Professional Documents

Culture Documents

An Optimal Solution To The Linear Programming Problem Using Lingo Solver: A Case Study of An Apparel Production Plant of Sri Lanka

An Optimal Solution To The Linear Programming Problem Using Lingo Solver: A Case Study of An Apparel Production Plant of Sri Lanka

Uploaded by

Hafis SayedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

An Optimal Solution To The Linear Programming Problem Using Lingo Solver: A Case Study of An Apparel Production Plant of Sri Lanka

An Optimal Solution To The Linear Programming Problem Using Lingo Solver: A Case Study of An Apparel Production Plant of Sri Lanka

Uploaded by

Hafis SayedCopyright:

Available Formats

International Journal of Computer Science and Business Informatics

IJCSBI.ORG

An Optimal Solution to the Linear

Programming Problem using Lingo

Solver: A Case Study of an Apparel

Production Plant of Sri Lanka

Z. A. M. S. Juman and W. B. Daundasekara

Department of Mathematics,

Faculty of Science, University of Peradeniya,

Sri Lanka

ABSTRACT

Operations Research (OR) is often concerned with determining the maximum of profit,

performance, yield etc. or minimum of cost, loss, risk, etc. of some real-world objectives.

The Linear Programming Problem (LPP), a branch of Operations Research consists of an

objective function which is linear and constraints are linear equations or inequalities. This

research paper presents a Mathematical Model of a LPP which is to minimize the

production cost, while satisfying operational limitations, of a production plant producing t-

shirts. This production plant is known as Silk Line (pvt) Ltd which is located in Sri Lanka.

The developed model is considered to be a large scale one which provides a fully functional

cost effective system finding optimum number of machine operators and workers in each of

the departments in the production plant as well as finding optimum raw material for the

entire t-shirts production. The optimal solution to the model is found using the commercial

software package called “LINGO SOLVER”. Moreover, a sensitivity analysis is

performed to complete the target (entire t-shirts production) within a given specific period

of time.

Keywords

Linear Programming Problem, Optimum number of machine operators, Lingo Solver,

Sensitivity analysis.

1. INTRODUCTION

Linear programming is an optimization technique which was developed

during the Second World War. An LPP consists of an objective function

which is linear and constraints are linear equations or inequalities. Objective

function and constraints are formed using the decision variables which are

defined according to the given problem. Decision variables are continuous

to be real valued variables which may have lower or upper bounds.

ISSN: 1694-2108 | Vol. 14, No. 2. AUGUST/SEPTEMBER 2014 1

International Journal of Computer Science and Business Informatics

IJCSBI.ORG

Objective function is to be maximized or minimized subject to the

constraints which form a convex feasible region. An LPP can be solved

using an iterative algorithm known as the Simplex Algorithm which was

developed by Dantzig in 1950‟s. This is the most the widely used and

accepted algorithm to solve LPPs because of its simplicity. The optimal

solution of the objective function may be bounded or unbounded whereas

optimal solution to the decision variables may or may not be unique.

Linear Programming has a broader area of applications in the fields of

productions, telecommunications, transportations, scheduling etc. The main

focus of linear programming is to optimize the available resources in the

best possible manner while achieving the objective.

This research paper is focusing on optimizing production cost of a t-shirts

production plant which is located in Sri Lanka. Although the plant‟s monthly

target is 30,000 t-shirts, the records show that the target level has not been

reached in a regular basis. Also, it can be observed that the plant‟s

operational costs are mainly due to workers monthly payments which are

more than what is needed. Due to low productivity and unnecessary

expenditures, at present the plant is facing major financial difficulties and

several other problems in designing the production process. Therefore, the

management is interested in implementing a cost effective system to reduce

the production cost while improving the production efficiency of t-shirts. In

fact, in this research paper, a large scale linear programming model is

developed to achieve these objectives. Then LINGO SOLVER is used to

solve the developed large scale model.

The remainder of this paper is organized as follows: Related literature

review is given in section 2. Section 3 deals with the Methods and Materials

of the LPP. In section 4 the solution to the large scale LPP is summarized.

Finally, the conclusion given in section 5 highlights the limitations and

future research scope on the topic.

2. LITERATURE REVIEW

Linear Programming problem and its solution have been studied by many

authors. Few of them are James and Tom [5], Brain [1], Dantzig [2] and

Taha [13]. A number of computer software is available in obtaining the

solutions to LPP. Some are based on the simplex method and its variants,

e.g. CPLEX, LINDO, TORA, MATLAB, EXCEL SOLVER, AMPL and

LINGO, and some are based on the interior point algorithms, e.g. MOSEX.

See Fourer [3]. Though the software based on simplex method and its

variants have been used widely in solving linear programming problems,

they solve LPP in exponential time. An algorithm that solves LPP in

ISSN: 1694-2108 | Vol. 14, No. 2. AUGUST/SEPTEMBER 2014 2

International Journal of Computer Science and Business Informatics

IJCSBI.ORG

polynomial time is considered to be efficient. A first attempt of solving LPP

in polynomial time was the development of interior point algorithm by

Karmarkar [8]. How to solve a large scale LPP by interior point method

under MATLAB environment was proposed by Zhang [15]. The existing

interior point algorithms have some drawbacks such as extensive calculation

requirements, large number of iterations and large computer space

requirements. See Terlaky and Boggs [14].In addition, Hitchcock [4] was

first to develop the transportation model. After that, the transportation

problem, a special class of linear programming problem has been studied by

many researchers. Sharma and Sharma [12] presented the transportation

problem in a slightly different form in getting a dual problem which has a

special structure. Then they proposed a new solution procedure to solve the

dual of the incapacitated transportation problem. Sharma and Prasad [11]

presented a heuristic that provides a very good initial solution to the

transportation problem in polynomial time. Schrenk et al. [10] analyzed

degeneracy characterizations for two classical problems: the transportation

paradox in linear transportation problems and the pure constant fixed charge

(there is no variable cost and the fixed charge is the same on all routes)

transportation problems. A new result on complexity of the pure constant

fixed charge transportation problem has been proved. Liu [9] investigated

the transportation problem when the demands and supplies were varying

within their respective ranges. Following these variations the minimal total

cost were also varied within an interval. So, he built a pair of mathematical

programs where at least one of the supply or the demand was varying, to

compute the lower and the upper bounds of the total transportation cost.

