument2 pagesDurapol UHT (Spray Grade) - 2014 PDFEngTamerNo ratings yet

- Ministry of Bahrain - Filling Material DetailsDocument6 pagesMinistry of Bahrain - Filling Material DetailsTejinder KumarNo ratings yet

- Satip H 002 11Document10 pagesSatip H 002 11Rauf ChaudharyNo ratings yet

- 18B. Protegol UR 32.55R Data SheetDocument3 pages18B. Protegol UR 32.55R Data SheetClarkFedele27No ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanMoghal AliNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection ChecklistAnantha PadmanabhanNo ratings yet

- Hempel Epoxy Filler 35230Document3 pagesHempel Epoxy Filler 35230Noman AhmedNo ratings yet

- Product Data Sheet: Hempafloor Durable 300Document2 pagesProduct Data Sheet: Hempafloor Durable 300Fadi MagdyNo ratings yet

- TDS Nitocote EPU Saudi ArabiaDocument4 pagesTDS Nitocote EPU Saudi ArabiaShaikhRizwan100% (1)

- Paint SystemDocument2 pagesPaint SystemYasir AsifNo ratings yet

- Jotafloor Coating: Technical Data SheetDocument5 pagesJotafloor Coating: Technical Data SheetBilher SihombingNo ratings yet

- Hempel'S Vinyl Ester GF 35910: Description: Recommended UseDocument2 pagesHempel'S Vinyl Ester GF 35910: Description: Recommended UseEngTamerNo ratings yet

- MSDS Primer S1301-M Parte ADocument2 pagesMSDS Primer S1301-M Parte AMichael Betetta AbadNo ratings yet

- SCM 400 Salt Contamination MeterDocument2 pagesSCM 400 Salt Contamination MeterJohn Watson100% (1)

- Removing Coatings and Cleaning Masonry Substrates: Kenneth A. Trimber KTA-Tator, IncDocument46 pagesRemoving Coatings and Cleaning Masonry Substrates: Kenneth A. Trimber KTA-Tator, IncMilagros MorantesNo ratings yet

- 09 SAMSS 089 (Final Draft - 2018)Document28 pages09 SAMSS 089 (Final Draft - 2018)lhanx2No ratings yet

- Paint System Recommendations PDFDocument6 pagesPaint System Recommendations PDFKumarNo ratings yet

- 09-SAMSS-068 Qualification Requirements For Coal Tar Epoxy in Buried or Immersion Services (APCS-3) For Steel and ConcreteDocument7 pages09-SAMSS-068 Qualification Requirements For Coal Tar Epoxy in Buried or Immersion Services (APCS-3) For Steel and ConcreteAbdul HannanNo ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportMoghal AliNo ratings yet

- Hempadur Mastic 45880-45881Document3 pagesHempadur Mastic 45880-45881David HoffmanNo ratings yet

- Hempel Curing Agent 98021 MsdsDocument10 pagesHempel Curing Agent 98021 MsdsM.FAIZAN ARSHADNo ratings yet

- Materials System SpecificationDocument8 pagesMaterials System SpecificationAjeetKumarNo ratings yet

- Nitomortar TC2000Document3 pagesNitomortar TC2000talatzahoorNo ratings yet

- ABRASIVE BLASTING SM PRESENTATION 2017.ppsxDocument18 pagesABRASIVE BLASTING SM PRESENTATION 2017.ppsxIsaac SamuelNo ratings yet

- Dfy - Coating Quality Key PointsDocument1 pageDfy - Coating Quality Key PointsMohammed SadiqNo ratings yet

- Apcs 117Document12 pagesApcs 117Ilyas AhmedNo ratings yet

- MasterSeal TC 244Document2 pagesMasterSeal TC 244EngTamerNo ratings yet

- Ai Hempadur 87540 EnglishDocument2 pagesAi Hempadur 87540 EnglishAmilcar BolagNo ratings yet

- Saes H 201Document9 pagesSaes H 201heartbreakkid132No ratings yet

- 3m & Fischer Firestop Material For Curtain Wall JointsDocument110 pages3m & Fischer Firestop Material For Curtain Wall JointsRenjith RaveendranNo ratings yet

- Coating Personnel Id FormatDocument1 pageCoating Personnel Id FormatShabbar Abbas MalikNo ratings yet

- 1 Pig Gauge (Model OG204) / Elcometer 121: St2/St3 St2/St3Document19 pages1 Pig Gauge (Model OG204) / Elcometer 121: St2/St3 St2/St3Akansha SharmaNo ratings yet

- Techno India University, Kolkata: (B.Tech Civil Engineering)Document3 pagesTechno India University, Kolkata: (B.Tech Civil Engineering)HimanshuNo ratings yet

- Cte Ongc SpecDocument21 pagesCte Ongc SpecMohamed HushainNo ratings yet

- PDS TOPAZ INTERIOR FILLER 38840 en-GBDocument4 pagesPDS TOPAZ INTERIOR FILLER 38840 en-GBJalil TahirNo ratings yet

