Professional Documents

Culture Documents

Lechler Epoxy Primer

Lechler Epoxy Primer

Uploaded by

Don GoneCopyright:

Available Formats

You might also like

- Application On Resident Engineer SingaporeDocument4 pagesApplication On Resident Engineer SingaporeIz ShafiNo ratings yet

- Traxit eDocument4 pagesTraxit ePero KolevNo ratings yet

- Soldering electronic circuits: Beginner's guideFrom EverandSoldering electronic circuits: Beginner's guideRating: 4.5 out of 5 stars4.5/5 (9)

- Module 3 Spitting Out The HookDocument3 pagesModule 3 Spitting Out The Hookapi-538740413No ratings yet

- 3mtm Scotch Weldtm Epoxy Adhesive 2216 B A PDFDocument8 pages3mtm Scotch Weldtm Epoxy Adhesive 2216 B A PDFFran GaritaNo ratings yet

- Temacoat GPL-S PrimerDocument4 pagesTemacoat GPL-S Primermp87_ingNo ratings yet

- TB Coroflake 23 PDFDocument2 pagesTB Coroflake 23 PDFHatem JafouraNo ratings yet

- 3M2216Document8 pages3M2216pat_kunal1601No ratings yet

- Accrolube SpecDocument3 pagesAccrolube SpecManuel GarniqueNo ratings yet

- Om 340Document3 pagesOm 340RNo ratings yet

- Epoxy Filler Sealer 51213-IDocument2 pagesEpoxy Filler Sealer 51213-IBudi_Salim_42590% (1)

- Fosroc Conbextra EP 0211Document4 pagesFosroc Conbextra EP 0211Tri SuhartantoNo ratings yet

- Barniz DolpsDocument3 pagesBarniz DolpsCordero FranciscoNo ratings yet

- CV1 - PR - B - Mipa TDSDocument2 pagesCV1 - PR - B - Mipa TDSradule021No ratings yet

- TDS Ep100-20Document2 pagesTDS Ep100-20radule021No ratings yet

- Tds Renolit Cxi 2 enDocument3 pagesTds Renolit Cxi 2 enAldair MezaNo ratings yet

- TDS Loctite 3355 PDFDocument3 pagesTDS Loctite 3355 PDFffincher4203No ratings yet

- Ambersil Copper High Temperature Anti Seize Paste TDSDocument2 pagesAmbersil Copper High Temperature Anti Seize Paste TDSjawnuolisNo ratings yet

- Renolit So-Gfb: Description AdvantagesDocument3 pagesRenolit So-Gfb: Description AdvantagesAhmed El TayebNo ratings yet

- Product Data Energol THB: DescriptionDocument2 pagesProduct Data Energol THB: Descriptionkarim karimNo ratings yet

- Pds Hempadur 15570 En-GbDocument3 pagesPds Hempadur 15570 En-GbdcsamaraweeraNo ratings yet

- Manuale HRI Rondoni Ing v.2.2!11!2010 - MQDocument24 pagesManuale HRI Rondoni Ing v.2.2!11!2010 - MQDiego ArriagadaNo ratings yet

- 1040 Stangard (ST) Epoxy MasticDocument5 pages1040 Stangard (ST) Epoxy MasticMayank Gupta50% (2)

- Technical Data Sheets: Fluid FilmDocument5 pagesTechnical Data Sheets: Fluid FilmRAHULNo ratings yet

- Chemflake SpecialDocument5 pagesChemflake SpecialBiju_PottayilNo ratings yet

- Coating ListDocument2 pagesCoating Listhectorgm89No ratings yet

- DS 164 02 ZincAnode304 MZSDocument2 pagesDS 164 02 ZincAnode304 MZSPower PowerNo ratings yet

- Technology Liquid Coating Resins Liquid Coating Resins Product Range Emea EnglishDocument8 pagesTechnology Liquid Coating Resins Liquid Coating Resins Product Range Emea EnglishUsama AwadNo ratings yet

- Loctite 243Document4 pagesLoctite 243ablemathew173974No ratings yet

- Leighs M505Document2 pagesLeighs M505Yogalingam ArumugamNo ratings yet

- Amerlock® 400 Voc: Product Data SheetDocument8 pagesAmerlock® 400 Voc: Product Data SheetCris gomezNo ratings yet

- Loctite 243™: Technical Data SheetDocument4 pagesLoctite 243™: Technical Data SheetRadu_ISNo ratings yet