Then the Lingo solver was used to solve the both mathematical programs to

attain the lower and the upper bounds of the minimal total transportation

costs. Juman and Hoque [7] demonstrated the deficiency of Liu‟s [9] method

in getting an upper bound of the minimal total costs of transportation. Then

they extended this Liu‟s model to include the inventory costs of the product

during transportation and at destinations, as they are interrelated factors.

In addition, they developed two new efficient heuristic solution techniques -

Algorithms 1 & 2 to find the upper and the lower minimal total cost

bounds respectively. By comparative studies of the solution techniques on

the solutions of small size numerical problems, it is observed that our

proposed heuristic technique (Algorithm1) performs the same or

significantly better in finding the upper bound of the minimal total cost as

compared with Liu‟s [9] approach. Algorithm 2 provided the same lower

bound of the minimal total costs to each of the numerical problems studied

as the one found by Liu‟s [9] approach. Moreover, numerical studies

demonstrated that the inclusion of inventory costs during transportation and

at destinations with the transportation costs changes the lower and the upper

minimal total cost bounds reasonably. Juman, Hoque and Bhuhari [6]

ISSN: 1694-2108 | Vol. 14, No. 2. AUGUST/SEPTEMBER 2014 3

International Journal of Computer Science and Business Informatics

IJCSBI.ORG

designed a C++ computational program of Vogel‟s Approximation Method

(to solve an unbalanced transportation problem by considering both the

balanced and unbalanced features respectively with and without adding a

dummy column) in obtaining an initial feasible solution (IFS) to an

unbalanced transportation problem (UTP). In order to get an initial feasible

solution to a large scale TP, this computational program of VAM is

preferred. Moreover, we examine the effect of dealing with the balanced and

the unbalanced features in applying the well-known VAM method for

solving an unbalanced transportation problem. First we illustrated the

solution procedures with numerical examples (chosen from the literature).

Then we demonstrated this effect by a comparative study on solutions of

some numerical problems obtained by VAM by considering the balanced

and the unbalanced features.

3. METHODS AND MATERIAL

3.1 Current approach

The current methodology, adopted by the plant, to increase the production

has failed due to several drawbacks. At present, the plant finds a feasible

solution by manually comparing alternative resource allocations. Although

the management is fully committed to improve the production process in

order to reach the optimum production, it has failed to achieve the objective.

It was observed that the current production process in the plant has several

weaknesses. This is mainly due to following reasons:

Mismanagement of human resources

Mismanagement of orders

Improper resource utilization

3.2 Data Collection

Data were collected using Questionnaires and Interviews. Then the

mathematical model for the month of August 2012 was formulated using the

collected data.

3.3 Formulation of the Mathematical Model

3.3.1Decision Variables of the Model

Decision variables of the proposed model are as follows:

x1,x2,...,x19, x20 and x52, x53 = # trained and untrained cutter, band knife,

normal, 5-tread, 4-tread, flat lock, button hole, button attach, blind hem,

double needle, and fusing machine operators; x21,x22 = # mechanics needed

ISSN: 1694-2108 | Vol. 14, No. 2. AUGUST/SEPTEMBER 2014 4

International Journal of Computer Science and Business Informatics

IJCSBI.ORG

in cutting and sewing departments; x23, x24, x54, x44 = # instructors needed in

cutting, sewing, QC (quality control) and packing departments;

x31, x32, x55, x42 = # supervisors needed in cutting, sewing, QC and packing

departments; x29, x30 = # table checkers needed in cutting and sewing

departments; x25, x26, x39 = # helpers needed in cutting, sewing and packing

departments; x33, x34, x56, x43 = # clerks needed in cutting, sewing, QC and

packing departments; x40 = # menders needed in packing department; x41 =

# quality checkers needed in QC department; x38, x35, x37 , x45 = # in chargers

needed in packing, cutting, QC and sewing departments; x48 = # personal

managers; x47 = # account clerks; x27 , x28 = # quality instructors needed in

cutting and sewing departments; x36 = # production managers; x46 = # iron

tables; x49, x50, x51 = # small, medium, large t-shirts produced in a month.

(Here, # denotes „number of ‟)

3.3.2 Objective Function of the Model

The objective of the linear programming model presented below is to

determine the minimum production cost of the production plant.

Mathematical formulation of objective function:

Cost Function

56 51

Minimize Production Cost Z

i 1

ci xi 4500 x46 c

j 49

j x j , where ci

i 46, 49, 50, 51

is the salary of the ith employee and cj is the raw material cost of the jth type

t-shirt subject to the following constraints :

3.3.3 Constraints of the Model

All the constraints in the model can be categorized into five different types

as shown in Table 1 below.

Table 1 Types of model constraints

Constraints Inequalities

30 x j 120x j1 c j ; j 5,7,9,...,19;

ISSN: 1694-2108 | Vol. 14, No. 2. AUGUST/SEPTEMBER 2014 5

International Journal of Computer Science and Business Informatics

IJCSBI.ORG

c j # t-shirts completed in a day by jth type of machines in the sewing department

Machine xk xk 1 ck ; k 1,3,5,...,17,19,52 ;

ck # machine operators needed for the k type

th

of machines in cutting and sewing

departments

Cutting, Sewing, QC and Packing Departments must have a minimum # workers to

perform the duties.

x55 1; # supervisors needed in QC department.

