Professional Documents

Culture Documents

Monthly Walkthrough & Inspection Checklist: For Underground Storage Tanks & Motor Fuel Dispensing Equipment

Monthly Walkthrough & Inspection Checklist: For Underground Storage Tanks & Motor Fuel Dispensing Equipment

Uploaded by

Dave PagaraCopyright:

Available Formats

You might also like

- Environmental Cleanliness Audit Tool For Care Homes Apr 2018Document2 pagesEnvironmental Cleanliness Audit Tool For Care Homes Apr 2018Dave PagaraNo ratings yet

- Certified List of Employees SampleDocument1 pageCertified List of Employees SampleDave Pagara100% (3)

- SS 212-2007Document6 pagesSS 212-2007274248150% (2)

- Land Rig Acceptance MasterDocument17 pagesLand Rig Acceptance Masterislam atif100% (1)

- Facility Inspection ChecklistDocument10 pagesFacility Inspection Checklistvas777100% (1)

- LG 001 ChecklistsDocument35 pagesLG 001 ChecklistsSomayajula Suryaram100% (1)

- Maintenance of Inert GasDocument1 pageMaintenance of Inert GasFarihna JoseNo ratings yet

- AST ChecklistsDocument16 pagesAST ChecklistsGary WoodsideNo ratings yet

- Tank and Tank Farm InspectionDocument5 pagesTank and Tank Farm InspectionAjao Joseph Olayinka100% (1)

- Employee Information Form 01Document1 pageEmployee Information Form 01Dave Pagara0% (1)

- Employee Information Form 01Document1 pageEmployee Information Form 01Dave PagaraNo ratings yet

- Technical Data Sheet Zinthobrite CLZ - 942 PDFDocument7 pagesTechnical Data Sheet Zinthobrite CLZ - 942 PDFMULYADI67% (3)

- Excel Template, Equipment Inventory ListDocument2 pagesExcel Template, Equipment Inventory ListiPakistan100% (1)

- Summary of HK Checklists: S No Checklist No Description RemarksDocument21 pagesSummary of HK Checklists: S No Checklist No Description RemarksMarisolNo ratings yet

- Building Maintenance ChecklistDocument2 pagesBuilding Maintenance ChecklistDavid tangkelangi100% (1)

- Facility Inspection ChecklistDocument50 pagesFacility Inspection ChecklistMurali Dharma Raja Praphu50% (2)

- Deep Cleaning ServicesDocument12 pagesDeep Cleaning ServicesHomemitraNo ratings yet

- Incident Report Template 2Document3 pagesIncident Report Template 2Bret ClarkNo ratings yet

- Full Business Needs Assessment Outrise ConsultingDocument22 pagesFull Business Needs Assessment Outrise ConsultingBitse TesfayeNo ratings yet

- Daily Office Cleanup ChecklistDocument1 pageDaily Office Cleanup ChecklistDavid HavensNo ratings yet

- Daily Machine Production ReportDocument1 pageDaily Machine Production ReportimtiazNo ratings yet

- Safety Insp ChecklistDocument2 pagesSafety Insp ChecklistHolartoonde_Ho_7736No ratings yet

- Building (Outside) Cleaning and Sanitation ScheduleDocument2 pagesBuilding (Outside) Cleaning and Sanitation ScheduleNor100% (1)

- Daily Checklist For DGDocument2 pagesDaily Checklist For DG7Days Facility ManagementNo ratings yet

- BlackBox - India's Best Fleet Management SystemDocument26 pagesBlackBox - India's Best Fleet Management SystemBlackBox GPSNo ratings yet

- Example Baghouse Agency Operation & Maintenance PlanDocument8 pagesExample Baghouse Agency Operation & Maintenance Plankashifbutty2kNo ratings yet

- Tank InspectionDocument3 pagesTank InspectionSubbarayan SaravanakumarNo ratings yet

- Maintenance Check List of HydraulicDocument7 pagesMaintenance Check List of HydraulicShubham SinghNo ratings yet

- Tank Inspection Standard Operating Procedures PDFDocument3 pagesTank Inspection Standard Operating Procedures PDFIfroz KhanNo ratings yet

- NEE Boiler-Inspection GuidelineDocument70 pagesNEE Boiler-Inspection GuidelinepiyushagaNo ratings yet

