Professional Documents

Culture Documents

Study of Variable Compression Ratio Engine VCR and

Study of Variable Compression Ratio Engine VCR and

Uploaded by

Sang PhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Study of Variable Compression Ratio Engine VCR and

Study of Variable Compression Ratio Engine VCR and

Uploaded by

Sang PhanCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/321630729

Study of Variable Compression Ratio Engine (VCR) and Different Innovations to

Achieve VCR

Article · November 2017

DOI: 10.22214/ijraset.2017.11213

CITATIONS READS

0 555

2 authors:

Mayur Takalkar Ibraheem Raza Khan

Clemson University Automotive Research Association of India

3 PUBLICATIONS 0 CITATIONS 19 PUBLICATIONS 3 CITATIONS

SEE PROFILE SEE PROFILE

Some of the authors of this publication are also working on these related projects:

MACLOCCULUSION View project

Steering System View project

All content following this page was uploaded by Ibraheem Raza Khan on 05 February 2019.

The user has requested enhancement of the downloaded file.

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor:6.887

Volume 5 Issue XI November 2017- Available at www.ijraset.com

Study of Variable Compression Ratio Engine

(VCR) and Different Innovations to Achieve

VCR

Ibraheem Raza Khan1, Mayur Kailas Takalkar2

Abstract:One of the important design parameters for internal combustion engines is the geometric compression ratio. It is

defined by the ratio of the maximum volume of the combustion chamber at the bottom dead centre (BDC) piston position and a

minimum volume of the combustion chamber at the top dead centre (TDC) piston position. Conventional engines have this

parameter set unchangeable, what is not the solution ensuring optimal benefits coming from the heat release in the combustion

process, especially under altering conditions of load and speed in which they perform powering the road vehicles. It is reflected

mainly in exhaust emission problem. Despite a considerable progress, further improving the ecological and energetic

performances of the piston engines faces severe system limits, elimination of which requires major changes in engine design,

including conversion the fixed compression ratio into the flexible one. For such innovative engine designs with so-called

variable compression ratio VCR feature the geometric compression ratio parameter is as the one of the operation regulators.

Keywords:Variable Compression Ratio, Variable-Length Connecting rod, Variation of Combustion Chamber Volume,

Connecting Rod Linkages, Variation of Piston Deck Height, Moving Crankshaft Axis

I. INTRODUCTION

One key features affecting thermal efficiency is the compression ratio, which is always a compromise in fixed compression ratio

spark ignition (SI) engines. If the compression ratio is higher than the designed limit, the fuel will pre-ignite causing knocking,

which could damage the engine. Generally, the operating conditions of SI engines vary widely, such as stop and go city traffic,

highway motoring at constant speed, or high-speed freeway driving. Unfortunately, most of the time SI engines in city driving

conditions operate at relatively low power levels under slow accelerations, low speeds, or light loads, which lead to low thermal

efficiency and hence higher fuel consumption [1].

As the engine load decreases, the temperature in the end gas drops, so that high compression ratio could be employed without

the risk of knocking in naturally aspirated or boosted engines. Raising the compression ratio from 8 to 14 produces an efficiency

gain from 50 to 65 per cent (a 15 per cent gain), whereas going from 16 to 20 produces a gain from 67 to 70 per cent (a 3 per

cent gain). The effects of compression ratio with respect to thermal efficiency. Designing high performance vehicles that are fuel

efficient and clean is difficult since we also want them to remain inexpensive. It is therefore necessary to find simple, low cost and

effective solutions and that is the whole strategy of the Variable Compression Ratio (VCR) engine producers. Far from being a

revolution, VCR engines are a major evolution of conventional engines.

The concept of variable compression ratio (VCR) promises improved engine performance, efficiency and reduced emissions. The

higher cylinder pressures and temperatures during the early part of combustion and small residual gas fraction owing to higher

compression ratio give faster laminar flame speed. Therefore, the ignition delay period is shorter. As a result, at low loads, the

greater the compression ratio, the shorter is the combustion time.

