Professional Documents

Culture Documents

Test Reports PDF

Test Reports PDF

Uploaded by

Tenders Mash0 ratings0% found this document useful (0 votes)

60 views2 pagesThis document summarizes test results for safety shoes from Mash & Company. The shoes were tested according to IS 15298 specification in a laboratory with temperature of 23+/-2°C and 50+/-5% relative humidity. All test results, including for the upper leather, lining materials, tongue, insole, and outsole met or exceeded the minimum requirements. Additional tests for upper thickness, water penetration and absorption, and antistatic testing also showed conformity.

Original Description:

Original Title

Test Reports.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document summarizes test results for safety shoes from Mash & Company. The shoes were tested according to IS 15298 specification in a laboratory with temperature of 23+/-2°C and 50+/-5% relative humidity. All test results, including for the upper leather, lining materials, tongue, insole, and outsole met or exceeded the minimum requirements. Additional tests for upper thickness, water penetration and absorption, and antistatic testing also showed conformity.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

60 views2 pagesTest Reports PDF

Test Reports PDF

Uploaded by

Tenders MashThis document summarizes test results for safety shoes from Mash & Company. The shoes were tested according to IS 15298 specification in a laboratory with temperature of 23+/-2°C and 50+/-5% relative humidity. All test results, including for the upper leather, lining materials, tongue, insole, and outsole met or exceeded the minimum requirements. Additional tests for upper thickness, water penetration and absorption, and antistatic testing also showed conformity.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

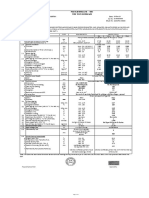

Supplier : Mash & Company Job No.

: 2K1805105

Contact : Mr. Suhaib Ayaz Date of Entry : 08.12.2018

Materials : Safety Shoe (Size – 8), Make - Blackburn Page : 1/2

Specification : IS 15298 (Part 2) : 2011

Job Start Date : 10.12.2018 Completion Date : 24.12.2018

Laboratory Environment

Temperature 23 +/- 2 ◦C

Relative Humidity 50 +/- 5 %

The sample was conditioned for 48 hours.

