Professional Documents

Culture Documents

Coupling: Silane

Coupling: Silane

Uploaded by

Akash YadavOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Coupling: Silane

Coupling: Silane

Uploaded by

Akash YadavCopyright:

Available Formats

REINFORCED PLASTICS SYMPOSIUM

SILANE

COUPLING AGENTS

SAMUEL STERMAN

JAMES G. MARSDEN

Downloaded from pubs.acs.org by KAROLINSKA INST on 01/23/19. For personal use only.

Dual reactivity of silane coupling agents affords

chemical bonding to both the reinforcing agent t’

Ind. Eng. Chem. 1966.58:33-37.

and the resin base and, hence, provides for im-

provement of physical properties of resin-based

composites

coupling agents are used in awide range of

Silane

applications because of their unique ability to bond

polymers with dissimilar materials such as inorganic

oxides—i.e., silica and alumina. The bond thus formed

has good initial strength as demonstrated by failure of the

composite by polymer rupture, and the bond exhibits

excellent retention of strength even after severe environ-

mental aging. The siliceous matter or metal may be in

the form of fibers, particulate fillers, or massive structures.

Almost every type of organic polymer is compatible

with silane coupling agents, ranging from thermoset

resins through elastomers to thermoplastic resins. The

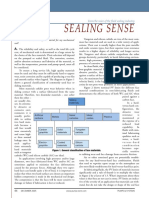

silane may be applied to the substrate as a pretreatment PHOTO COURTESY OF UNION CARBIDE SILICONES DIVISION

or, in many systems, the silane may be added to the resin Electron micrograph of Union Carbide A 1100 silane coupling agent

(72, 14) where it migrates to the substrate during normal on glass cloth shows an effective loading of less than 0.1% silane re-

mixing and application procedures. The application of maining after 4 hr. of water extraction treatment

silane coupling agents to promote bonding has led to im-

proved physical properties of composite materials such as

filled and reinforced resins, filled elastomers, caulks for

taming the physical integrity of glass immediately subse-

adhesion of metal and glass, and resin-coated and painted

quent to the drawing operation. A continuation of this

metal. Use of silane coupling agents in glass reinforced

approach led to the development of the starch-oil or No.

plastics has resulted in a particularly notable improve- 630 size. This size not only gave protection to the fiber

ment of materials performance, and this application is after drawing but was also adequate for the weaving op-

the subject of this paper. eration.

Woven glass fabrics treated with the starch-oil size

Development of Coupling Agents were used as reinforcement for phenol-formaldehyde

The earliest attempts to apply organic sizes to glass resins as late as the early 1940’s. During this same

fiber were carried out in the mid-1930’s by Slayter and period, Hyde (4) and, shortly thereafter, Biefeld (4)

Thomas (4) and were directed primarily toward main- filed patent applications covering the use of silicon-based

VOL. 58 NO. 3 MARCH 1 966 33

materials as components in sizes. These materials were afford higher strengths in the resulting composites and

potentially capable of reacting with the glass surface, but reactivity with a wider range of resins.

not with the matrix resin, and they contributed water Specific functional requirements of a silane coupling

repellency and lubricity to the treated glass. agent are discussed below.

In the mid-1940'"s, three patent applications were filed

that laid the foundation for coupling agents as we know Silane to Glass Bonding. Silanes bond chemically

them today. Steinman (4) filed on the use of methallyl to glass by the condensation of an active group on

silicate, Te Grotenhuis (4) on vinylsiloxanes, and Goebel silicone, such as OH, Cl, OR, or OAc, with a silanol on

and tier (4) on methacrylato chromic chloride. These the glass surface. Supporting evidence for this type of

patents were all concerned with improving the adhesion reaction is difficult to obtain in practical commercial

of matrix resins to glass fiber by the use of a coupling systems. This conclusion is based on a large number of

agent. empirical results and a limited amount of more basic

work.

Mechanism of Adhesion

Islinger (6) has studied the vapor phase chemisorption

The study of the theory of mechanism of adhesion has of chlorosilanes on E-glass fibers and has concluded that

been pursued from many viewpoints using both empirical siloxane bonds are formed at the interface. Infrared

and classical methods. R. M. Vasenin (75), in a recent techniques have been used by White (77) to study the

article, attempted to classify most of the current theories reaction of chlorosilanes with high surface silicas. He

of adhesion. His classification is as follows: mechani- concludes that a reversible physical reaction takes place

cal, adsorption, diffusion, chemical, and physical. The at room temperature but that irreversible chemisorption

first three of these involve intermolecular forces, the occurs at higher temperatures. Sterman and Bradley

fourth involves chemical bonds, and the fifth, electrostatic (70) studied the tenacity of the silane glass bond by

forces. aqueous and solvent extraction of silane-finished E-glass

A recent view (79) is that the relative surface tension of cloth. Their w'ork indicated that some of the finish can

substrate and adherent is most important, so that an be removed by this technique, but that a tightly bonded

adhesive of lower surface tension will spread and wet a quantity of silicone remains equivalent to two to four theo-

substrate of higher surface tension with good adhesion, retical monolayers.

but the reverse is not true. A modification of this latter Theoretically, one hydrolyzable group per silicon atom

view has been presented by W. D. Bascom (7). He W'ould be sufficient if the coupling agent could be applied

assumes the need of a silane coupling agent and proposes under anhydrous conditions. Obviously, this anhydrous

the use of a surfactant to promote better wetting of the condition is not present in commercial systems where the

glass fiber by the resin with subsequent reduction of voids preferred application solvent is water. The use of silanes

and an increase in strength. in water results in the hydrolysis of the silane to a silanol,

