Professional Documents

Culture Documents

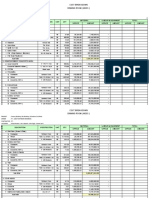

Site Inspection Checklist For Tibig 1 Waterway Bridge WB18.ods

Site Inspection Checklist For Tibig 1 Waterway Bridge WB18.ods

Uploaded by

Glenda SibongaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Site Inspection Checklist For Tibig 1 Waterway Bridge WB18.ods

Site Inspection Checklist For Tibig 1 Waterway Bridge WB18.ods

Uploaded by

Glenda SibongaCopyright:

Available Formats

C.M. PANCHO CONSTRUCTION, INC.

QUALITY CONTROL / QUALITY ASSURANCE ( QA/QC )

SITE INSPECTION REPORT

Date of Inspection : ____________________________ Weather: ____________ FORM-SIR-1119-000

A. PROJECT DETAILS:

Project Name:

Station:

B. ACTIVITY Item No. __________ -Tibig 1 Waterway Bridge WB18

Scope of Works

Location:

Manpower :

Equipment Used:

C. DURATION:

Date Started :

Target Date of Finished:

D. ACCOMPLISHMENT:

Amount Accomplished this period PhP

Previous Amount Accomplished PhP

Amount Accomplished to Date PhP

Percent Accomplished to Date %

Schedule Percent of Accomplishment %

Slippage, % (+/-) %

E. AREA OF CONCERNS

PARTICULARS STATUS

( detailed areas for Checking ) NON-COMPLYING (NC)

COMPLYING HINTS FOR DEADLINE OF

/ GOOD IMPROVEME NON-

DESCRIPTION OF NON-COMPLIANCE COMPLIANCE RECOMMENDED ACTION ( includes manpower, IMPLEMENTATION OF

PRACTICE NT materials, equipment requirements) CORRECTION /

REPORT #

CORRECTIVE ACTION

1. Availability of Construction Methodology and interview

with the assigned Field Engineer regarding awareness on

the approved construction methodology

2. Conduct and availability of Survey Records

3. Approved Plan

4 Construction of crane way

4.1 Clearing and grubbing

4.2 Excavation works

4.3 Waterway pipings

4.4 Safety passage way

5 Bored Piling

5.1 Reference elevation and horizontal control for

bored piles, pier and abutment location

5.2 Cut an fill section

5.3 Drilling procedure

5.4 Final horizontal and vertical elevation.

5.5 Perform sounding

5.6 Installation of fabricated reinforcement cage

5.7 Concrete placement

5.8 Extraction of temporary casing

5.9 PIT and PDA test in accordance to the plans and

specifications

6 Construction of Abutment Coping and backwall, Column

and Pier Coping

6.1 Reference elevation and horizontal control

6.2 Excavation or trimming

6.3 Base compaction

6.4 Elevation and limits

6.5 Lean concrete pouring

6.6 Installation of reinforcing steel bars in accordance

with the approved shop drawing

6.6.1 Proper splicing

6.7 Formworks installation

6.8 Checking necessary miscellaneous materials for

risers and abutment seats including anchor bars

6.9 Concrete pouring

6.9.1 Cleanliness prior to concrete pouring

6.9.2 All minor equipment and tools such as

vibrator and likes, are ready at site

6.9.3 Quality control of RMC

6.9.4 Proper handling of concrete

6.10 removal of forms

6.11 Application of curing compound

7 Launching of girder

7.1 Preparatory Works

7.1.1 Final checking of horizontal and vertical

alignment

7.1.2 Safety inspection

7.1.3 Checking access road / craneway

7.2 Traffic Management Plan

7.3 Launching activity

7.3.1 Approved WIR and site inspection

7.3.2 Placement of girder

7.3.3 Checking of elevation and alignment

8 Construction of Superstructure

8.1 Established horizontal control and final elevation for

every sequence of works for superstructures

8.2 Initial safety paraphernalia’s including support and

protection foe execution of works on bridge

superstructures such as diaphragms, deck slab, wing walls

and8.3

railings.