- PEI UST Inspection ChecklistDocument6 pagesPEI UST Inspection ChecklistdamonfitzNo ratings yet

- Major Works To Be DoneDocument6 pagesMajor Works To Be DoneAustin UdofiaNo ratings yet

- ATTACH 3 LOG SHEET UpdatedDocument12 pagesATTACH 3 LOG SHEET UpdatedHedi Ben MohamedNo ratings yet

- Reference Tank Handbook PDFDocument10 pagesReference Tank Handbook PDFIvan AvilesNo ratings yet

- Steam Turbine Loss Prevention Data Dismantled Inspection: GAP.6.1.1.0.2.CDocument2 pagesSteam Turbine Loss Prevention Data Dismantled Inspection: GAP.6.1.1.0.2.Casad khanNo ratings yet

- Quickie Purchase ChecklistDocument7 pagesQuickie Purchase Checklistaquilacorp.entNo ratings yet

- API 653 Tank InspectionDocument53 pagesAPI 653 Tank InspectionWàhränî Là Cläşş100% (3)

- Nitrogen Tank SM1 Checklist - Controlled PDFDocument3 pagesNitrogen Tank SM1 Checklist - Controlled PDFMaxim Kanibetov50% (2)

- Aquaseal Factory Qatar: Operations and Maintenance ChecklistDocument1 pageAquaseal Factory Qatar: Operations and Maintenance ChecklistSafwan MirNo ratings yet

- Boiler Safety Program Boiler ProgramDocument8 pagesBoiler Safety Program Boiler Programsalman akbarNo ratings yet

- Ewp Annual or Third Party Inspection ChecklistDocument5 pagesEwp Annual or Third Party Inspection ChecklistScott BoogemansNo ratings yet

- Ammonia Plant Maint.Document11 pagesAmmonia Plant Maint.mahmadwasiNo ratings yet

- Manitowoc 4600 S4 Lubrication Guide PDFDocument40 pagesManitowoc 4600 S4 Lubrication Guide PDFnamduong368100% (1)

- Standpipe and Hos 20 SystemsDocument1 pageStandpipe and Hos 20 SystemsJeferson Binay-anNo ratings yet

- Preventive Maintenance ChecklistDocument3 pagesPreventive Maintenance ChecklistjjmemeNo ratings yet

- 8 6 20Document4 pages8 6 20sonerNo ratings yet

- Sample Check ListDocument2 pagesSample Check ListHarsun HarNo ratings yet

- Each Life Raft Must Contain A Few ItemsDocument2 pagesEach Life Raft Must Contain A Few ItemsMar SundayNo ratings yet

- Emergency Generator MaintenanceDocument8 pagesEmergency Generator MaintenanceGerardo Rubio100% (1)

- MAINTENANCE OF RAW WATER DISTRIBUTION SYSTEM - Pharmaceutical GuidanceDocument2 pagesMAINTENANCE OF RAW WATER DISTRIBUTION SYSTEM - Pharmaceutical Guidancedecio ventura rodrigues miraNo ratings yet

- Overhead-CranesDocument52 pagesOverhead-CranesShivanand PandaNo ratings yet

- Stručni Test Engleskog JezikaDocument3 pagesStručni Test Engleskog JezikadjukalNo ratings yet

- Boiler Safety ProgramDocument8 pagesBoiler Safety ProgramHussain KhanNo ratings yet

- Operations and Maintenance Checklist: Check The Following Items DailyDocument1 pageOperations and Maintenance Checklist: Check The Following Items DailySafwan MirNo ratings yet

- 01 12fps-Nfpa ch02 - DDocument2 pages01 12fps-Nfpa ch02 - DMohamed Ilias HamaniNo ratings yet

- Lift Station SOGDocument7 pagesLift Station SOGEdwin Collado FigueroaNo ratings yet

- Automatic Tank Gauging For Underground Storage TanksDocument3 pagesAutomatic Tank Gauging For Underground Storage TanksShailesh DeshmukhNo ratings yet

- Accessories Preventive Maintenance ChecklistDocument1 pageAccessories Preventive Maintenance ChecklisttmamputsiNo ratings yet

- Overhead Crane Safety and Inspection RequirementsDocument69 pagesOverhead Crane Safety and Inspection RequirementsAhmed ReguiegNo ratings yet