One of the difficulties with much of the classical work which is the active species in bonding to glass. Com-

on adhesion is that it has been primarily concerned with petitive with the condensation of coupling agent silanol

the strength of adhesion under room temperature condi- with a silanol on the glass surface is a condensation of

tions. While this is an area of importance in glass rein- silanols on two coupling agent molecules. Therefore, the

forced plastics, of equal importance is the retention of use of a silane coupling agent having one or two hydro-

properties under more severe conditions. It is true that lyzable groups per silicon atom can result in the forma-

no clear unequivocal proof for the mechanism of resin tion of di- or polysiloxanes having little or no ability to

adhesion to glass fiber has been demonstrated; and bond to glass under the normal use conditions. For

while several of the suggested mechanisms may contribute these reasons and because of the solubility requirement

to adhesion, the majority of available evidence indicates for aqueous application, all commercially used coupling

that the controlling mechanism in most cases is chemical agents have three hydrolyzable groups per silicon atom.

bonding of the resin to the glass through a coupling The group on silicon that is hydrolyzed to form the

agent. This is a plausible explanation of the good reten- silanol has little effect on the performance of the coupling

tion of properties exhibited by reinforced composites agent in the resulting composite. It is, therefore, chosen

containing silane coupling agents. on the basis of handling ease, nature of hydrolysis by-

products (HC1, HOAc, or ROH), and, occasionally, by

The Chemical Bridge ease or feasibility of synthesis.

The dual reactivity of a coupling agent permits chemi- Table I show's the essentially equivalent performance

cal bonding to both the glass fiber and resin, thereby of a series of trifunctional vinylsilanes in a standard

forming a chemical bridge across the glass-resin interface. 12-ply 181-style glass cloth reinforced polyester lam-

This type of bonding, at this critical region of the com- inate. This equivalency of performance of different

posite, produces high mechanical strength and good reten- hydrolyzable groups is typical for many types of silanes

tion of properties even under severe conditions. Mate- in a number of resin systems.

rials capable of performing this function were introduced

in the mid-1940’s as methacrylato-chromium chloride Resin Reactivity. The variety of organofunctional

complexes and vinylsilanes. Since that time, a number groups presently available on silanes provides at least

of new silane coupling agents have been developed which one (and often several) coupling agent that is highly

34 INDUSTRIAL AND ENGINEERING CHEMISTRY

reactive with all of the current thermoset resin systems. Commercially Available Thermoset Resins

Unlike the hydrolyzable groups discussed in the preced- Silane Coupling Agents of Common Use

ing section, these groups must be bonded to silicon in CH2==CHSi=

a hydrolytically and thermally stable manner. The

ch3o

chemistry and performance of coupling-agent types can

best be discussed in terms of specific resin systems, but the

CH2=C—C—OCH2CH2CH2Si= Polyester, diallyl

following list is representative of silanes that have proved phthalate

commercial utility in glass reinforced plastics and the CH2—CHCH2OCH2CH2CH2Si=

resin systems in which they are commonly used.

O

Polyester, epoxy,

TABLE I. EFFECT OF X ON FLEXURAL STRENGTH —CH2CH2Siss

OF ViSiXs FINISHED GLASS CLOTH REINFORCED

melamine

POLYESTER RESIN COMPOSITES» NH2CH2CH2CH2Si=

Flexural Strength H

CHi—CHSiXz P.S.I. X 70-*

X Dry 8-Hr. Boil NH2CH2CH2NCH2CH2CH2Síe= Epoxy, melamine,

—Cl 68.5 58.1 phenolic

—OCHs 65.0 59.0 The relative performance of a number of silanes in

—OC2H5 66.0 57.0 several resin systems is presented in the following sections,

—och2ch2och3 69.0 61.0 based on results obtained on woven glass cloth rein-

o forced laminates. This choice of composite allows

II

II the use of readily available heat-cleaned glass fabric

—oc—ch3 64.0 57.0

which offers good reproducibility and allows the effect

—N(CH3)2 72.2 57.8

of the silane to be studied free of possible interference by

»

Laminates constructed from 72 plies of glass and a general-purpose other materials. Woven glass reinforced laminates limit

polyester resin. the number of mechanical properties that can be mean-

ingfully tested and the use of a coupling agent as a finish

TABLE II. FLEXURAL STRENGTH OF VARIOUS GLASS does not evaluate its compatibility with and utility in a

REINFORCED POLYESTER RESIN COMPOSITES»

complete binder system.

Flexural

Glass Content, The absolute strength values obtained for a given resin

Type of Glass Strength,

Reinforcement Wt. % P.S.I. X 70-* system depend on the type as well as the amount of glass

Chopped strand mat 35-45 32 reinforcement used. Table II shows the strength values

Woven roving 55 40 obtained with various forms of reinforcements in a poly-

cloth ester resin (3). These values seem somewhat conserva-

Satin weave 62 55

tive when compared to the values obtained with the

Unidirectional roving 70 150

newer coupling agents, but they illustrate the trend of

»

General purpose polyester resin. type of reinforcement vs. mechanical strength.

It has been shown empirically that the relative per-

TABLE III. EFFECT OF R GROUP REACTIVITY ON formance of a series of coupling agents is essentially the

PERFORMANCE OF RSi= ON COUPLING AGENTS IN same regardless of the form of glass used. Therefore, it

GLASS REINFORCED POLYESTER RESIN LAMINATES»

appears that the evaluation of silanes in a woven glass

Flexural Strength, laminate system can provide meaningful design data if

P.S.I. X 70-z

it is realized that additional work is required to convert

Silane Finish Dry 8-Hr. Boil

such systems to a complete binder system.