Workers

x33 x56 x43 ; same # clerks needed in cutting, QC and packing departments.

x28 7 ; # quality instructors needed in sewing department.

Raw material 29x49 30x50 32x51 899964 inches

( raw material needed for the entire t-shirt production)

29 80 30 80 32 80

49x 50x 51 x Rs.1999920

36 36 36

Raw material cost

(raw material cost for the entire production)

11 . 66 x 11 .66 x 11 .66 x 12480

49 50 51 minutes

20 20 20

Time

( time available for the entire t-shirt production )

3.4 Linear Programming Model (LPM)

Finally, Linear Programming Model (LPM) for the existing problem could

be formulated as below. Optimal solution of the model is obtained using the

software known as LINGO as illustrated below:

ISSN: 1694-2108 | Vol. 14, No. 2. AUGUST/SEPTEMBER 2014 6

International Journal of Computer Science and Business Informatics

IJCSBI.ORG

Figure 1 LINGO Mainframe Window

Linear Programming Model:

MinZ 4200 X 1 6200 X 2 4200 X 3 6200 X 4 4200 X 52 6200 X 53 4200 X 5 6200 X 6

4200 X 7 6200 X 8 4200 X 9 6200 X 10 4200 X 11 6200 X 12 4200 X13 6200 X14

4200 X 15 6200 X 16 4200 X17 6200 X18 4200 X19 6200 X 2010000 X 21 10000 X 22

15000 X 23 15000 X 24 10000 X 54 10000 X 44 8000 X 27 8000 X 28 4500 X 29 4500 X 30

(1)

4500 X 40 10000 X 31 10000 X 32 10000 X 55 10000 X 42 5000 X 33 5000 X 34

5000 X 56 5000 X 43 12000 X 47 5000 X 41 4000 X 25 4000 X 26 4000 X 39 14000 X 48

30000 X 36 20000 X 35 20000 X 37 20000 X 38 20000 X 45 4500 X 46 2320 36X 49

2400 36X 50 2560 36X 51

subject to

30X 5 120X 6 1200 ; 30X 7 120X 8 600 ; 30X 9 120X 10 600 ;

30X 11 120X 12 1000 ; 30X 13 120X 14 1500 ; 30X 15 120X 16 1500 ; (2)

30X 17 120X 18 1500 ; 30X 19 120X 20 1500

X 1 X 2 3 ; X 3 X 4 1 ; X 52 X 53 2 ; X 5 X 6 115 ; X 7 X 8 15 ;

X 9 X 10 8 ; X 11 X 12 4 ; X 13 X 14 2 ; X 15 X 16 3; X 17 X 18 2 ; (3)

X 19 X 20 12

ISSN: 1694-2108 | Vol. 14, No. 2. AUGUST/SEPTEMBER 2014 7

International Journal of Computer Science and Business Informatics

IJCSBI.ORG

3X 2 1200; 3X 4 1200 ; 3X 53 1200 (4)

X 5 X 6 X 7 X 8 X 9 X 10 X 11 X 12 X 13 X 14 X 15 X 16 (5)

45X 22 X X X X

17 18 19 20

45X 21 X1 X 2 X 3 X 4 X 52 X 53 0 ; 20X 23 X1 X 2 X 3 X 4 X 52 X 53 0 (6)

X 24 2X 23 ; X 54 2X 23 ; X 44 X 23 (7)

20X 31 X 1 X 2 X 3 X 4 X 52 X 53 (8)

X 5 X 6 X 7 X 8 X 9 X10 X11 X 12 X13 X14 X15 X16

60X 32 X X X X

(9)

17 18 19 20

X 55 1 ; 50X 42 X 39 X 40 X 46 ; X 29 8 ; X 30 X 29 (10)

X 5 X 6 X 7 X 8 X 9 X 10 X 11 X 12 X 13 X 14 X 15 X 16

9X 26 X X X X (11)

17 18 19 20

20X 25 13X 26 0 ; 20X 39 8X 26 0 (12)

X 5 X 6 X 7 X 8 X 9 X 10 X 11 X 12 X 13 X 14 X 15 X 16

40X 34 X X X X (13)

17 18 19 20

4X 33 X 34 0 ; X 33 X 56 X 43 (14)

X 40 12 ; X 41 24

(15)

X 38 1 ; X 35 1 ; X 37 1 (16)

161

X 3; X X ; X ; X 7 ; 2X X 0; X 1; X 1 (17)

48 47 48 22 28 27 28 36 45

45

ISSN: 1694-2108 | Vol. 14, No. 2. AUGUST/SEPTEMBER 2014 8

International Journal of Computer Science and Business Informatics

IJCSBI.ORG

X 46 8; 29X 49 30X 50 32X 51 899964 (18)

2320X 49 2400X 50 2560X 51 71997120 (19)

11.66 X 11.66 X 11.66 X 12480

49 50 51 (20)

20 20 20

X 49 14350 ; X 50 10450 ; X 51 5200 (21)

X 0 and integers ; X is the column vector consisting of decision variables. (22)

4. RESULTS

By solving the developed large scale mathematical model (as shown in

section 3.4) using Lingo solver, the solutions obtained are given below in

Table 2 and Figures 2-5. The comparison between the optimal number of

each type of machines and number of machines currently being used in the

plant is shown in the following table:

Table 2The optimal table for the types of machines

Departments Type of machine Available # Optimal # machines

machines

Cutter 3 3

Department of

cutting Band knife 1 1

Fusing 2 2

Normal 115 115

5-tread 13 15

4-tread 8 8

Department of Flat lock 4 8

sawing Button hole 12 13

Button attach 12 13

Blind hem 10 13

Double needle 12 13

where x1+x2 =# cutter machines;x3+x4= # band knife machines; x52+x53 = #

fusing machines;x5+x6 =# normal machines;x7+x8 =# 5-tread

machines;x9+x10= # 4-tread machines;x11+x12 = # flat lock machines;x13+x14

ISSN: 1694-2108 | Vol. 14, No. 2. AUGUST/SEPTEMBER 2014 9

International Journal of Computer Science and Business Informatics

IJCSBI.ORG

= # button hole machines;x15+x16 = # button attach machines; x17+x18= #

blind hem machines; x19+x20= # double needle machines.