- RMS - Boiler Maintenance & Periodic Testing ChecklistDocument5 pagesRMS - Boiler Maintenance & Periodic Testing ChecklistERplant RefinersNo ratings yet

- Boiler_Maintenance_Checklist_And_LogsDocument7 pagesBoiler_Maintenance_Checklist_And_LogsTrần Văn Trọng 7350No ratings yet

- ChecklistDocument2 pagesChecklistdassayevNo ratings yet

- Generators Expected ServicesDocument3 pagesGenerators Expected Servicesmoaz zahidNo ratings yet

- Purge Points Are Pipe Nipples InstalledDocument2 pagesPurge Points Are Pipe Nipples Installedengg_mech77No ratings yet

- API RP 576 Section 5Document5 pagesAPI RP 576 Section 5kaltumanikNo ratings yet

- Fire Pump Testing - Periodic Operational TestDocument5 pagesFire Pump Testing - Periodic Operational TestToa Suhandita100% (1)

- ECC Major AmendmentsDocument3 pagesECC Major AmendmentsDave PagaraNo ratings yet

- FORM-CR2 Sample Letter For Required Documents SubmissionDocument1 pageFORM-CR2 Sample Letter For Required Documents SubmissionDave PagaraNo ratings yet

- Employee Information Form 06Document3 pagesEmployee Information Form 06Dave PagaraNo ratings yet

- Bookkeeping With Entrepreneurship Course OutlineDocument5 pagesBookkeeping With Entrepreneurship Course OutlineDave PagaraNo ratings yet

- HDMF ESRS ModuleDocument6 pagesHDMF ESRS ModuleDave PagaraNo ratings yet

- PCO Accreditation ChecklistDocument1 pagePCO Accreditation ChecklistDave PagaraNo ratings yet

- Bir Form 2307Document2 pagesBir Form 2307Dave Pagara100% (5)

- Critical Thickness of Insulation of A SphereDocument7 pagesCritical Thickness of Insulation of A Sphereدنيا قيس كاظمNo ratings yet

- Report SubmissionDocument65 pagesReport Submissionvidit SinghNo ratings yet

- Unidrive SP Elevator BrochureDocument8 pagesUnidrive SP Elevator BrochuresalesgglsNo ratings yet

- ASME B31.3 & Expansion Joints PDFDocument2 pagesASME B31.3 & Expansion Joints PDFsammar_10No ratings yet

- SPE 134169 Designing and Testing Cement System For SAGD ApplicationDocument12 pagesSPE 134169 Designing and Testing Cement System For SAGD Applicationadvantage025No ratings yet

- Raffles 25,000T Cement Silo - Structural Calculations - ST 09Document606 pagesRaffles 25,000T Cement Silo - Structural Calculations - ST 09gutmontNo ratings yet

- Manual Equipo Pintura Titan SpeefloDocument32 pagesManual Equipo Pintura Titan SpeefloJulio Rolong OrtizNo ratings yet

- Gs01e08b01-00e (9) CaDocument9 pagesGs01e08b01-00e (9) CaNguyen ThuongNo ratings yet

- Mortar (Masonry) - Wikipedia PDFDocument37 pagesMortar (Masonry) - Wikipedia PDFEndhy Wisnu NovindraNo ratings yet

- CERTIFICATES - Certified Competition EquipmentDocument12 pagesCERTIFICATES - Certified Competition Equipmentleocaobelli2022No ratings yet

- Regulators-67 AFR, 1301Document2 pagesRegulators-67 AFR, 1301saad kamranNo ratings yet

- Is 1865 - 2Document1 pageIs 1865 - 2Svapnesh ParikhNo ratings yet

- Glands Qty: Sr. No Boq# Description (Gland Size For Wires) Glands Remaining Remarks Required (Rev) Store ReceivedDocument2 pagesGlands Qty: Sr. No Boq# Description (Gland Size For Wires) Glands Remaining Remarks Required (Rev) Store ReceivedUmer RashidNo ratings yet

- Machine Chest (Pulp and Paper Plant Design)Document4 pagesMachine Chest (Pulp and Paper Plant Design)Mark Vicson100% (1)