112 (heat-cleaned cloth) 61.0 23.0

CH3CH2Si= 43.5 29.7 Matrix Resins

CH2=CHSi= 69.0 61.0

The choice of the matrix resin in all-glass reinforced

CHS O composites depends on a great many factors including

strength requirements, method of fabrication, electrical

1 II

CH2=C—C—OCH2CH2CH2Si== 87.0 79.0

requirements, use conditions (temperature, humidity),

»

Laminate constructed from 12 plies of glass and a general-purpose and cost. Silane coupling agents have demonstrated sig-

polyester resin. nificant improvements in and retention of general me-

chanical and electrical properties in glass reinforced

composites of all thermosetting resins. In some of these

AUTHORS Samuel Sterman is Supervisor, Product Development, systems the improvement of a specific property is of equal

Resins, Monomers, and Functional Fluids; and James G. or greater importance than over-all performance improve-

Marsden is Group Leader of the Product Development Group for ment. For example, the use of y-aminopropyltriethoxy-

Resins and Monomers at Union Carbide's Silicones Division silane as a finish in glass cloth reinforced phenolic resin

Research and Development Laboratories in Tonawanda, N. Y. laminates produces dry and wet strength improvements

VOL. 58 NO. 3 MARCH 19 6 6 35

TABLE IV. PERFORMANCE OF NONOLEFIN 1C SI LANES but its more important contribution may be the retention

AS COUPLING AGENTS FOR GLASS REINFORCED

POLYESTER RESIN LAMINATES" of strength at elevated temperatures.

The two thermoset resins that command the greatest

Flexural Strength,

P.S.I. X 7CM attention in the field of glass reinforcement today are

Silane Finish Dry 8-Hr. Boil polyester and epoxy resins. Polyester resins comprise

112 (heat-cleaned cloth) 61.0 23.0 a major part of the reinforced plastics market today and

CH2—CH—CH2OCH2CH2CH2Si= 76.0 58.0 epoxy resins represent the highest strength systems.

\ Z Polyester Resins. The free radical initiated polym-

O erization of unsaturated polyester resins lends itself

to modification of the resin by copolymerization with

71.0 58.0 other materials of appropriate reactivity. Indeed, the

oc(¡jrCH‘CH‘Si· commercial form of most polyester resins contains a

°

Laminates constructed from 72 plies of glass and a general-purpose reactive monomer, such as styrene, that serves to reduce

polyester resin. the viscosity of the resin and to copolymerize during the

cure. Silane coupling agents can react with unsaturated

components of polyester resins by the same copolymeriza-

TABLE V. EFFECT OF SILANES ON THE MECHANICAL tion mechanism.

PROPERTIES OF 181-TYPE GLASS CLOTH REINFORCED

EPOXY RESIN LAMINATES" Current theories of double bond polymerization pre-

dict that optimum copolymerization is obtained from

Flexural Strength,

P.S.I. X 70"3 monomers that have similar orders of reactivity. The

Silane Finish Dry 72-Hr. Boil relative reactivity of monomers may be estimated from

112 (heat-cleaned

cloth) 78.0 29.0 q-e values derived by Schwan and Price (9). In this sys-

90.0 54.0 tem, q represents the resonance stabilization of a radical

NH2CH2CH2CH2Si=

by adjacent groups and ranges 0 to —4.4 kcal./mole,

while e indicates the polarity of monomer radical forming

ocJ+T^011·*- 101.0 66.0

the end of a grow-ing chain. These e values range from

CH2—CHCH2— OCH2CH2CH2Si= 87.0 56.0 —

0.61 X 10-10 to +0.76 X 10-10 in electrostatic units.

\ Z The results obtained using silanes of varying reactivity

o

as finishes for glass cloth reinforced polyester laminates

(HOCH2CH2)2NCH2CH2CH2Si== 96.0 65.0

are shown in Table II. Because ethyl silane has no

Laminates constructed from 12 plies of glass and

°

an amine-hardened double bond reactivity, it is ineffective. Vinylsilane is

glycidyl ether-type epoxy resin.

relatively unreactive and produces marginal improve-

ment in dry strength and good wret strength, while the

highly reactive methacryloxypropylsilane produces ex-

TABLE VI. EFFECT OF SILANE FINISHES ON ME- cellent dry and wet values. Plueddmann et al. (S) have

CHANICAL PROPERTIES OF GLASS CLOTH RE-

INFORCED THERMOPLASTIC RESINS" evaluated a number of silanes as finishes in glass cloth

reinforced polyester resin and compared the results with

Flexural Strength

% Improvement Over ControD the q-e values of Schwan and Price (9). Good agree-

Resin Silane Dry Wet° Temp.,

0

F. ment is obtained between the results predicted from q-e

CH3 O values and those actually obtained. It would appear

\ ¡1 from these results that good coreactivity with styrene is

Polystyrene ch2=c—c— 100.0 95.0 70.0 (200) more important than coreactivity with the maleate por-

och2ch2ch2-

Si= tion of the polyester resin.