Time loss is subsequently reducd. Therefore, it seems reasonable that fuel consumption rate is lower with high compression ratios at

part load. The VCR can make a significant contribution to thermodynamic efficiency. [2] The main feature of the VCR engine is to

operate at different compression ratios, depending on the vehicle performance needs. A VCR engine can continuously vary the

compression ratio by changing the combustion chamber volume. In a VCR engine, thermodynamic benefits appear throughout the

engine map [3]. At low power levels, the VCR engine operates at a higher compression ratio to capture high fuel efficiency benefits,

while at high power levels the engine operates at low compression ratio to prevent knock. The optimum compression ratio is

determined as a function of one or more vehicle operating parameters such as inlet air temperature, engine coolant temperature,

exhaust gas temperature, engine knock, fuel type, octane rating of fuel etc. In a VCR engine, the operating temperature is more or

less maintained at optimum, where combustion efficiency is high.

©IJRASET (UGC Approved Journal): All Rights are Reserved 1473

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor:6.887

Volume 5 Issue XI November 2017- Available at www.ijraset.com

II. BENEFITS AND ECONOMICS

A. Benefits of the VCR engine can be summarized as follows

1) Optimum combustion efficiency in the whole load and speed range.

2) Low fuel consumption and low exhaust emissions.

3) The VCR provides better control over pollutant generation and after-treatment than a conventional fixed compression ratio

(FCR) engine also extends the life expectancy of a three way catalytic converter.

4) As the geometrical volumetric ratio is under control on VCR engines, the engine always operates below the knock limit,

whatever the load.

5) The VCR engine provides excellent fuel flexibility, since the compression ratio can be varied and adjusted to suit the properties

of the fuel, and therefore the engine will always run at the compression ratio best suited to the fuel being used for bi-fuel

(compressed natural gas (CNG)/gasoline) power-trains; the realization of VCR is of specific interest. High fuel flexibility, with

optimal combustion efficiency.

6) Very smooth idle and full load accelerations are achieved.

7) It provides better indicated thermal efficiency than that of FCR engines.

8) It allows for a significant idle speed reduction because of reduced misfiring and cyclic irregularities, resulting in low vibration

levels.

9) Reduction in low-frequency noise because of constant peak pressures.

10) Smoother combustion because the rate of heat release is the same (short) both at low and high compression ratios.

11) Cold starting emissions can be reduced greatly by early catalyst warm-up in the catalytic converter.

12) Improvement in the low end torque of a petrol engine without the risk of detonation.

13) Potential technology for future high-boosting super lean burn engines.

14) Low CO2 emissions by down-sizing for the same power output.

15) Good idling performance at low ambient temperatures.

16) Constant frictional losses owing to almost constant peak pressures.

B. Economics

Choosing an appropriate VCR technology is a decisive step to determine the cost of VCR implementation in future vehicle. The

different available VCR technologies have to be compared by focusing on all the positive and negative impacts on engine

components and their operations. The benefits of VCR also include increased power density, reduced number of cylinders,

sophisticated injection technologies, and complex after-treatment Indeed, to be marketable, the VCR technology has to present

indispensable features such as robustness, durability, easy integration into all vehicles and low noise and vibration levels. The real

potential of VCR engines will be realized when they are used in combination with down-sizing and supercharging.

III. METHODS TO ACHIEVE VCR

A. Variable-length connecting rod,

The connecting rod length variation is realized by means of a rotation of an eccentric bearing in the connecting rod small end

[4].The moment acting on the eccentric, resulting from superimposed gas and inertia forces, is used to adjust the connecting rod

length. This is the key feature to meet a cost effective VCR solution, because no expensive and power consuming actuators are

needed and all functional elements are concentrated into only one component, the connecting rod. The two support chambers are

connected to the oil circuit via one check valve each, and by means of a 3/2 check valve, a passage from the chamber to the

crankcase can be opened as shown in figure 1. Thus it is possible for one hydraulic piston to enter more deeply into its support

chamber, displacing oil from it in the process, while the other support chamber is being filled with oil. Consequently, the eccentric is

able to rotate in one direction only. The adjustment process takes several working cycles to conclude; the number of cycles required

for the adjustment depends on the operating point as well as the hydraulic resistance. The hydraulic resistance, which can be

controlled by means of orifices, is to be adjusted in such a way that the adjustment process is finished as quick as possible, so as to

avoid engine knocking during step load changes from part load to full load and, in addition, to be able to make immediate use of the

improved efficiency of the higher compression at load changes to part load.