- Utilization of Fly Ash, Rice Husk Ash, and Palm Oil Fuel Ash in Glass Fiber-Reinforced ConcreteDocument8 pagesUtilization of Fly Ash, Rice Husk Ash, and Palm Oil Fuel Ash in Glass Fiber-Reinforced ConcreteKEVIND PARINDINGNo ratings yet

- The Essential CNC Cost Reduction ChecklistDocument5 pagesThe Essential CNC Cost Reduction Checklistajaxleon100% (1)

- API 510 Recert Test GuideDocument2 pagesAPI 510 Recert Test Guidekatycwi100% (1)

- Variable Compression Ratio: by S. RoshanDocument19 pagesVariable Compression Ratio: by S. RoshanHimanshu SharmaNo ratings yet

- NFPA 96 and Building Code Requirements For Commercial Kitchen Hood SystemsDocument49 pagesNFPA 96 and Building Code Requirements For Commercial Kitchen Hood SystemsLuis Gabriel BautistaNo ratings yet

- TK-315 CPI2 - 1 - NonReacting SystemsDocument33 pagesTK-315 CPI2 - 1 - NonReacting SystemsBayu Purnama Ridjadi75% (4)

- Glossery of Terms: AggregateDocument7 pagesGlossery of Terms: AggregateAssane RoqueNo ratings yet

- J. H. Fletcher & Co.: Cj151E Face DrillDocument2 pagesJ. H. Fletcher & Co.: Cj151E Face DrilljiaozhongxingNo ratings yet

- Boqs For STC Containers P2 S1/S2/Rev: Sr. No. Description Size Unit P 2 S1 P2 S2 Rev Total Weight (KG) RemarksDocument3 pagesBoqs For STC Containers P2 S1/S2/Rev: Sr. No. Description Size Unit P 2 S1 P2 S2 Rev Total Weight (KG) Remarksmc160403810 Usman AliNo ratings yet

- Nagel Finisher PC DU7-3105-000Document139 pagesNagel Finisher PC DU7-3105-000Willian S.No ratings yet

- TuringMachine Expanders 1.1Document14 pagesTuringMachine Expanders 1.1Nico PinealNo ratings yet

- Chromatofocusing HandbookDocument44 pagesChromatofocusing HandbookDolphingNo ratings yet

- Ceramic FabricationDocument38 pagesCeramic FabricationAlexander DavidNo ratings yet

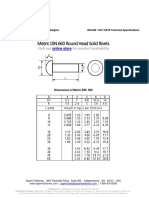

- Metric DIN SpecDocument5 pagesMetric DIN SpecSajid ManzoorNo ratings yet

Monthly Walkthrough & Inspection Checklist: For Underground Storage Tanks & Motor Fuel Dispensing Equipment

Monthly Walkthrough & Inspection Checklist: For Underground Storage Tanks & Motor Fuel Dispensing Equipment

Uploaded by

Dave PagaraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Monthly Walkthrough & Inspection Checklist: For Underground Storage Tanks & Motor Fuel Dispensing Equipment

Monthly Walkthrough & Inspection Checklist: For Underground Storage Tanks & Motor Fuel Dispensing Equipment

Uploaded by

Dave PagaraCopyright:

Available Formats

Monthly Walkthrough & Inspection Checklist

For Underground Storage Tanks & Motor Fuel Dispensing Equipment

At least monthly, conduct basic walkthrough inspections of the facility to make To document walkthroughs, record the date of each monthly inspection under

sure that all essential equipment is working properly and that there are fuel release the month name. For each device/system inspected, mark whether it was working

response supplies on hand. Perform the monthly inspection on the last working day properly (for example, “ok”) or was defective and needed repair (for example, “not

of the month. ok” or “needs repair”). Initial all entries, especially if more than one person performs

inspections. Make sure to keep records of all repairs and record the dates and parts

The first section of this monthly checklist addresses the basic inspection areas repaired/replaced on the maintenance log.

applicable to all gas stations. The second section addresses inspection areas for

facilities that choose to retain Stage II vapor recovery systems (monthly inspections

of Stage II equipment are not required but recommended - see page 66).

Inspection point Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec

Inspection date

Underground storage tanks and motor fuel dispensing equipment

Release detection system

Inspect for proper operation. Run quick “self-

test” of automatic tank gauging (ATG) to

verify correct operation, or check manual dip

stick for wear or warping.