- Cor Ban 27LDocument4 pagesCor Ban 27LVirender KumarNo ratings yet

- Hi - Temp 900Document5 pagesHi - Temp 900bhavesh solankiNo ratings yet

- Ceplattyn 300Document3 pagesCeplattyn 300rodrigomessiasNo ratings yet

- Boletim Técnico Interplus 356Document4 pagesBoletim Técnico Interplus 356Erik RochaNo ratings yet

- Perkenalan Produk Solvet BaseDocument10 pagesPerkenalan Produk Solvet BaseRenold DarmasyahNo ratings yet

- Temacoat HB 30: Type SuitabilityDocument2 pagesTemacoat HB 30: Type Suitabilitymiagheorghe25No ratings yet

- Endo Angl v2011Document58 pagesEndo Angl v2011Yousab CreatorNo ratings yet

- High Performance Industrial Coal Tar Epoxy: Description and Uses Product ApplicationDocument4 pagesHigh Performance Industrial Coal Tar Epoxy: Description and Uses Product ApplicationChandresh M SachdevNo ratings yet

- Product CatalogueDocument12 pagesProduct Cataloguesusu222000No ratings yet

- Phoenix Water Based PrimerDocument5 pagesPhoenix Water Based PrimerbooklandNo ratings yet

- Aceite MR520Document4 pagesAceite MR520capc.asesoriasNo ratings yet

- PPG HI-TEMP 1027™: Product Data SheetDocument6 pagesPPG HI-TEMP 1027™: Product Data Sheettanmay rahmanNo ratings yet

- 100D Shower Cabine Silicone Sealant: 1 - DescriptionDocument3 pages100D Shower Cabine Silicone Sealant: 1 - DescriptionAleksandar ŽivanovićNo ratings yet

- MyPDF 2Document2 pagesMyPDF 2nikenNo ratings yet

- SigmaCover 280Document5 pagesSigmaCover 280ajuhaseenNo ratings yet

- 5010 Gulf Crown EP 2Document1 page5010 Gulf Crown EP 2Rena NandaNo ratings yet

- Temal 400: Type Suitability Examples of USE Technical DataDocument2 pagesTemal 400: Type Suitability Examples of USE Technical Datammicu18No ratings yet

- MMC TDSDocument3 pagesMMC TDSroshan_khNo ratings yet

- Hi Temp 1027......Document6 pagesHi Temp 1027......mohammed talha khanNo ratings yet

- Pa 10Document3 pagesPa 10LymeParkNo ratings yet

- Fusion Bonded Epoxy Powder Sample ReportDocument1 pageFusion Bonded Epoxy Powder Sample Reportengrmukhtiar70No ratings yet

- Sikafloor®-264: Product Data SheetDocument5 pagesSikafloor®-264: Product Data SheetEaswar KumarNo ratings yet

- 134 TDS Updated Feb 2016 78-8141-8528-2 Rev ADocument6 pages134 TDS Updated Feb 2016 78-8141-8528-2 Rev AUriel GarciaNo ratings yet

- Heat Resisting Silicone Aluminium PaintDocument3 pagesHeat Resisting Silicone Aluminium Paintrumi_2kNo ratings yet

- Azko Coating Hjf14r r4 Es eDocument4 pagesAzko Coating Hjf14r r4 Es eKrishna KumarNo ratings yet

- Simacover EP Tar Epoxy 3404-00Document4 pagesSimacover EP Tar Epoxy 3404-00Perseroan MustikaNo ratings yet

- PDS - EP-10 Etch PrimerDocument2 pagesPDS - EP-10 Etch Primercarlogeretto2No ratings yet

- H70SDocument1 pageH70SJustin SantiagoNo ratings yet

- Mini Habits - Smaller Habits, Bigger Results (PDFDrive) - 100-366Document267 pagesMini Habits - Smaller Habits, Bigger Results (PDFDrive) - 100-366Marlena RiveraNo ratings yet

- What Is Text, Discourse DefinedDocument2 pagesWhat Is Text, Discourse DefinedChristine BlabagnoNo ratings yet

- Instrumentation and Control of Heat ExchangerDocument29 pagesInstrumentation and Control of Heat Exchangerpra578No ratings yet

- Quick Start PF70Document18 pagesQuick Start PF70selvan_rsk761No ratings yet

- PM Handbook - Business Club, IIT BHUDocument54 pagesPM Handbook - Business Club, IIT BHUYOGESH GUTTA 5-Yr IDD Material Sci. & Tech.No ratings yet