©IJRASET (UGC Approved Journal): All Rights are Reserved 1474

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor:6.887

Volume 5 Issue XI November 2017- Available at www.ijraset.com

Figure 1

IV. NAMED SVC (SAAB VARIABLE COMPRESSION),

The inclinable cylinder head and cylinder, the SVC engine has a cylinder head with integrated cylinders - which is known as mono

head as shown in figure 2. The mono head is pivoted at the crankcase and its slope can be adjusted slightly up to 4 degreesin

relation to the engine block, pistons, crankcase etc. By means of a hydraulic actuator, therefore the volume of the combustion

chamber, when piston is in compressed position, can be varied. SAAB VCR engine.SVC is cleverer than any previous patents for

variable compression ratio engines because it involves no additional moving parts at the combustion chamber or any reciprocating

components, so in theory is simple, durable and free of leakage. The mono head is self-contained, that means it has its own

cooling system. Cooling passages across the head and the cylinder wall [5]. There is a rubber sealing between the mono head and

engine block. The VC allows the Saab engine to run on very high supercharging pressure - 2.8 bar. So high that today’s

turbochargers cannot provide. Therefore it employs supercharger instead. At other speed, the VC is adjustable continuously

according to needs - depends on load, temperature, fuel used, all decided by engine management system. Therefore power and fuel

consumption can be optimized at any conditions.

Figure 2

©IJRASET (UGC Approved Journal): All Rights are Reserved 1475

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor:6.887

Volume 5 Issue XI November 2017- Available at www.ijraset.com

V. VARIATION OF COMBUSTION CHAMBER VOLUME

In order to vary the combustion chamber volume a secondary piston or valve is used .The piston could be maintained at an

Intermediate position, as shown in figure 3, corresponding to the optimum compression ratio for a particular condition .The

combustion chamber volume is increased to reduce the compression ratio by moving a small secondary piston or valve which

communicates with the Chamber [6].

Figure 3

VI. CONNECTING ROD LINKAGES

A popular approach has been developed to replace the conventional con rod with a two piece design in which an upper member

connects with the piston while a lower member connects with the crankshaft [7]. The shorter crank throw allowed room for the link

system, as shown in figure 4 which is anchored by an eccentric rotary actuator.

Figure 4

©IJRASET (UGC Approved Journal): All Rights are Reserved 1476

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor:6.887

Volume 5 Issue XI November 2017- Available at www.ijraset.com

VII. VARIATION OF PISTON DECK HEIGHT

The Daimler-Benz VCR piston design shows variation in compression height of the piston and offers potentially the most attractive

route to a production VCR engine, as shown in figure 5 since it requires relatively minor changes to the base engine architecture

when compared to other options [8].

Figure 5

VIII. MOVING THE CRANKSHAFT AXIS

In this method a crankshaft bearings are carried in an eccentrically mounted carrier that can rotate to raise or lower the top dead

centre (TDC) positions of the pistons in the cylinders as shown in figure 6. The compression ratio is adjustable by varying the

rotation of the eccentric carrier [9].

Figure 6

IX. FUTURE SCOPE

The future for heavy commercial vehicles (HCV) depends on VCR, as the emission regulation go on stringent it is difficult at

achieve it with fixed single fuel compression ration engines. HCV is far from actually been getting fully electric because of its high

rate of energy requirement. The only possible option is to have a bi fuel with variable compression ratio engine, for example a

Diesel Compressed Natural Gas (D-CNG) engine. This engine will be compatible to burn both diesel as well as natural gas, to

understand its possible working, while the vehicle is heavily loaded it uses diesel+ (CNG mixed with air) [10] which reduces the

requirement of diesel but maintains the power for torque and while the vehicle is on kerb (no load) weight it runs on CNG, it is well

understood that diesel is burnt by Compression Ignition and CNG by Spark Ignition, but it can be achieved by Variable

Compression Ratio Engines with provisions for spark ignition.