(HOCH2CH2)2- 83.0 100.0 There is another group of silanes that does not contain

Polyvinyl

chloride nch2ch2ch2- any double bonds, yet is effective as coupling agents in

81

polyester resin systems. Many of these compounds are

Nylon (HOCH2CH2)2- 110.0 160.0 150.0 (400) believed to interact with the resin by chain transfer (76).

nch2ch2ch2- Two such materials are -glycidoxypropyltrimethoxy-

Si=

silane and /3-(3,4-epoxycyclohexyl)ethyltrimethoxy-

Polycar- nh2ch2ch2ch2- 30.0 60.0 20.0 (250)

bonate Si= silane. They are about as effective as vinylsilanes as

finishes for glass reinforced polyesters. Typical values

Polymethyl nh2ch2ch2ch2- 45.0 90.0 25.0 (200)

meth- SlE= are shown in Table IV.

acrylate Epoxy Resins. The silane coupling agents that are

Acrylo- ch2—chch2- 145.0 228.0 145.0 (150) effective in epoxy resins can be divided into two types:

nitrile- \z (1) those that have the same chemical reactivity as the

buta- o

diene— OCH2CH2CH2- resin and react with the hardner in the same way,

styrene Si= such as the epoxysilanes, and (2) those that are chemi-

cally similar to the hardner and react with the epoxy

°

Laminates contain 11 plies of 181-type glass cloth, 40-45% resin.

6

Control is heat-cleaned glass cloth reinforcement. c Immersion for 16 groups of the resin, such as the aminoalkylsilanes.

hr. in water at 120° F. Neither type is preferred over the other on a general

36 INDUSTRIAL AND ENGINEERING CHEMISTRY

basis, although in a specific resin there may be unex- Elastomers. The use of glass, with its low elonga-

pectedly wide variations in results. Table V shows the tion and high tensile strength, as a reinforcement for

results obtained when silanes of both types were used as rubber has been a long sought goal. However, the lack

finishes in an amine-hardened glycidyl ether bisphenol- of adhesion of rubber to glass and the destructive seif-

A-type epoxy resin. abrasion of the glass fibers have prevented realization of

this goal. Recent developments appear to have over-

come these problems and offer the promise of glass rein-

forcement in a variety of rubber mechanical goods, in-

New Systems

cluding tires.

The foregoing discussion has been directed primarily Marzocchi and Lachut (7) reported the development of

a rubber-impregnated glass yarn suitable as reinforcement

at glass reinforced thermosetting resins because they

represent the bulk of the present market. There are, for several rubber stocks. The use of silane coupling

however, two new areas that are relatively small now but agents to improve the adhesion of a variety of rubbers

represent tremendous growth potentials. These are to glass was reported by Vanderbilt and Clayton {13).

glass reinforced thermoplastics and elastomers. This work states that the use of the proper coupling agent

Thermoplastics. Thermoplastics offer many attrac- produces excellent bonding to glass for 11 different rub-

tive properties including relatively low cost, great ber stocks. In five types of rubber the bonding to glass

was strong enough to result in cohesive failure of the

versatility of chemical type, and ease of fabrication into

end-use products. Several resins have been limited in rubber on rupture. A companion paper by Clayton and

structural and engineering applications because of low Kolek {2) describes the application of these results to

mechanical properties, especially modulus. These de- binder compositions and yarn constructions necessary to

ficiencies can be overcome by the use of glass fiber optimize results in a practical continuous process.

treated with silane coupling agent without adversely While the final and optimum glass reinforcement for

affecting the processing characteristics of the polymers. rubber has not been developed, great progress has been

The mechanism of silane-resin interaction has been made and it appears that silane coupling agents will be

an important component of the final system.

reported on by Sterman and Marsden {11), and while it

is not completely understood, empirical results indicate In addition to glass reinforced systems, silanes are

that, in at least some systems, chemical coreaction sim- applied in some filled elastomers. They are particularly

ilar to that discussed for thermoset resin is operative. effective in mineral-filled compositions of the newer

In the case of polystyrene, those silanes capable of ethylene-propylene copolymers and terpolymers. Fusco

undergoing addition polymerization or chain transfer (5) has reported on the tensile strength improvements

reaction perform best. Processing temperatures of poly- obtained by the use of vinyl silanes in silica-filled EPR,

styrenes are such that chain scission and free radical gen- and Wolfe and Roche {18) describe the retention of elec-

eration can occur, and it is suggested that the reaction of trical properties under wet conditions and the higher

the silane is with these active polymer fragments. modulus with vinylsilanes in clay-filled EPT.

Nylon, on the other hand, is a “reactive” thermo-

plastic. The silanes that are the most useful with nylon REFERENCES

are capable of reacting either with the amido hydrogen (1) Bascom, W. D., “Some Surface Chemical Aspects of Glass-Resin Composites;

Part I—Wetting Behavior of Epoxy Resins on Glass Filaments,” 20th Annual

of the polymer or by rearrangement of the amide linkage. SPI Preprints, February 1965.

However, many anomalies remain. Table VI shows (2) Clayton, R, E., Kolek, R. L., Rubber World 151 (5), 95 (1965).

(3) De Dani, A., “Glass Fibre Reinforced Plastics,” Interscience, New York, 1960

the results obtained by reinforcing a series of thermo- (4) Eakins, William J., “Glass/Resin Interface: Patent Survey, Patent List and

General Bibliography,” Plastics Technical Evaluation Center, Picatinny Arsenal,

plastic resins with 181-style glass cloth with and without Dover, N. J., September 1964.

silane coupling agent. These results show that the in- (5) Fusco, J. V., “New Cures for EPR,” Rubber World, pp. 48—54 (February 1963),

(6) Islinger, J. S., et al., “Mechanism of Reinforcement of Fiber-Reinforced Struc-

corporation of glass typically doubles the flexural strength tural Plastics and Composites,” WADC Technical Report 59-600. Part I.

of a given resin, while the use of glass with the proper (7) Marzocchi, A., Lachut, F. J., “Glass Fiber for Reinforcement,” Rubber World,

pp. 62-64 (December 1962).

coupling agent doubles this value again. Also of con- (8) Plueddmann, E. P., “Evaluation of New Silane Coupling Agents for Glass

Fiber Reinforced Plastics,” 17th Annual SPI Preprints, February 1962.

siderable interest is the retention of mechanical strength (9) Schwan, T. C., Price, C. C., J. Polymer Sci. XL, 457-68 (1959).

