Professional Documents

Culture Documents

Minimum Bending Radii For Cables: Solid Conductor Solid Conductor

Minimum Bending Radii For Cables: Solid Conductor Solid Conductor

Uploaded by

RinodhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Minimum Bending Radii For Cables: Solid Conductor Solid Conductor

Minimum Bending Radii For Cables: Solid Conductor Solid Conductor

Uploaded by

RinodhCopyright:

Available Formats

BARE COPPER

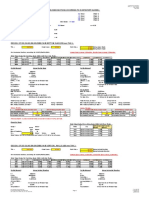

MINIMUM BENDING RADII FOR CABLES

SOLID CONDUCTOR

Insulated Conductor Without Metallic Shielding

Bare ororTinned

Armor

Overall Conductor Diameter (inches)

Soft (Annealed), Medium Hard, Hard Drawn

Minimum Bending Radius as a Multiple of Cable Diameter

1.000" & less 4

1.001" - 2.000" 5

2.001" & over 6

Power and Control Cables With Metallic Shielding and/or Armor

Description: Standards:

Soft Drawn: Easily formed into place.Cable Description ASTM Standards: B-1 (hard

Minimum Bending drawn),

Radius B-2 (medium

as a Multiple of Cable hard drawn),

Diameter

Hard Drawn: Higher tensile strength. Retains Shape. More difficult to form. B-3 (soft or annealed), B-33 (tinned)

Interlocked Armor (with non-shielded conductors) 7

REA/RUS Approved

Application: Metallic Tape Shielded (conductors or cable) Federal Standard QQ-W-343 12/7(1)

Suitable for use in electrical grounding systems and on insulators for overhead RoHS Compliant

(1) 12 x individual shielded conductor diameter, or 7 x overall cable diameter, whichever is greater

transmission and distribution applications.

Above tables per ICEA S-95-658/NEMA WC70, Appendix F

SOFT

(TINNED)

HARD HARD MED HARD MED HARD SOFT DC

(BARE) Resistance

Part Nominal Approx. DRAWN DRAWN DRAWN DRAWN (OHMS/1000')

Number Min. Breaking Strength DC Resistance Min. Breaking Strength DC Resistance DC Resistance Ampacity*

Size Diameter Net Weight (lbs.) (OHMS/1000') @20°C (lbs.) (OHMS/1000') @20°C (OHMS/1000') @20°C @20°C

(AWG) (in.) (lb./1000')

BSOS18 18 0.0403 4.92 85 6.6400 67 6.6100 6.3900 6.6400 -

BSOS16 16 0.0508 7.82 135 4.1800 106 4.1600 4.0200 4.1800 -

BSOS14 14 0.0641 12.43 214 2.6300 167 2.6100 2.5200 2.6200 -

BSOS12 12 0.0808 19.77 337 1.6500 262 1.6400 1.5900 1.6500 -

BSOS10 10 0.1019 31.43 529 1.0390 410 1.0330 0.9988 1.0430 -

BSOS8 8 0.1285 49.98 826 0.6532 644 0.6498 0.6281 0.6426 98

BSOS6 6 0.1620 79.46 1,280 0.4110 1,010 0.4088 0.3952 0.4109 124

BSOS4 4 0.2043 126.40 1,970 0.2584 1,584 0.2571 0.2485 0.2528 155

BSOS2 2 0.2576 200.90 3,002 0.1625 2,450 0.1617 0.1563 0.1580 209

BSOS1 1 0.2893 253.30 3,688 0.1289 3,024 0.1282 0.1239 - -

BSOS1/0 1/0 0.3249 319.50 4,518 0.1011 3,731 0.1016 0.0982 - 282

BSOS2/0 2/0 0.3648 402.80 5,519 0.0802 4,600 0.0798 0.0779 - 329

BSOS3/0 3/0 0.4096 507.80 6,720 0.0636 5,666 0.0633 0.0618 - 382

BSOS4/0 4/0 0.4600 640.50 8,143 0.0504 6,980 0.0502 0.0490 - 444

*Per NEC Table 310.15 (B)(21). Based on conductor temperature of 80°C; ambient temperature of 40°C; 2 ft./sec. wind. **Ref ASTM B-787 NOTE: The data shown is approximate and subject to standard

industry tolerance.

Service Wire Company believes the information presented herein is, to the best of our knowledge, true and accurate based on currently available industry data.

However no warranties, either expressed or implied, are made as to the accuracy or completeness of any information contained herein. Consequently, Service Wire

Company makes no guarantee of the results and assumes no obligation or liability whatsoever in connection with this information.