- Magazine of Concrete ResearchDocument11 pagesMagazine of Concrete ResearchKathlene Lacosta LastimosaNo ratings yet

- Foundation Design ProjectDocument31 pagesFoundation Design ProjectChoco Late100% (1)

- Train The Trainer ModelDocument2 pagesTrain The Trainer ModeltrixiegariasNo ratings yet

- Employment News 30 September - 06 OctoberDocument39 pagesEmployment News 30 September - 06 OctoberNishant Pratap Singh100% (1)

- Physics Category 1 9th - 10th Grades SAMPLE TESTDocument4 pagesPhysics Category 1 9th - 10th Grades SAMPLE TESTAchavee SukratNo ratings yet

- Passenger/Itinerary Receipt: Electronic Ticket 220-2332362081Document2 pagesPassenger/Itinerary Receipt: Electronic Ticket 220-2332362081Dzeri LoganNo ratings yet

- 1st Year Exam (Re-Exam) 1. Årsprøve (Reeksamen) : August 2021Document14 pages1st Year Exam (Re-Exam) 1. Årsprøve (Reeksamen) : August 2021SafridNo ratings yet

- Bangladesh Country PaperDocument27 pagesBangladesh Country PaperFaruque As Sunny SunnyNo ratings yet

- Elementary Assignment Test: GrammarDocument1 pageElementary Assignment Test: Grammarferml20No ratings yet

- Multiple Choice QuestionsDocument3 pagesMultiple Choice QuestionsManthan Gaming YtNo ratings yet

- Eurasian PlateDocument6 pagesEurasian PlateJoshua SalazarNo ratings yet

- CDA ResumewithFolioDocument25 pagesCDA ResumewithFoliocdabandoNo ratings yet

- The Simplifiers: Our Pre-Impregnated Materials Made From Carbon, Glass, and Aramid FibersDocument16 pagesThe Simplifiers: Our Pre-Impregnated Materials Made From Carbon, Glass, and Aramid FibersVladimir KunitsaNo ratings yet

- A Project Report Peer PressureDocument17 pagesA Project Report Peer PressureTannu GuptaNo ratings yet

- BX - Cleansweep Pro ManualDocument10 pagesBX - Cleansweep Pro ManualVICTOR CHRISTIAN VASQUEZ CHAVEZNo ratings yet

- Asymptotic Analysis PDFDocument26 pagesAsymptotic Analysis PDFSitti Arraya TsabitahNo ratings yet

- A Methodology To Develop Computer Vision Systems in Civil Engineering - Applications in Material Testing and Fish Tracking PDFDocument309 pagesA Methodology To Develop Computer Vision Systems in Civil Engineering - Applications in Material Testing and Fish Tracking PDFMicrodigital WareNo ratings yet

- F520Document2 pagesF520Marcos AldrovandiNo ratings yet

- The Effects of Fuel Dilution With Biodiesel On Lubricant Acidity, Oxidation and Corrosion - A Study With CJ-4 and CI-4 PLUS LubricantsDocument21 pagesThe Effects of Fuel Dilution With Biodiesel On Lubricant Acidity, Oxidation and Corrosion - A Study With CJ-4 and CI-4 PLUS Lubricantsgilar herliana putraNo ratings yet

- Lesson 3 Symbolic Interaction TheoryDocument15 pagesLesson 3 Symbolic Interaction TheoryThiviya RameshNo ratings yet

- Physics Project of Class 11 IscDocument1 pagePhysics Project of Class 11 Iscpratima patelNo ratings yet

- Midterm Examination - Entrepreneurial LeadershipDocument5 pagesMidterm Examination - Entrepreneurial LeadershipDINO DIZONNo ratings yet

- Ap43 Access Point DatasheetDocument6 pagesAp43 Access Point DatasheetPaisarn UmpornjarassaengNo ratings yet

Lechler Epoxy Primer

Lechler Epoxy Primer

Uploaded by

Don GoneOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lechler Epoxy Primer

Lechler Epoxy Primer

Uploaded by

Don GoneCopyright:

Available Formats

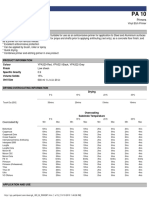

Technical Data Sheet n° 0356-GB

LECHSYS

LS107 (29107)

EPOXYPRIMER

1000 ml + 22-30” DIN 4 Ø 1,6-1,9 mm Air drying at 20° C

500 ml + at 20° C 3,5-4,5 Bar Handling: 5 h

0-100 ml HVLP: Sanding: 18 h

Ø 1,4-1,8 mm Low bake:

Pot-life at 20° C 2-2,5 Bar 30 min. at 60°C

4h N° of coats: 2-3 45 min. at 50°C

DESCRIPTION

Two-pack epoxy primer-sealer/filler with anticorrosion power and zinc-phosphate.