©IJRASET (UGC Approved Journal): All Rights are Reserved 1477

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor:6.887

Volume 5 Issue XI November 2017- Available at www.ijraset.com

X. CONCLUSION

The VCR engine has great potential for improving part-load thermal efficiency, more efficient operation, ability to down size the

engine, multi fuel flexibility and reducing the harmful emissions when compared to other competing technologies. The main

obstacles to adoption of VCR are incompatibility with major components in current production and difficulties of combining VCR

and non-VCR manufacturing within existing plant. The Potential of these technologies needs to be evaluated by a trade -off

between cost and consumption benefit. It is potentially one of the profitable sources to investigate for the automotive industry.

Under full load conditions, the performance and efficiency of an engine with a compression ratio that is adapted to load demands is

capable of reducing knock susceptibility. In addition, the risk of pre-ignition, mega knocking effects and engine jerking, as the result

of retarded combustion phases, can be reduced. The VCR also provides further potential to control the exhaust gas temperature,

contributing to protecting component temperatures. Combustion, a reduced CR results in a lower peak firing pressure. A compiled

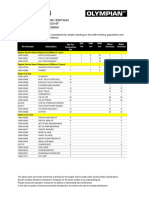

view of all the possible innovation is shown in figure 7.

Figure 7

REFERENCES

[1] M. P. Joshi, “VARIABLE COMPRESSION RATIO (VCR) ENGINE- A REVIEW OF FUTURE POWER PLANT FOR AUTOMOBILE,”

InternationInternational Journal of Mechanical Engineering Research and Development (IJMERD), ISSN 2248 – 9347, vol. 2, no. 1, pp. 2-3, 2012.

[2] U. K. Saha, “Internal Combustion Engine,” QIP-D Cell Project, 2008, pp. 5-8.

[3] R. mishra, “Design of Variable Length Connecting rod for VCR Engine,” International Journal of Engineering Research and Applications (IJERA) ISSN:

2248-9622 , vol. 2, no. 1, pp. 2-3, 2014.

[4] H. K. Paweá WoĞ, “EXHAUST EMISSION FEATURES OF VARIABLE COMPRESSION RATIO (VCR) DIESEL ENGINE,” Journal of KONES

Powertrain and Transport, vol. 17, no. 3, pp. 3-6, 2010.

[5] M. S. S. A. Supee, “Performance of Diesel-Compressed Natural Gas (CNG) Dual Fuel (DDF) Engine via CNG-Air Venturi Mixjector Application,” Arab J Sci

Eng, vol. 10, no. 2, pp. 1-3, 2014.

[6] S. A. P. Quadri, “Emission Study of CNG Substituted Diesel Engine under Dual Fuel Mode,” Scholars Journal of Engineering and Technology (SJET) , vol. 4,

no. 3, pp. 1-3, 2013.

[7] T. J. Rychter, “VARIABLE COMPRESSION RATIO ENGINE - VR/LE CONCEPT,” in Institute of Heat Engineering Warsaw University of Technology ,

Warsaw, 1995, pp. 18-23.

[8] S. Tomar, “Optimisation of Connecting Rod Design to Achieve Vcr,” Savita tomar et al Int. Journal of Engineering Research and Applications , vol. 3, no. 6,

pp. 281-286, 2013.

[9] K.Satyanarayana, “Variable Compression Ratio Diesel Engine Performance Analysis,” International Journal of Engineering Trends and Technology (IJETT,

vol. 28, no. 1, pp. 6-11, 2015.

[10] U. K. Saha, “Internal combustion Engine,” Guwahati, Indian Institute of Technology Guwahati, 2011, pp. 5-15.