(10) Sterman, S., Bradley, . B., “Evaluation of Existing and Development of New

at higher temperature produced by the use of coupling Analytical Procedures for Use in the Analysis of Finishes for Glass Fabric Ma-

terial,” WADD Technical Report 60-318, (April 1960).

agents. Composites containing glass and silane typically (11) Sterman, S,, Marsden, J. G., “The Effect of Silane Coupling Agents in Im-

have flexural strengths at 200° F. and higher, equivalent proving the Properties of Filled or Reinforced Thermoplastics,” 21st Annual

SPE Preprints, March 1965.

to the flexural strength of composites without silane at (12) Sterman, S., Marsden, J. G., “Silane Coupling Agents as ‘Integral Blends’ in

Resin Filler Systems,” 18th Annual SPI Preprints, February 1963.

room temperature. This can possibly increase the useful (13) Vanderbilt, B. M., Clayton, R. E., Ind. Eng. Chem. Prod. Res. Develop.

4 (1), 18 (1965).

temperature range of many thermoplastics. (14) Vanderbilt, B. M., Clayton, R. E., “Premixes Based on Hydrocarbon Resins,”

While these results were obtained with woven glass 16th Annual SPI Preprints, February 1961.

(15) Vasenin, R. M., Adhesives Age 8 (5, 6), 18—22 (1965).

cloth, and the market appears to be moving in the direc- (16) Wallace, T., Gretter, R., “Free Radical Rearrangement of Epoxides,” Ab-

tion of chopped glass reinforcement, they are useful in stract, 142nd ACS Meeting, 65Q No. 118.

(17) White, T. E., “A Study of the Reactions of Surface Hydroxyl Groups of Silica

indicating the kind of improvement that is possible. by Means of Infra-Red Spectroscopy,” 20th Annual SPI Preprints, February

1965.

Obviously, there is need for much additional work, par- (18) Wolfe, J. R., Jr., Roche, I. D., “Factors Influencing the Electrical Properties

of Ethylene-Propylene Terpolymer Vulcanízales,” presented at 145th Meeting

ticularly in the systems closer to the conditions of actual AGS, September 1963, New York.

use. (19) Zisman, W. A., “Surface Chemistry of Glass Fiber Reinforced Plastics,”

19th Annual Meeting SPI, February 1964.

VOL. 58 NO. 3 MARCH 1 966 37

You might also like

- Anusavice K.J., Shen C., Rawls H.R. - Phillips' Science of Dental Materials-291-320Document30 pagesAnusavice K.J., Shen C., Rawls H.R. - Phillips' Science of Dental Materials-291-320Maryama AflahaNo ratings yet

- Unsaturated Polyester1 ResinsDocument74 pagesUnsaturated Polyester1 ResinsAkash YadavNo ratings yet

- A New Filler Dispersion Technology: Valerie Smits Pierre Chevalier Damien Deheunynck Scott MillerDocument7 pagesA New Filler Dispersion Technology: Valerie Smits Pierre Chevalier Damien Deheunynck Scott MillerXuân Giang Nguyễn100% (1)

- Effect of Glass Fiber Surface Chemistry On The Mechanical Properties of GF-rubber-Toughened Nylon 6Document15 pagesEffect of Glass Fiber Surface Chemistry On The Mechanical Properties of GF-rubber-Toughened Nylon 6Oumeyma HamlauiNo ratings yet

- A Study On The Rheological and Mechanical PropertiDocument12 pagesA Study On The Rheological and Mechanical PropertiWolf TechnoNo ratings yet

- Absolubilization of Styrene and Isoprene in Cetyltrimethylammonium Bromide Admicelle On Precipitated SilicaDocument7 pagesAbsolubilization of Styrene and Isoprene in Cetyltrimethylammonium Bromide Admicelle On Precipitated SilicaAnonymous Zwf0H4HwwNo ratings yet

- Mechanisms of Stabilization of Water-in-Crude Oil EmulsionsDocument6 pagesMechanisms of Stabilization of Water-in-Crude Oil EmulsionsDEV RAJNo ratings yet

- Surface Treatments of Natural FibreDocument8 pagesSurface Treatments of Natural Fibrevuquynhlyly15No ratings yet

- Polymer CompositesDocument4 pagesPolymer CompositesYuvaraj RajuNo ratings yet

- Zeolite-Like Performance For Xylene Isomer Purification Using Polymer-Derived Carbon MembranesDocument8 pagesZeolite-Like Performance For Xylene Isomer Purification Using Polymer-Derived Carbon Membranesmissmoh85No ratings yet

- Cement Type Early Age Properties 23 Jun 11 PDFDocument3 pagesCement Type Early Age Properties 23 Jun 11 PDFJoãoPauloAzevedoNo ratings yet

- Origin and Early Development of Rubber-Toughened Plastics: I ÎatureDocument11 pagesOrigin and Early Development of Rubber-Toughened Plastics: I ÎatureAsheesh shipra sharmaNo ratings yet

- Journal of Adhesion Science and TechnologyDocument7 pagesJournal of Adhesion Science and TechnologyDaniel L. FrandsenNo ratings yet

