Professional Documents

Culture Documents

Test Report - Metallography: Customer Name& Address

Test Report - Metallography: Customer Name& Address

Uploaded by

P NAVEEN KUMAROriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Test Report - Metallography: Customer Name& Address

Test Report - Metallography: Customer Name& Address

Uploaded by

P NAVEEN KUMARCopyright:

Available Formats

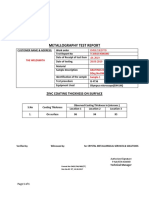

TEST REPORT – METALLOGRAPHY

Customer Name& address : Work Order No. CMSS/19/1919

Test Report No TC685010900000P

Date of Receipt of test Item 03-10-2019

ARUN EXCELLO URBAN Date of Testing 04-10-2019

INFRASTRUCTURE.PVT.LTD, Sample Description Fillet Weld Joint

HPCL – IPPS3, KALAKADA, Material IS 2062 E250 BR

CHITOOR DISTRICT - 517236 PQR NO: AEUIPL/WP/HPCL/IPPS3-PQR 03

Identification of the sample Welder Name: DEEPAK

Welding Process: SMAW

Position : 3G (VERTICAL)

Equipment used BX 41M LED

ASME SEC IX-2017;

Test Procedure

IS: 7739(Part 1)-1975

For Sample 1 & 2 Macro examination of the weld shows free from Planar

OBSERVATION

defects, individual or group cavities worm holes and porosity

RESULT: THE ABOVE TESTED SAMPLES ARE ACCEPTED ACCORDING TO ASME SEC IX, SINCE THERE IS NO

OBSERVATIONS OF ABOVE SAID DEFECTS

Verified by: Witnessed by: For CRYSTAL METALLURGICAL SERVICES & SOLUTIONS

Authorized Signature

(P.NAVEEN KUMAR)

Format No CMSS/FM48A (MET)

Rev No.01: DT; 23-01-2017

Page 1 of 1

You might also like

- RFI Welding TestDocument18 pagesRFI Welding TestDimas agungNo ratings yet

- Tensile Test Report: CMSS/18/659 CMSS/TT/18/504 22-05-2018 30-05-2018Document2 pagesTensile Test Report: CMSS/18/659 CMSS/TT/18/504 22-05-2018 30-05-2018ESHWAR CHARYNo ratings yet

- Tensile Test Report: CMSS/18/659 CMSS/TT/18/505 29-05-2018 30-05-2018Document2 pagesTensile Test Report: CMSS/18/659 CMSS/TT/18/505 29-05-2018 30-05-2018ESHWAR CHARYNo ratings yet

- Tensile Test Report: CMSS/18/659 CMSS/TT/18/503 22-05-2018 30-05-2018Document2 pagesTensile Test Report: CMSS/18/659 CMSS/TT/18/503 22-05-2018 30-05-2018ESHWAR CHARYNo ratings yet

- Tensile Test Report: CMSS/18/659 CMSS/TT/18/506 22-05-2018 30-05-2018Document2 pagesTensile Test Report: CMSS/18/659 CMSS/TT/18/506 22-05-2018 30-05-2018ESHWAR CHARYNo ratings yet

- 3Q-Industrial Services: Magnetic Particle Inspection ReportDocument2 pages3Q-Industrial Services: Magnetic Particle Inspection Reportmani kumarNo ratings yet

- 074 - ANPAM EnggDocument1 page074 - ANPAM EnggvinuNo ratings yet

- Test Report - Metallography: Customer Name& AddressDocument2 pagesTest Report - Metallography: Customer Name& AddressESHWAR CHARYNo ratings yet

- Test Report - Metallography: Customer Name& AddressDocument2 pagesTest Report - Metallography: Customer Name& AddressnareshNo ratings yet

- AK2 - RevADocument13 pagesAK2 - RevAChirag ShahNo ratings yet

- 7451 (16-32) TENSILE-BOLT AFCO-newDocument17 pages7451 (16-32) TENSILE-BOLT AFCO-newMOHAMEDNo ratings yet

- Castings Pvt. LTD: Magnetic Particle Test ReportDocument3 pagesCastings Pvt. LTD: Magnetic Particle Test ReportHimanshu SinghNo ratings yet

- DPT Report 02Document2 pagesDPT Report 02Amit Hasan100% (1)