©IJRASET (UGC Approved Journal): All Rights are Reserved 1478

View publication stats

You might also like

- 2206 SpecDocument36 pages2206 Specasadiqbalansari100% (4)

- D20S-7 Sb1159e01 PDFDocument678 pagesD20S-7 Sb1159e01 PDFGORDNo ratings yet

- Manual Bajaj Avenger 200 DespieceDocument45 pagesManual Bajaj Avenger 200 DespieceJulio SrKaraokeNo ratings yet

- Ais 137 (Part - 4) Bs ViDocument446 pagesAis 137 (Part - 4) Bs ViVenkatesh GirdharNo ratings yet

- Autodiagnos LanciaDocument10 pagesAutodiagnos Lanciajoxaiv100% (1)

- Isuzu 4j Series Diesel EngineDocument360 pagesIsuzu 4j Series Diesel EngineAlbert Briceño82% (22)

- Perkins 804C-33 ManualDocument25 pagesPerkins 804C-33 ManualIbrahim Awad50% (2)

- Commercial MD HD TruckFuelEfficiencyTechStudyDocument302 pagesCommercial MD HD TruckFuelEfficiencyTechStudyddi11No ratings yet

- Eddy Current Dynamometer SystemDocument19 pagesEddy Current Dynamometer SystemtantibaNo ratings yet

- 10 Wartsila K Portin Performance DF Engines in LNG CarriersDocument21 pages10 Wartsila K Portin Performance DF Engines in LNG Carriersali kharalNo ratings yet

- Winserver2 Volvo Viewinglibrary ST 160 2012 07 10 PDFDocument29 pagesWinserver2 Volvo Viewinglibrary ST 160 2012 07 10 PDFLuis JesusNo ratings yet

- Valve Train Secrets RevealedDocument7 pagesValve Train Secrets Revealedapi-239528001100% (1)

- Kia Sportage RHD EN PDFDocument666 pagesKia Sportage RHD EN PDFSepher YasharNo ratings yet

- BS IV To BS VI Tata Motors PDFDocument3 pagesBS IV To BS VI Tata Motors PDFKaranNo ratings yet

- Turbocharge SystemDocument95 pagesTurbocharge SystemMonish RajNo ratings yet

- Optimal Valve TimingDocument19 pagesOptimal Valve TimingjehadyamNo ratings yet

- Engine PartsDocument19 pagesEngine PartsIbrahim KhanNo ratings yet

- Variable Compression Ratio EnginesDocument24 pagesVariable Compression Ratio EnginesAzher UddinNo ratings yet

- DTC P3107Document2 pagesDTC P3107Erick DavidNo ratings yet

- 2011-Comparison of Methodologies Estimating Emissions of Aircraft Pollutants, Environmental Impact Assessment Around AirportsDocument13 pages2011-Comparison of Methodologies Estimating Emissions of Aircraft Pollutants, Environmental Impact Assessment Around Airportsipagoni1No ratings yet

- VolkswagenDocument32 pagesVolkswagenterrys_85No ratings yet

- Fuse Box Diagram Volkswagen Golf IV - Bora (Mk4 1997-2004)Document14 pagesFuse Box Diagram Volkswagen Golf IV - Bora (Mk4 1997-2004)Rabia GhabagNo ratings yet

- Factors Affecting Car Fuel ConsumptionDocument23 pagesFactors Affecting Car Fuel ConsumptionScribd898989100% (1)

- Engine Knock Sensors - Part TwoDocument4 pagesEngine Knock Sensors - Part TwoFabricio LimaNo ratings yet

- Full Paper No 43 M 2Document9 pagesFull Paper No 43 M 2Anonymous 8qUHG4SlNo ratings yet

- Technical Specification - Rev - 2 July14Document21 pagesTechnical Specification - Rev - 2 July14مراد احمدNo ratings yet

- Tightening Torques Items N.M KGF.M LB-FT: 4 Wheel Drive (4WD) SystemDocument35 pagesTightening Torques Items N.M KGF.M LB-FT: 4 Wheel Drive (4WD) SystemZM OhnNo ratings yet

- Fuel Flow MetersDocument7 pagesFuel Flow MetersAMIYA SHANKAR PANDANo ratings yet

- Obd II Body CodesDocument19 pagesObd II Body CodesTrevor EmbNo ratings yet

- The Refrigerant R1234yf in Air ConditionDocument11 pagesThe Refrigerant R1234yf in Air ConditionAby Torres HernándezNo ratings yet