S. No. Test Name Clause Value Requirement Conformity

1. Design 5.2 A, Low Shoe A, Low Shoe Conforms

a. Height of Upper 5.2.1 < 113 mm < 113 mm Conforms

b. Seat Region 5.2.2 Closed Closed Conforms

2. Test on Complete Footwear

a. Upper/Outsole Bond 5.3.1.2 4.9 N/mm 4 N/mm (min) Conforms

b. Internal Toecap Length 5.3.2.2 40 mm 39 mm (min) Conforms

c. Impact Resistance (200 J) 5.3.2.3 17.5 mm 14 mm (min) Conforms

d. Compression Resistance(15 kN) 5.3.2.4 17.0 mm 14 mm (min) Conforms

3. Test on Upper – Leather (Black) – Barton

a. Tear Strength 5.4.3 243 N 120 N (min) Conforms

b. Tensile Strength 5.4.4 26.5 N/mm2 15 N/mm2 (min) Conforms

c. Water Vapour Permeability 5.4.6 0.95 N/mm2 0.8 mg/cm2h (min) Conforms

d. Water Vapour Coefficient 5.4.6 27.8 N/mm2 15 mg/cm2 (min) Conforms

5. Test on Vamp Lining (Non Woven)

a. Tear Strength 5.5.1 72 N 15 N (min) Conforms

b. Martindale Abrasion 5.5.2

Dry – 25600 cycles. No Holes No damage/hole formation Conforms

Wet – 12800 cycles. No Holes No damage/hole formation Conforms

c. Water Vapour Permeability 5.5.3 21.6 N/mm2 2.0 mg/cm2h (min) Conforms

d. Water Vapour Coefficient 5.5.3 173.4 N/mm2 20.0 mg/cm2 (min) Conforms

6. Test on Quarter Lining (Cambrelle)

a. Tear Strength 5.5.1 20.9 N 15 N (min) Conforms

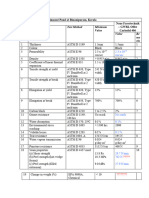

2K1805105 Page 2/2

S. No. Test Name Clause Value Requirement Conformity

b. Martindale Abrasion 5.5.2

Dry – 25600 cycles. No Holes No damage/hole formation Conforms

Wet – 12800 cycles. No Holes No damage/hole formation Conforms

c. Water Vapour Permeability 5.5.3 29.0 N/mm2 2.0 mg/cm2h (min) Conforms

d. Water Vapour Coefficient 5.5.3 232.5 N/mm2 20.0 mg/cm2 (min) Conforms

7. Test on Tongue – Synthetic

a. Tear Strength 5.6.1 23 N 18 N (min) Conforms

8. Test on Insole & Insock (Textile)

a. Thickness (insole) 5.7.1 > 2.0 mm 2 mm (min) Conforms

9. Test on Outsole – Double Density (PU Sole)

b. Tear Strength 5.8.2 7.9 kN/m 5 kN/m Conforms

c. Abrasion Resistance 5.8.3 92.3 mm3 250 mm3 Conforms

d. Flexing Resistance 5.8.4 No cut growth 4 mm (max) cut growth Conforms

e. Sole Interlayer Bond Strength 5.8.6 4.6 N/m 4 N/mm (min) Conforms

f. Resistance to fuel Oil 5.8.7 0.91 % 12 % (max) Conforms

h. Thickness (Cleated Out sole) 6.4.2 > 4.0 mm d1 ≥ 4.0 mm Conforms

i. Cleat Height 6.4.3 > 2.5 mm d2 ≥ 2.5 mm Conforms

Additional Details as per given specification.

Material Parameter Tested Observation/ Value Requirement Conformity

Upper Thickness 1.9 mm 1.8 mm to 2.0 mm Conforms

Water Penetration Absorption – 6.4 % Water Absorption ≤ 30 % Conforms

and Absorption Penetration - 0.03 g Water Penetration ≤ 0.2 g Conforms

Whole Footwear Test Name Value/Observation Requirement Conformity

Antistatic Test 708 M Ohm 100 k Ohm – 1000 M Ohm Conforms

Sole Fixation DIP DIP Conforms

Antiskid Antiskid due to cleats Antiskid in nature Conforms

Rajesh Mishra Shailendar Saxena

(Senior Technologist) (Chief Technologist and Head – Physical Lab)

You might also like

- Din 17102 PDFDocument10 pagesDin 17102 PDFEvriMert RüzgArdaNo ratings yet

- 12.02.2020 TTC - Kohinoor SalesDocument1 page12.02.2020 TTC - Kohinoor SalesAlok PandeyNo ratings yet

- 1554-2Cx6mm AluminumDocument3 pages1554-2Cx6mm AluminumSandeep BhutaniNo ratings yet

- 1035 TD 20 Product Data Sheet ViscopasteDocument2 pages1035 TD 20 Product Data Sheet ViscopasteUrooj IlyasNo ratings yet

- N-4 Shriji Power & Automation Private LimitedDocument1 pageN-4 Shriji Power & Automation Private LimitedShriji AutomationNo ratings yet

- Section 888-Waterproofing Membrane Materials: 888.1 General DescriptionDocument4 pagesSection 888-Waterproofing Membrane Materials: 888.1 General DescriptionpeyostailNo ratings yet

- Design Mix M 30Document4 pagesDesign Mix M 30SOIGNE ENGINEERING CONSULTANTSNo ratings yet

- WRC SpecificationDocument2 pagesWRC SpecificationTrungThanh TranNo ratings yet

- GreenlamDocument1 pageGreenlamSK Emran AliNo ratings yet

- Laminate TDSDocument1 pageLaminate TDSSK Emran AliNo ratings yet

- 3m VHB Tape 5958frDocument9 pages3m VHB Tape 5958frDonald A HuntNo ratings yet

- 3MTM VHBTM Tape 5962 - 20230923Document10 pages3MTM VHBTM Tape 5962 - 20230923Trí TrừNo ratings yet

- 3M™ VHB™ Tape 5962 - 20231024Document10 pages3M™ VHB™ Tape 5962 - 20231024energyengineerestNo ratings yet