The Table 2 clearly shows the available number of machines and their

respective optimal amount. The cutting department consists of three cutter,

one band knife and two fusing machines in the plant. The optimum

quantities for these machines in the cutting department are the same. The

sawing department consists of hundred and fifteen normal machines,

thirteen 5-tread machines, eight 4-tread machines, four flat lock machines,

twelve button hole machines, twelve button attach machines, ten blind hem

machines, and twelve double needle machines. The optimum quantities for

these machines in the sawing department are 115, 15, 8, 8, 13, 13, 13, 13

respectively.

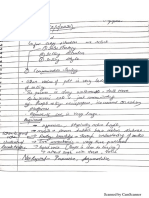

No. of mechanics in cutting dept.

Number of Workers currently working in the Factory No. of mechanics in sawing dept

No. of instructors in cutting dept.

30

28 No. of instructors in sawing dept.

No. of instructors in QC dept.

26 No. of instructors in packing dept.

No. of quality instructors in cutting dept.

25 No. of quality instructors in sawing dept.

No. of table checker in cutting dept.

No. of table checker in sawing dept.

20 No. of menders in packing dept.

20 No. of supervisors in cutting dept.

No. of supervisors in sawing dept.

No. of supervisors in QC dept.

17 No. of supervisors in packing dept.

15 14 No. of clerks in cutting dept.

12

No. of clerks in sawing dept.

Fig 1 No. of clerks in QC dept.

11

No. of clerks in packing dept.

10

No. of account clerks

No. of quality checkers in QC dept.

7 7 No. of helpers in cutting dept.

6 No. of helpers in sawing dept.

No. of helpers in packing dept.

5

3 3 3 3 No. of personal managers

2 22 2 2 No. of production managers

1 1 1 1 1 1 11 1 11 1 No. of cutting in chargers

No. of QC in chargers

0 No. of packing in chargers

Workers No. of work-study in chargers in sawing dept.

No. of iron tables

Figure 2 Number of workers currently working in the factory

The bar charts in Figure 2 clearly depict the available number of workers

who are currently working in the plant as follows: The cutting department

consists of a mechanic, three instructors, two quality instructors, eleven

table checkers, two supervisors, three clerks, seventeen helpers, and two

cutting-in-chargers. The sawing department consists of seven mechanics,

ISSN: 1694-2108 | Vol. 14, No. 2. AUGUST/SEPTEMBER 2014 10

International Journal of Computer Science and Business Informatics

IJCSBI.ORG

one instructor, one quality instructor, twelve table checkers, two

supervisors, six clerks, twenty six helpers, and one work-study-in-charger.

The QC department consists of one instructor, one supervisor, one clerk,

twenty eight quality checkers, and one QC in-charger. The packing

department consists of one instructor, twenty menders, two supervisors, one

clerk, seven helpers, and one packing in-charger. In addition to there are

three account clerks, three personal managers, one production manager, and

fourteen iron tables in the factory.

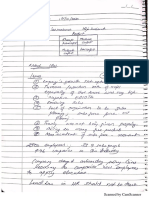

Optimum Number of Workers needed

for the Monthly Production

No. of mechanics in cutting dept.

No. of mechanics in sawing dept

No. of instructors in cutting dept.

25 24 No. of instructors in sawing dept.

No. of instructors in QC dept.

22 No. of instructors in packing dept.

No. of quality instructors in cutting dept.

No. of quality instructors in sawing dept.

20 No. of table checker in cutting dept.

No. of table checker in sawing dept.

No. of menders in packing dept.

No. of supervisors in cutting dept.

No. of supervisors in sawing dept.

15 14 No. of supervisors in QC dept.

No. of supervisors in packing dept.

12 No. of clerks in cutting dept.

No. of clerks in sawing dept.

No. of clerks in QC dept.

10 9 No. of clerks in packing dept.

8 No. of account clerks

88

No. of quality checkers in QC dept.

No. of helpers in cutting dept.

5 No. of helpers in sawing dept.

5

No. of helpers in packing dept.

4

No. of personal managers

3 3 3

No. of production managers

2

No. of cutting in chargers

1 111 1 1 1

11111 No. of QC in chargers

00 0 00 No. of packing in chargers

0

No. of work-study in chargers in sawing dept.

No. of iron tables

Figure 3 Optimum number of workers needed for the monthly production

The bar charts in Figure 3 clearly depict the optimum number of workers

needed for the monthly production of the plant as follows: The cutting

department consists of one mechanic, one instructor, eight table checkers,

one supervisor, two clerks, fourteen helpers, and one cutting-in-charger. The

sawing department consists of four mechanics, one instructor, eight table

checkers, three supervisors, five clerks, twenty two helpers, and one work-

study-in-charger. The QC department consists of one instructor, twenty four

ISSN: 1694-2108 | Vol. 14, No. 2. AUGUST/SEPTEMBER 2014 11

International Journal of Computer Science and Business Informatics

IJCSBI.ORG

quality checkers, and one QC in-charger. The packing department consists

of one instructor, twelve menders, one supervisor, nine helpers, and one

packing in-charger. In addition to there are three account clerks, three

personal managers, one production manager, and eight iron tables in the

factory.It should be noted that the total number of workers working in the

plant is 182 (see Figure 2). The Optimum number of workers needed for the

monthly production of t-shirts is 137 (see Figure 3). Thusour model which is

presented in this paper reduces the total number of workers by 32.9 %.