- Fuel Eff Ice NcyDocument9 pagesFuel Eff Ice Ncymanoj262400/2No ratings yet

- Overall Requirements 1. Scope: Applicable Gazette Notification Under CMVRDocument23 pagesOverall Requirements 1. Scope: Applicable Gazette Notification Under CMVRsingh_ranveerNo ratings yet

- Lab Sheet (Anti-Lock Braking System)Document23 pagesLab Sheet (Anti-Lock Braking System)Encik Arham100% (1)

- VCR SeminarDocument19 pagesVCR SeminarJyothi Reddy100% (2)

- Boost Pressure Sensor (BPS)Document50 pagesBoost Pressure Sensor (BPS)Gian Fran0% (1)

- Electronically Controlled Electronically Controlled Fuel Injection JDocument44 pagesElectronically Controlled Electronically Controlled Fuel Injection J89faisalNo ratings yet

- GLK Class EnglishDocument80 pagesGLK Class Englisheng_farNo ratings yet

- Engine Performance Optimization - GT PowerDocument2 pagesEngine Performance Optimization - GT Powermanoj262400/2No ratings yet

- 02 - Power BalancingDocument8 pages02 - Power Balancingveer sainNo ratings yet

- Electrical Supercharging For Future Diesel Powertrain ApplicationsDocument10 pagesElectrical Supercharging For Future Diesel Powertrain ApplicationsAbdoel Wahied ArohmanNo ratings yet

- Powertrain & Calibration 101Document85 pagesPowertrain & Calibration 101babermughalNo ratings yet

- Powertrain IntegrationDocument4 pagesPowertrain IntegrationmenonmoonNo ratings yet

- Longer and Heavy VehiclesDocument49 pagesLonger and Heavy VehiclesMarcusHuynh88No ratings yet

- Engine Testing TechniqueDocument8 pagesEngine Testing TechniqueNur YakhinNo ratings yet

- Modeling of Variable Intake Valve Timing in SI EngineDocument15 pagesModeling of Variable Intake Valve Timing in SI EngineHuneza AtaNo ratings yet

- MATChapter 11EngFundamentals PDFDocument20 pagesMATChapter 11EngFundamentals PDFBrendan BrodieNo ratings yet

- Fiat Marelli PDFDocument21 pagesFiat Marelli PDFmazacotesNo ratings yet

- KAYO EFI Instructions: 1 Operating PrincipleDocument16 pagesKAYO EFI Instructions: 1 Operating Principlekenny nieuwenwegNo ratings yet

- Electronic Diesel Control (Edc)Document9 pagesElectronic Diesel Control (Edc)SUNIL TNo ratings yet

- Crompton DC MotorsDocument6 pagesCrompton DC MotorsAzed-dine BoughmarNo ratings yet

- LPG Diesel Dual Fuel Engine - A Critical Review: Alexandria Engineering JournalDocument22 pagesLPG Diesel Dual Fuel Engine - A Critical Review: Alexandria Engineering JournalSai HS BodduNo ratings yet

- 2006.01 Motor Toyota EVAP-Non-Intrusive SystemDocument2 pages2006.01 Motor Toyota EVAP-Non-Intrusive SystemMNo ratings yet

- A Review of Ammonia As A Compression Ignition Engine FuelDocument21 pagesA Review of Ammonia As A Compression Ignition Engine FuelHammad KhanNo ratings yet

- Halderman AutoTec ch09Document29 pagesHalderman AutoTec ch09tornomanNo ratings yet

- After Treatment Devices EcoCAT-1Document33 pagesAfter Treatment Devices EcoCAT-1Arjun SikkaNo ratings yet

- Correlation ETC-WHTC (Plus Additional Data) FINALDocument5 pagesCorrelation ETC-WHTC (Plus Additional Data) FINALyogeshkaliaNo ratings yet

- The Electric CarDocument22 pagesThe Electric CarAsok Rawat100% (1)

- 30N12T0 - CVT Diagnosis and Service - 2004Document62 pages30N12T0 - CVT Diagnosis and Service - 2004Trịnh Quốc Anh KhoaNo ratings yet

- The Combustion, Hybrid and Electric EngineDocument55 pagesThe Combustion, Hybrid and Electric EngineDiego Felipe BlancoNo ratings yet