- TDS Aqua SealerDocument2 pagesTDS Aqua SealerFaiz Zainudin100% (1)

- SATIP-H-002-05 Epoxy For Atmospheric Up To 150CDocument2 pagesSATIP-H-002-05 Epoxy For Atmospheric Up To 150ChossamalsherbinyNo ratings yet

- Coating As An Ideal Prevention For Corrosion in Manufacture and Infrastructure IndustryDocument43 pagesCoating As An Ideal Prevention For Corrosion in Manufacture and Infrastructure IndustryLarasanto Larasanto100% (1)

- 05 Aramco Approved Coating SystemDocument3 pages05 Aramco Approved Coating SystemRyanNo ratings yet

- Materials System SpecificationDocument10 pagesMaterials System SpecificationAjeetKumar100% (1)

- STDs ListDocument5 pagesSTDs ListIlyas AhmedNo ratings yet

- SATIP-H-002-06 Coating For Submerged Services-APCS 113 ABCDocument2 pagesSATIP-H-002-06 Coating For Submerged Services-APCS 113 ABChossamalsherbinyNo ratings yet

- Hempadur Quattro 17634: Product Characteristics Product SafetyDocument4 pagesHempadur Quattro 17634: Product Characteristics Product Safetyulul100% (1)

- Focus Assessment FADocument2 pagesFocus Assessment FAkousick sundararajanNo ratings yet

- Sigmacover 410Document4 pagesSigmacover 410gstketutNo ratings yet

- Safety Talk For Painting WorkDocument3 pagesSafety Talk For Painting WorkBashir KhanNo ratings yet

- 01 Saveto Bond 2 - Group 180821Document2 pages01 Saveto Bond 2 - Group 180821iwcksa22No ratings yet

- SAIC-H-2001 Rev 7Document3 pagesSAIC-H-2001 Rev 7Satheesh Rama SamyNo ratings yet

- Basf Masterprotect 1815 TdsDocument3 pagesBasf Masterprotect 1815 TdsEngTamer100% (1)

- Surface Treatment and Painting ProcedureDocument7 pagesSurface Treatment and Painting ProcedureMohamedNo ratings yet

- Chemical Resistance GuideDocument11 pagesChemical Resistance GuideMohamed NouzerNo ratings yet

- Fenomastic Hygiene Emulsion SilkDocument4 pagesFenomastic Hygiene Emulsion Silkمحمد عزتNo ratings yet

- Renderoc MPRDocument2 pagesRenderoc MPRtalatzahoorNo ratings yet

- Paints and Coatings FinalDocument5 pagesPaints and Coatings FinalSheena GagarinNo ratings yet

- A1-80-3 External Painting and Coating - 1Document16 pagesA1-80-3 External Painting and Coating - 1ZYW100% (1)

- Product Data Sheet: Topaz Matt Emulsion 588MEDocument2 pagesProduct Data Sheet: Topaz Matt Emulsion 588MEJoseph DarwinNo ratings yet

- Pds Maestro Matt Emulsion 594me En-GbDocument2 pagesPds Maestro Matt Emulsion 594me En-GbDipin Nediya Parambath0% (1)

- Maestro WB Primer 28830 28830 En-GbDocument2 pagesMaestro WB Primer 28830 28830 En-GbMohamed NouzerNo ratings yet

- Data SheetsDocument98 pagesData SheetsTejinder KumarNo ratings yet

- Ar-Ty-978 Typical Garbage Chute DetailsDocument1 pageAr-Ty-978 Typical Garbage Chute DetailsTejinder KumarNo ratings yet

- Finish WRDocument2 pagesFinish WRTejinder KumarNo ratings yet

- BITUFLAME P 4180, P 4200 & P 4260: - DescriptionDocument2 pagesBITUFLAME P 4180, P 4200 & P 4260: - DescriptionTejinder KumarNo ratings yet

- Epilux 155Document2 pagesEpilux 155Tejinder KumarNo ratings yet

- UCRETE PRIMER RG Tds 130900Document2 pagesUCRETE PRIMER RG Tds 130900Tejinder KumarNo ratings yet

- Epilux Concrete PrimerDocument3 pagesEpilux Concrete PrimerTejinder KumarNo ratings yet

- Contex SB Primer 26630Document2 pagesContex SB Primer 26630Tejinder KumarNo ratings yet

- Installation Guide: Polystorm Lite and PolystormDocument15 pagesInstallation Guide: Polystorm Lite and PolystormTejinder KumarNo ratings yet

- Vetonit Doc Technical Map en 3193Document2 pagesVetonit Doc Technical Map en 3193Tejinder KumarNo ratings yet

- 5535 7644 1 PB PDFDocument12 pages5535 7644 1 PB PDFTejinder KumarNo ratings yet

- NITOPROOFDocument4 pagesNITOPROOFTejinder KumarNo ratings yet

- Vitra Retains The Right To Change Details About The Products and Technical Specifications Without Prior NoticeDocument1 pageVitra Retains The Right To Change Details About The Products and Technical Specifications Without Prior NoticeTejinder KumarNo ratings yet