- 15.07 2020 - TTC 2Document1 page15.07 2020 - TTC 2Alok PandeyNo ratings yet

- 4.0 SQ.MM-FR-LSH-100 MTR-JAN-2021Document1 page4.0 SQ.MM-FR-LSH-100 MTR-JAN-2021Gopikrishnan ThangarajNo ratings yet

- N-8 Shriji Power & Automation Private LimitedDocument1 pageN-8 Shriji Power & Automation Private LimitedShriji AutomationNo ratings yet

- FGI PVC Geomembrane Specification: Effective January 1, 2017Document3 pagesFGI PVC Geomembrane Specification: Effective January 1, 2017Paul Alex Quiroz BarrionuevoNo ratings yet

- 1.5 SQ.MM-FR-LSH-100 MTR-JAN-2021Document1 page1.5 SQ.MM-FR-LSH-100 MTR-JAN-2021Gopikrishnan ThangarajNo ratings yet

- Sigma Kraft Paper 4 Mil TCDocument1 pageSigma Kraft Paper 4 Mil TCShashivendra ShuklaNo ratings yet

- BinanizincspecsDocument6 pagesBinanizincspecsJimmy ThomasNo ratings yet

- An Experimental Study of Using Manufactured Sand in ConcreteDocument7 pagesAn Experimental Study of Using Manufactured Sand in Concretenught surNo ratings yet

- Recubrimiento Ext TanqueDocument2 pagesRecubrimiento Ext Tanquehenry307No ratings yet

- Quality Control Report: Üntel Kablolari Sanayi Ve Ticaret A.ŞDocument3 pagesQuality Control Report: Üntel Kablolari Sanayi Ve Ticaret A.Şomar100% (1)

- Tensile and Elongation Report: Sample DetailsDocument2 pagesTensile and Elongation Report: Sample DetailsCalebNo ratings yet

- Viscowrap-Ht: Product Data SheetDocument2 pagesViscowrap-Ht: Product Data SheetFarid HarisNo ratings yet

- IS: 10262:2019 Guidelines Keeping in View The Recommended Mix Standard Deviations and Targeted Mean StrengthDocument4 pagesIS: 10262:2019 Guidelines Keeping in View The Recommended Mix Standard Deviations and Targeted Mean StrengthROHIT KUMARNo ratings yet

- 3MTM VHBTM Tape - Specialty Tape 4910 - 20230923Document9 pages3MTM VHBTM Tape - Specialty Tape 4910 - 20230923Trí TrừNo ratings yet

- Directorate of Erbil Construction Laboratory Testing Ceramic TilesDocument2 pagesDirectorate of Erbil Construction Laboratory Testing Ceramic TilesBestoon RamadhanNo ratings yet

- 3M™ VHB™ Tape RP+040GF - 20230121Document8 pages3M™ VHB™ Tape RP+040GF - 20230121tripathi prashantNo ratings yet

- Masterflow 920 Ans: Epoxy Acrylate (Styrene-Free) Resin Based High Performance Anchoring GroutDocument5 pagesMasterflow 920 Ans: Epoxy Acrylate (Styrene-Free) Resin Based High Performance Anchoring GroutMuhammad Fadhil ImansyahNo ratings yet

- 75 MM PN 20 Tensile Test Report28.08.2020 He3460lsDocument2 pages75 MM PN 20 Tensile Test Report28.08.2020 He3460lsCalebNo ratings yet

- M2XCH Flex (FI) 5G25 (Black) - 60Document1 pageM2XCH Flex (FI) 5G25 (Black) - 60omarNo ratings yet

- Masterflow 916 An TdsDocument4 pagesMasterflow 916 An TdsThet LinnNo ratings yet

- Tyre Flap (EPDM) Specification306 - 83 - SEP - 2016Document5 pagesTyre Flap (EPDM) Specification306 - 83 - SEP - 2016Purchase and Stores Officer Contract Cell-II100% (1)

- 3M™ Adhesive Transfer Tape 9472LE - 20240628Document8 pages3M™ Adhesive Transfer Tape 9472LE - 20240628Nguyễn MyNo ratings yet