104

servicewire.com

Phoenix, AZ Culloden, WV Houston, TX

877-623-9473 800-624-3572 800-231-9473

You might also like

- Max Pulling TensionsDocument1 pageMax Pulling TensionssatheeskrsnaNo ratings yet

- Coaxial Connectors: Rohs CompliantDocument9 pagesCoaxial Connectors: Rohs CompliantYounes AlzyoudNo ratings yet

- Apxverr20x CDocument2 pagesApxverr20x CJCARLOS COLQUENo ratings yet

- 7336.10 Indoor Multiband Panel Vertical PolarizedDocument1 page7336.10 Indoor Multiband Panel Vertical PolarizedMaksim PatrushevNo ratings yet

- RF X-Treme Cross Polarized Triple Band Antenna, 790-2170Mhz, 65deg, 16/17.7/18.2dbi, 2.0M, Vet, 2-12degDocument2 pagesRF X-Treme Cross Polarized Triple Band Antenna, 790-2170Mhz, 65deg, 16/17.7/18.2dbi, 2.0M, Vet, 2-12degDmytrii NikulinNo ratings yet

- GTP 120Document2 pagesGTP 120er.manishnhpcNo ratings yet

- Messengersfor AerialDocument1 pageMessengersfor AerialPrabhat RanjanNo ratings yet

- Aisc 14 Edition (Asd) : 14/jan/16 SN SN 0 1Document2 pagesAisc 14 Edition (Asd) : 14/jan/16 SN SN 0 1GousePeerzadeNo ratings yet

- ALXC Cross Polarized 7331.02B: Electrical SpecificationsDocument1 pageALXC Cross Polarized 7331.02B: Electrical SpecificationsДобрыня ЭдяNo ratings yet

- General Design Parameters (For Uncracked Section According To Is:3370 (Part-Ii) - 2009)Document6 pagesGeneral Design Parameters (For Uncracked Section According To Is:3370 (Part-Ii) - 2009)sumit_7285No ratings yet

- Side-By-Side Dual Polarized Antenna, 1710-2700, 65deg, 16.7-17.5dbi, 1.3M, Vet, 2-12degDocument2 pagesSide-By-Side Dual Polarized Antenna, 1710-2700, 65deg, 16.7-17.5dbi, 1.3M, Vet, 2-12degИгорь Сторожок100% (1)

- Low Broadband Cross Polarized 7477.06: Electrical SpecificationsDocument1 pageLow Broadband Cross Polarized 7477.06: Electrical SpecificationsсержNo ratings yet

- Apxverr20x CDocument2 pagesApxverr20x CAnonymous kC8oFmSNo ratings yet

- AW3363Document5 pagesAW3363nivesh vermaNo ratings yet

- ALXC Cross Polarized 7330.02B: Electrical SpecificationsDocument1 pageALXC Cross Polarized 7330.02B: Electrical SpecificationsДобрыня ЭдяNo ratings yet

- ALXC Cross Polarized 7330.02B: Electrical SpecificationsDocument1 pageALXC Cross Polarized 7330.02B: Electrical SpecificationsДобрыня ЭдяNo ratings yet

- Utv 02 LBDocument1 pageUtv 02 LBHector CardosoNo ratings yet

- 4H 15m APXVLL13S-C OkDocument2 pages4H 15m APXVLL13S-C Okcmsd01No ratings yet

- AW3363Document5 pagesAW3363Aravind BalajiNo ratings yet

- 900 MHZ Omni AntennaDocument2 pages900 MHZ Omni AntennaFURIVANNo ratings yet

- CN 05Document3 pagesCN 05GousePeerzadeNo ratings yet

- RCC A3 Size ChartDocument1 pageRCC A3 Size ChartRam TqrNo ratings yet

- RF X-Treme Triple Band Antenna, 694-2690Mhz, 65deg, 14-18.2dbi, 1.4M, Vet, 2-15/2-12degDocument2 pagesRF X-Treme Triple Band Antenna, 694-2690Mhz, 65deg, 14-18.2dbi, 1.4M, Vet, 2-15/2-12degRigonatoAlencarNo ratings yet

- 4168 11 33Document1 page4168 11 33mrdirsirNo ratings yet

- NYCWYDocument1 pageNYCWYacarisimovicNo ratings yet

- Aisc 14 Edition (Asd) : 0 1 18/jan/16 13/jun/16 SN SN AN ANDocument5 pagesAisc 14 Edition (Asd) : 0 1 18/jan/16 13/jun/16 SN SN AN ANGousePeerzadeNo ratings yet

- GTP 185Document3 pagesGTP 185er.manishnhpcNo ratings yet

- Alliance Distributor For RFS Base Station Antenna AP906516 CT0Document2 pagesAlliance Distributor For RFS Base Station Antenna AP906516 CT0Добрыня ЭдяNo ratings yet

- ZFBT 4R2G 2b-2581446Document3 pagesZFBT 4R2G 2b-2581446Orlando DíazNo ratings yet