- TreeParker Installation Guidelines EnglishDocument36 pagesTreeParker Installation Guidelines EnglishTejinder KumarNo ratings yet

- Data Sheet - CreavitDocument11 pagesData Sheet - CreavitTejinder KumarNo ratings yet

- 2 BRC FabricDocument6 pages2 BRC FabricTejinder KumarNo ratings yet

- Fosroc Dekguard E2000: (Also Known As Nitocote FBC)Document4 pagesFosroc Dekguard E2000: (Also Known As Nitocote FBC)Tejinder KumarNo ratings yet

- JotunDocument30 pagesJotunTejinder KumarNo ratings yet

- Fosroc Supercast SW20: Constructive SolutionsDocument2 pagesFosroc Supercast SW20: Constructive SolutionsTejinder KumarNo ratings yet

- Cutting and FillingDocument12 pagesCutting and FillingTejinder KumarNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerSathish Kumar SelvarajNo ratings yet

- 22 Principles of Plumbing From The Revised National Plumbing Code of The Philippines PDFDocument2 pages22 Principles of Plumbing From The Revised National Plumbing Code of The Philippines PDFMARK ANGELO CONSUL100% (1)

- Fike Fm-200 With SHP ProDocument8 pagesFike Fm-200 With SHP ProGovinda GopinathNo ratings yet

- Drilling Products: Engineering Excellence in A Global MarketDocument12 pagesDrilling Products: Engineering Excellence in A Global MarketGustavo CunhaNo ratings yet

- TDS - RheoFIT 726 PDFDocument2 pagesTDS - RheoFIT 726 PDFAlexi ALfred H. TagoNo ratings yet

- API579 EXAMPLE CalculationsDocument4 pagesAPI579 EXAMPLE CalculationsJaclyn Henderson80% (5)

- Bo Dowswell, P.E., PH.D.: Experience ConsultantDocument6 pagesBo Dowswell, P.E., PH.D.: Experience ConsultantdpkNo ratings yet

- Manual BombasDocument56 pagesManual BombasLuis Cespedes NorambuenaNo ratings yet

- XRD in The Cement IndustryDocument56 pagesXRD in The Cement IndustryIvanoff Vladimir Rojas Tello100% (1)

- Advances in Material Forming and Joining-5th AIMTDR PDFDocument385 pagesAdvances in Material Forming and Joining-5th AIMTDR PDFAbhijeetNo ratings yet

- Section 200 Pipe DataDocument26 pagesSection 200 Pipe DataHunterNo ratings yet

- Typical Bollard Detail: 4" Dia. (Min) Steel Pipe Filled With ConcreteDocument1 pageTypical Bollard Detail: 4" Dia. (Min) Steel Pipe Filled With ConcreteaishahrahmanNo ratings yet

- Concrete Moisture Testing Guide 1-15Document2 pagesConcrete Moisture Testing Guide 1-15soutrick BaruiNo ratings yet

- QST E380 TMDocument2 pagesQST E380 TMParthi NatarajNo ratings yet

- Model Working Estimate - NREGSDocument89 pagesModel Working Estimate - NREGSD.V.Srinivasa RaoNo ratings yet

- Civil Engineering Material Lecture NotesDocument4 pagesCivil Engineering Material Lecture Notes11520035No ratings yet

- Molylube 3% Moly Extreme Pressure Grease LC - 5Document2 pagesMolylube 3% Moly Extreme Pressure Grease LC - 5DAnielNo ratings yet

- Weller CatalogDocument88 pagesWeller CatalogcammellieNo ratings yet

- Material List Interior r1Document3 pagesMaterial List Interior r1FikriNo ratings yet

- MINE292 Lecture7 Energy Used in Comminution 2013Document87 pagesMINE292 Lecture7 Energy Used in Comminution 2013Waris La Joi Wakatobi100% (2)

- Qdoc - Tips Practical Handbook of Grouting Soil Rock and Struc 19 43Document25 pagesQdoc - Tips Practical Handbook of Grouting Soil Rock and Struc 19 43Diego Quispe CondoriNo ratings yet

- ABAQUS Tutorial: Dr. Ahmed ElkadyDocument6 pagesABAQUS Tutorial: Dr. Ahmed ElkadyHuseinNo ratings yet

- 01 Bar Schedule PILE CAP & COLUMNDocument2 pages01 Bar Schedule PILE CAP & COLUMNorode franklynNo ratings yet

- Concealed TypeDocument2 pagesConcealed TypeSubhash NairNo ratings yet

- Energy PlusDocument29 pagesEnergy Plusbloodpaint87No ratings yet

- Frigidaire Refrigerator Next Generation Controls - Replacing The Control and Damper AssemblyDocument3 pagesFrigidaire Refrigerator Next Generation Controls - Replacing The Control and Damper AssemblySamurai Appliance Repair Man100% (2)

- Marshall Mix DesignDocument2 pagesMarshall Mix DesignTakdir Satria NandaNo ratings yet