- 3Q-Industrial Services: Magnetic Particle Inspection ReportDocument2 pages3Q-Industrial Services: Magnetic Particle Inspection Reportmani kumarNo ratings yet

- GBDFFDocument1 pageGBDFFESHWAR CHARYNo ratings yet

- Rahul Kumar W-010Document3 pagesRahul Kumar W-010veera Satya saiNo ratings yet

- RQ # 7days ReportDocument1 pageRQ # 7days Reportirfan hussainNo ratings yet

- Final Visual Inspection Sc-03 v100 Part-02Document1 pageFinal Visual Inspection Sc-03 v100 Part-02Sam RajaNo ratings yet

- Tensile Test Report: CMSS/18/556 CMSS/TT/18/455 30-04-2018 03-05-2018Document12 pagesTensile Test Report: CMSS/18/556 CMSS/TT/18/455 30-04-2018 03-05-2018nareshNo ratings yet

- Website Documents TF 01 CUBETEST (BS 1881) DibbaDocument1 pageWebsite Documents TF 01 CUBETEST (BS 1881) Dibbasulman iqbalNo ratings yet

- QAP Seamless PipeDocument2 pagesQAP Seamless Pipechetan85No ratings yet

- 80mm Zigzag MTCDocument1 page80mm Zigzag MTCQAQC ZFNo ratings yet

- Tensile Test ReportDocument1 pageTensile Test ReportESHWAR CHARYNo ratings yet

- Test Report - Metallography: Customer Name& AddressDocument2 pagesTest Report - Metallography: Customer Name& AddressP NAVEEN KUMARNo ratings yet

- 7451 (1-15) Rebar - Tensile-Grade 105 and 55Document15 pages7451 (1-15) Rebar - Tensile-Grade 105 and 55MOHAMEDNo ratings yet

- Fin 30-12-2023Document2 pagesFin 30-12-2023wasimakramraju336No ratings yet

- Camy Plants: Shell Long Seam Back-Chip D.P. Test ReportDocument5 pagesCamy Plants: Shell Long Seam Back-Chip D.P. Test Reportnarendra vermaNo ratings yet

- F-02 (Magnetic Particle Test) - (NEW) ..Latest 006Document42 pagesF-02 (Magnetic Particle Test) - (NEW) ..Latest 006Himanshu SinghNo ratings yet

- T-3, F- 10, 11 U.T ProtocalDocument2 pagesT-3, F- 10, 11 U.T ProtocaltrivikramraoNo ratings yet

- Metallography Test Report: Zinc Coating Thickness On SurfaceDocument1 pageMetallography Test Report: Zinc Coating Thickness On SurfaceP NAVEEN KUMARNo ratings yet

- 028120-SPL-007 Pipeline Protective Coatings Rev. CDocument12 pages028120-SPL-007 Pipeline Protective Coatings Rev. CRokan Pipeline100% (1)

- 3Q-Industrial Services: Magnetic Particle Inspection ReportDocument1 page3Q-Industrial Services: Magnetic Particle Inspection Reportmani kumarNo ratings yet

- 2539 4046 02 A1001 003 - Datasheet For Manual Valve - Rev ADocument8 pages2539 4046 02 A1001 003 - Datasheet For Manual Valve - Rev ANguyễn ThựcNo ratings yet

- O2 Analyzer - Document - REV-B - 24-03-2018 PDFDocument10 pagesO2 Analyzer - Document - REV-B - 24-03-2018 PDFambeshNo ratings yet

- B Cathodic Protection GRP 08 Ts000 Sgcrs Ele Cvs 00001 Rev.02Document42 pagesB Cathodic Protection GRP 08 Ts000 Sgcrs Ele Cvs 00001 Rev.02adnanyaseenzrgrNo ratings yet

- Tensile Test ReportDocument1 pageTensile Test ReportESHWAR CHARYNo ratings yet

- SACEP - RTCC - Delivery #0971541-10Document16 pagesSACEP - RTCC - Delivery #0971541-10Ryan condeNo ratings yet

- Metrosil Test Report: Site Test Report Date: 29/07/2020 Customer: Sec-Eoa Name of SubstationDocument2 pagesMetrosil Test Report: Site Test Report Date: 29/07/2020 Customer: Sec-Eoa Name of Substationمحمد عادلNo ratings yet