Expected number of T-shirts to be produced in August 2012

No. of small t-shirts

16000

14000 14350

12000

10000 10450 No. of medium t-

shirts

8000

6000

4000 5200

No. of large t-shirts

2000

Figure 4 Expected numbers of t-shirts (small, medium, and large) to be

produced in August

The bar charts in Figure 4 clearly depict the expected total number of t-

shirts to be produced in August 2012. The expected numbers of small,

medium and large size t-shirts are 14350, 10450, and 5200 respectively.

Result obtained in the Proposed Model

No. of m edium t-shirts

15000 produced in over tim e

Num ber of 3393

10000

Medium T-

5000 7057

shirts

0 No. of m edium t-shirts

1

Medium T-shirts

Figure 5 Number of medium size t-shirts produced in normal and over time

ISSN: 1694-2108 | Vol. 14, No. 2. AUGUST/SEPTEMBER 2014 12

International Journal of Computer Science and Business Informatics

IJCSBI.ORG

The bar chart in Figure 5 clearly shows the exact numbers of medium size t-

shirts produced in normal and over times. The bottom of the bar chart

represents that the 7057 medium size t-shirts are produced in normal time

whereas the remaining 3393 (shown in top of the bar chart) are produced in

over time. It should be noted that, in order to complete the entire t-shirts

production in a specific time period, 3393 medium sized t-shirts must be

produced in overtime. See the Figure 5 given above.

Current & Optimum Production

Cost in August 2012

4,300,000

Current

production

4,200,000 4,230,283 cost

4,100,000

4,000,000

Optimum

3,900,000 production

3,800,000

cost

3,802,183

3,700,000

3,600,000

3,500,000

Figure 6 Comparative result of current and optimum production cost

Figure 6 clearly shows that the optimal monthly production cost of the plant

is Rs. 3,802,183. But, for the same month the plant estimated average

monthly production cost for this plant to be Rs. 4,230,283.

5. CONCLUSION

According to the optimal solution of the proposed model for the month of

August 2012, the monthly optimal production cost of the plant is Rs.

3,802,183. But in the same month the plant‟s estimated average monthly

cost is Rs.4,230,283. This clearly indicates that the plant is spending in

excess of Rs.428,100 than what is actually needed. Therefore, the plant can

save a maximum of Rs. 428,100 (10%) per month by implementing the

proposed method. Moreover, a sensitivity analysis is performed to complete

ISSN: 1694-2108 | Vol. 14, No. 2. AUGUST/SEPTEMBER 2014 13

International Journal of Computer Science and Business Informatics

IJCSBI.ORG

the t-shirts production within the specified period of time (one month). After

performing a sensitivity analysis, it was revealed that the production plant

needs at least 22760 meters of raw material to meet the given target.

In this research only the production cost is considered while assuming that

the monthly demand is a fixed quantity. But, in practice, for the manufacture

(production plant), there are setup costs and inventory costs of raw-material,

work-in-process and finished goods as well. In addition, buyers incur

transportation costs, ordering costs and inventory costs during transportation

and at the destination (buyer/retailer). Thus, future research might be carried

out by taking these costs of setup, inventory, ordering and transportation

into account. Also, demand can be considered as stochastic. Hence, an

integrated single-manufacture-multi-buyer model with stochastic demand

can be obtained. How to develop a streamline method to tackle this large

scale LPP after considering these costs is challenging and potential future

research.

ACKNOWLEDGMENTS

The authors acknowledge that this research is supported by the research

grant of University of Peradeniya, Sri Lanka. Also, they are grateful to the

referees for their valuable, constructive commentsand suggestions.

REFERENCES

[1] Brain, D.B. Basic Linear Programming. London, Spottiswoode Ballantyne Ltd,1984.

[2] Dantzig, G.B. Linear Programming and extensions. Princeton, NJ: Princeton

University press, 1963.

[3] Fourer, R. Survey of linear programming software. OR/MS today, (2001), pp. 58-68.

[4] Hitchcock, F.L. The distribution of a product from several sources to numerous

locations. Journal of mathematical physics, 20, (1941), pp. 224-230.

[5] James, P.I. and Tom, M.C. Linear Programming. Prentice, Hall, Inc, 1994.

[6] Juman, Z.A.M.S., Hoque, M.A. and Buhari, M.I.A sensitivity analysis and an

implementation of the well-known Vogel‟s approximation method for solving

unbalanced transportation problems. Malaysian Journal of Science, 32,1(2013), pp. 66-

72.

[7] Juman, Z.A.M.S., Hoque, M.A. A heuristic solution technique to attain the minimal

total cost bounds of transporting a homogeneous product with varying demands and

supplies. European Journal of Operational Research, 239, (2014)pp. 146-156.

[8] Karmarkar, N. A new polynomial time algorithm for linear programming.

Combinatorial, 4, (1984), pp. 373-395.

[9] Liu, S.T. The total cost bounds of the transportation problem with varying demand and

supply.Omega, 31,(2003), pp.247-251.

ISSN: 1694-2108 | Vol. 14, No. 2. AUGUST/SEPTEMBER 2014 14

International Journal of Computer Science and Business Informatics

IJCSBI.ORG

[10] Schrenk, S., Finke, G and Cung, V.D. Two classical transportation problems revisited:

Pure constant fixed charges and the paradox. Mathematical and Computer Modeling,

54,(2011), pp. 2306-2315.