Spill buckets

Ensure spill buckets are clean, empty and free

of debris.

Overfill alarm

Inspect for proper operation. Make sure

alarm is easily seen and heard.

Impressed current cathodic protection

system Inspect for proper operation. Check

and log rectifier at least every 60 days.

Fill and monitoring ports

Inspect to make sure covers and caps are

tightly sealed and locked.

Spill and overfill response supplies

Inventory emergency spill response supplies

and restock if supplies are low. Inspect

supplies for deterioration and improper

functioning.

2019-2020 Compliance Calendar for WI Gasoline Facilities, page 56

Monthly Walkthrough & Inspection Checklist (continued)

Inspection point Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec

Inspection date

Dispenser hoses, nozzles, breakaways

Inspect for loose fittings, deterioration, obvious

signs of leakage or improper functioning.

Dispensers and dispenser sumps

Open each dispenser and inspect visible piping,

fittings, and couplings for signs of leakage. If

any water or product is present, remove and

dispose of it properly. Remove debris from

sump.

Piping sumps

Inspect visible piping, fittings and couplings

for signs of leakage. If any water or product

is present, remove and dispose of it properly.

Remove debris from sump.

Gasoline dispensing equipment at facilities that choose to retain Stage II vapor recovery systems

(inspecting the equipment below is optional but recommended - see page 66)

Vapor return line

Make sure line is not crimped, flattened or

blocked and has no holes or slits. Make sure

poppets work properly and seal tightly. Inspect

breakaways and swivels.

Nozzle bellows

Inspect to ensure there are no holes larger than

0.25” or slits larger than 1” (if applicable).

Nozzle faceplate or facecone

Inspect to ensure it is not torn or missing more

than 25 percent of its surface (if applicable).

Nozzle

Inspect to make sure it is operating properly

and has an automatic overfill control

mechanism.

Vapor processing unit

Check for defects including leaking return line,

intermittent process interruptions, low vapor

pressure in return to tank line or inoperable

Stage I control, e.g. pressure vacuum vent.

2019-2020 Compliance Calendar for WI Gasoline Facilities, page 57

You might also like

- Environmental Cleanliness Audit Tool For Care Homes Apr 2018Document2 pagesEnvironmental Cleanliness Audit Tool For Care Homes Apr 2018Dave PagaraNo ratings yet

- Certified List of Employees SampleDocument1 pageCertified List of Employees SampleDave Pagara100% (3)

- SS 212-2007Document6 pagesSS 212-2007274248150% (2)

- Land Rig Acceptance MasterDocument17 pagesLand Rig Acceptance Masterislam atif100% (1)

- Facility Inspection ChecklistDocument10 pagesFacility Inspection Checklistvas777100% (1)

- LG 001 ChecklistsDocument35 pagesLG 001 ChecklistsSomayajula Suryaram100% (1)

- Maintenance of Inert GasDocument1 pageMaintenance of Inert GasFarihna JoseNo ratings yet

- AST ChecklistsDocument16 pagesAST ChecklistsGary WoodsideNo ratings yet

- Tank and Tank Farm InspectionDocument5 pagesTank and Tank Farm InspectionAjao Joseph Olayinka100% (1)

- Employee Information Form 01Document1 pageEmployee Information Form 01Dave Pagara0% (1)

- Employee Information Form 01Document1 pageEmployee Information Form 01Dave PagaraNo ratings yet

- Technical Data Sheet Zinthobrite CLZ - 942 PDFDocument7 pagesTechnical Data Sheet Zinthobrite CLZ - 942 PDFMULYADI67% (3)

- Excel Template, Equipment Inventory ListDocument2 pagesExcel Template, Equipment Inventory ListiPakistan100% (1)

- Summary of HK Checklists: S No Checklist No Description RemarksDocument21 pagesSummary of HK Checklists: S No Checklist No Description RemarksMarisolNo ratings yet

- Building Maintenance ChecklistDocument2 pagesBuilding Maintenance ChecklistDavid tangkelangi100% (1)

- Facility Inspection ChecklistDocument50 pagesFacility Inspection ChecklistMurali Dharma Raja Praphu50% (2)