USE

Suitable in Industrial Truck Refinishing and Industry in general as a primer or as a sealer-filler.

CHARACTERISTICS

Easy to apply

Very good adhesion to:

▪ steel

▪ zinc-coated steel (electro-galvanised and hot dip galvanised steel)

▪ aluminium and light alloys

Excellent anticorrosion power

High filling power

Fairly good sanding

Sinkage free when overcoated

Possible application by wet-on-wet cycles

Chrome and lead free

SUBSTRATE PREPARATION

Black steel sheet: microsand or sand.

Steel sheet: degrease carefully with 00695 SILICONE REMOVER SLOW and sand or sandblast.

Aluminium and light alloys: clean and degrease with 00695 SILICONE REMOVER SLOW. Abrade or sand

carefully.

Electro galvanised steel: degrease carefully with 00695 SILICONE REMOVER SLOW.

Hot dip galvanised steel: degrease with 00695 SILICONE REMOVER SLOW and sand or rub.

Fibreglass: Degrease again and again with 00695 SILICONE REMOVER SLOW. If necessary sand.

APPLICATION

Spraying.

Mixing ratio: weight volume

LS107 EPOXYPRIMER (derived from binder 29107) 1000 g 1000 ml

29370 (Standard)-29371 (Fast) LECHSYS EPOXYPRIMER HARDENERS 300 g 500 ml

00516 LECHSYS EPODUR THINNER or 0-50 g 0-100 ml

00556 LECHSYS EPODUR PF THINNER *

*for extra-EEC countries only

LECHLER S.p.A. 22100 Como Italy – Via Cecilio,17 Tel. +39/031/586.111

Pot-life at 20°C: 4 hours (with standard hardener)

Spray viscosity at 20 °C: 22 - 30” DIN4

Ø Air cap: 1.6 - 1.9 mm; HVLP: 1.4 - 1.8 mm

Air pressure: 3.5 - 4.5 bar; HVLP: 2 - 2.5 bar

Number of coats: 2 - 3

Film thickness: 70-100 µ

Theoretical coverage: 1 l mixture = 4.5 m² at 100 µ

1 kg mixture = 3.5 m² at 100 µ

DIR 2004/42/CE: Primer IIB/c – VOC ready for use 540 g/l

This product ready for use contains at most 500 g/l VOC

Two-pack performance coatings –

EUԛlimit value for this product (cat. j/BS): 500 g/l (2010) VOC product ready for use

This product ready for use contains at most 500 g/l VOC

DRYING TIME

Air drying at 20 °C

Dust-free: 15-20 min.

Handling: 5 h

Sanding: 18 hours

Through-drying: 48 hours

Low bake:

at 60 °C: 30 min.

at 50 °C: 45 min.

Try not to dry the product under 15 °C

SANDING

When using EPOXYPRIMER as a primer dry sand with P180 - 220

When using EPOXYPRIMER as a sealer-filler dry sand with P280 - 320

SUGGESTED OVERCOATINGS

Dry-on-dry cycle:

After 8 to 10 hours at 20 °C from the application it can be overcoated with knifing polyester putty.

It can be overcoated by itself if used as a sealer-filler or by other epoxy and polyurethane sealers-fillers.

Generally it is used in Industrial Car Refinish in “two products” cycles, that is overcoated directly by the

enamels of LECHSYS range: ISOLACK – ACRITOP.

Wet-on-wet cycle:

Wait from 1 hour to 24 hours at 20°C and overcoat directly with two-pack polyurethane enamels (ISOLACK-

ACRITOP).

NOTES

The binder 29107 is chrome and lead free. By the formulations try not to add the base colours 29011, 29012

and 29026 in order to maintain the chrome and lead free characteristics of the final product.

The use of the fast hardener causes a reduction of the pot-life times.

The catalysed and thinned product is also usable with electrostatic units.