- Wiring Diagram-OMNIDocument4 pagesWiring Diagram-OMNIafi100% (1)

- E31 Relays and FusesDocument1 pageE31 Relays and FusesAndre Vershun Pernell II100% (1)

- Hybrid2009 SKBDocument6 pagesHybrid2009 SKBsovon adhikaryNo ratings yet

- The DSG DQ200 LifespanDocument1 pageThe DSG DQ200 Lifespanqt99qzyhrbNo ratings yet

- Plug-In Hybrid Electric Vehicles The Ultimate Step-By-Step GuideFrom EverandPlug-In Hybrid Electric Vehicles The Ultimate Step-By-Step GuideNo ratings yet

- MGC1101FOUDocument35 pagesMGC1101FOUThomas HultstedtNo ratings yet

- Ignition & ElectronicsDocument16 pagesIgnition & Electronicswordpower777No ratings yet

- D41e-6 Kepb002801Document410 pagesD41e-6 Kepb002801JeffersonDiasNo ratings yet

- Nissan hr16 Taller PDFDocument237 pagesNissan hr16 Taller PDFJhon Sanchez Lopez100% (2)

- Parts Catalogue: Achiever (Apr, 2010)Document100 pagesParts Catalogue: Achiever (Apr, 2010)Divakar MassNo ratings yet

- 2 SM PDFDocument20 pages2 SM PDFYogi Kawar Ganga NathNo ratings yet

- Internship ReportDocument20 pagesInternship ReportSahr, Cyprian FillieNo ratings yet

- Engine Model 1106C-E66TAG4 Alternator Model LL5014F Engine Build PK38659Document2 pagesEngine Model 1106C-E66TAG4 Alternator Model LL5014F Engine Build PK38659TadeleNo ratings yet

- Apisonador Mikasa MT65H Rev 4 ManualDocument64 pagesApisonador Mikasa MT65H Rev 4 ManualRafael Cabra100% (1)

- Kubota Kx121 2 Parts Sec Wat Part 2Document20 pagesKubota Kx121 2 Parts Sec Wat Part 2erin100% (54)

- Workshop Manual: Competence Level 2Document388 pagesWorkshop Manual: Competence Level 2rafaelrgr100% (1)

- CaptivaDocument311 pagesCaptivaDaniel Marin100% (3)

- Cylinder Head, Valves, Gasket KitDocument22 pagesCylinder Head, Valves, Gasket KitKarthii AjuNo ratings yet

- Engine PartsDocument352 pagesEngine Partsdeisy ortega75% (4)

- "Racing in Their Blood" Ch. 6 ExcerptDocument45 pages"Racing in Their Blood" Ch. 6 ExcerptBentley Publishers100% (2)

- XL 100 Spare PartsDocument35 pagesXL 100 Spare PartsTEJAA TVS100% (1)

- Cylinder Head Gasket (Hatchback) - Installation (05 - 2013 - ) (Cylinder Head Assembly) - Yaris HeadDocument9 pagesCylinder Head Gasket (Hatchback) - Installation (05 - 2013 - ) (Cylinder Head Assembly) - Yaris HeadFran SanchezNo ratings yet

- VW SSPDocument46 pagesVW SSPMauri accattoliNo ratings yet

- Mahindra Parts CatalogDocument909 pagesMahindra Parts CatalogSiddhartha Naidu Palanki71% (7)

- Combustion & Combustion Chamber Design: Lecture-5 by Zewdie Alemayehu Automotive Engineering December 2021Document68 pagesCombustion & Combustion Chamber Design: Lecture-5 by Zewdie Alemayehu Automotive Engineering December 2021ahmed jemalNo ratings yet

- Parts Manual: Shibaura Diesel EngineDocument36 pagesParts Manual: Shibaura Diesel Enginecesar100% (1)

- Technical Data - Engine 400/520 SX, MXC, Exc Racing 2001Document2 pagesTechnical Data - Engine 400/520 SX, MXC, Exc Racing 2001RostilsavNo ratings yet

- ENGINE Timing 4ZZ-FEDocument31 pagesENGINE Timing 4ZZ-FEAriel100% (1)