Diaphram

8.3.1 Installation of formworks and falseworks

8.3.2 Installation of reinforcing steel bars

8.3.3 Checking elevation and alignment prior to

concrete pouring

8.3.4 Concrete pouring

8.3.4.1 Cleanliness prior to concrete pouring

8.3.4.2 Availability of necessary tools and minor

equipment

8.3.4.3 Quality control of RMC

8.4 Deck slab

8.4.1 Installation of metal deck

8.4.2 Installation of reinforcing steel bars in

accordance with the approved shop drawing

8.4.2.1 Proper splicing

8.4.3 Installation of pouring guide on top of

reinforcement

8.4.3.1 Checking 2.0% slope at bridge deck slab

8.4.3.1 Checking final elevation

8.4.4 Concrete pouring

8.4.4.1 Cleanliness prior to concrete pouring

8.4.4.2 Availability of necessary tools and minor

equipment

8.4.4.3 Quality control of RMC

8.4.4.4 Installation of bridge drain

8.4.4.5 Installation of embedded item for

parapet railings

8.4.4.6 Proper handling of concrete

8.4.4.7 Application of curing compound

8.5 Construction of parapet railings

8.6 Backfilling of abutment back wall

8.7 Construction of approach slab

8.7.1 Installation of reinforcing steel bars

8.7.2 Installation of bridge expansion joint and cork

fill

8.7.3 Concrete pouring

9 Checking of completeness of Personal Protective

Equipment of all manpower

10 Checking of Equipment Safety Operations

11 Checking availability and completeness of early

warning devices / traffic management system

12 Checking of cleanliness on job site and orderliness of

materials on the area

Inspector: Responsible Person: Conformed by: Noted by:

________________________________________________ ____________________________________ _____________________

QA - QC Engineer FE/ME / PE / PM VP For Operations GERARDO V. Pancho

President

You might also like

- Erection Tower Method StatementDocument23 pagesErection Tower Method StatementJatmiko Purwo Saputro100% (2)

- Earth Dam Construction Method StatementDocument19 pagesEarth Dam Construction Method StatementJohn BandaNo ratings yet

- N5012 CS PCP 0013 03 Magnetic ExtensometersDocument16 pagesN5012 CS PCP 0013 03 Magnetic Extensometersbaga begaNo ratings yet

- Concrete Method Statement PDF FreeDocument14 pagesConcrete Method Statement PDF FreeAli Kaya100% (2)

- CV-0013-002 - Method Statement For Soil Improvement WorkDocument14 pagesCV-0013-002 - Method Statement For Soil Improvement Work한상호No ratings yet

- Method Statement DuctingDocument29 pagesMethod Statement DuctingAnish Kumar100% (8)

- Method Statement For Block Works PDFDocument9 pagesMethod Statement For Block Works PDFrayNo ratings yet

- Method Statement For Staircase HandrailDocument18 pagesMethod Statement For Staircase HandrailEnviron Support50% (2)

- Method Statement For Transfer SlabDocument11 pagesMethod Statement For Transfer Slabray100% (1)

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- POUR CARD New FormatDocument5 pagesPOUR CARD New FormatCivil Site 1775% (4)

- SURFACE WATER DRAINAGE (Baru Punya Woi)Document164 pagesSURFACE WATER DRAINAGE (Baru Punya Woi)hazhaz59100% (2)

- Construction Methodology For Slope Stability.Document19 pagesConstruction Methodology For Slope Stability.mehra.yogesh160No ratings yet

- MS - Road and PavingDocument15 pagesMS - Road and PavingbukhoriNo ratings yet

- WMS Excavation & BACKFILLINGDocument28 pagesWMS Excavation & BACKFILLINGRepl microsoft, PuneNo ratings yet

- Role of Erection EngDocument15 pagesRole of Erection Englightsons100% (1)

- MS For Survey and Setting OutDocument4 pagesMS For Survey and Setting OutShan THALANo ratings yet

- N5012-CS-PCP-0010-02 - InclinometerDocument13 pagesN5012-CS-PCP-0010-02 - Inclinometerdiego ahumadaNo ratings yet

- Belgaon Volume 2 RevisedDocument247 pagesBelgaon Volume 2 RevisedSeshu kvNo ratings yet

- Separator Installation Report (Repaired)Document9 pagesSeparator Installation Report (Repaired)Novan RosyandyNo ratings yet

- MST For Below Ground UPVC Drainage PipesDocument13 pagesMST For Below Ground UPVC Drainage Pipesمقاول تكييف كهرباء وصحيNo ratings yet

- A Con Pro 000 38658 BDocument13 pagesA Con Pro 000 38658 BHussein Adnan FneishNo ratings yet

- Method Statament of DuctingDocument29 pagesMethod Statament of Ductingwahyoe.ir88No ratings yet

- PCC Method StatementDocument10 pagesPCC Method StatementChirag SharmaNo ratings yet

- Method Stataement of DuctingDocument29 pagesMethod Stataement of Ductingwahyoe.ir88No ratings yet

- Buildings Department Practice Note For Authorized Persons, Registered Structural Engineers and Registered Geotechnical Engineers ADM-18Document6 pagesBuildings Department Practice Note For Authorized Persons, Registered Structural Engineers and Registered Geotechnical Engineers ADM-18Kwok MorrisNo ratings yet