- The Effects of Silanized Ultrafine Silica On The Curing Characteristics, Tensile Properties, and Morphological Study of Natural Rubber CompoundsDocument8 pagesThe Effects of Silanized Ultrafine Silica On The Curing Characteristics, Tensile Properties, and Morphological Study of Natural Rubber CompoundsGeorgeThorogoodNo ratings yet

- Glossary of TermsDocument10 pagesGlossary of TermsKanupriya JainNo ratings yet

- 12 Composite ResinsDocument20 pages12 Composite ResinssimranNo ratings yet

- Ascemt 1943-5533Document9 pagesAscemt 1943-5533Martin DuarteNo ratings yet

- Activated Carbon From Oil Palm Shell As A Good AdsorbentDocument1 pageActivated Carbon From Oil Palm Shell As A Good AdsorbentMeidita KsNo ratings yet

- Polyester and Vinyl Ester CoatingsDocument14 pagesPolyester and Vinyl Ester Coatingsrasool100% (2)

- Bonding Adhesion: Resistance of Adhesives, Sealants, and Coatings To Corrosive EnvironmentsDocument3 pagesBonding Adhesion: Resistance of Adhesives, Sealants, and Coatings To Corrosive EnvironmentsZarul ZafranuddinNo ratings yet

- 14-硅烷偶联剂-Effect of different silane couplingagents on cryogenic properties of silica-reinforced epoxy compositesDocument14 pages14-硅烷偶联剂-Effect of different silane couplingagents on cryogenic properties of silica-reinforced epoxy compositeszeyu wenNo ratings yet

- LF, GgbsDocument8 pagesLF, Ggbsneetika tiwariNo ratings yet

- HS PDFDocument11 pagesHS PDFYoukhanna ZayiaNo ratings yet

- Surface Modification of Silica and Its Compounding With Polydimethylsiloxane Matrix: Interaction of Modified Silica Filler With PDMSDocument8 pagesSurface Modification of Silica and Its Compounding With Polydimethylsiloxane Matrix: Interaction of Modified Silica Filler With PDMSelilarasan90No ratings yet

- Polymers 14 03076Document17 pagesPolymers 14 03076Motahareh MirzadehNo ratings yet

- Manuscript For Mechanical ExpDocument26 pagesManuscript For Mechanical ExpKarthikNo ratings yet

- Dental Materials Reviewer Pt. 10Document5 pagesDental Materials Reviewer Pt. 10Ryo MiyataNo ratings yet

- Joshi 2014Document7 pagesJoshi 2014mahadev barNo ratings yet

- Grumos Na Polimerização em EmulsãoDocument9 pagesGrumos Na Polimerização em Emulsãojlvieira1994No ratings yet

- Esthetic Restorative Materials 4Document1 pageEsthetic Restorative Materials 4Tayyuba AslamNo ratings yet

- Silquest and Other Momentive Silanes: A Selection and Handling GuideDocument24 pagesSilquest and Other Momentive Silanes: A Selection and Handling Guideifasdifasidfjaisdfjaisdfj dajjdjNo ratings yet

- CCDocument16 pagesCCMohammad Abo DebNo ratings yet

- (Asce) MT 1943-5533 0003479 PDFDocument10 pages(Asce) MT 1943-5533 0003479 PDFAli YousefNo ratings yet

- Design Analysis and Fabrication of 4-Stroke Honda EngineDocument4 pagesDesign Analysis and Fabrication of 4-Stroke Honda EngineAgus WijayaNo ratings yet

- Recent Advances in Composites PDFDocument7 pagesRecent Advances in Composites PDFShriya Shahu100% (1)

- Clinical Performance of Glass IonomerDocument8 pagesClinical Performance of Glass Ionomerblue nNo ratings yet

- Comptes Rendus ChimieDocument9 pagesComptes Rendus Chimiemap vitcoNo ratings yet

- Iran Polym J 2010, 19, 853 Compositos de NR-SBR en Nylon Propiedades Mecanicas y MorfologicasDocument9 pagesIran Polym J 2010, 19, 853 Compositos de NR-SBR en Nylon Propiedades Mecanicas y MorfologicasDavid ContrerasNo ratings yet

- Arlanxeo Baypren Brochure en WebDocument7 pagesArlanxeo Baypren Brochure en WebBudi Sapto AjiNo ratings yet

- Saenz Pantelides 2006 Short and Medium Term Durability Evaluation of FRP Confined Circular ConcreteDocument10 pagesSaenz Pantelides 2006 Short and Medium Term Durability Evaluation of FRP Confined Circular Concreteทินกร โกฎกรรจ์No ratings yet

- 1.2.2 Molecular Structure of Plastic Materials: Crystalline Structure Amorphous MoleculesDocument3 pages1.2.2 Molecular Structure of Plastic Materials: Crystalline Structure Amorphous Moleculesพัฒนา ปะหะกิจNo ratings yet

- Role of SiC in Mechacical Strength of SiC Refractory - JournalDocument6 pagesRole of SiC in Mechacical Strength of SiC Refractory - JournalSaravana KumarNo ratings yet

- Xiameter OFS-6020 Silane: Diaminofunctional Silane Features ApplicationsDocument2 pagesXiameter OFS-6020 Silane: Diaminofunctional Silane Features ApplicationsDelovita GintingNo ratings yet

- Radiation Curable Polysiloxane - Synthesis To ApplicationsDocument14 pagesRadiation Curable Polysiloxane - Synthesis To ApplicationsDr. Suresh ShisodiaNo ratings yet