The formulations of the coloured undercoats are listed under “SOTT” on the Data Box.

Choose the colour in the relevant colour-card.

TECHNICAL DATA SHEET N° 0356-GB

UPDATED 03/2010

All information here included is the result of carefully controlled tests and expresses our best and up to date knowledge. This news is given

only as an information, so the firm cannot be accountable for further results. Furthermore it cannot be used as a contestation related to the

use of the described product. All this is due to the fact that use conditions are not under our control.

LECHLER S.p.A. 22100 Como Italy – Via Cecilio,17 Tel. +39/031/586.111

You might also like

- Application On Resident Engineer SingaporeDocument4 pagesApplication On Resident Engineer SingaporeIz ShafiNo ratings yet

- Traxit eDocument4 pagesTraxit ePero KolevNo ratings yet

- Soldering electronic circuits: Beginner's guideFrom EverandSoldering electronic circuits: Beginner's guideRating: 4.5 out of 5 stars4.5/5 (9)

- Module 3 Spitting Out The HookDocument3 pagesModule 3 Spitting Out The Hookapi-538740413No ratings yet

- 3mtm Scotch Weldtm Epoxy Adhesive 2216 B A PDFDocument8 pages3mtm Scotch Weldtm Epoxy Adhesive 2216 B A PDFFran GaritaNo ratings yet

- Temacoat GPL-S PrimerDocument4 pagesTemacoat GPL-S Primermp87_ingNo ratings yet

- TB Coroflake 23 PDFDocument2 pagesTB Coroflake 23 PDFHatem JafouraNo ratings yet

- 3M2216Document8 pages3M2216pat_kunal1601No ratings yet

- Accrolube SpecDocument3 pagesAccrolube SpecManuel GarniqueNo ratings yet

- Om 340Document3 pagesOm 340RNo ratings yet

- Epoxy Filler Sealer 51213-IDocument2 pagesEpoxy Filler Sealer 51213-IBudi_Salim_42590% (1)

- Fosroc Conbextra EP 0211Document4 pagesFosroc Conbextra EP 0211Tri SuhartantoNo ratings yet

- Barniz DolpsDocument3 pagesBarniz DolpsCordero FranciscoNo ratings yet

- CV1 - PR - B - Mipa TDSDocument2 pagesCV1 - PR - B - Mipa TDSradule021No ratings yet

- TDS Ep100-20Document2 pagesTDS Ep100-20radule021No ratings yet

- Tds Renolit Cxi 2 enDocument3 pagesTds Renolit Cxi 2 enAldair MezaNo ratings yet

- TDS Loctite 3355 PDFDocument3 pagesTDS Loctite 3355 PDFffincher4203No ratings yet

- Ambersil Copper High Temperature Anti Seize Paste TDSDocument2 pagesAmbersil Copper High Temperature Anti Seize Paste TDSjawnuolisNo ratings yet

- Renolit So-Gfb: Description AdvantagesDocument3 pagesRenolit So-Gfb: Description AdvantagesAhmed El TayebNo ratings yet

- Product Data Energol THB: DescriptionDocument2 pagesProduct Data Energol THB: Descriptionkarim karimNo ratings yet

- Pds Hempadur 15570 En-GbDocument3 pagesPds Hempadur 15570 En-GbdcsamaraweeraNo ratings yet

- Manuale HRI Rondoni Ing v.2.2!11!2010 - MQDocument24 pagesManuale HRI Rondoni Ing v.2.2!11!2010 - MQDiego ArriagadaNo ratings yet

- 1040 Stangard (ST) Epoxy MasticDocument5 pages1040 Stangard (ST) Epoxy MasticMayank Gupta50% (2)

- Technical Data Sheets: Fluid FilmDocument5 pagesTechnical Data Sheets: Fluid FilmRAHULNo ratings yet

- Chemflake SpecialDocument5 pagesChemflake SpecialBiju_PottayilNo ratings yet

- Coating ListDocument2 pagesCoating Listhectorgm89No ratings yet

- DS 164 02 ZincAnode304 MZSDocument2 pagesDS 164 02 ZincAnode304 MZSPower PowerNo ratings yet

- Technology Liquid Coating Resins Liquid Coating Resins Product Range Emea EnglishDocument8 pagesTechnology Liquid Coating Resins Liquid Coating Resins Product Range Emea EnglishUsama AwadNo ratings yet