- AQU4518R19v06: Antenna SpecificationsDocument2 pagesAQU4518R19v06: Antenna SpecificationsЕвгений Грязев0% (1)

- CABT CablesDocument1 pageCABT CablesKristaNo ratings yet

- ALP Broadband Vertical Polarized 7838.00: Electrical SpecificationsDocument1 pageALP Broadband Vertical Polarized 7838.00: Electrical SpecificationskapaiNo ratings yet

- 7233.04 Urban Vertical Polarized: Powerwave Single Band AntennasDocument1 page7233.04 Urban Vertical Polarized: Powerwave Single Band AntennasyacasiestaNo ratings yet

- Alg 7228 08Document1 pageAlg 7228 08Philippe RUBIONo ratings yet

- 7233.14 Allgon (Powerwave) PDFDocument2 pages7233.14 Allgon (Powerwave) PDFСавелийNo ratings yet

- Pro Ar12 4 Gs N.en GBDocument1 pagePro Ar12 4 Gs N.en GBBao Quoc MaiNo ratings yet

- LS Cable Power CableDocument4 pagesLS Cable Power CableNikola PrasnjakNo ratings yet

- nh360qm D 2xr Product SpecificationsDocument3 pagesnh360qm D 2xr Product SpecificationsantlozNo ratings yet

- ABC Self Support SANS 1418Document1 pageABC Self Support SANS 1418Awelani MandavhaNo ratings yet

- Low Broadband Cross Polarized 5488.00: Electrical SpecificationsDocument1 pageLow Broadband Cross Polarized 5488.00: Electrical SpecificationsMaksim PatrushevNo ratings yet

- Alg 7233 08Document2 pagesAlg 7233 08Philippe RUBIONo ratings yet

- Low Broadband Antenna: 65 2.0 M X-Polarized FET AntennaDocument2 pagesLow Broadband Antenna: 65 2.0 M X-Polarized FET AntennaJura GirskiNo ratings yet

- P360-3-Vchw2-0 824-960/1710-2700Mhz 360° Ceiling Mount Indoor Omni AntennaDocument1 pageP360-3-Vchw2-0 824-960/1710-2700Mhz 360° Ceiling Mount Indoor Omni AntennaValery ShevchenkoNo ratings yet

- M17 Power: Plug-In Connector RLSDocument8 pagesM17 Power: Plug-In Connector RLS705695No ratings yet

- Stranded Bare AWGDocument1 pageStranded Bare AWGgerrzen64No ratings yet

- Acs - Catálogo InglêsDocument3 pagesAcs - Catálogo InglêsPaulo SergioNo ratings yet

- 8755 0ST B100 001 PDFDocument1 page8755 0ST B100 001 PDFsamarNo ratings yet

- Cma Ubdhh 6521 E1-10 H2Document1 pageCma Ubdhh 6521 E1-10 H2yevobimNo ratings yet

- MTS46 Mb3bhdmf-65-16.519de-In-43Document3 pagesMTS46 Mb3bhdmf-65-16.519de-In-43Андрей ФедоровNo ratings yet

- Optimizer® Dual Polarized Antenna, 1710-2170, 65deg, 14.7/14.9dbi, 0.6M, Fet, 0degDocument2 pagesOptimizer® Dual Polarized Antenna, 1710-2170, 65deg, 14.7/14.9dbi, 0.6M, Fet, 0degКурбан УмархановNo ratings yet

- File 0 63368600 1471845727Document5 pagesFile 0 63368600 1471845727Gasper JenkoNo ratings yet

- ANT AQU4517R4 1873 DatasheetDocument2 pagesANT AQU4517R4 1873 DatasheetayhankaanNo ratings yet

- HFBV Viaduct - IdeaDocument1 pageHFBV Viaduct - Ideastavros stergiopoulosNo ratings yet

- ANT-AQU4517R4-1873 DatasheetDocument2 pagesANT-AQU4517R4-1873 DatasheetСергей МирошниченкоNo ratings yet

- Apxvbll26x C I20 PDFDocument2 pagesApxvbll26x C I20 PDFYaCeTo12No ratings yet

- Cma Ubdhhh 6520 E2-10 C1Document1 pageCma Ubdhhh 6520 E2-10 C1Anonymous OM5uU6No ratings yet

- Single Band Urban Antenna: 65° 2.6 M Vertical Polarized FET AntennaDocument2 pagesSingle Band Urban Antenna: 65° 2.6 M Vertical Polarized FET AntennaOtmanNo ratings yet

- ONE ZA'ABEEL Cable Sizing Report Rev-1Document15 pagesONE ZA'ABEEL Cable Sizing Report Rev-1zaheer29310% (1)