[11] Sharma, R.R.K. and Prasad, S. Obtaining a good primal solution to the uncapacitated

transportation problem. European Journal of Operational Research, 144, (2003) , pp.

560-564.

[12] Sharma, R.R.K and Sharma, K.D. A new dual based procedure for the transportation

problem. European Journal of Operational Research, 122, 3 (2000),pp. 611-624.

[13] Taha H. A. Operation Research: An introduction. Prentice-Hall of India, 8th edition,

2006.

[14] Terlaky, T. and Boggs, P.T. Interior point method. Faculty of information technology,

Delft. Netherlands, 2005.

[15] Zhang, Y. Solving large scale linear programming by interior point method under

MATLAB environment. Technical report, Mathematics Department, University of

Maryland, Baltimore Country, 1996.

This paper may be cited as:

Juman, Z. A. M. S. and Daundasekara, W. B., 2014. An Optimal Solution to

the Linear Programming Problem using Lingo Solver: A Case Study of an

Apparel Production Plant of Sri Lanka. International Journal of Computer

Science and Business Informatics, Vol. 14, No. 2, pp. 1-15.

ISSN: 1694-2108 | Vol. 14, No. 2. AUGUST/SEPTEMBER 2014 15

You might also like

- Operation Research Project TransportationDocument11 pagesOperation Research Project TransportationAmit87% (23)

- Software Documentation-Internal and ExternalDocument7 pagesSoftware Documentation-Internal and ExternalBini LyngdohNo ratings yet

- Linear Programming: An Introduction to Finite Improvement Algorithms: Second EditionFrom EverandLinear Programming: An Introduction to Finite Improvement Algorithms: Second EditionRating: 5 out of 5 stars5/5 (2)

- Computer-Controlled Systems: Theory and Design, Third EditionFrom EverandComputer-Controlled Systems: Theory and Design, Third EditionRating: 3 out of 5 stars3/5 (4)

- Operations Research ProjectDocument21 pagesOperations Research ProjectDeepak KanojiaNo ratings yet

- Vol 14 No 2 - September 2014Document149 pagesVol 14 No 2 - September 2014ijcsbiNo ratings yet

- Research Paper On Linear ProgrammingDocument6 pagesResearch Paper On Linear Programmingtrsrpyznd100% (3)

- Comparison Between Goal Programming and Other Linear Programming MethodsDocument4 pagesComparison Between Goal Programming and Other Linear Programming MethodsIJRASETPublicationsNo ratings yet

- 4th Semester, Applied Operations ResearchDocument5 pages4th Semester, Applied Operations ResearchZid ZidNo ratings yet

- Hindusthan College of Engineering and Technology: 16ma6111 & Operations ResearchDocument13 pagesHindusthan College of Engineering and Technology: 16ma6111 & Operations Researchkumaresanm MCET-HICETNo ratings yet

- Reflection of Critical PathDocument12 pagesReflection of Critical PathArchana MunusamyNo ratings yet

- Decision Making With Simplex Model: A Case StudyDocument8 pagesDecision Making With Simplex Model: A Case Studyreehammostafa77No ratings yet

- Mb0032 - Operation Research Set - 1 Solved AssignmentDocument13 pagesMb0032 - Operation Research Set - 1 Solved AssignmentAbhishek GuptaNo ratings yet

- MSC DissertationDocument108 pagesMSC DissertationBogdan ProfirNo ratings yet

- Project (2) - CopyDocument30 pagesProject (2) - Copygelo kingNo ratings yet

- Research Paper Linear ProgrammingDocument6 pagesResearch Paper Linear Programmingzxqefjvhf100% (1)

- OOPSLA23 BDocument27 pagesOOPSLA23 BVan Tien LeNo ratings yet

- Basic Concepts of Operation ResearchDocument11 pagesBasic Concepts of Operation ResearchAarti AhujaNo ratings yet

- Habiba FullDocument7 pagesHabiba FullShashwat JhaNo ratings yet

- Solving Applied Optimization Problems Using TOMLABDocument9 pagesSolving Applied Optimization Problems Using TOMLABNicholas KormanikNo ratings yet

- LPP Project - Profit Maximization Through Optimization TechniqueDocument38 pagesLPP Project - Profit Maximization Through Optimization TechniqueMonish Ansari100% (2)

- Unit 2Document21 pagesUnit 2Rebecca SanchezNo ratings yet

- MB0048 Set 1 & 2Document14 pagesMB0048 Set 1 & 2Shravanti Bhowmik SenNo ratings yet

- Mail - Iiitdmj.ac - in Squirrelmail SRC Webmail NewDocument17 pagesMail - Iiitdmj.ac - in Squirrelmail SRC Webmail NewsharathkumarposaNo ratings yet

- Application of Transportation Problem in Operational ResearchDocument17 pagesApplication of Transportation Problem in Operational ResearchTina JinaNo ratings yet

- Profitoptimization 2015Document8 pagesProfitoptimization 2015Henok AsemahugnNo ratings yet

- Linear Programming TheoryDocument99 pagesLinear Programming TheoryRamez SafwatNo ratings yet

- Thesis Linear ProgrammingDocument6 pagesThesis Linear Programmingnqvgequgg100% (2)

- QT Project HighlightedDocument8 pagesQT Project HighlightedSumanya KumariNo ratings yet

- Lab Report 2Document6 pagesLab Report 2Rabia UmerNo ratings yet

- An Automatic Design Optimization Tool and Its Application To Computational Fluid DynamicsDocument12 pagesAn Automatic Design Optimization Tool and Its Application To Computational Fluid DynamicsVishal DwivediNo ratings yet