- 09jamr01 1185Document7 pages09jamr01 1185shahrozaligondalNo ratings yet

- PPCJ ArticleDocument2 pagesPPCJ Articlenc5r8fkp6zNo ratings yet

- Synthesis and Characterization of Fiber-Reinforced Resorcinol Epoxy Acrylate Applied To Stereolithography 3D PrintingDocument10 pagesSynthesis and Characterization of Fiber-Reinforced Resorcinol Epoxy Acrylate Applied To Stereolithography 3D PrintingPrarthi DesaiNo ratings yet

- RSC Advances: PaperDocument7 pagesRSC Advances: Paperalvaro rodriguez molina do santosNo ratings yet

- Sealing SenseDocument4 pagesSealing SenseHazim HazimNo ratings yet

- Pillai Hoc College of Engineering and Technology Rasayani - 410207Document6 pagesPillai Hoc College of Engineering and Technology Rasayani - 410207Pranit Malkar ArtNo ratings yet

- A Silane Primer Chemistry and Application of Alcoxy SilanesDocument4 pagesA Silane Primer Chemistry and Application of Alcoxy SilanesNeri EmeraudeNo ratings yet

- Synthesis and Utilization of Epoxidized PolybutadiDocument14 pagesSynthesis and Utilization of Epoxidized PolybutadiabdulqadirNo ratings yet

- Surface Modification of Nano-Silica With Amides and Imides For Use in Polyester NanocompositesDocument8 pagesSurface Modification of Nano-Silica With Amides and Imides For Use in Polyester Nanocompositesrabbitwzq1314No ratings yet

- Joining Silicon Nitride To Itself and To MetalsDocument5 pagesJoining Silicon Nitride To Itself and To MetalsVivek SinghNo ratings yet

- TMP FE2 FDocument8 pagesTMP FE2 FFrontiersNo ratings yet

- Construction and Building Materials: H. Assaedi, F.U.A. Shaikh, I.M. LowDocument12 pagesConstruction and Building Materials: H. Assaedi, F.U.A. Shaikh, I.M. LowAliNo ratings yet

- Bonding To Silica-Based CeramicsDocument10 pagesBonding To Silica-Based CeramicsValeria Vanessa Membreño AgüeroNo ratings yet

- Effectofcement C3 AcontentonpropertiesofcementitioussystemscontainingDocument13 pagesEffectofcement C3 AcontentonpropertiesofcementitioussystemscontainingJuliano. PQMNo ratings yet

- A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessFrom EverandA Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessNo ratings yet

- D3574 11 PDFDocument149 pagesD3574 11 PDFAkash YadavNo ratings yet

- 0 0 20 May 2015 1624470301PFR ManavChemicals PDFDocument16 pages0 0 20 May 2015 1624470301PFR ManavChemicals PDFAkash YadavNo ratings yet

- Astm8.3 Plastic PDFDocument206 pagesAstm8.3 Plastic PDFAkash YadavNo ratings yet

- Effect of Metal Oxides As AcivatorDocument13 pagesEffect of Metal Oxides As AcivatorAkash YadavNo ratings yet

- Chlorinated Paraffin Wax - Manufacturing Plant PDFDocument6 pagesChlorinated Paraffin Wax - Manufacturing Plant PDFAkash Yadav0% (1)

- Short-Chain Chlorinated Paraffins (SCCPS) PDFDocument11 pagesShort-Chain Chlorinated Paraffins (SCCPS) PDFAkash YadavNo ratings yet

- Part B - Type Questions: Corporate Training and PlanningDocument19 pagesPart B - Type Questions: Corporate Training and PlanningAkash YadavNo ratings yet

- Poly Phenylene Oxide (PPO) : Corporate Training and PlanningDocument27 pagesPoly Phenylene Oxide (PPO) : Corporate Training and PlanningAkash YadavNo ratings yet

- Is 10810 10 1984 PDFDocument6 pagesIs 10810 10 1984 PDFAkash YadavNo ratings yet

- CH CH C CH CH - C N N: PolymerizationDocument16 pagesCH CH C CH CH - C N N: PolymerizationAkash YadavNo ratings yet

- Akrochem Perioxide Comparison HalfDocument1 pageAkrochem Perioxide Comparison HalfAkash YadavNo ratings yet

- Epoxy Resins: Corporate Training and PlanningDocument53 pagesEpoxy Resins: Corporate Training and PlanningAkash YadavNo ratings yet

- Trevor Pope. Stator Rubber Innovation Vs ApplicationDocument11 pagesTrevor Pope. Stator Rubber Innovation Vs ApplicationAkash YadavNo ratings yet

- Blend Term DefinitionDocument14 pagesBlend Term DefinitionAkash YadavNo ratings yet

- Urea & Melamine Formaldehyde ResinsDocument33 pagesUrea & Melamine Formaldehyde ResinsAkash Yadav50% (2)

- AdditivesDocument148 pagesAdditivesAkash Yadav100% (2)

- CH CH CH - CH CL CL N N: PolymerizationDocument40 pagesCH CH CH - CH CL CL N N: PolymerizationAkash YadavNo ratings yet

- Sector Wise End Use Applications of Plastics: Corporate Training and PlanningDocument24 pagesSector Wise End Use Applications of Plastics: Corporate Training and PlanningAkash YadavNo ratings yet

- Specialty Plastics: Polyvinylfluoride (PVF)Document14 pagesSpecialty Plastics: Polyvinylfluoride (PVF)Akash YadavNo ratings yet

- AdditivesDocument148 pagesAdditivesAkash Yadav100% (2)

- Bonding of Untreated Cellulose Fibers To Natural RubberDocument10 pagesBonding of Untreated Cellulose Fibers To Natural RubberAkash YadavNo ratings yet