- 3MTM VHBTM Structural Glazing Tape B23F - 20230923Document6 pages3MTM VHBTM Structural Glazing Tape B23F - 20230923Trí TrừNo ratings yet

- Material Test Certificate (MTC) : Properties of Aluminium Coil: AW 5005Document4 pagesMaterial Test Certificate (MTC) : Properties of Aluminium Coil: AW 5005Waleed Obieden100% (1)

- 10 SQ.MM-FR-LSH-100 MTR-JAN-2021Document1 page10 SQ.MM-FR-LSH-100 MTR-JAN-2021Gopikrishnan ThangarajNo ratings yet

- Continental GorillaDocument1 pageContinental GorillabaglinoNo ratings yet

- N-6 Shriji Power & Automation Private LimitedDocument1 pageN-6 Shriji Power & Automation Private LimitedShriji AutomationNo ratings yet

- Carlisle Epdm 60 MIL MTC - IIIDocument1 pageCarlisle Epdm 60 MIL MTC - IIIHimanshu ChaudharyNo ratings yet

- Trelleborg ATP Ballast Mat BrochureDocument8 pagesTrelleborg ATP Ballast Mat BrochureÜmit KukulaNo ratings yet

- 3M™ Adhesive Transfer Tape 950 - 20240112Document8 pages3M™ Adhesive Transfer Tape 950 - 20240112qualityNo ratings yet

- Pressurization Skid FilterDocument4 pagesPressurization Skid FilterHANo ratings yet

- 11.3. Technical Schedule 11.3.1Document3 pages11.3. Technical Schedule 11.3.1Jayantha SampathNo ratings yet

- Viscotaq Pads RleDocument2 pagesViscotaq Pads Rlehenry307No ratings yet

- Standard Specifications Standard Specifications: (For Pef (For Pef and PP Grade)Document2 pagesStandard Specifications Standard Specifications: (For Pef (For Pef and PP Grade)tuan nguyenNo ratings yet

- Sikaflex®-2c SL: Two-Component, Self-Levelling, Polyurethane Elastomeric SealantDocument3 pagesSikaflex®-2c SL: Two-Component, Self-Levelling, Polyurethane Elastomeric SealantRay GongNo ratings yet

- Tds Wikon Ip. C 7&8Document1 pageTds Wikon Ip. C 7&8deni prastikoNo ratings yet

- PaverDocument2 pagesPavershalini sivaNo ratings yet

- Test Certificate-In Situ Density by Sand Replacement MethodDocument10 pagesTest Certificate-In Situ Density by Sand Replacement Methodm.manikkavasagamNo ratings yet

- 2.5 SQ.MM-FR-LSH-100 MTR-JAN-2021Document1 page2.5 SQ.MM-FR-LSH-100 MTR-JAN-2021Gopikrishnan ThangarajNo ratings yet

- PVC SpecDocument2 pagesPVC SpecMuhammad Noor FizuanNo ratings yet

- Flexible Cementitious Waterproof Membrane (Water-Based) - For Use With Concrete Water TankDocument1 pageFlexible Cementitious Waterproof Membrane (Water-Based) - For Use With Concrete Water TankXiao Ying 林No ratings yet

- HDPE Double Side TextureDocument1 pageHDPE Double Side TextureArun Chandra BabuNo ratings yet

- KC97 Product Description-EN201903Document5 pagesKC97 Product Description-EN201903Humberto TorresNo ratings yet

- 1.0 SQ.MM-FR-LSH-100 MTR-JAN-2021Document1 page1.0 SQ.MM-FR-LSH-100 MTR-JAN-2021Gopikrishnan ThangarajNo ratings yet

- Dogger Bank ADocument11 pagesDogger Bank AGRZEGORZ GNo ratings yet

- 3M Adhesive Transfer Tape 950Document6 pages3M Adhesive Transfer Tape 950Michael McQueenNo ratings yet

- Method Statement FX-E400 TDS 170714Document4 pagesMethod Statement FX-E400 TDS 170714Ranmal AbhaNo ratings yet