- Survey Paper On Linear Programming in Machine LearningDocument3 pagesSurvey Paper On Linear Programming in Machine LearningInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Linear Programming Is A Mathematical Method For Optimizing Operations Given RestrictionsDocument10 pagesLinear Programming Is A Mathematical Method For Optimizing Operations Given RestrictionsJyoti SahuNo ratings yet

- Operations Research AssignmentDocument14 pagesOperations Research AssignmentGodfred AbleduNo ratings yet

- Opt Chapter 3Document7 pagesOpt Chapter 3MikiasNo ratings yet

- Lpp1 - Doc 2 Auto Saved)Document38 pagesLpp1 - Doc 2 Auto Saved)Sonia VermaNo ratings yet

- Automatic Static Feature Generation For Compiler Optimization ProblemsDocument10 pagesAutomatic Static Feature Generation For Compiler Optimization ProblemsDeepi NatarajanNo ratings yet

- Research Paper of MinorDocument5 pagesResearch Paper of Minoraadityapawar210138No ratings yet

- Paper 1Document26 pagesPaper 1vramosNo ratings yet

- Course: Student Name: Godfred Kwame Abledu Identification Number: UD17440HST25230Document31 pagesCourse: Student Name: Godfred Kwame Abledu Identification Number: UD17440HST25230Godfred AbleduNo ratings yet

- Ipsoftware RevDocument43 pagesIpsoftware RevNelson Espejo BarraNo ratings yet

- Optimization Efficiency + SavingsDocument13 pagesOptimization Efficiency + SavingsMitik PopoviciNo ratings yet

- On-Line Resource Management With Application To Routing and SchedulingDocument28 pagesOn-Line Resource Management With Application To Routing and SchedulingpostscriptNo ratings yet

- PCX - ReportDocument4 pagesPCX - ReportespantocdNo ratings yet

- DS Unit - VDocument19 pagesDS Unit - VsriaishwaryaNo ratings yet

- Mathematical Modelling of Engineering Problems: Received: 30 November 2021 Accepted: 9 June 2022Document9 pagesMathematical Modelling of Engineering Problems: Received: 30 November 2021 Accepted: 9 June 2022Engr Shahzaib ShahNo ratings yet

- Critique Paper2 - Ateneo MBADocument3 pagesCritique Paper2 - Ateneo MBAChenelly AlcasidNo ratings yet

- SEM 2 MB0032 1 Operations ResearchDocument13 pagesSEM 2 MB0032 1 Operations Researchalokmitra_upNo ratings yet

- OR Project Work AlphaDocument1 pageOR Project Work AlphaBereket MulugetaNo ratings yet

- Assignment Report: "Optimization Models For Industry"Document6 pagesAssignment Report: "Optimization Models For Industry"Ashad CoolNo ratings yet

- Application of Linear Programming To Analyze Profit of FoodDocument7 pagesApplication of Linear Programming To Analyze Profit of FoodNalla vedavathi100% (1)

- Learning To Cut Tang20aDocument10 pagesLearning To Cut Tang20aj3qbzodj7No ratings yet

- A Case Study On The Optimization of Multi-Objective Functions Transportation Model For Public Transport Authority (Egypt)Document13 pagesA Case Study On The Optimization of Multi-Objective Functions Transportation Model For Public Transport Authority (Egypt)Mohamed KhalilNo ratings yet

- Literature Review On Application of Linear ProgrammingDocument6 pagesLiterature Review On Application of Linear ProgrammingafmabreouxqmrcNo ratings yet

- Linear Programming ChapterDocument43 pagesLinear Programming ChapterParisha PandeyNo ratings yet

- 7 1526465877 - 16-05-2018 PDFDocument7 pages7 1526465877 - 16-05-2018 PDFAnonymous lPvvgiQjRNo ratings yet

- Introduction To LPPDocument10 pagesIntroduction To LPPAmiya ArnavNo ratings yet

- Optimization for Decision Making: Linear and Quadratic ModelsFrom EverandOptimization for Decision Making: Linear and Quadratic ModelsNo ratings yet

- 19PGP177 Session12 PDFDocument4 pages19PGP177 Session12 PDFHafis SayedNo ratings yet

- 19PGP177 Session13 PDFDocument3 pages19PGP177 Session13 PDFHafis SayedNo ratings yet

- 19PGP177 Session13 PDFDocument3 pages19PGP177 Session13 PDFHafis SayedNo ratings yet

- 19PGP177 Session4 PDFDocument5 pages19PGP177 Session4 PDFHafis SayedNo ratings yet

- 19PGP177 Session11 PDFDocument5 pages19PGP177 Session11 PDFHafis SayedNo ratings yet

- 19PGP177 Session10 PDFDocument5 pages19PGP177 Session10 PDFHafis SayedNo ratings yet

- 19PGP177 Session9 PDFDocument4 pages19PGP177 Session9 PDFHafis SayedNo ratings yet

- 19PGP177 Session5 PDFDocument5 pages19PGP177 Session5 PDFHafis SayedNo ratings yet

- 19PGP177 Session8 PDFDocument5 pages19PGP177 Session8 PDFHafis SayedNo ratings yet

- 19PGP177 Session6 PDFDocument6 pages19PGP177 Session6 PDFHafis SayedNo ratings yet

- 19PGP177 Session7 PDFDocument4 pages19PGP177 Session7 PDFHafis SayedNo ratings yet

- 19PGP177 Session12 PDFDocument4 pages19PGP177 Session12 PDFHafis SayedNo ratings yet

- 19PGP177 Session11 PDFDocument5 pages19PGP177 Session11 PDFHafis SayedNo ratings yet

- 19PGP177 Session10 PDFDocument5 pages19PGP177 Session10 PDFHafis SayedNo ratings yet

- 19PGP177 Session14 PDFDocument5 pages19PGP177 Session14 PDFHafis SayedNo ratings yet