- Loctite 243Document4 pagesLoctite 243ablemathew173974No ratings yet

- Leighs M505Document2 pagesLeighs M505Yogalingam ArumugamNo ratings yet

- Amerlock® 400 Voc: Product Data SheetDocument8 pagesAmerlock® 400 Voc: Product Data SheetCris gomezNo ratings yet

- Loctite 243™: Technical Data SheetDocument4 pagesLoctite 243™: Technical Data SheetRadu_ISNo ratings yet

- Cor Ban 27LDocument4 pagesCor Ban 27LVirender KumarNo ratings yet

- Hi - Temp 900Document5 pagesHi - Temp 900bhavesh solankiNo ratings yet

- Ceplattyn 300Document3 pagesCeplattyn 300rodrigomessiasNo ratings yet

- Boletim Técnico Interplus 356Document4 pagesBoletim Técnico Interplus 356Erik RochaNo ratings yet

- Perkenalan Produk Solvet BaseDocument10 pagesPerkenalan Produk Solvet BaseRenold DarmasyahNo ratings yet

- Temacoat HB 30: Type SuitabilityDocument2 pagesTemacoat HB 30: Type Suitabilitymiagheorghe25No ratings yet

- Endo Angl v2011Document58 pagesEndo Angl v2011Yousab CreatorNo ratings yet

- High Performance Industrial Coal Tar Epoxy: Description and Uses Product ApplicationDocument4 pagesHigh Performance Industrial Coal Tar Epoxy: Description and Uses Product ApplicationChandresh M SachdevNo ratings yet

- Product CatalogueDocument12 pagesProduct Cataloguesusu222000No ratings yet

- Phoenix Water Based PrimerDocument5 pagesPhoenix Water Based PrimerbooklandNo ratings yet

- Aceite MR520Document4 pagesAceite MR520capc.asesoriasNo ratings yet

- PPG HI-TEMP 1027™: Product Data SheetDocument6 pagesPPG HI-TEMP 1027™: Product Data Sheettanmay rahmanNo ratings yet

- 100D Shower Cabine Silicone Sealant: 1 - DescriptionDocument3 pages100D Shower Cabine Silicone Sealant: 1 - DescriptionAleksandar ŽivanovićNo ratings yet

- MyPDF 2Document2 pagesMyPDF 2nikenNo ratings yet

- SigmaCover 280Document5 pagesSigmaCover 280ajuhaseenNo ratings yet

- 5010 Gulf Crown EP 2Document1 page5010 Gulf Crown EP 2Rena NandaNo ratings yet

- Temal 400: Type Suitability Examples of USE Technical DataDocument2 pagesTemal 400: Type Suitability Examples of USE Technical Datammicu18No ratings yet

- MMC TDSDocument3 pagesMMC TDSroshan_khNo ratings yet

- Hi Temp 1027......Document6 pagesHi Temp 1027......mohammed talha khanNo ratings yet

- Pa 10Document3 pagesPa 10LymeParkNo ratings yet

- Fusion Bonded Epoxy Powder Sample ReportDocument1 pageFusion Bonded Epoxy Powder Sample Reportengrmukhtiar70No ratings yet

- Sikafloor®-264: Product Data SheetDocument5 pagesSikafloor®-264: Product Data SheetEaswar KumarNo ratings yet

- 134 TDS Updated Feb 2016 78-8141-8528-2 Rev ADocument6 pages134 TDS Updated Feb 2016 78-8141-8528-2 Rev AUriel GarciaNo ratings yet

- Heat Resisting Silicone Aluminium PaintDocument3 pagesHeat Resisting Silicone Aluminium Paintrumi_2kNo ratings yet

- Azko Coating Hjf14r r4 Es eDocument4 pagesAzko Coating Hjf14r r4 Es eKrishna KumarNo ratings yet

- Simacover EP Tar Epoxy 3404-00Document4 pagesSimacover EP Tar Epoxy 3404-00Perseroan MustikaNo ratings yet

- PDS - EP-10 Etch PrimerDocument2 pagesPDS - EP-10 Etch Primercarlogeretto2No ratings yet

- H70SDocument1 pageH70SJustin SantiagoNo ratings yet

- Mini Habits - Smaller Habits, Bigger Results (PDFDrive) - 100-366Document267 pagesMini Habits - Smaller Habits, Bigger Results (PDFDrive) - 100-366Marlena RiveraNo ratings yet