- Engineering Data Sheet: Bill of MaterialDocument7 pagesEngineering Data Sheet: Bill of MaterialJairo andres Guarnizo SuarezNo ratings yet

- 3Q-Industrial Services: Magnetic Particle Inspection ReportDocument1 page3Q-Industrial Services: Magnetic Particle Inspection Reportmani kumarNo ratings yet

- QAP-UEPL-BHOPAL-54-9550-01 Rev.03Document6 pagesQAP-UEPL-BHOPAL-54-9550-01 Rev.03udayakarnaNo ratings yet

- Magnetic Particle Examination: Ies-Industrial Engineering ServicesDocument2 pagesMagnetic Particle Examination: Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Magnetic Particle Examination: Ies-Industrial Engineering ServicesDocument2 pagesMagnetic Particle Examination: Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Gpti Qicl J931 Mut 041Document3 pagesGpti Qicl J931 Mut 041uselessinstaid52No ratings yet

- 3Q-Industrial Services: Magnetic Particle Inspection ReportDocument1 page3Q-Industrial Services: Magnetic Particle Inspection Reportmani kumarNo ratings yet

- SACEP - RTCC - Delivery #0971542-11Document16 pagesSACEP - RTCC - Delivery #0971542-11Ryan condeNo ratings yet

- Request For Inspection: Rfi No: Abis-Mech-Yr/72Document7 pagesRequest For Inspection: Rfi No: Abis-Mech-Yr/72Richard PeriyanayagamNo ratings yet

- 04, Intial Visual Inspection Gs-Asme-035 03 V100Document1 page04, Intial Visual Inspection Gs-Asme-035 03 V100Sam RajaNo ratings yet

- CBDFDocument1 pageCBDFESHWAR CHARYNo ratings yet

- Tensile Test ReportDocument1 pageTensile Test ReportESHWAR CHARYNo ratings yet

- 1042238180-2141571394-RT Request Co1Document1 page1042238180-2141571394-RT Request Co1iankulehNo ratings yet

- 3Q-Industrial Services: Magnetic Particle Inspection ReportDocument1 page3Q-Industrial Services: Magnetic Particle Inspection Reportmani kumarNo ratings yet

- Binder 1Document3 pagesBinder 1Sam RajaNo ratings yet

- Website Documents TF 01 CUBETEST (BS 1881)Document1 pageWebsite Documents TF 01 CUBETEST (BS 1881)sulman iqbalNo ratings yet

- Magnetic Particle Examination: Ies-Industrial Engineering ServicesDocument2 pagesMagnetic Particle Examination: Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Gpti Qicl J931 Mut 004Document3 pagesGpti Qicl J931 Mut 004uselessinstaid52No ratings yet

- 6206 Qap R0 DT 30.01.24Document3 pages6206 Qap R0 DT 30.01.24PRASHANTNo ratings yet

- Test Report - Metallography: Customer Name& AddressDocument2 pagesTest Report - Metallography: Customer Name& AddressP NAVEEN KUMARNo ratings yet

- Test Report Customer AddressDocument4 pagesTest Report Customer AddressP NAVEEN KUMARNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Test Report Customer AddressDocument4 pagesTest Report Customer AddressP NAVEEN KUMARNo ratings yet

- RACKDocument3 pagesRACKP NAVEEN KUMARNo ratings yet

- Test Report For Chemical Testing: Chemical Analysis (%) Specified Values (WT %)Document1 pageTest Report For Chemical Testing: Chemical Analysis (%) Specified Values (WT %)P NAVEEN KUMARNo ratings yet

- Test Report - MetallographyDocument2 pagesTest Report - MetallographyP NAVEEN KUMARNo ratings yet

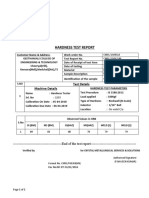

- Hardness Test Report: Customer Name & AddreshghjDocument3 pagesHardness Test Report: Customer Name & AddreshghjP NAVEEN KUMARNo ratings yet

- Test Report - Metallography: Customer Name& AddressDocument2 pagesTest Report - Metallography: Customer Name& AddressP NAVEEN KUMARNo ratings yet

- Hardness Sfdsgmall Sample - 2Document1 pageHardness Sfdsgmall Sample - 2P NAVEEN KUMARNo ratings yet