- 19PGP177 Session7 PDFDocument4 pages19PGP177 Session7 PDFHafis SayedNo ratings yet

- 19PGP177 Session9 PDFDocument4 pages19PGP177 Session9 PDFHafis SayedNo ratings yet

- 19PGP177 Session6Document6 pages19PGP177 Session6Hafis SayedNo ratings yet

- 19PGP177 Session3Document3 pages19PGP177 Session3Hafis SayedNo ratings yet

- 19PGP177 Session8 PDFDocument5 pages19PGP177 Session8 PDFHafis SayedNo ratings yet

- 19PGP177 Session5Document5 pages19PGP177 Session5Hafis SayedNo ratings yet

- 19PGP177 Session4Document5 pages19PGP177 Session4Hafis SayedNo ratings yet

- 19PGP177 Session20 PDFDocument2 pages19PGP177 Session20 PDFHafis SayedNo ratings yet

- 19PGP177 Session2 PDFDocument3 pages19PGP177 Session2 PDFHafis SayedNo ratings yet

- 19PGP177 Session17 PDFDocument3 pages19PGP177 Session17 PDFHafis SayedNo ratings yet

- 19PGP177 Session1 PDFDocument3 pages19PGP177 Session1 PDFHafis SayedNo ratings yet

- 19PGP177 Session18 PDFDocument5 pages19PGP177 Session18 PDFHafis SayedNo ratings yet

- 19PGP177 Session19 PDFDocument3 pages19PGP177 Session19 PDFHafis SayedNo ratings yet

- 19PGP177 Session1Document2 pages19PGP177 Session1Hafis SayedNo ratings yet

- 19PGP177 Session8Document5 pages19PGP177 Session8Hafis SayedNo ratings yet

- Devops Propsal 3Document27 pagesDevops Propsal 3BirdNo ratings yet

- How To Disable Write Protection: Basic FixesDocument11 pagesHow To Disable Write Protection: Basic Fixessarge18No ratings yet

- Accounts of Blind PersonsDocument8 pagesAccounts of Blind PersonshvenkiNo ratings yet

- Aqwa-Intro 14.5 WS02.1 AqwaWB HDDocument59 pagesAqwa-Intro 14.5 WS02.1 AqwaWB HDMisael Oré100% (3)

- LIANSHI Survey SoftwareDocument53 pagesLIANSHI Survey SoftwareCamilo Andres Rocha TorresNo ratings yet

- Aconexplaybookapril 2018 FinalwebDocument22 pagesAconexplaybookapril 2018 FinalwebObilesu RekatlaNo ratings yet

- Report 1Document28 pagesReport 1BlessonThomasNo ratings yet

- BSNL PM UM 05 Breakdown Maintenance Process V3.0 12042013Document375 pagesBSNL PM UM 05 Breakdown Maintenance Process V3.0 12042013dmkraju100% (3)

- Digital Libraries and The Social Web - ScholarshipDocument34 pagesDigital Libraries and The Social Web - ScholarshipLibrary DaiictNo ratings yet

- Fault CodesDocument6 pagesFault CodesLuis Miguel Mojica AgudeloNo ratings yet

- B R E A K: Tribhuvan University Institute of Engineering, Pulchowk CampusDocument8 pagesB R E A K: Tribhuvan University Institute of Engineering, Pulchowk CampusDavid BeckhamNo ratings yet

- Oracle - PLSQLDocument32 pagesOracle - PLSQLLeo MallickNo ratings yet

- MIA UniversityDocument10 pagesMIA UniversityraviNo ratings yet

- PeopleTools 8.58 Reporting Web ServiceDocument222 pagesPeopleTools 8.58 Reporting Web ServiceJorman MorilloNo ratings yet

- EICAR Test: Pre-Questions Pre - QuestionsDocument7 pagesEICAR Test: Pre-Questions Pre - QuestionsAnggha Muhammad100% (1)

- Threats, Vulnerabilities, and AttacksDocument9 pagesThreats, Vulnerabilities, and AttacksJohn Hector SaynoNo ratings yet

- Definitions of MatrixDocument7 pagesDefinitions of MatrixneophymenNo ratings yet

- Startopia - ManualDocument26 pagesStartopia - ManualAhmad Mujahid HuzaidiNo ratings yet

- B 2648 PDFDocument6 pagesB 2648 PDFbcanilkumar007No ratings yet

- Nombre: Nancy Alejandra Sanchez Serrato #1Document4 pagesNombre: Nancy Alejandra Sanchez Serrato #1Lina Katerin Sanchez SerratoNo ratings yet

- Symmetricsds User GuideDocument170 pagesSymmetricsds User Guidegloubi1977No ratings yet

- Starview Smart Switch and Socket SSL-AU-MG SeriesDocument14 pagesStarview Smart Switch and Socket SSL-AU-MG SeriesDuc NguyenNo ratings yet

- ArunDocument25 pagesArunTYAGI PROJECTSNo ratings yet

- Alysse BaerDocument1 pageAlysse BaerAlysse BaerNo ratings yet

- The Sed CommandDocument4 pagesThe Sed CommandTAPAN TALUKDARNo ratings yet

- REX Essential Help PDF File FSX FS9 FSFLYDocument65 pagesREX Essential Help PDF File FSX FS9 FSFLYstranger2502No ratings yet

- Parallel Registry Internet Explorer Registry (DC - GPO)Document6 pagesParallel Registry Internet Explorer Registry (DC - GPO)Samer BellarNo ratings yet

- ALOM CommandsDocument22 pagesALOM CommandsVictoria PhelpsNo ratings yet

- Catia V5 Tutorial Work BookDocument17 pagesCatia V5 Tutorial Work Bookavaakayi100% (2)