- Method of Statement For VD FLOORINGDocument7 pagesMethod of Statement For VD FLOORINGPrasanta ParidaNo ratings yet

- 05 Spec Works Spec For PVD Installation 08 Sept 20Document15 pages05 Spec Works Spec For PVD Installation 08 Sept 20Ahmed MahmoudNo ratings yet

- Itp PipingDocument15 pagesItp PipingEkhy Transmisi100% (1)

- JCF-C009 - Ceiling Works RequestDocument2 pagesJCF-C009 - Ceiling Works Requestkaty leeNo ratings yet

- 02 Method of Statment - DX High Wall Split Unit - PSDocument12 pages02 Method of Statment - DX High Wall Split Unit - PSUnique PlanningNo ratings yet

- Form No. DI-QAC-006-0Document1 pageForm No. DI-QAC-006-0dindoochavesquintanNo ratings yet

- Aea 1305 WC El MS 0003Document15 pagesAea 1305 WC El MS 0003Adil HasanovNo ratings yet

- Concrete Method Statement PDF FreeDocument14 pagesConcrete Method Statement PDF FreeAli KayaNo ratings yet

- Qality Assurance Inspection and Test Plan: Piping Fabrication & InstallationDocument16 pagesQality Assurance Inspection and Test Plan: Piping Fabrication & Installationmanoj thakkarNo ratings yet

- Excavation Method StatementDocument6 pagesExcavation Method StatementWaleed SalihNo ratings yet

- MS For B.F.& Compaction For Squadron Operation - 23 Jan. 2019Document12 pagesMS For B.F.& Compaction For Squadron Operation - 23 Jan. 2019Alvene TagocNo ratings yet

- Wind Prospect LTD Method Statement: Project: Method Statement Title Ref No: Date: Prepared byDocument7 pagesWind Prospect LTD Method Statement: Project: Method Statement Title Ref No: Date: Prepared byjaouad id boubkerNo ratings yet

- Concreting WorkDocument14 pagesConcreting WorkSantosh KumarNo ratings yet

- WORK PLAN METHODOLOGY Phase2Document12 pagesWORK PLAN METHODOLOGY Phase2Kamutura Ga TerereNo ratings yet

- MS For Surface Rock Bolts and Dowels (Rev-2)Document23 pagesMS For Surface Rock Bolts and Dowels (Rev-2)shahzadNo ratings yet

- 03 Method of Statment - VRF Units - PSDocument12 pages03 Method of Statment - VRF Units - PSUnique PlanningNo ratings yet

- Boxt Field Quality PlanDocument86 pagesBoxt Field Quality PlanHariom GuptaNo ratings yet

- Soil Nail MethodDocument9 pagesSoil Nail MethodsayzdanielNo ratings yet

- Ga Qu MS Civ 008Document14 pagesGa Qu MS Civ 008henry.anthirayasNo ratings yet

- Naukri LALSONTHOMAS (14y 2m)Document5 pagesNaukri LALSONTHOMAS (14y 2m)asmacsNo ratings yet

- IEM Bored Pile Supervision - 19112015Document81 pagesIEM Bored Pile Supervision - 19112015TanNo ratings yet

- Field Inspection &test PlanDocument4 pagesField Inspection &test PlanSofda ImelaNo ratings yet

- QA Monitoring Checklist Vertical Subic November 25, 2016 - EDITEDDocument4 pagesQA Monitoring Checklist Vertical Subic November 25, 2016 - EDITEDAyna LaoNo ratings yet

- Form No. DI-QAC-009-0Document1 pageForm No. DI-QAC-009-0dindoochavesquintanNo ratings yet

- 01 MS For Fcu - PSDocument11 pages01 MS For Fcu - PSASHWANINo ratings yet

- Method Statement of Coring Work & Pipe Installation & MaintenanceDocument9 pagesMethod Statement of Coring Work & Pipe Installation & Maintenancejinex123No ratings yet

- TD Esc 03 de en 12 020 Rev003 Siteworks InspectionDocument4 pagesTD Esc 03 de en 12 020 Rev003 Siteworks InspectionarhipadrianNo ratings yet

- GS Concrete Pavers Method Statement-DRAFTDocument15 pagesGS Concrete Pavers Method Statement-DRAFTMahmoud FakhereddinNo ratings yet

- Underck Insulation MSTDocument8 pagesUnderck Insulation MSTmahesh naikNo ratings yet

- MS For Form - WorksDocument8 pagesMS For Form - WorksImho Tep100% (1)