- DIY TeardropDocument12 pagesDIY TeardropAnonymous MyUcfo100% (1)

- National Rural Infrastructure Development AgencyDocument5 pagesNational Rural Infrastructure Development Agencypmgsy psdNo ratings yet

- Roof Mount: Shanghai CHIKO Solar Technology Co., LTDDocument2 pagesRoof Mount: Shanghai CHIKO Solar Technology Co., LTDabed aqtashNo ratings yet

- Concure PI: Membrane Concrete Curing Compound UsesDocument2 pagesConcure PI: Membrane Concrete Curing Compound UsesTechnicalproducts 02 Indo Riau PerkasaNo ratings yet

- CVBC-SC-Weekly Report No. 43Document10 pagesCVBC-SC-Weekly Report No. 43Eleazar SacloloNo ratings yet

- API Modified TdsDocument1 pageAPI Modified Tdssigit praNo ratings yet

- MT8 Datasheet 0821Document8 pagesMT8 Datasheet 0821Nitin KurupNo ratings yet

- Spec ListDocument27 pagesSpec ListArun CPNo ratings yet

- Pengaruh Air Hujan Pada Proses Pemadatan Di Lapangan Terhadap CampuranDocument11 pagesPengaruh Air Hujan Pada Proses Pemadatan Di Lapangan Terhadap CampurandeliaNo ratings yet

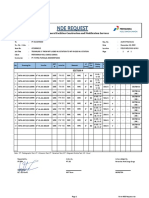

- Request NDT Section 4 TGL 16-12-2022Document1 pageRequest NDT Section 4 TGL 16-12-2022Ferdie OSNo ratings yet

- Catalogo Tosaca 1216Document16 pagesCatalogo Tosaca 1216isa.cuenta.26No ratings yet

- Evaluation of Pre-Tensioned Prestressed Concrete Beam Behavior by Finite Element Analysis Using ATENA 3DDocument9 pagesEvaluation of Pre-Tensioned Prestressed Concrete Beam Behavior by Finite Element Analysis Using ATENA 3Dsami stelNo ratings yet

- Tri-Rated Rev005Document2 pagesTri-Rated Rev005Jean Pierre Goossens100% (1)

- Elevators: Interiors, Ceilings, Handrails, Doors, Lobby Walls & MaterialsDocument32 pagesElevators: Interiors, Ceilings, Handrails, Doors, Lobby Walls & MaterialsAbu NijamNo ratings yet

- Bardessono Hotel and Spa - WATG - ArchDailyDocument11 pagesBardessono Hotel and Spa - WATG - ArchDailySarah Eid abd elmagied eid khaleelNo ratings yet

- Basic Tyre LENGKAP-1Document50 pagesBasic Tyre LENGKAP-1Dayatd BeteNo ratings yet

- Raft Modeling in Etabs - Foundation Design - Structural Engineering Forum of Pakistan PDFDocument1 pageRaft Modeling in Etabs - Foundation Design - Structural Engineering Forum of Pakistan PDFKenny Manuel Vettoor100% (1)

- ELTS Essay Question2Document6 pagesELTS Essay Question2salbina arabiNo ratings yet

- Ancla Tubing in Ficha Tecnica-WeatherfordDocument3 pagesAncla Tubing in Ficha Tecnica-WeatherfordDaniel Eduardo Ramos RicardezNo ratings yet

- General ToolsDocument20 pagesGeneral ToolsM Darma Susilo AjiNo ratings yet

- Manufacturing LectureDocument43 pagesManufacturing Lecturemohtram1037No ratings yet

- Installation Procedure-Chockfast RedDocument29 pagesInstallation Procedure-Chockfast RedSahaporn PhadungpongNo ratings yet

- Society Interior 201411Document204 pagesSociety Interior 201411albsteinporNo ratings yet

- Minutes of Meeting 02 (1) .08Document1 pageMinutes of Meeting 02 (1) .08Sateesh BalaniNo ratings yet

- Ce 315 RCC IiDocument100 pagesCe 315 RCC IiMd. Abdullah Al ArafatNo ratings yet

- Iraya Norte Work ProgramDocument12 pagesIraya Norte Work Programrosecel jayson ricoNo ratings yet

- Sealing PlugsDocument12 pagesSealing PlugsGepef ProduçãoNo ratings yet

- Project Insurance by Er. Amrit Lal Meena, SBM National Insurance Company LTDDocument52 pagesProject Insurance by Er. Amrit Lal Meena, SBM National Insurance Company LTDDr S Rajesh KumarNo ratings yet

- Historic Building Materials and Factors Causing DamageDocument64 pagesHistoric Building Materials and Factors Causing DamageMert AvlarNo ratings yet

- Cable TrayDocument28 pagesCable Traykirink73No ratings yet