- Deep Cleaning ServicesDocument12 pagesDeep Cleaning ServicesHomemitraNo ratings yet

- Incident Report Template 2Document3 pagesIncident Report Template 2Bret ClarkNo ratings yet

- Full Business Needs Assessment Outrise ConsultingDocument22 pagesFull Business Needs Assessment Outrise ConsultingBitse TesfayeNo ratings yet

- Daily Office Cleanup ChecklistDocument1 pageDaily Office Cleanup ChecklistDavid HavensNo ratings yet

- Daily Machine Production ReportDocument1 pageDaily Machine Production ReportimtiazNo ratings yet

- Safety Insp ChecklistDocument2 pagesSafety Insp ChecklistHolartoonde_Ho_7736No ratings yet

- Building (Outside) Cleaning and Sanitation ScheduleDocument2 pagesBuilding (Outside) Cleaning and Sanitation ScheduleNor100% (1)

- Daily Checklist For DGDocument2 pagesDaily Checklist For DG7Days Facility ManagementNo ratings yet

- BlackBox - India's Best Fleet Management SystemDocument26 pagesBlackBox - India's Best Fleet Management SystemBlackBox GPSNo ratings yet

- Example Baghouse Agency Operation & Maintenance PlanDocument8 pagesExample Baghouse Agency Operation & Maintenance Plankashifbutty2kNo ratings yet

- Tank InspectionDocument3 pagesTank InspectionSubbarayan SaravanakumarNo ratings yet

- Maintenance Check List of HydraulicDocument7 pagesMaintenance Check List of HydraulicShubham SinghNo ratings yet

- Tank Inspection Standard Operating Procedures PDFDocument3 pagesTank Inspection Standard Operating Procedures PDFIfroz KhanNo ratings yet

- NEE Boiler-Inspection GuidelineDocument70 pagesNEE Boiler-Inspection GuidelinepiyushagaNo ratings yet

- PEI UST Inspection ChecklistDocument6 pagesPEI UST Inspection ChecklistdamonfitzNo ratings yet

- Major Works To Be DoneDocument6 pagesMajor Works To Be DoneAustin UdofiaNo ratings yet

- ATTACH 3 LOG SHEET UpdatedDocument12 pagesATTACH 3 LOG SHEET UpdatedHedi Ben MohamedNo ratings yet

- Reference Tank Handbook PDFDocument10 pagesReference Tank Handbook PDFIvan AvilesNo ratings yet

- Steam Turbine Loss Prevention Data Dismantled Inspection: GAP.6.1.1.0.2.CDocument2 pagesSteam Turbine Loss Prevention Data Dismantled Inspection: GAP.6.1.1.0.2.Casad khanNo ratings yet

- Quickie Purchase ChecklistDocument7 pagesQuickie Purchase Checklistaquilacorp.entNo ratings yet

- API 653 Tank InspectionDocument53 pagesAPI 653 Tank InspectionWàhränî Là Cläşş100% (3)

- Nitrogen Tank SM1 Checklist - Controlled PDFDocument3 pagesNitrogen Tank SM1 Checklist - Controlled PDFMaxim Kanibetov50% (2)

- Aquaseal Factory Qatar: Operations and Maintenance ChecklistDocument1 pageAquaseal Factory Qatar: Operations and Maintenance ChecklistSafwan MirNo ratings yet

- Boiler Safety Program Boiler ProgramDocument8 pagesBoiler Safety Program Boiler Programsalman akbarNo ratings yet

- Ewp Annual or Third Party Inspection ChecklistDocument5 pagesEwp Annual or Third Party Inspection ChecklistScott BoogemansNo ratings yet

- Ammonia Plant Maint.Document11 pagesAmmonia Plant Maint.mahmadwasiNo ratings yet

- Manitowoc 4600 S4 Lubrication Guide PDFDocument40 pagesManitowoc 4600 S4 Lubrication Guide PDFnamduong368100% (1)

- Standpipe and Hos 20 SystemsDocument1 pageStandpipe and Hos 20 SystemsJeferson Binay-anNo ratings yet

- Preventive Maintenance ChecklistDocument3 pagesPreventive Maintenance ChecklistjjmemeNo ratings yet