- Viton Related Chemicals Handling PrecautionsDocument22 pagesViton Related Chemicals Handling PrecautionsrplNo ratings yet

- Tensile and Tear Behavior of Anisotropic Double Networks of A Black-Filled Natural Rubber VulcanizateDocument15 pagesTensile and Tear Behavior of Anisotropic Double Networks of A Black-Filled Natural Rubber VulcanizateAkash YadavNo ratings yet

- AkasDocument12 pagesAkasAkash YadavNo ratings yet

- Plant Design BookDocument301 pagesPlant Design BookLana MahmoudNo ratings yet

- Vinyl Additive Technology - 2021 - Abdel Hakim - Performance Evaluation of Modified Fabricated Cotton Membrane For OilDocument13 pagesVinyl Additive Technology - 2021 - Abdel Hakim - Performance Evaluation of Modified Fabricated Cotton Membrane For OilRiham AliNo ratings yet

- Wa0015Document24 pagesWa0015ashas waseemNo ratings yet

- Rapid Preparation of Polymersomes by A Water Addition - Solvent Evaporation MethodDocument20 pagesRapid Preparation of Polymersomes by A Water Addition - Solvent Evaporation MethodMuhammad FitrianorNo ratings yet

- Use of Modified Bituminous Binders in India - Current ImperativesDocument25 pagesUse of Modified Bituminous Binders in India - Current ImperativesProf. Prithvi Singh Kandhal100% (4)

- Dyeing Acrylic With Cationic Dyes PDFDocument6 pagesDyeing Acrylic With Cationic Dyes PDFAwais ImranNo ratings yet

- Polychloroprene ContDocument10 pagesPolychloroprene ContGilberto Monteiro100% (1)

- Engineering Chemistry Polymers and Polymerization: BSC 102: Course Name: Topic Course CodeDocument21 pagesEngineering Chemistry Polymers and Polymerization: BSC 102: Course Name: Topic Course CodeAshok KumarNo ratings yet

- Polypropylene Structure - StructureDocument237 pagesPolypropylene Structure - StructureClaudio LimaNo ratings yet

- Super AbsorbentDocument21 pagesSuper Absorbentkang8886021No ratings yet

- DF002 Polymer Chemistry 7Document35 pagesDF002 Polymer Chemistry 7Asad KhanNo ratings yet

- Antiburnish Dead Matted GMADocument8 pagesAntiburnish Dead Matted GMACublktigressNo ratings yet

- Copolymerization of Styrene and N-Butyl Acrylate With Itaconic Acid: in Uence OF Carboxylic Groups Distribution On Performance of Decorative PaintsDocument12 pagesCopolymerization of Styrene and N-Butyl Acrylate With Itaconic Acid: in Uence OF Carboxylic Groups Distribution On Performance of Decorative PaintsMohamed HalemNo ratings yet

- Technical Bulletin Water Treatment Product Selection Global enDocument2 pagesTechnical Bulletin Water Treatment Product Selection Global enmasoud moradjooNo ratings yet

- Quan Et Al. - 2016 - Effect of Modification Degree of Nanohydroxyapatite On Biocompatibility and Mechanical Property of Injectable Poly (Document9 pagesQuan Et Al. - 2016 - Effect of Modification Degree of Nanohydroxyapatite On Biocompatibility and Mechanical Property of Injectable Poly (Morteza AtaeiNo ratings yet

- Da Silva - New Additives For The Pour Point Reduction of Petroleum Middle Distillates, 2004Document6 pagesDa Silva - New Additives For The Pour Point Reduction of Petroleum Middle Distillates, 2004oreamigNo ratings yet

- Ma 0718806Document8 pagesMa 0718806Jalili KiyumarsNo ratings yet

- Self Healing MaterialsDocument418 pagesSelf Healing Materialsmaged_abdnagho100% (1)

- Energetic BinderDocument48 pagesEnergetic Binderrommy214u100% (1)

- Solvent-Free Polymerization of Citric Acid and D-SorbitolDocument9 pagesSolvent-Free Polymerization of Citric Acid and D-SorbitolAris SusantoNo ratings yet

- GATE Engineering SciencesDocument6 pagesGATE Engineering SciencesstudyurselfNo ratings yet

- Poly (Propene) (Polypropylene)Document5 pagesPoly (Propene) (Polypropylene)rmehta26No ratings yet

- Poly 104Document29 pagesPoly 104Khôi NguyênNo ratings yet

- Additives FOR Specialty Chemistry Formulations PER Function: Product ListDocument16 pagesAdditives FOR Specialty Chemistry Formulations PER Function: Product ListLong An Đỗ100% (1)

- Understanding PolymersDocument216 pagesUnderstanding PolymersCrucifiedBishwarup100% (1)

- Block and Graft PolymerizationDocument5 pagesBlock and Graft PolymerizationTeza Nur FirlyansyahNo ratings yet

- 2-Ethylhexyl Acrylate: Technical Information PetrochemicalsDocument2 pages2-Ethylhexyl Acrylate: Technical Information PetrochemicalsnurparinNo ratings yet

- An Introduction To Biodegradable Polymers As Implant MaterialsDocument18 pagesAn Introduction To Biodegradable Polymers As Implant Materialsratnav_ratanNo ratings yet

- Introduction To Polymerphysic: Che - Untirta.ac - IdDocument32 pagesIntroduction To Polymerphysic: Che - Untirta.ac - IdIlham Kiki ShahilaNo ratings yet

- Chloroprene Rubber 99259 WP PUBLIC Box393196BDocument229 pagesChloroprene Rubber 99259 WP PUBLIC Box393196BbowcoastieNo ratings yet