- Reduced Syllabus of JEE Main 2024 - Chemistry-1698910649896Document8 pagesReduced Syllabus of JEE Main 2024 - Chemistry-1698910649896Ryaan MansuriNo ratings yet

- 1156-PT-038 (306) RP 1317Document1 page1156-PT-038 (306) RP 1317el_sharkawy2011No ratings yet

- 6 Elektrokimia SOALAN 2Document2 pages6 Elektrokimia SOALAN 2Noranita HusseinNo ratings yet

- Machine ToolDocument23 pagesMachine ToolMohammad Anaitullah HassanNo ratings yet

- Termodinamica de Hidrocarburos: Maria A. BarrufetDocument61 pagesTermodinamica de Hidrocarburos: Maria A. Barrufet13670319No ratings yet

- Speed TimeGraphsDocument2 pagesSpeed TimeGraphsAnonymous XXgFR0MINo ratings yet

- Alignment Chart For Effective Length of Columns in Continuous FramesDocument1 pageAlignment Chart For Effective Length of Columns in Continuous Framesivan bolañosNo ratings yet

- Tabel Baja WF PDFDocument19 pagesTabel Baja WF PDFRafly PutraNo ratings yet

- Abbenumber WikipediaDocument3 pagesAbbenumber WikipediadanyNo ratings yet

- Gyptone Tiles Planks Boards BrochureDocument16 pagesGyptone Tiles Planks Boards BrochureCynthia MillerNo ratings yet

- El Nino 3Document8 pagesEl Nino 3nisAfiqahNo ratings yet

- Electrical Optical PropertiesDocument17 pagesElectrical Optical Propertieschen18111004 KFUEITNo ratings yet

- V Sem 'B' Section Ese Result Analysis FormatDocument3 pagesV Sem 'B' Section Ese Result Analysis FormatRavichandran GNo ratings yet

- Sci WK 1 Day 1Document24 pagesSci WK 1 Day 1Yam YrrehcNo ratings yet

- Fast EvoDocument64 pagesFast Evogti54726No ratings yet

- SP 41 04Document21 pagesSP 41 04masoud132No ratings yet

- CO2 Handbook IIARDocument190 pagesCO2 Handbook IIAROnofreHalberNo ratings yet

- Lesson 15 SectionVDocument157 pagesLesson 15 SectionVAhmed shabanNo ratings yet

- Che 101 NoteDocument39 pagesChe 101 Noteadebowalepeace502No ratings yet

- Chapter4 OF mATERIAL ENGINEERINGDocument6 pagesChapter4 OF mATERIAL ENGINEERINGaljhun fujitsuNo ratings yet

- Klasyfikacje Oceny MasywuDocument11 pagesKlasyfikacje Oceny MasywuDaniel MoravanskýNo ratings yet

- Ut - Gen Proce-API RP 2xDocument6 pagesUt - Gen Proce-API RP 2xmadhunikhil100% (1)

- Calculation of Timur PermeabilityDocument3 pagesCalculation of Timur PermeabilitybhupenderNo ratings yet

- CH # 3 CouplingsDocument24 pagesCH # 3 CouplingsWaris Ali BozdarNo ratings yet

- Tutorial 9. Using The Mixing Plane Model: PreparationDocument30 pagesTutorial 9. Using The Mixing Plane Model: PreparationMisael RamirezNo ratings yet

- Capacity Regulator CpceDocument8 pagesCapacity Regulator CpceNovan AndriantoNo ratings yet

- Prospects of Organic Electrode Materials For Practical Lithium Batteries. Nature Reviews Chemistry, 4, Pages127-142 (2020)Document16 pagesProspects of Organic Electrode Materials For Practical Lithium Batteries. Nature Reviews Chemistry, 4, Pages127-142 (2020)elderwanNo ratings yet

- Hydro May. 2017 Prob PDFDocument8 pagesHydro May. 2017 Prob PDFDroffilc Nav Cm MulihamNo ratings yet

- Numerical Study of Depressurization Rate During Blowdown Based On Lumped Model AnalysisDocument11 pagesNumerical Study of Depressurization Rate During Blowdown Based On Lumped Model AnalysisamitNo ratings yet