- 8 6 20Document4 pages8 6 20sonerNo ratings yet

- Sample Check ListDocument2 pagesSample Check ListHarsun HarNo ratings yet

- Each Life Raft Must Contain A Few ItemsDocument2 pagesEach Life Raft Must Contain A Few ItemsMar SundayNo ratings yet

- Emergency Generator MaintenanceDocument8 pagesEmergency Generator MaintenanceGerardo Rubio100% (1)

- MAINTENANCE OF RAW WATER DISTRIBUTION SYSTEM - Pharmaceutical GuidanceDocument2 pagesMAINTENANCE OF RAW WATER DISTRIBUTION SYSTEM - Pharmaceutical Guidancedecio ventura rodrigues miraNo ratings yet

- Overhead-CranesDocument52 pagesOverhead-CranesShivanand PandaNo ratings yet

- Stručni Test Engleskog JezikaDocument3 pagesStručni Test Engleskog JezikadjukalNo ratings yet

- Boiler Safety ProgramDocument8 pagesBoiler Safety ProgramHussain KhanNo ratings yet

- Operations and Maintenance Checklist: Check The Following Items DailyDocument1 pageOperations and Maintenance Checklist: Check The Following Items DailySafwan MirNo ratings yet

- 01 12fps-Nfpa ch02 - DDocument2 pages01 12fps-Nfpa ch02 - DMohamed Ilias HamaniNo ratings yet

- Lift Station SOGDocument7 pagesLift Station SOGEdwin Collado FigueroaNo ratings yet

- Automatic Tank Gauging For Underground Storage TanksDocument3 pagesAutomatic Tank Gauging For Underground Storage TanksShailesh DeshmukhNo ratings yet

- Accessories Preventive Maintenance ChecklistDocument1 pageAccessories Preventive Maintenance ChecklisttmamputsiNo ratings yet

- Overhead Crane Safety and Inspection RequirementsDocument69 pagesOverhead Crane Safety and Inspection RequirementsAhmed ReguiegNo ratings yet

- RMS - Boiler Maintenance & Periodic Testing ChecklistDocument5 pagesRMS - Boiler Maintenance & Periodic Testing ChecklistERplant RefinersNo ratings yet

- Boiler_Maintenance_Checklist_And_LogsDocument7 pagesBoiler_Maintenance_Checklist_And_LogsTrần Văn Trọng 7350No ratings yet

- ChecklistDocument2 pagesChecklistdassayevNo ratings yet

- Generators Expected ServicesDocument3 pagesGenerators Expected Servicesmoaz zahidNo ratings yet

- Purge Points Are Pipe Nipples InstalledDocument2 pagesPurge Points Are Pipe Nipples Installedengg_mech77No ratings yet

- API RP 576 Section 5Document5 pagesAPI RP 576 Section 5kaltumanikNo ratings yet

- Fire Pump Testing - Periodic Operational TestDocument5 pagesFire Pump Testing - Periodic Operational TestToa Suhandita100% (1)

- ECC Major AmendmentsDocument3 pagesECC Major AmendmentsDave PagaraNo ratings yet

- FORM-CR2 Sample Letter For Required Documents SubmissionDocument1 pageFORM-CR2 Sample Letter For Required Documents SubmissionDave PagaraNo ratings yet

- Employee Information Form 06Document3 pagesEmployee Information Form 06Dave PagaraNo ratings yet

- Bookkeeping With Entrepreneurship Course OutlineDocument5 pagesBookkeeping With Entrepreneurship Course OutlineDave PagaraNo ratings yet

- HDMF ESRS ModuleDocument6 pagesHDMF ESRS ModuleDave PagaraNo ratings yet

- PCO Accreditation ChecklistDocument1 pagePCO Accreditation ChecklistDave PagaraNo ratings yet

- Bir Form 2307Document2 pagesBir Form 2307Dave Pagara100% (5)

- Critical Thickness of Insulation of A SphereDocument7 pagesCritical Thickness of Insulation of A Sphereدنيا قيس كاظمNo ratings yet

- Report SubmissionDocument65 pagesReport Submissionvidit SinghNo ratings yet

- Unidrive SP Elevator BrochureDocument8 pagesUnidrive SP Elevator BrochuresalesgglsNo ratings yet

- ASME B31.3 & Expansion Joints PDFDocument2 pagesASME B31.3 & Expansion Joints PDFsammar_10No ratings yet