- Bev PCDocument7 pagesBev PCLim Kang HaiNo ratings yet

- 79 MethodologyDocument6 pages79 MethodologyKamutura Ga TerereNo ratings yet

- Qaqc Section: Presented To QAQC Safety Session at Jakarta MRT Project July 15, 2017Document17 pagesQaqc Section: Presented To QAQC Safety Session at Jakarta MRT Project July 15, 2017Wildan Al BaihaqiNo ratings yet

- Work Method Statement: Delhi Metro Rail CorporationDocument17 pagesWork Method Statement: Delhi Metro Rail Corporationsunil tyagiNo ratings yet

- Marina Project Piles CalculationDocument127 pagesMarina Project Piles Calculationstructural designer100% (1)

- Master List of Checklist New With All LOGOsDocument22 pagesMaster List of Checklist New With All LOGOsRahul Jaiswal100% (1)

- Tunnel Steel Formwork DesignDocument4 pagesTunnel Steel Formwork Designeric bargasNo ratings yet

- DACE Labour Norms Civil V2Document7 pagesDACE Labour Norms Civil V2Amir AbazaNo ratings yet

- Investigation of The Structural Strength of An Existing TwoStorey MultiPurpose Barangay Hall Due To An Additional 3rd Storey Without Using An As Built PlanDocument238 pagesInvestigation of The Structural Strength of An Existing TwoStorey MultiPurpose Barangay Hall Due To An Additional 3rd Storey Without Using An As Built PlanMichael June Borcena Felix100% (1)

- Diesel Generator Room Roof Slab Formwork Layout: General Arrangement DrawingDocument1 pageDiesel Generator Room Roof Slab Formwork Layout: General Arrangement DrawingissaNo ratings yet

- Rate AnalysisDocument13 pagesRate AnalysisAshish RanaNo ratings yet

- Catálogo VARIOKIT PERI PDFDocument44 pagesCatálogo VARIOKIT PERI PDFHenry MorenoNo ratings yet

- Performance of Concrete in XS1, XS2 and XS3 EnvironmentsDocument11 pagesPerformance of Concrete in XS1, XS2 and XS3 EnvironmentsSelvaganeshNo ratings yet

- ISAA BC-3 (Unit-1 RCC)Document9 pagesISAA BC-3 (Unit-1 RCC)Soukhya PrattipatiNo ratings yet

- MivanDocument19 pagesMivanshamkumavatNo ratings yet

- Project Planning Organising Tracking: David H. MoloneyDocument60 pagesProject Planning Organising Tracking: David H. MoloneyVanny LaNo ratings yet

- Hta KatDocument56 pagesHta KatFlorin BenteNo ratings yet

- MASS CONCRETE METHOD STATEMENT - FinalDocument89 pagesMASS CONCRETE METHOD STATEMENT - FinalMichael Assefa100% (1)

- LT 32571Document12 pagesLT 32571haiduong_ktdtNo ratings yet

- Design RC StructureDocument58 pagesDesign RC StructureAmr Abdelraouf MahmoudNo ratings yet

- Specifications A4Document43 pagesSpecifications A4jologscresenciaNo ratings yet

- BOQ MessDocument10 pagesBOQ Messalfian adriansyahNo ratings yet

- Bill of Quantity For RCC BuildingsDocument16 pagesBill of Quantity For RCC BuildingsAaron SolisNo ratings yet

- The Living LabDocument4 pagesThe Living LabAakankshaDadheechNo ratings yet

- Slabs: One-Way Slab (Simply Supported Slab)Document25 pagesSlabs: One-Way Slab (Simply Supported Slab)tmskieNo ratings yet

- I-Introduction: This System Is One of The Most Traditional System in Acrow Form Work Because It Is Multiuse SystemDocument59 pagesI-Introduction: This System Is One of The Most Traditional System in Acrow Form Work Because It Is Multiuse SystemanilNo ratings yet

- Errata: Transportation OfficialsDocument68 pagesErrata: Transportation OfficialsRandy CamaclangNo ratings yet

- MSC Topic 3B - C21Document40 pagesMSC Topic 3B - C21myint phyoNo ratings yet

- Supercast PCDocument2 pagesSupercast PCSYED SOHAILNo ratings yet

- Doka Top H 20Document20 pagesDoka Top H 20radem3No ratings yet

- Hybrid MMC PDFDocument11 pagesHybrid MMC PDFVignesh AyyathuraiNo ratings yet

- Schmidt Family Sales Flyer English HighDocument6 pagesSchmidt Family Sales Flyer English HighAksanNo ratings yet

- I2114-OPR-ITP-CHK-007A (01) Pour Inspection Checklist - RCCDocument3 pagesI2114-OPR-ITP-CHK-007A (01) Pour Inspection Checklist - RCCPrasant Kumar SahooNo ratings yet

- P01511 December 2020Document10 pagesP01511 December 2020tholoana sentiNo ratings yet