- What Is Text, Discourse DefinedDocument2 pagesWhat Is Text, Discourse DefinedChristine BlabagnoNo ratings yet

- Instrumentation and Control of Heat ExchangerDocument29 pagesInstrumentation and Control of Heat Exchangerpra578No ratings yet

- Quick Start PF70Document18 pagesQuick Start PF70selvan_rsk761No ratings yet

- PM Handbook - Business Club, IIT BHUDocument54 pagesPM Handbook - Business Club, IIT BHUYOGESH GUTTA 5-Yr IDD Material Sci. & Tech.No ratings yet

- Magazine of Concrete ResearchDocument11 pagesMagazine of Concrete ResearchKathlene Lacosta LastimosaNo ratings yet

- Foundation Design ProjectDocument31 pagesFoundation Design ProjectChoco Late100% (1)

- Train The Trainer ModelDocument2 pagesTrain The Trainer ModeltrixiegariasNo ratings yet

- Employment News 30 September - 06 OctoberDocument39 pagesEmployment News 30 September - 06 OctoberNishant Pratap Singh100% (1)

- Physics Category 1 9th - 10th Grades SAMPLE TESTDocument4 pagesPhysics Category 1 9th - 10th Grades SAMPLE TESTAchavee SukratNo ratings yet

- Passenger/Itinerary Receipt: Electronic Ticket 220-2332362081Document2 pagesPassenger/Itinerary Receipt: Electronic Ticket 220-2332362081Dzeri LoganNo ratings yet

- 1st Year Exam (Re-Exam) 1. Årsprøve (Reeksamen) : August 2021Document14 pages1st Year Exam (Re-Exam) 1. Årsprøve (Reeksamen) : August 2021SafridNo ratings yet

- Bangladesh Country PaperDocument27 pagesBangladesh Country PaperFaruque As Sunny SunnyNo ratings yet

- Elementary Assignment Test: GrammarDocument1 pageElementary Assignment Test: Grammarferml20No ratings yet

- Multiple Choice QuestionsDocument3 pagesMultiple Choice QuestionsManthan Gaming YtNo ratings yet

- Eurasian PlateDocument6 pagesEurasian PlateJoshua SalazarNo ratings yet

- CDA ResumewithFolioDocument25 pagesCDA ResumewithFoliocdabandoNo ratings yet

- The Simplifiers: Our Pre-Impregnated Materials Made From Carbon, Glass, and Aramid FibersDocument16 pagesThe Simplifiers: Our Pre-Impregnated Materials Made From Carbon, Glass, and Aramid FibersVladimir KunitsaNo ratings yet

- A Project Report Peer PressureDocument17 pagesA Project Report Peer PressureTannu GuptaNo ratings yet

- BX - Cleansweep Pro ManualDocument10 pagesBX - Cleansweep Pro ManualVICTOR CHRISTIAN VASQUEZ CHAVEZNo ratings yet

- Asymptotic Analysis PDFDocument26 pagesAsymptotic Analysis PDFSitti Arraya TsabitahNo ratings yet

- A Methodology To Develop Computer Vision Systems in Civil Engineering - Applications in Material Testing and Fish Tracking PDFDocument309 pagesA Methodology To Develop Computer Vision Systems in Civil Engineering - Applications in Material Testing and Fish Tracking PDFMicrodigital WareNo ratings yet

- F520Document2 pagesF520Marcos AldrovandiNo ratings yet

- The Effects of Fuel Dilution With Biodiesel On Lubricant Acidity, Oxidation and Corrosion - A Study With CJ-4 and CI-4 PLUS LubricantsDocument21 pagesThe Effects of Fuel Dilution With Biodiesel On Lubricant Acidity, Oxidation and Corrosion - A Study With CJ-4 and CI-4 PLUS Lubricantsgilar herliana putraNo ratings yet

- Lesson 3 Symbolic Interaction TheoryDocument15 pagesLesson 3 Symbolic Interaction TheoryThiviya RameshNo ratings yet

- Physics Project of Class 11 IscDocument1 pagePhysics Project of Class 11 Iscpratima patelNo ratings yet

- Midterm Examination - Entrepreneurial LeadershipDocument5 pagesMidterm Examination - Entrepreneurial LeadershipDINO DIZONNo ratings yet

- Ap43 Access Point DatasheetDocument6 pagesAp43 Access Point DatasheetPaisarn UmpornjarassaengNo ratings yet