- SPE 134169 Designing and Testing Cement System For SAGD ApplicationDocument12 pagesSPE 134169 Designing and Testing Cement System For SAGD Applicationadvantage025No ratings yet

- Raffles 25,000T Cement Silo - Structural Calculations - ST 09Document606 pagesRaffles 25,000T Cement Silo - Structural Calculations - ST 09gutmontNo ratings yet

- Manual Equipo Pintura Titan SpeefloDocument32 pagesManual Equipo Pintura Titan SpeefloJulio Rolong OrtizNo ratings yet

- Gs01e08b01-00e (9) CaDocument9 pagesGs01e08b01-00e (9) CaNguyen ThuongNo ratings yet

- Mortar (Masonry) - Wikipedia PDFDocument37 pagesMortar (Masonry) - Wikipedia PDFEndhy Wisnu NovindraNo ratings yet

- CERTIFICATES - Certified Competition EquipmentDocument12 pagesCERTIFICATES - Certified Competition Equipmentleocaobelli2022No ratings yet

- Regulators-67 AFR, 1301Document2 pagesRegulators-67 AFR, 1301saad kamranNo ratings yet

- Is 1865 - 2Document1 pageIs 1865 - 2Svapnesh ParikhNo ratings yet

- Glands Qty: Sr. No Boq# Description (Gland Size For Wires) Glands Remaining Remarks Required (Rev) Store ReceivedDocument2 pagesGlands Qty: Sr. No Boq# Description (Gland Size For Wires) Glands Remaining Remarks Required (Rev) Store ReceivedUmer RashidNo ratings yet

- Machine Chest (Pulp and Paper Plant Design)Document4 pagesMachine Chest (Pulp and Paper Plant Design)Mark Vicson100% (1)

- Utilization of Fly Ash, Rice Husk Ash, and Palm Oil Fuel Ash in Glass Fiber-Reinforced ConcreteDocument8 pagesUtilization of Fly Ash, Rice Husk Ash, and Palm Oil Fuel Ash in Glass Fiber-Reinforced ConcreteKEVIND PARINDINGNo ratings yet

- The Essential CNC Cost Reduction ChecklistDocument5 pagesThe Essential CNC Cost Reduction Checklistajaxleon100% (1)

- API 510 Recert Test GuideDocument2 pagesAPI 510 Recert Test Guidekatycwi100% (1)

- Variable Compression Ratio: by S. RoshanDocument19 pagesVariable Compression Ratio: by S. RoshanHimanshu SharmaNo ratings yet

- NFPA 96 and Building Code Requirements For Commercial Kitchen Hood SystemsDocument49 pagesNFPA 96 and Building Code Requirements For Commercial Kitchen Hood SystemsLuis Gabriel BautistaNo ratings yet

- TK-315 CPI2 - 1 - NonReacting SystemsDocument33 pagesTK-315 CPI2 - 1 - NonReacting SystemsBayu Purnama Ridjadi75% (4)

- Glossery of Terms: AggregateDocument7 pagesGlossery of Terms: AggregateAssane RoqueNo ratings yet

- J. H. Fletcher & Co.: Cj151E Face DrillDocument2 pagesJ. H. Fletcher & Co.: Cj151E Face DrilljiaozhongxingNo ratings yet

- Boqs For STC Containers P2 S1/S2/Rev: Sr. No. Description Size Unit P 2 S1 P2 S2 Rev Total Weight (KG) RemarksDocument3 pagesBoqs For STC Containers P2 S1/S2/Rev: Sr. No. Description Size Unit P 2 S1 P2 S2 Rev Total Weight (KG) Remarksmc160403810 Usman AliNo ratings yet

- Nagel Finisher PC DU7-3105-000Document139 pagesNagel Finisher PC DU7-3105-000Willian S.No ratings yet

- TuringMachine Expanders 1.1Document14 pagesTuringMachine Expanders 1.1Nico PinealNo ratings yet

- Chromatofocusing HandbookDocument44 pagesChromatofocusing HandbookDolphingNo ratings yet

- Ceramic FabricationDocument38 pagesCeramic FabricationAlexander DavidNo ratings yet

- Metric DIN SpecDocument5 pagesMetric DIN SpecSajid ManzoorNo ratings yet